Aluminium ion battery and preparation method thereof

An aluminum ion battery, aluminum ion technology, applied in the direction of electrolyte battery manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as unfavorable commercial application, poor cycle performance, low specific capacity, etc., and achieve abundant reserves and thermal stability. Good, good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

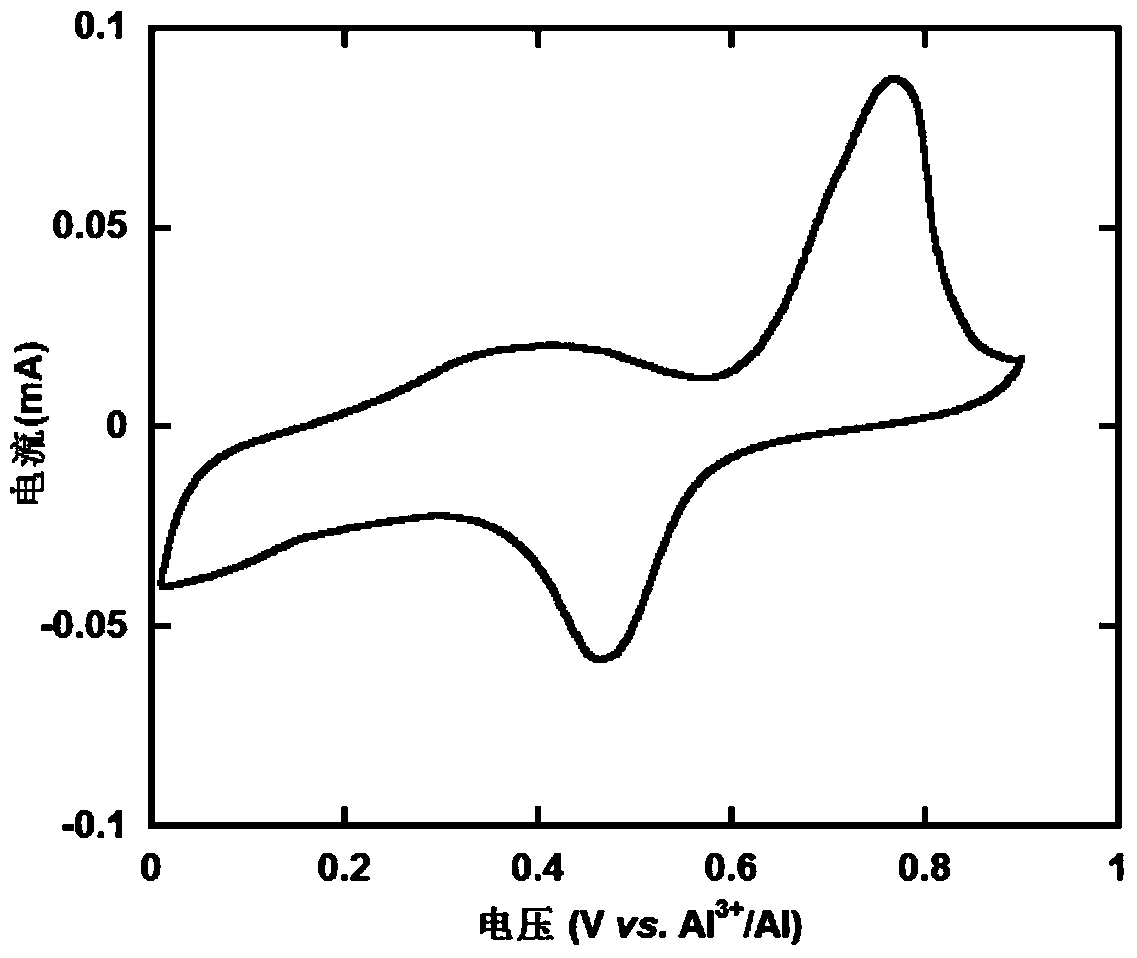

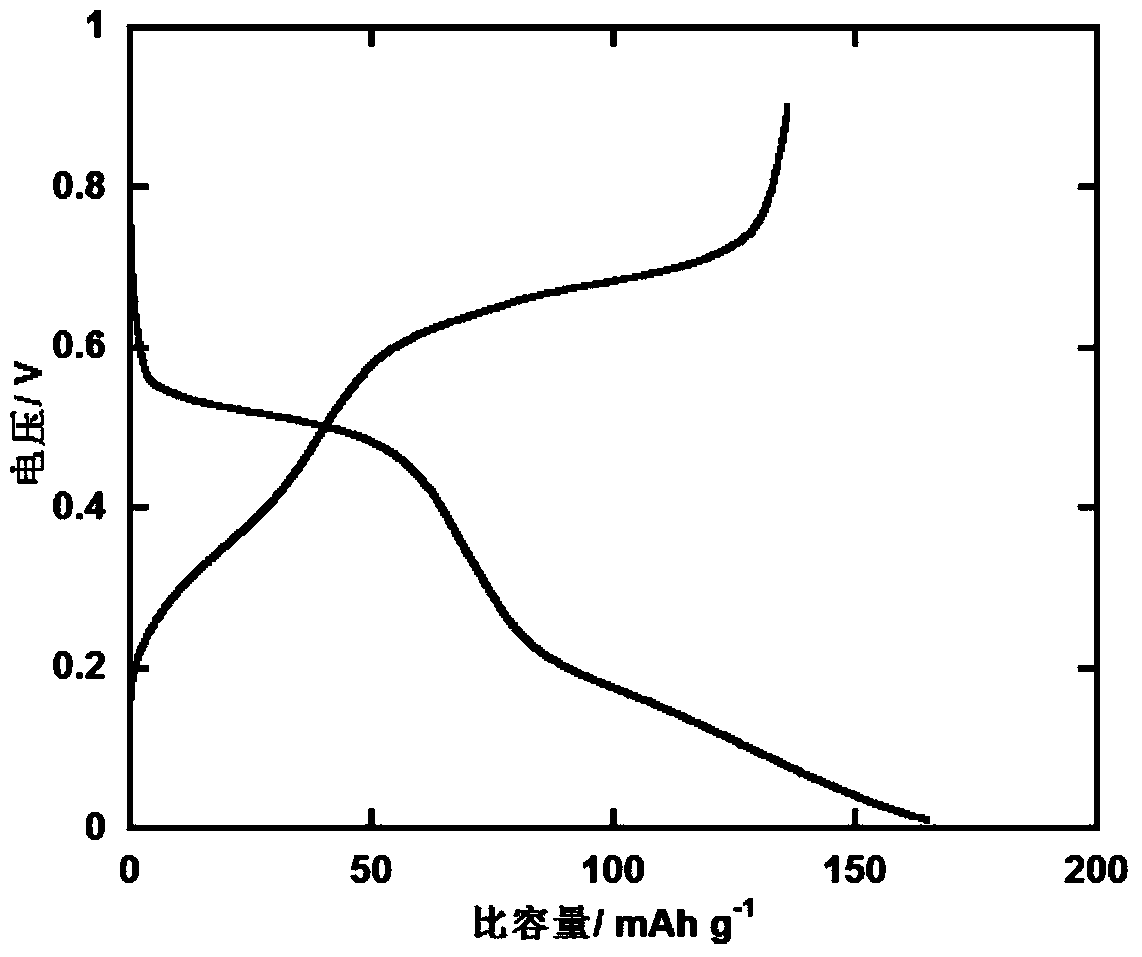

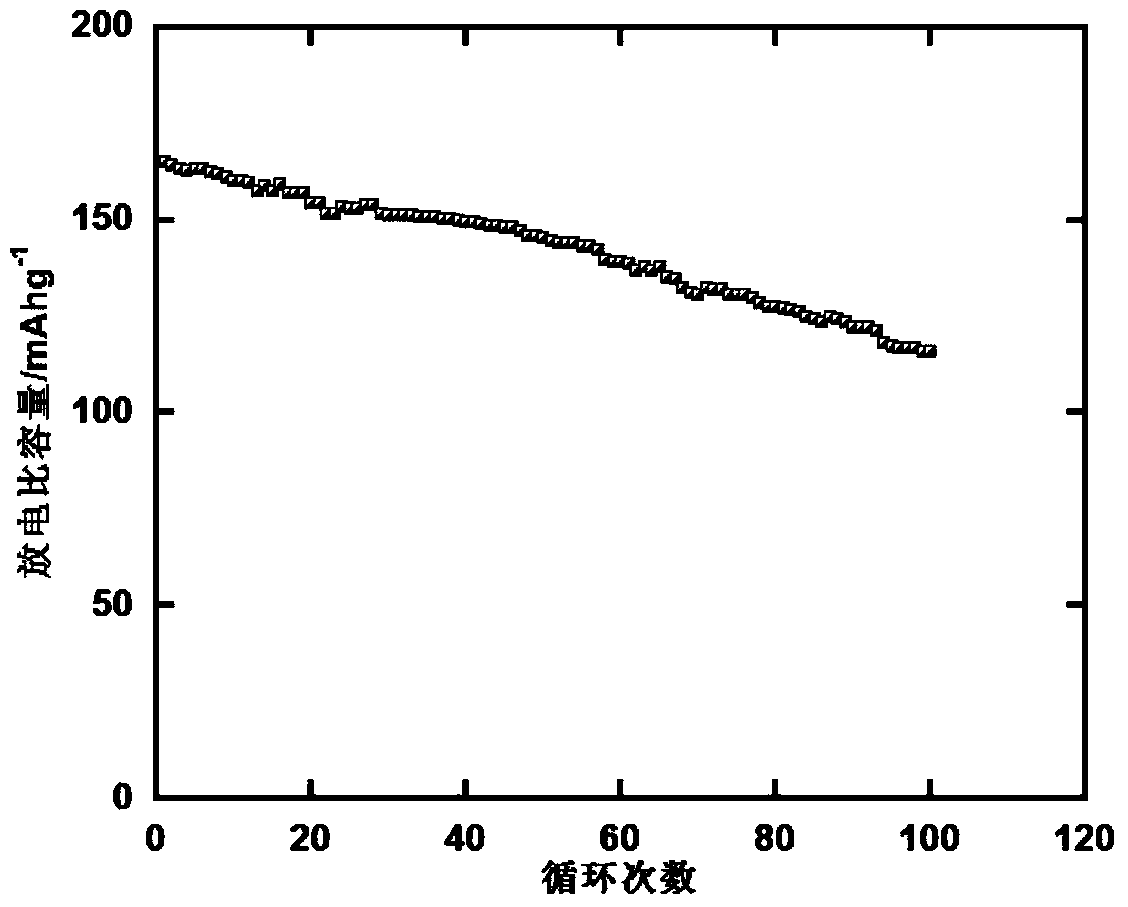

[0031] use VO 2 As the positive electrode active material, it is mixed with the conductive agent acetylene black and the binder polytetrafluoroethylene (PTFE) in a mass ratio of 75:15:10, added to absolute ethanol for dispersion, and ultrasonically vibrated at 60 °C oven to dry to gel, the gel evenly coated on stainless steel foil, as a hypervalent ion battery positive, it was dried in 120 °C oven for 12 hours, and then in the gloves filled with argon Assemble the battery in the box. The counter electrode is a high-purity metal aluminum sheet, which is soaked in absolute ethanol for 3 hours, ultrasonically vibrated, and dried to serve as the negative electrode. AlCl 3 and 1-butyl-3-methylimidazolium chloride in a mass ratio of 1:1 to synthesize an ionic liquid as the electrolyte of the hypervalent ion battery of the present invention. The diaphragm is fiberglass (GF / D, Whatman). After the battery is sealed, cleaned, packaged, edging and inspected, a super-price ion battery...

Embodiment 2

[0034] use Ta 2 o 5 As the positive electrode active material, it is mixed with conductive agent super carbon and binder polytetrafluoroethylene (PTFE) in a mass ratio of 80:10:10, added to absolute ethanol for dispersion, and ultrasonically vibrated at 60 ℃ oven to dry to gel, the gel evenly coated on the stainless steel foil, as a hypervalent ion battery cathode. After drying in an oven at 120 °C for 12 h, the cells were assembled in an argon-filled glove box. The counter electrode is a high-purity metal aluminum sheet. AlBr 3and 1-ethyl-3-methylimidazolium chloride in a mass ratio of 1.1:1 to synthesize an ionic liquid as the electrolyte of the hypervalent ion battery of the present invention. The diaphragm is polypropylene microporous diaphragm material. After the battery is sealed, cleaned, packaged, edging and inspected, a super-price ion battery product is obtained.

[0035]

Embodiment 3

[0037] with Nb 2 o 5 As the positive electrode active material, it is mixed with conductive carbon nanotubes and binder polyvinylidene fluoride (PVDF) at a mass ratio of 75:15:10, added to absolute ethanol for dispersion, and ultrasonically oscillated Finally, it is dried in an oven at 60°C until it becomes gel, and the gel is evenly coated on the nickel foam to serve as the positive electrode of the hypervalent ion battery. After drying in an oven at 120 °C for 12 h, the cells were assembled in an argon-filled glove box. The counter electrode is a high-purity metal aluminum sheet. AlCl 3 and 1-propyl-3-methylimidazolium chloride in a mass ratio of 1.2:1 to synthesize an ionic liquid as the electrolyte of the hypervalent ion battery of the present invention. The diaphragm is polyethylene microporous diaphragm material. After the battery is sealed, cleaned, packaged, edging and inspected, a super-price ion battery product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com