Electric coupling assembly of double-row planet gear apparatus of mixed dynamic vehicle

A hybrid vehicle, double-row planetary technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of less speed ratio and uncompact transmission system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

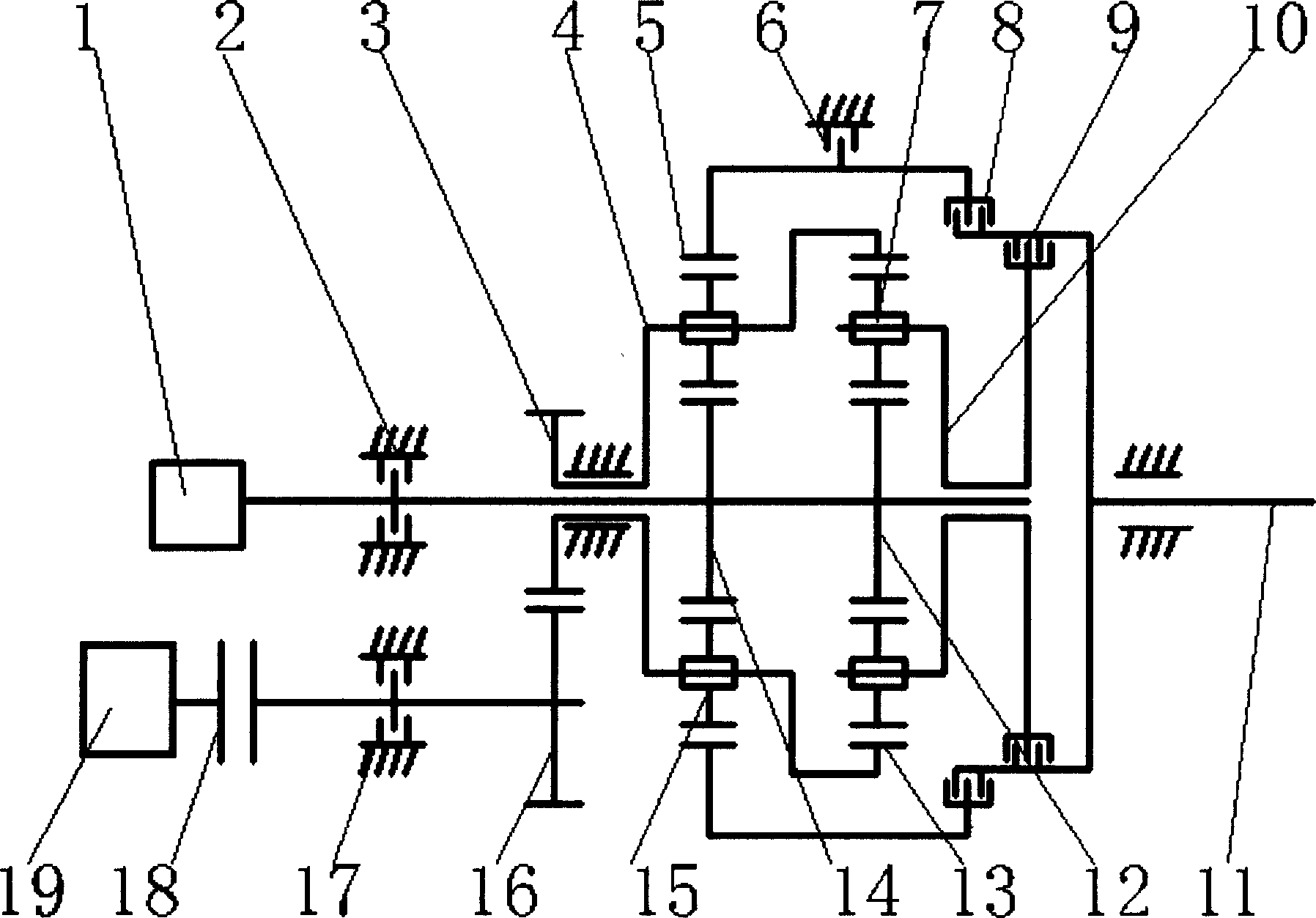

[0008] Now in conjunction with accompanying drawing for further explanation.

[0009] The present invention is composed of motor 1, three clutches 8,9,18, three brakes 2,6,17, a pair of constant mesh gears 3,16, front planetary row 4,5,14,15, rear planetary row 7, 10,12,13, output shaft 11, engine 19 forms. The output shaft of the motor 1 is connected with the front sun gear 14 and the rear sun gear 12, the engine 19 is connected with the driving gear 16 through the engine clutch 18, the driven gear 3 is connected with the front planetary carrier 4 and the rear ring gear 13 as one, and the output shaft 11 The connection with the front ring gear 5 or the rear planet carrier 10 is realized through the front ring gear clutch 8 and the rear planet carrier clutch 9 .

[0010] Through the combination of different states of the three clutches 8, 9, 18 and the three brakes 2, 6, 17, various working modes of the hybrid electric vehicle using this assembly can be obtained, as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com