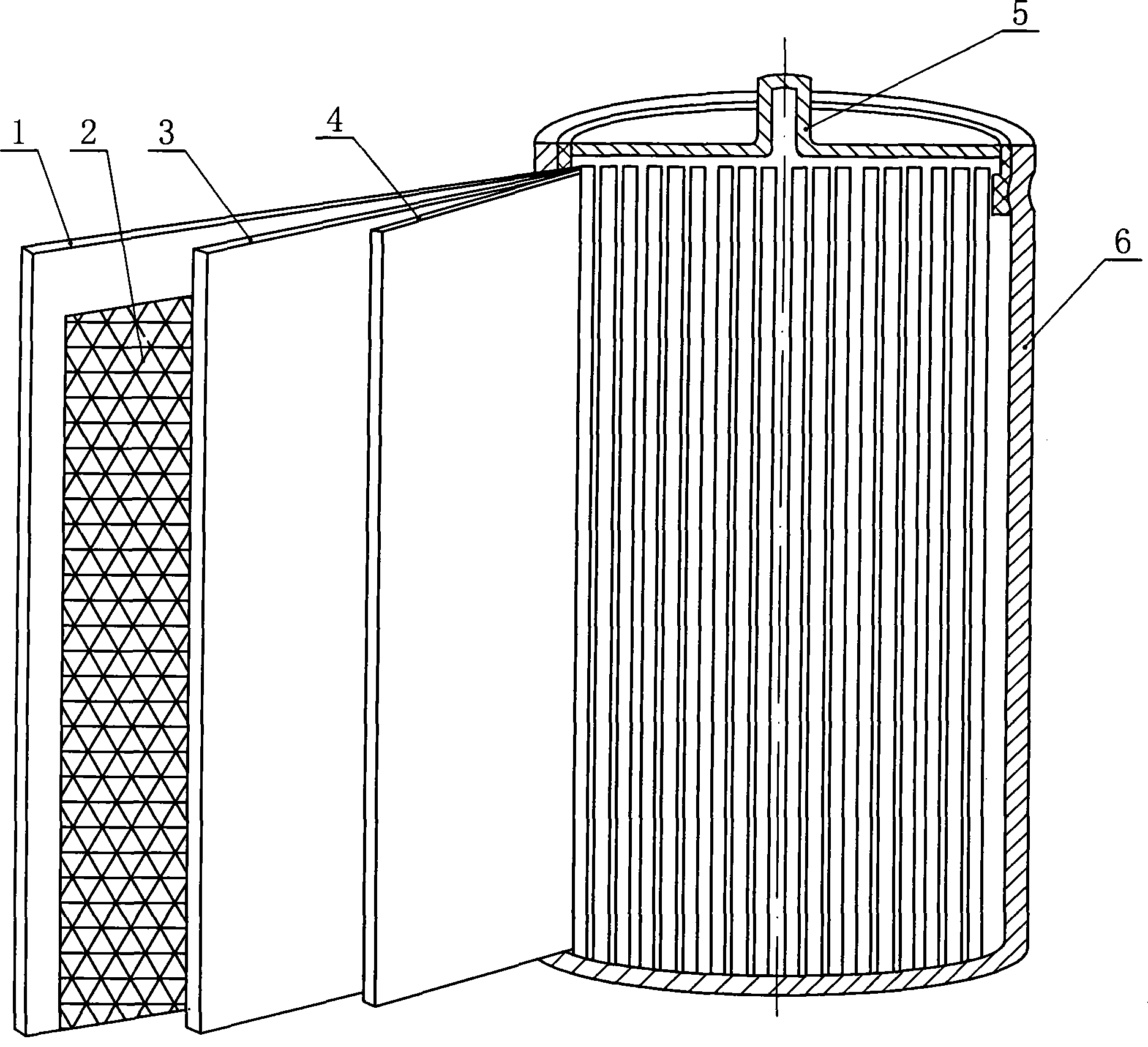

Improved type lithium-ferrous disulfide battery and manufacturing method of the same

An improved technology of ferrous disulfide, which is applied in primary batteries, primary battery electrodes, battery electrodes, etc., can solve the problems that batteries dominate, cannot meet the needs of heavy-load work of market electrical appliances, and have large discharge capacity. High discharge platform, improved high current discharge capacity, and good discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The present invention is made through the following steps:

[0067] (1) Make positive electrode slurry. The raw materials are proportioned according to the following parts by weight:

[0068] Positive active material ferrous disulfide (FeS 2 ) 85;

[0069] Binder polyvinylidene fluoride (PVDF) 10;

[0070] Conductive agent acetylene carbon black 5;

[0071] Production method: first dissolve 10 parts by weight of polyvinylidene fluoride (PVDF) in 90 parts by weight of nitrogen-methylpyrrolidone (NMP), and then add 85 parts by weight of ferrous disulfide (FeS 2 ), 5 parts by weight of acetylene carbon black are mixed, stirred and dispersed to form a uniform positive electrode slurry.

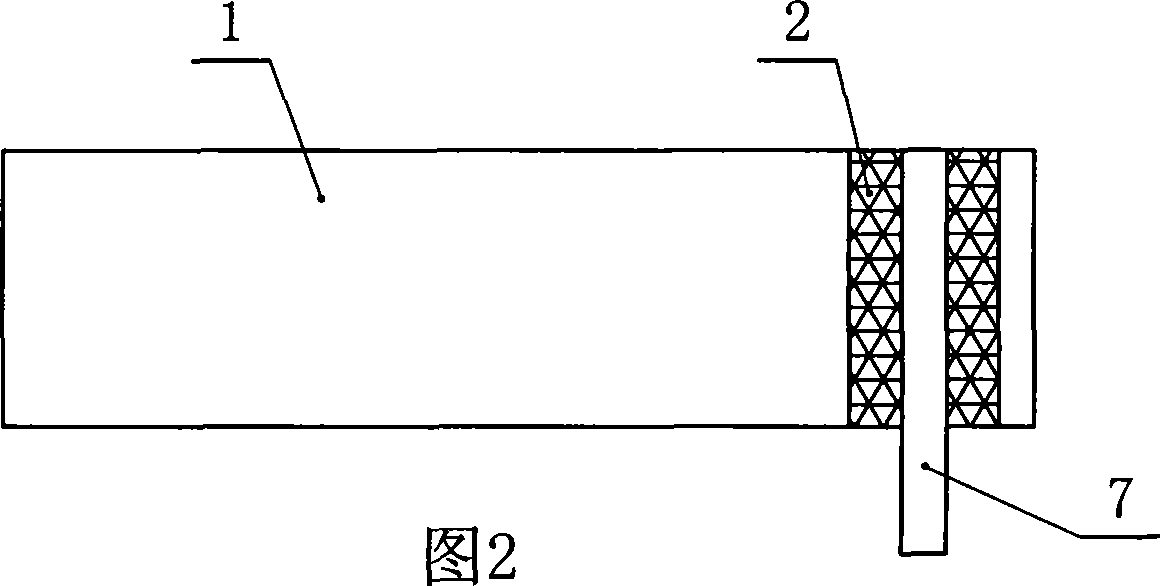

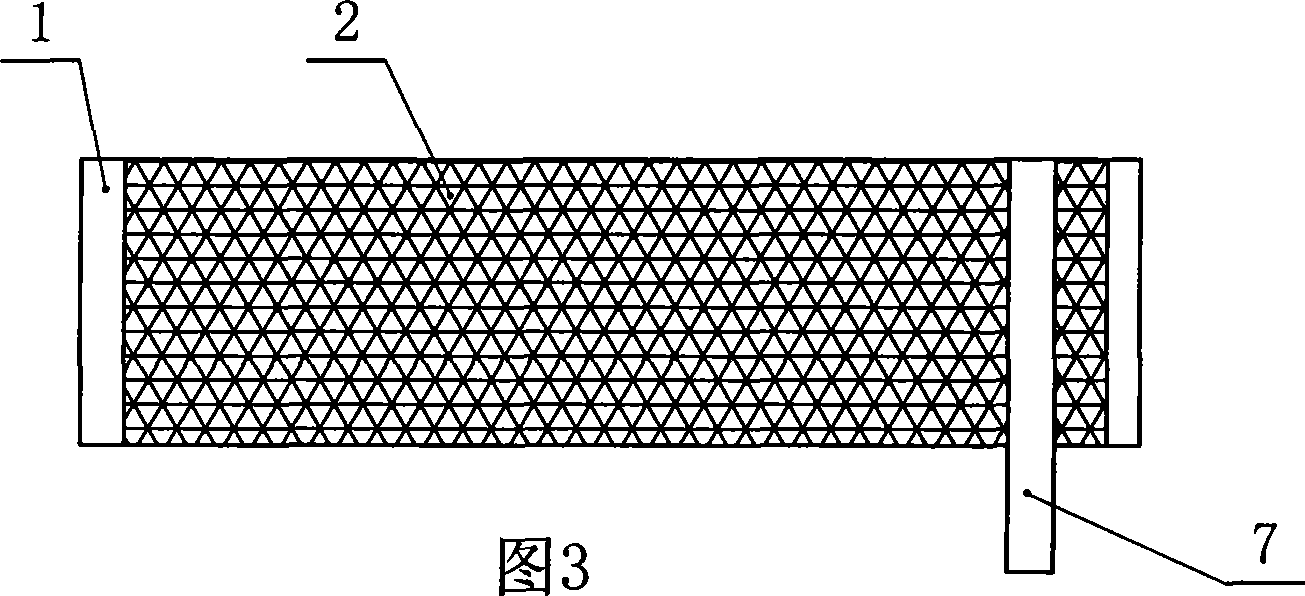

[0072] (2) The positive electrode slurry is cast-coated on the surface of the aluminum foil to form a positive electrode sheet, which is pressed on a tablet press and cut into appropriate sizes. The positive electrode slurry of the present invention can be coated on one or both sides of the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com