Anode material and cathode material for lithium ion battery and modifying method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor conductivity of lithium iron phosphate, and achieve the effects of simplifying the manufacturing process, simplifying the manufacturing process, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

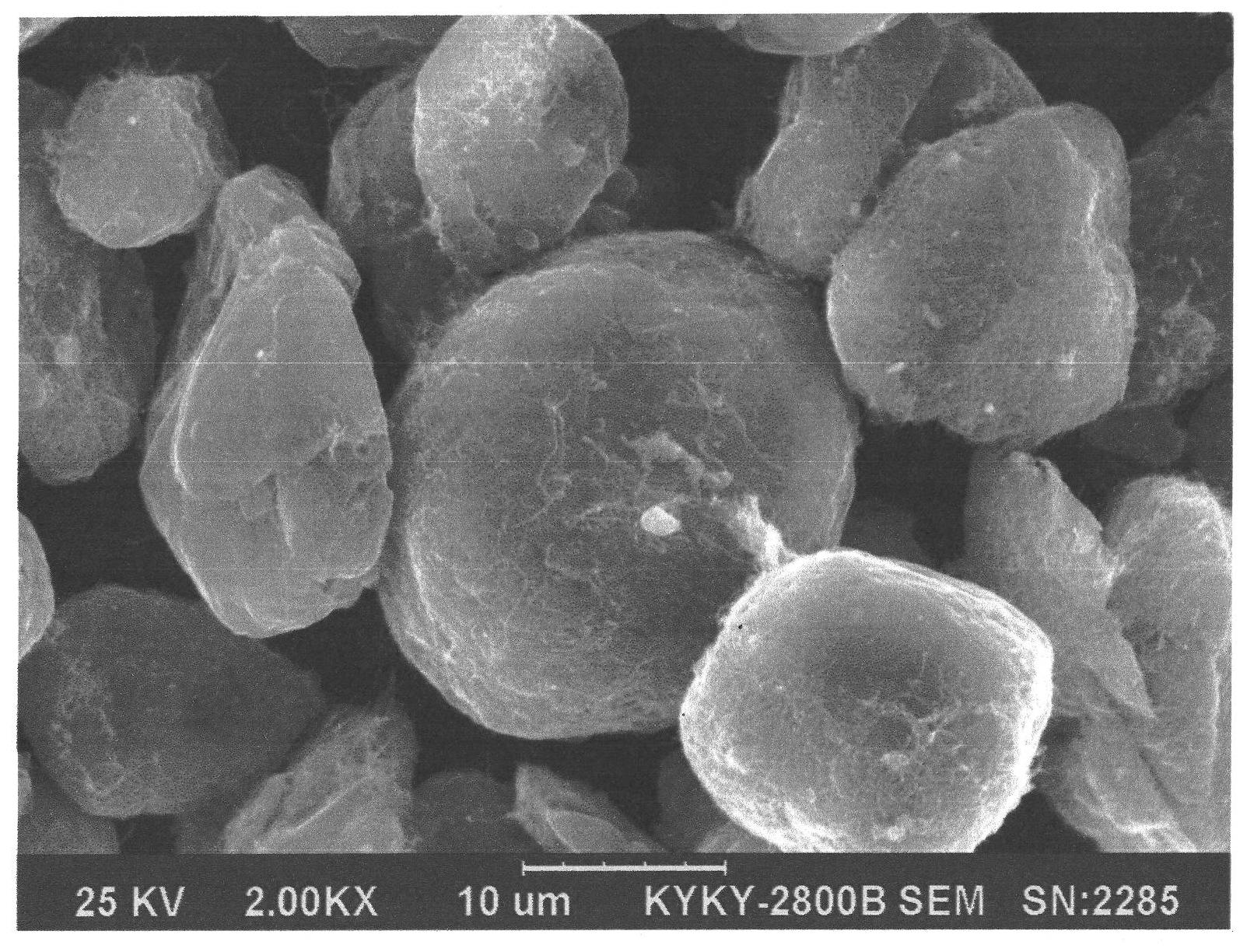

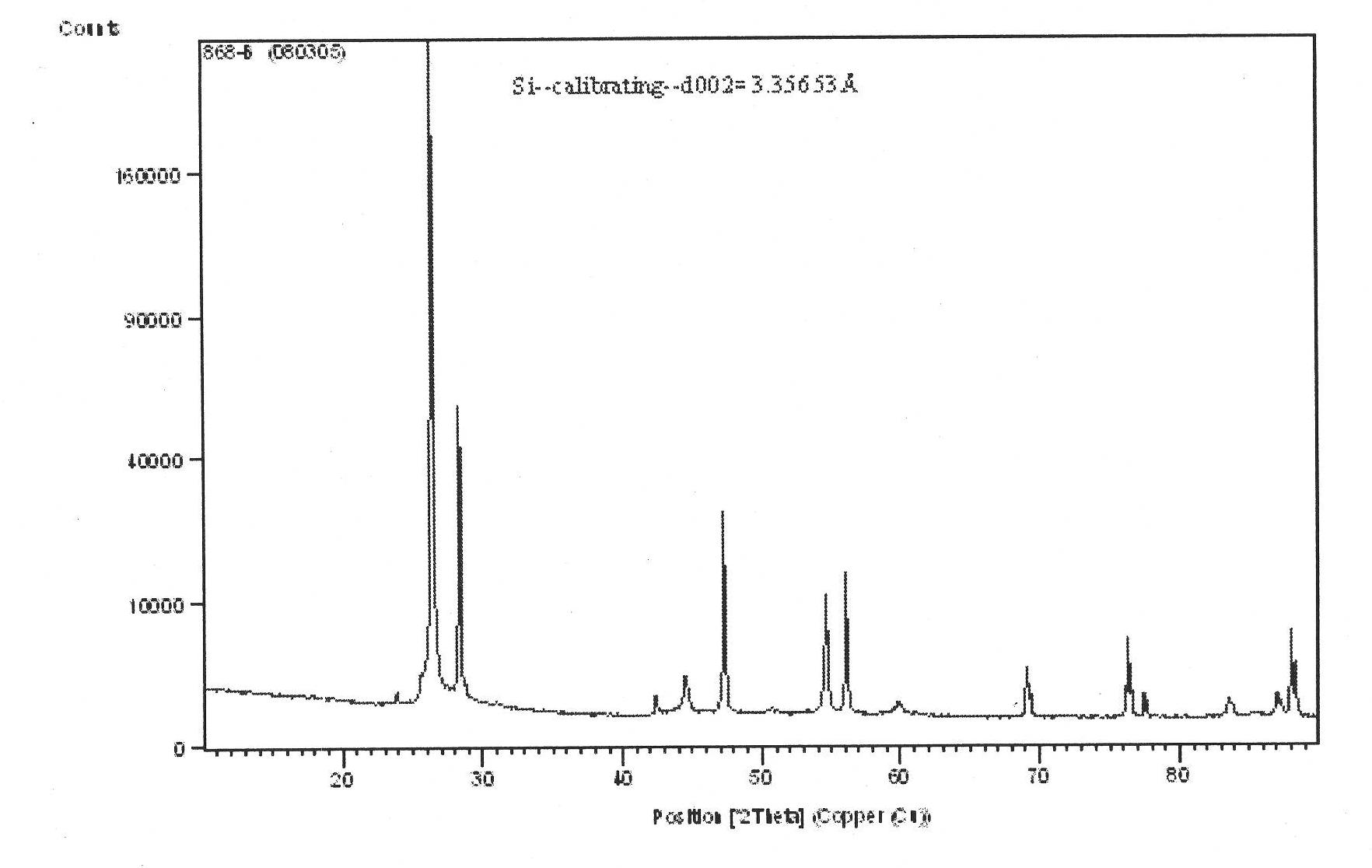

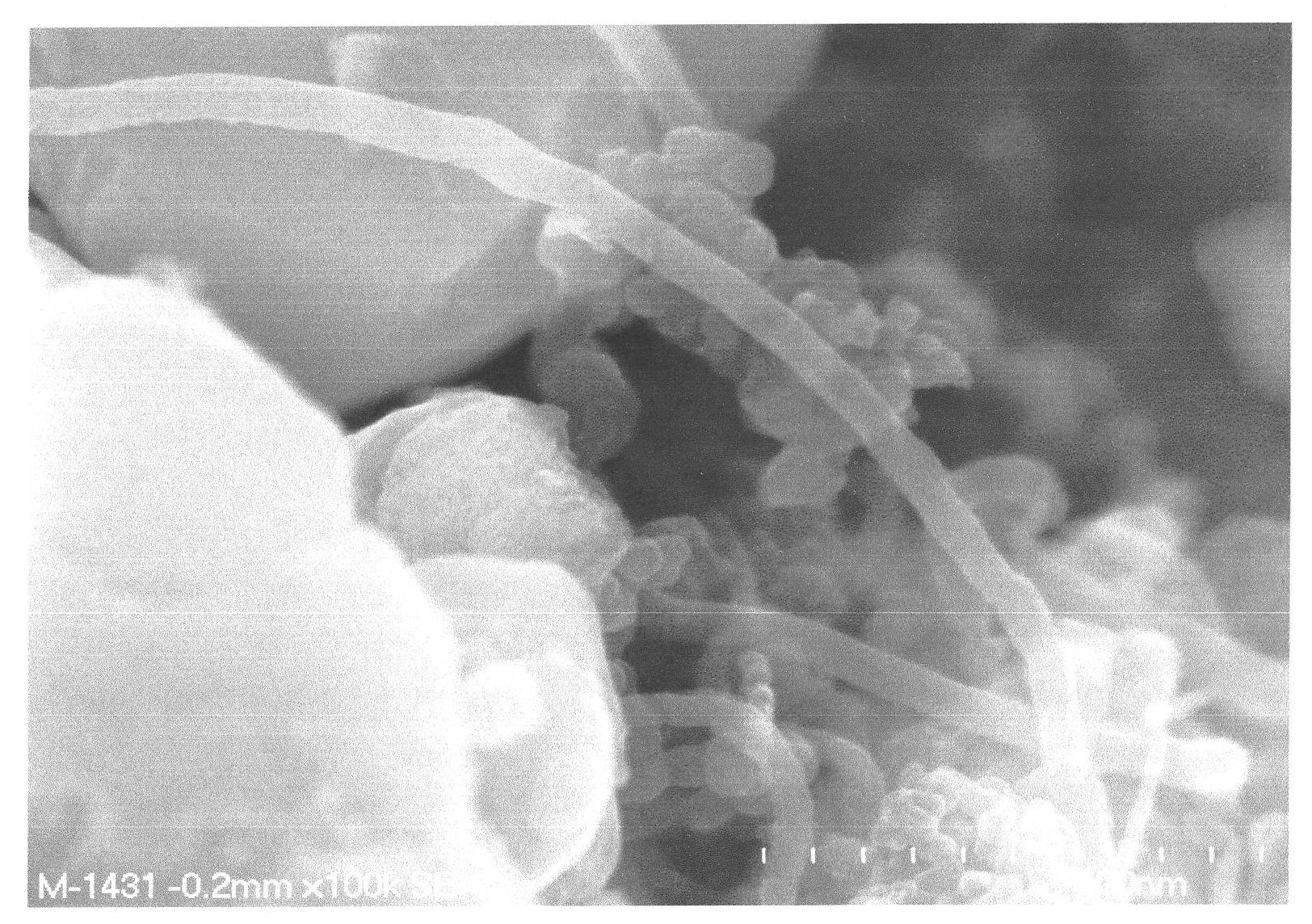

[0030] Example 1, 0.3 gram of ferrocene and 300 gram of natural spherical graphite were mixed with a planetary ball mill to make them evenly mixed. Put the mixture of ferrocene and natural spherical graphite into a graphite crucible, place it in a tube furnace, and pass it with a mixed gas of acetylene and nitrogen, the volume ratio of which is 0.1:1. Heating at a heating rate of 0.2° C. / min to 900° C. and keeping it warm for 1 hour. After the reaction was completed, the sample after the reaction was tested with a scanning electron microscope. Mix the mixture of catalyst, graphite and carbon nanotubes with the mixed acid of concentrated sulfuric acid and concentrated nitric acid at a mass ratio of 1:1, slowly add water and stir until the slurry becomes a paste, then move it into the reactor at 5°C / min The heating rate was heated to 400°C and reacted for 1 hour, and stirred every 1 hour during the reaction, and the interval was 5 minutes. Afterwards, the slurry is moved into a...

Embodiment 2

[0032] Embodiment 2, 0.6 grams of ferrocene and 300 grams of natural spherical graphite are mixed with a roller ball mill to make them evenly mixed. Put the mixture of ferrocene and natural spherical graphite into a graphite crucible, place it in a tube furnace, and pass it with a mixed gas of xylene and argon with a volume ratio of 3:1. Heating at a heating rate of 2°C / min to 800°C for 20 hours. After the reaction was completed, the sample after the reaction was tested with a scanning electron microscope. Mix the mixture of catalyst, graphite and carbon nanotubes with the mixed acid of concentrated hydrochloric acid and hydrofluoric acid at a mass ratio of 1:50, slowly add water and stir, and move the slurry into the reactor after it becomes a paste, and heat it at 5°C / The heating rate of 1 minute is heated to 300° C. for 5 hours, and the reaction is stirred once every 1 hour during the reaction, and the interval time is 5 minutes. Afterwards, the slurry is moved into a cen...

Embodiment 3

[0034] Embodiment 3, 15 grams of nickel foam and 300 grams of artificial spherical graphite are mixed with a roller ball mill to make them evenly mixed. Put the mixture of foamed nickel and artificial spherical graphite into a graphite crucible, place it in a tube furnace, and pass it with a mixed gas of acetylene and nitrogen, the volume ratio of which is 10:1. Heat at a heating rate of 10°C / min to 400°C and keep warm for 72 hours. After the reaction is completed, use a scanning electron microscope to test the sample after the reaction. Mix the mixture of catalyst, graphite and nano-carbon fiber with concentrated hydrochloric acid and hydrofluoric acid. The acid is mixed according to the mass ratio of 1:50, slowly add water and stir, and after the slurry becomes a paste, move it into the reactor and heat it to 50°C at a heating rate of 5°C / min to react for 20 hours. Stir every 1 hour for 5 minutes. Afterwards, the slurry is moved into a centrifugal washing device, and contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com