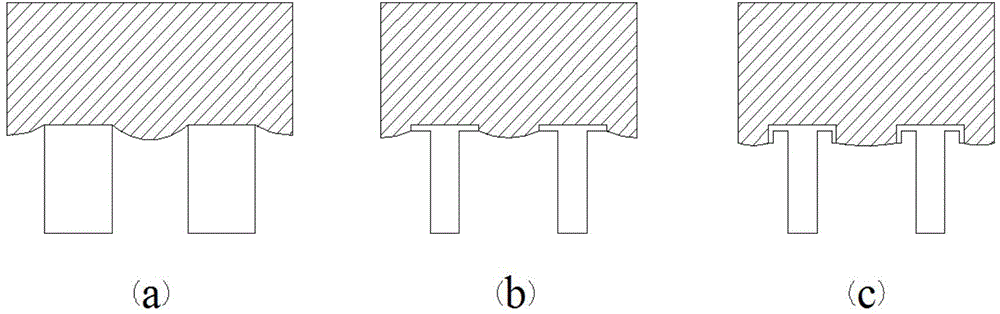

Preparing method of superhydrophobic concave angle T-shaped microcolumn structure

A super-hydrophobic, micro-pillar technology, applied in micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of difficult process, expensive equipment, poor controllability, etc., to achieve a wide process window and accelerated filling rate. , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

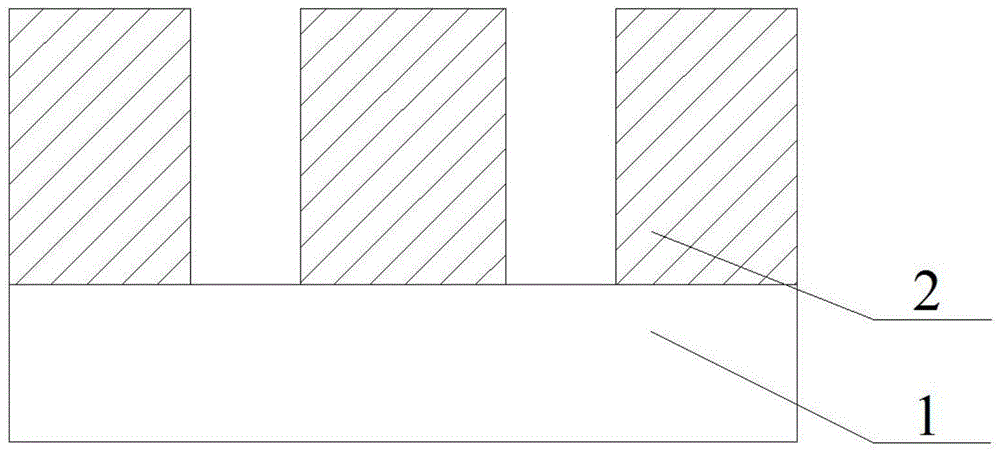

Examples

Embodiment 1

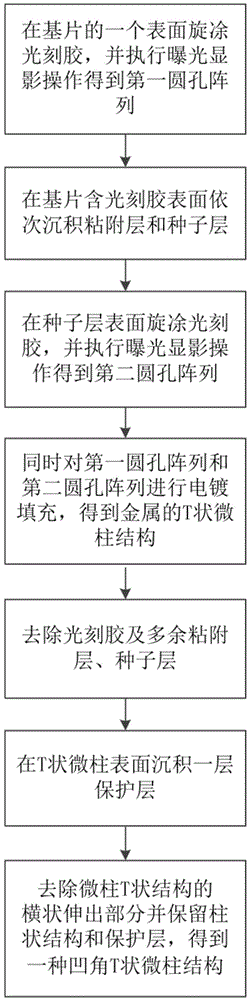

[0046] The technical scheme of the present embodiment 1 can be specifically implemented through the following steps:

[0047] Step 1, photolithography

[0048] Spin-coat NR26-25000P negative photoresist on a clean substrate with a thickness of 20 μm; use a mask with a circular array pattern, the circular area is opaque, the diameter of the circle is 10 μm, and the spacing is 30 μm; use MA6 contact photoresist engraving machine.

[0049] Step 2, developing

[0050] Put the substrate after step 1 into RD6 developing solution for development, and obtain the first circular hole array structure of photoresist on the substrate.

[0051] Step 3, Magnetron Sputtering

[0052] The substrate with the photoresist circular hole array structure after development in the second step is deposited with the magnetron sputtering method to sequentially deposit the adhesion layer Ti and the seed layer Cu, and the thickness of Ti / Cu is 10nm / 50nm.

[0053] Step 4, photolithography

[0054] Spin...

Embodiment 2

[0066] The technical scheme of present embodiment 2 can be specifically implemented through the following steps:

[0067] Step 1, photolithography

[0068] Spin-coat NR26-25000P negative photoresist on a clean substrate with a thickness of 20 μm; use a mask with a circular array pattern, the circular area is transparent, the diameter of the circle is 10 μm, and the spacing is 100 μm; use MA6 contact photolithography machine.

[0069] Step 2, developing

[0070] Put the substrate after step 1 into RD6 developing solution for development, and obtain the first circular hole array structure of photoresist on the substrate.

[0071] Step 3, Magnetron Sputtering

[0072] The substrate with the photoresist circular hole array structure after development in the second step is deposited with an adhesion layer Ti and a seed layer Cu in sequence by magnetron sputtering, and the thickness of Ti / Cu is 10 / 50nm.

[0073] Step 4, photolithography

[0074] Spin-coat PR1-1000A positive pho...

Embodiment 3

[0088] The technical scheme of present embodiment 3 can be specifically implemented through the following steps:

[0089] Step 1, photolithography

[0090] Spin-coat NR26-25000P negative photoresist on a clean substrate with a thickness of 60 μm; use a mask with a circular array pattern, the circular area is transparent, the diameter of the circle is 20 μm, and the spacing is 120 μm; use MA6 contact photolithography machine.

[0091] Step 2, developing

[0092] Put the substrate after step 1 into RD6 developing solution for development, and obtain the first circular hole array structure of photoresist on the substrate.

[0093] Step 3, Magnetron Sputtering

[0094] On the substrate with the photoresist circular hole array structure developed in the second step, the adhesion layer Ti and the seed layer Cu are sequentially deposited by magnetron sputtering, and the thickness of Ti / Cu is 50 / 100nm.

[0095] Step 4, photolithography

[0096]Spin-coat PR1-4000A positive photore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com