Method for preparing anode material of lithium ion battery in series of phosphate of olivine type

A lithium-ion battery, olivine-type technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problem of difficulty in preparing mixed uniform metal ion-doped lithium iron phosphate cathode materials, affecting the energy density of cathode materials, and being unable to suppress Oxidation and other problems, to achieve uniform distribution of chemical components, good cycle performance, easy to control the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

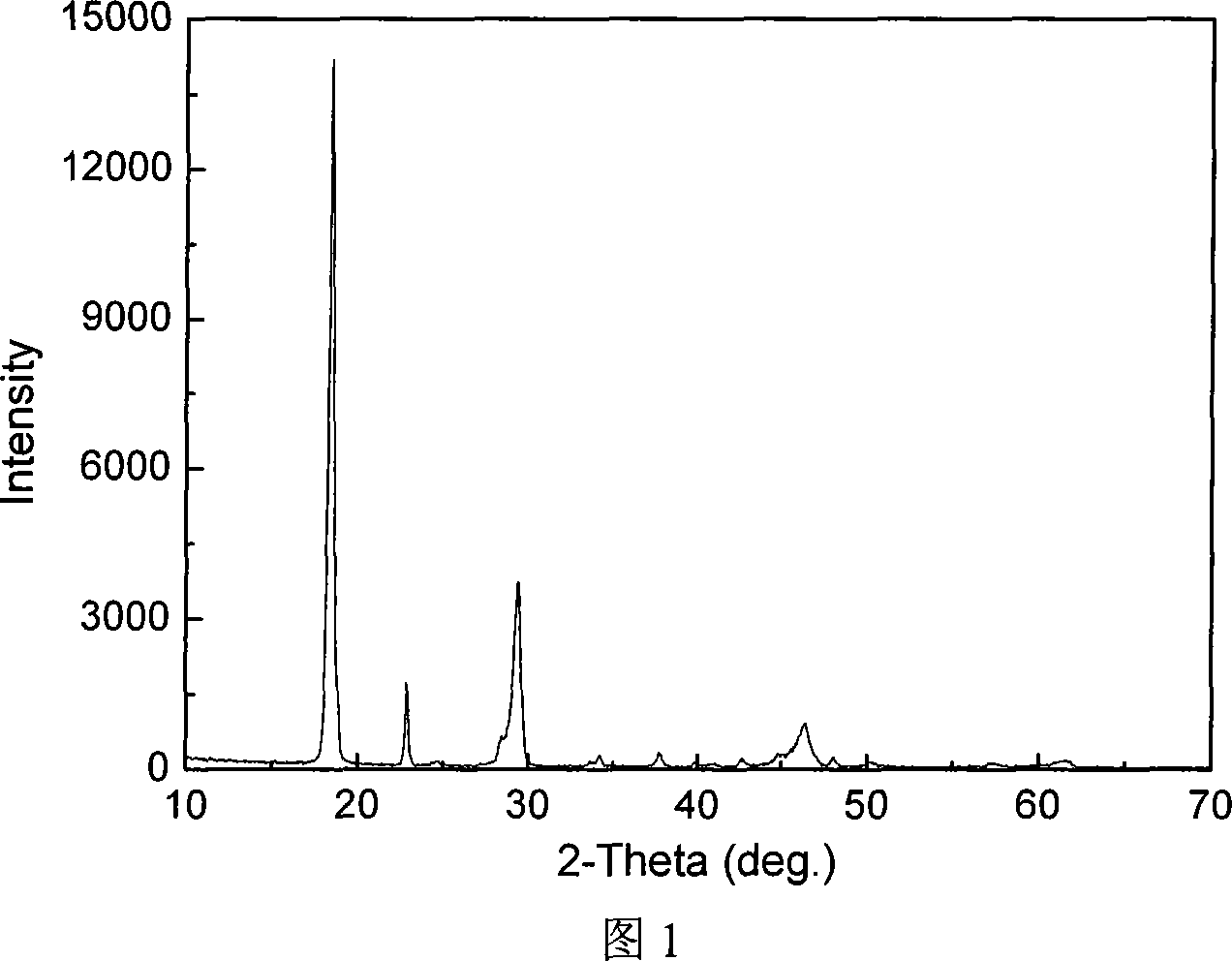

[0027] Mix 1.0mol / L oxalic acid solution with 0.8mol / L ferrous sulfate and nickel sulfate mixed solution (wherein the molar ratio of iron to nickel is: N Fe2+ :N Ni2+ = 4:1) mixed, controlled reaction temperature 50°C, reaction pH value 2.0, obtained compound oxalate precipitate, filtered, washed and dried, mixed with stoichiometric ratio NH 4 h 2 PO 4 and Li 2 CO 3 , adding an appropriate amount of absolute ethanol, milling on a ball mill for 5 hours, and drying to obtain a sample. The sample was transferred to a closed reaction furnace, under the protection of argon atmosphere, decomposed at 380°C for 5h, heated to 600°C, burned for 20h, and then cooled to room temperature with the furnace. The X-ray diffraction analysis of the obtained product shows that it is an orthorhombic olivine-type lithium iron phosphate with a complete crystal structure.

Embodiment 2

[0029] The total concentration (Fe+Ni) is 0.8mol / L, different Fe 2+ with you 2+ Mix the molar ratio mixed solution with 1.2mol / L oxalic acid solution, the reaction pH value is 2.0, and the reaction temperature is 50°C. After the reaction precipitate is filtered, washed and dried, an appropriate amount of NH is added according to the stoichiometric ratio. 4 h 2 PO 4 , Li 2 CO 3, ball milled in ethanol medium for 5h. After the ball-milled mixed sample was dried and screened, it was transferred to a closed reaction furnace, under the protection of an argon atmosphere, it was thermally decomposed at 380°C for 5h, heated to 600°C for 20h, and then cooled to room temperature with the furnace. The obtained product was assembled into an experimental battery, and its initial discharge specific capacity was measured by constant current charge and discharge technology, and the constant current discharge was carried out at a discharge current of 0.1C. Their initial discharge specific...

Embodiment 3

[0032] The total concentration (Fe+Ni) is 0.8mol / L, Fe 2+ with you 2+ The molar ratio is: N Fe2+ :N Ni2+ = The mixed solution of 0.95:0.05 is mixed with 1.2mol / L oxalic acid solution, the reaction pH value is controlled to 2.0, and the reaction temperature is 50°C. After the reaction precipitate is filtered, washed and dried, an appropriate amount of NH is added according to the stoichiometric ratio. 4 h 2 PO 4 , Li 2 CO 3 , ball milled in ethanol medium for 5h. After the ball-milled mixed sample was dried and sieved, it was transferred to a closed reaction furnace, under the protection of argon atmosphere, it was thermally decomposed at different pretreatment temperatures for 5 hours, heated to 600 ° C for 20 hours, and then cooled to room temperature with the furnace. The obtained product was assembled into an experimental battery, and its initial discharge specific capacity was measured by constant current charge and discharge technology, and the constant current dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com