Method for preparing novel lithium battery diaphragm by coaxial electrostatic spinning

A technology of coaxial electrospinning and lithium battery diaphragm, which is applied in the direction of electrospinning, filament/wire forming, battery pack components, etc., can solve the problems of unfavorable, high ion conductivity and electrochemical performance, and achieve Improve tensile strength, improve high temperature thermal stability, and increase the effect of effective bonding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

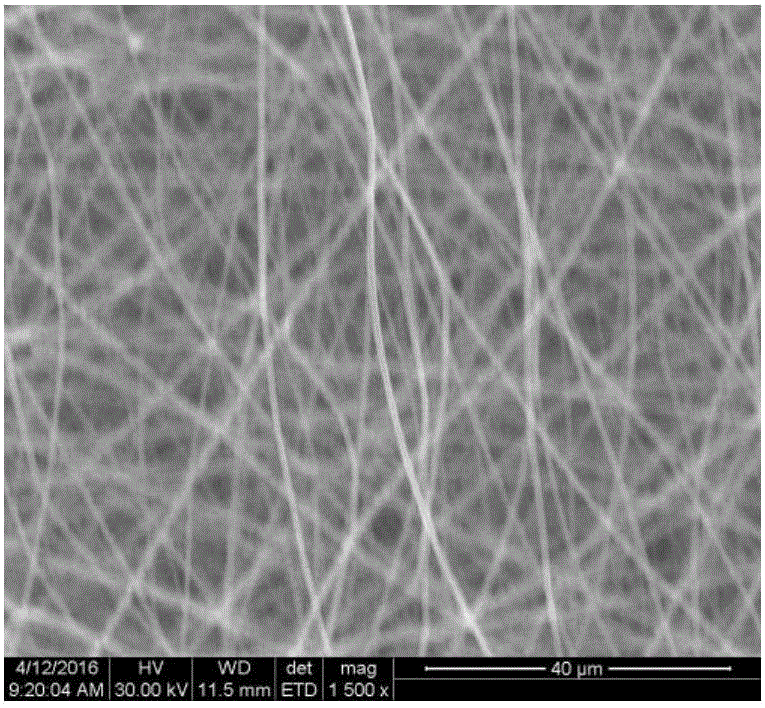

Embodiment 1

[0031] Take a certain amount of tetrahydrofuran and N-methylpyrrolidone mixed solvent with a volume ratio of 3:7, dissolve a certain amount of PPESK powder in a round bottom flask, and prepare a PPESK polymer solution with a mass fraction of 10%; take a certain volume ratio A 4:6 mixed solvent of N,N dimethylacetamide (DMAc) and acetone was used to dissolve a certain amount of PVDF powder in a round bottom flask to prepare a PVDF solution with a mass fraction of 8%, and the two solutions were respectively Place in a magnetic stirrer at a constant temperature of 60°C for 12 hours to obtain a spinning solution, which is then stored in a brown glass bottle for use. Use a disposable syringe with a capacity of 10ml to take 4ml of polyarylether sulfone ketone spinning solution and 10ml of polyvinylidene fluoride spinning solution respectively, choose a flat stainless steel needle with a diameter of 0.3mm as the core layer solution needle for coaxial spinning, and place the two The t...

Embodiment 2

[0034] Take a certain amount of tetrahydrofuran and N,N dimethylacetamide (DMAc) mixed solvent with a volume ratio of 4:6, dissolve a certain amount of PPESK powder in a round bottom flask, and prepare a PPESK polymer solution with a mass fraction of 15%. ; Remove a certain amount of N,N dimethylacetamide (DMAc) and acetone mixed solvent with a volume ratio of 3:7, dissolve a certain amount of PVDF powder in a round bottom flask, and prepare a PVDF solution with a mass fraction of 12% , the two solutions were respectively placed in a magnetic stirrer at a constant temperature of 60°C for 12 hours to obtain a spinning solution, which was then stored in a brown glass bottle for use. Use a disposable syringe with a capacity of 10ml to take 4ml of polyarylether sulfone ketone spinning solution and 10ml of polyvinylidene fluoride spinning solution respectively, choose a flat stainless steel needle with a diameter of 0.3mm as the core layer solution needle for coaxial spinning, and p...

Embodiment 3

[0037] Take a certain amount of tetrahydrofuran and N,N dimethylformamide (DMF) mixed solvent with a volume ratio of 6:4, dissolve a certain amount of PPESK powder in a round bottom flask, and prepare a PPESK polymer solution with a mass fraction of 20%. ; Remove a certain amount of N,N dimethylacetamide (DMAc) and acetone mixed solvent with a volume ratio of 5:5, dissolve a certain amount of PVDF powder in a round bottom flask, and prepare a PVDF solution with a mass fraction of 16% , the two solutions were respectively placed in a magnetic stirrer at a constant temperature of 60°C for 12 hours to obtain a spinning solution, which was then stored in a brown glass bottle for use. Use a disposable syringe with a capacity of 10ml to take 6ml of polyarylether sulfone ketone spinning solution and 8ml of polyvinylidene fluoride spinning solution respectively, choose a flat stainless steel needle with a diameter of 0.3mm as the core layer solution needle for coaxial spinning, and put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com