Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

An artificial graphite negative electrode, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity, low degree of graphitization, low compaction density, etc., and achieve long cycle life and high rate performance. , the effect of increasing capacity and compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

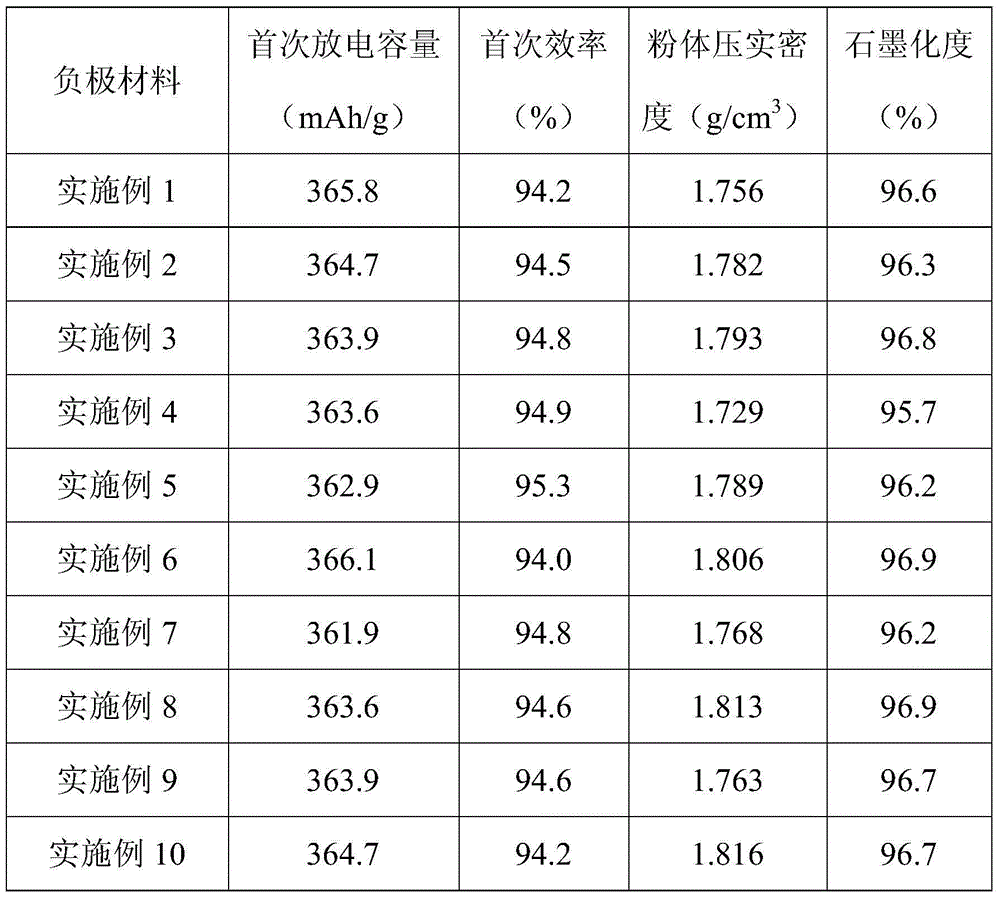

Examples

Embodiment 1

[0055] The needle coke with a carbon content of 93.0% and a volatile content of 10.0% is crushed, spheroidized, and graded to obtain a 3-50 μm powder material; The mass ratio of 100:15:10 is mixed with a kneader. After mixing evenly, the above material is cold molded to obtain a cylindrical molded product. The processing temperature is 25°C, the processing pressure is 20.0MPa, and the processing time is 0.2h. Put the above-mentioned cylindrical shaped product at 600°C for thermal roasting treatment for 360 hours, and after cooling to room temperature, crush and ball mill the above-mentioned pressed product. The ball-milling treatment time is 480 minutes, the processing temperature is 30.0°C, and the rotation speed is 600r / min. The above powder was graphitized at 3300° C. for 12 hours, and the obtained material was sieved, demagnetized, and sieved to obtain a lithium-ion battery graphite negative electrode material with an average particle size of 16.8 μm.

Embodiment 2

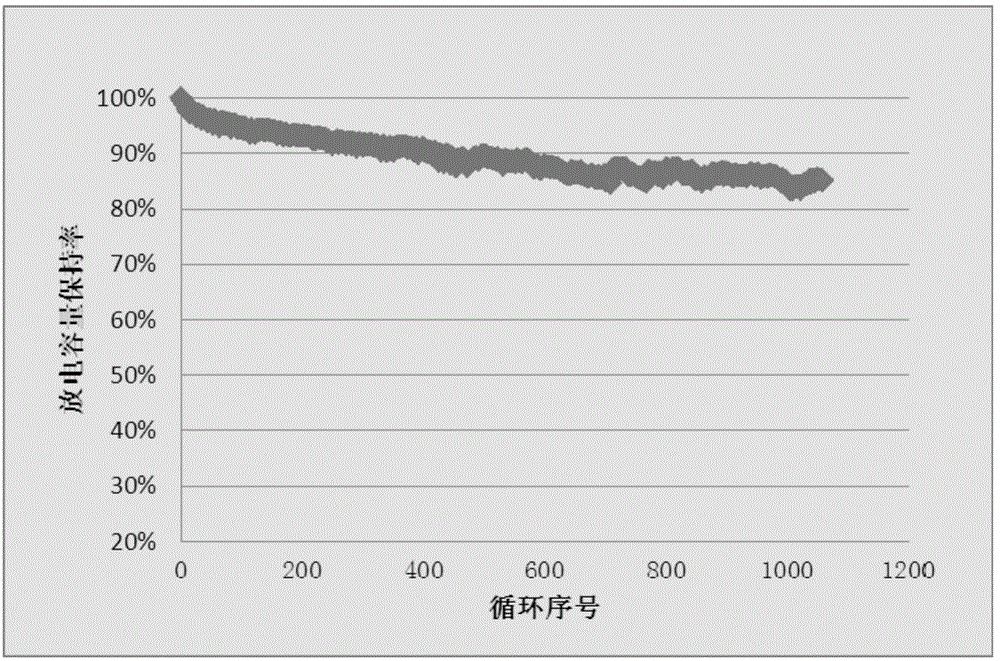

[0057] The petroleum residue with a carbon content of 85.0% and a volatile content of 18.0% is crushed, spheroidized, and graded to obtain a 3-50 μm powder material; : The mass ratio of 12:5 is mixed with a kneader. After mixing evenly, the above materials are subjected to isostatic pressing to obtain a square-shaped pressed product. The processing temperature is 200°C, the processing pressure is 150.0MPa, and the processing time is 2.0h. Put the above-mentioned square-shaped pressed product at 900°C for 240 hours, and after cooling to room temperature, crush and ball-mill the above-mentioned pressed piece. min. The above powder was graphitized at 3300° C. for 16 hours, and the obtained material was sieved, demagnetized, and sieved to obtain a lithium-ion battery graphite negative electrode material with an average particle size of 17.5 μm. figure 2 It is the charge-discharge cycle performance diagram at normal temperature 1C of the present embodiment.

Embodiment 3

[0059] The mesophase carbon microspheres with a carbon content of 99% and a volatile content of 5% are crushed, spheroidized, and graded to obtain a 3-50 μm powder material; According to the mass ratio of 100:8:12, the vacuum kneader is used for mixing treatment. After mixing evenly, the above materials are subjected to isostatic pressing treatment to obtain a block-shaped pressed product. The treatment temperature is 300 ° C, the treatment pressure is 120.0 MPa, and the treatment time is 1.0h. Put the above-mentioned square-shaped molded product at 450°C for 450 hours of thermal roasting treatment, and after cooling to room temperature, carry out crushing and fusion treatment on the above-mentioned pressed molded product. min. The above powder was graphitized at 3350° C. for 18 hours, and the obtained material was sieved, demagnetized, and sieved to obtain a lithium-ion battery graphite negative electrode material with an average particle size of 19.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com