Method for producing ultrathin ultrahigh-strength steel plate

An ultra-high-strength, production method technology, applied in the production of ultra-thin ultra-high-strength steel plates, can solve the problem of not getting the technical approval of the pump truck manufacturer, extremely high requirements for the ability of straightening equipment, and prone to scoops in cutting and bending. Curling and other problems, to achieve the effect of increasing crack propagation resistance, qualified components, and facilitating successful curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

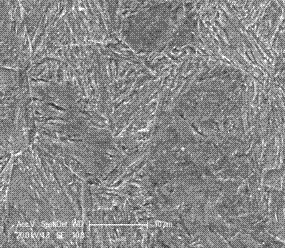

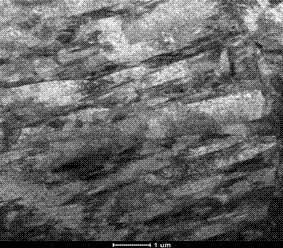

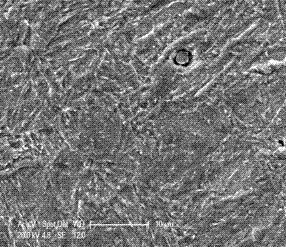

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical characteristics of this program, the present invention will be further described in detail below by way of examples:

[0023] The first specific implementation mode:

[0024] Using KR hot metal pretreatment for desulfurization, converter smelting, LF+RH refining and degassing, the chemical composition of the smelting analysis steel plate is: C: 0.15%, Si: 0.06%, Mn: 1.06%, P: 0.010%, S: 0.003%, Cr: 0.25%, Ni: 0.36%, Ti: 0.023%, Mo: 0.32%, Alt: 0.040%, CEN: 0.35%. The molten steel treated with Ca is poured into a slab with a thickness of 150 mm by an ASP casting machine.

[0025] The slab is cooled off the assembly line for 50 hours. Continuous casting slab reheating: heating time is 2 hours, heating temperature is 1225-1246°C, rolling deformation is carried out on a 1700mm ASP hot rolling line, the cumulative reduction rate in the rough rolling stage is 73.3%, and the end temperature of rough rolling is 1140°C. Rapidly car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com