Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "High hydrostatic pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

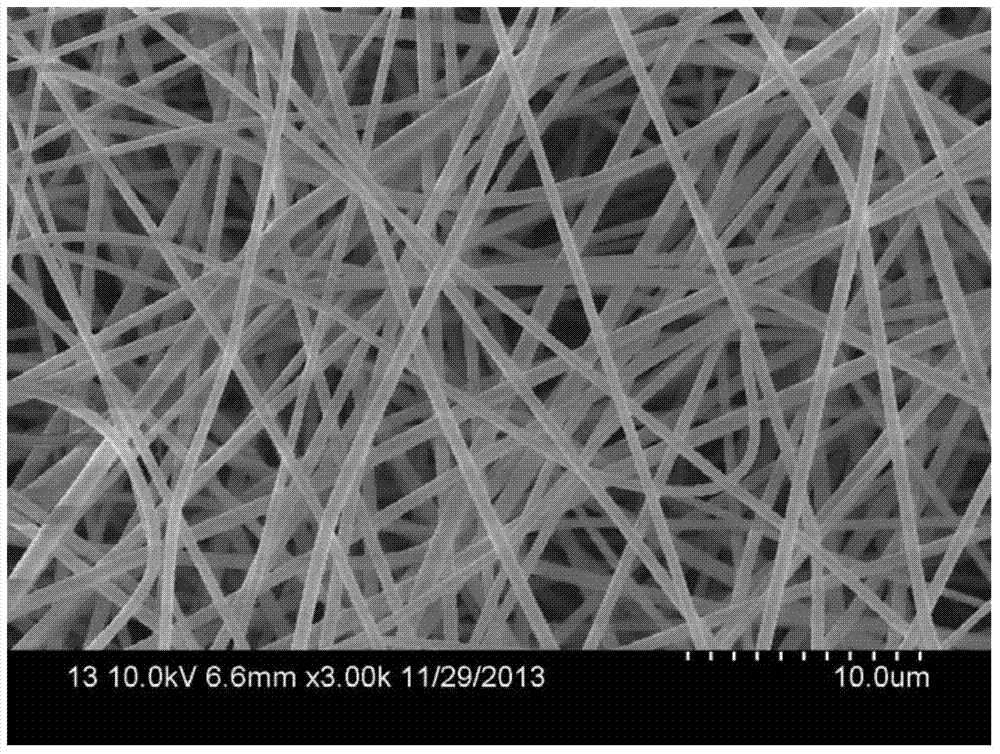

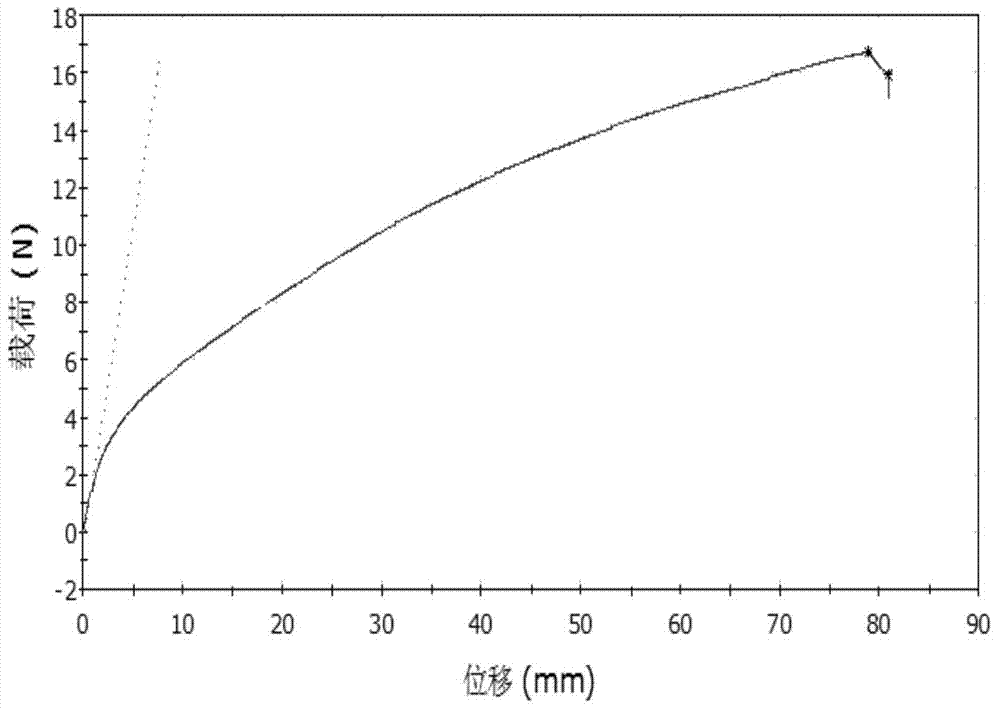

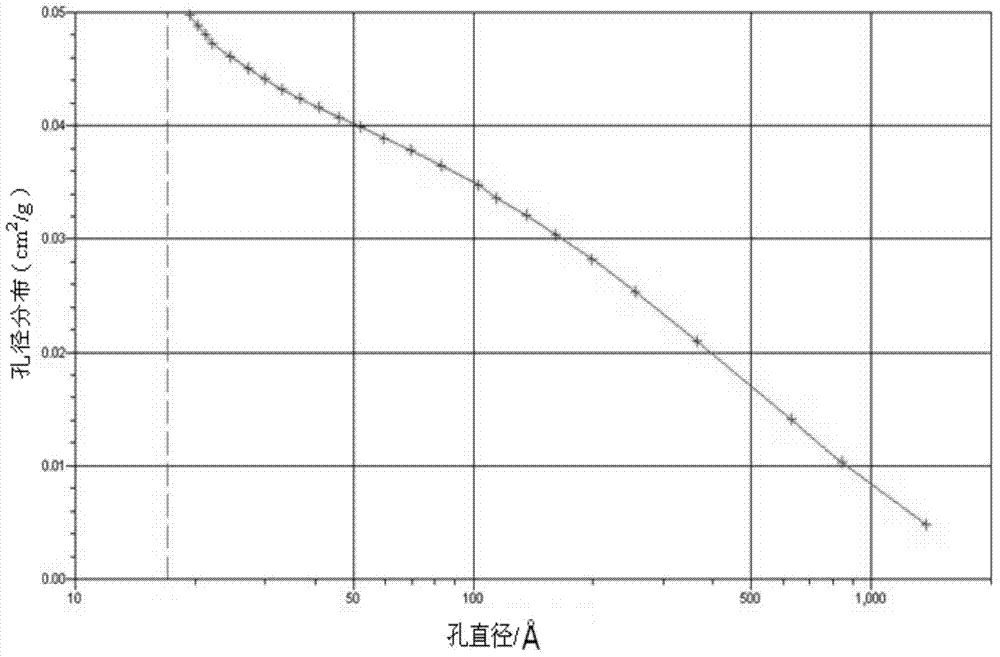

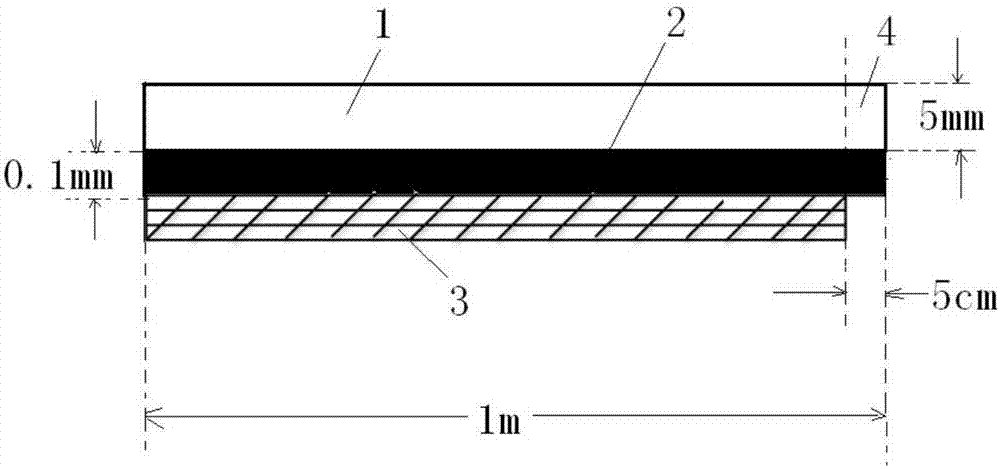

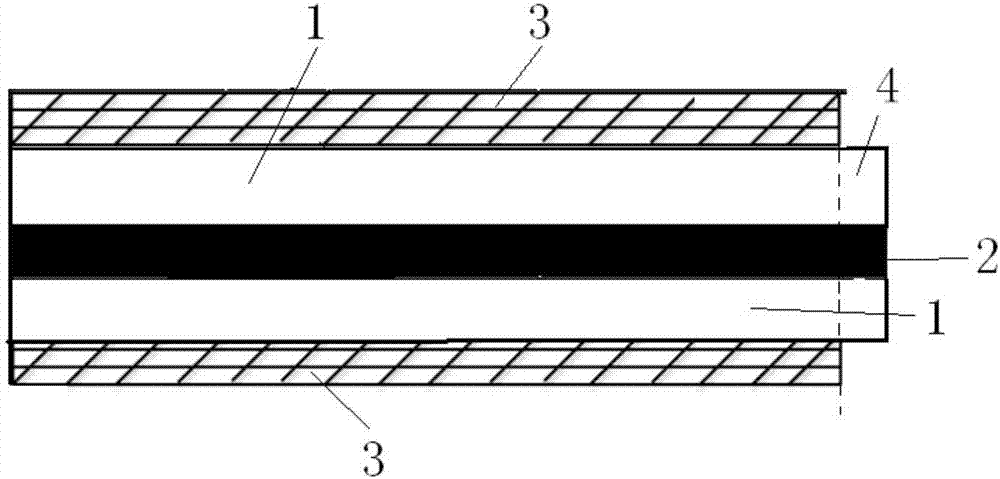

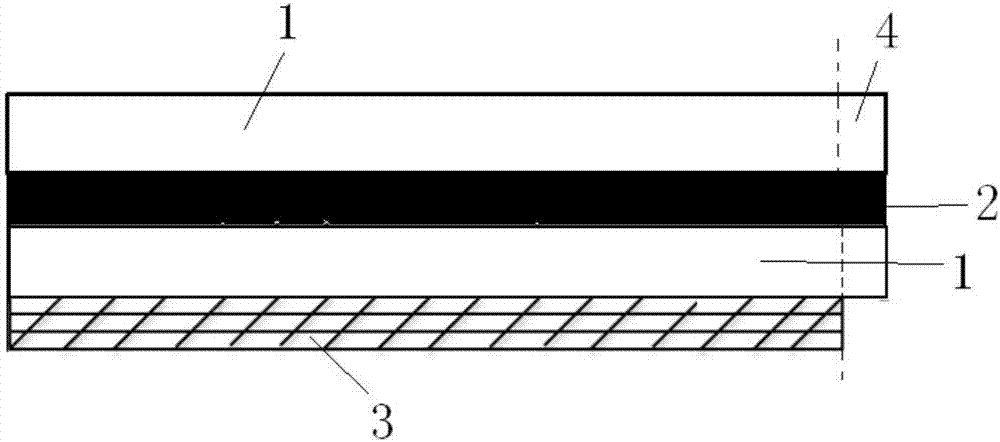

Nanofiber composite membrane and preparation method thereof

InactiveCN104727016AWide range of usesHigh hydrostatic pressure resistanceNon-woven fabricsAdhesivesPolymer scienceNanofiber

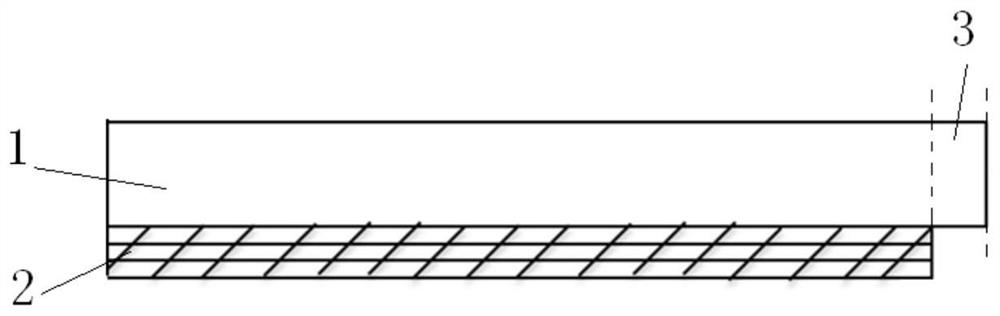

The invention provides a preparation method of a nanofiber composite membrane. The method includes the steps that a spinning solution and melt of a high-melting-point polymer are provided, a spinning solution and melt of a low-melting-point polymer are provided, and the melting point difference of the high-melting-point polymer and the low-melting-point polymer is not smaller than 10 DEG C; the spinning solution of the high-melting-point polymer and the spinning solution of the low-melting-point polymer are subjected to electrostatic spinning, and accordingly an electrostatic spinning high-melting-point polymer fiber membrane and an electrostatic spinning low-melting-point polymer fiber membrane are obtained; the low-melting-point polymer melt and the high-melting-point polymer melt are subjected to melt-blowing spinning, so that a melt-blowing spinning low-melting-point polymer fiber membrane and a melt-blowing spinning high-melting-point polymer fiber membrane are obtained; the melt-blowing spinning high-melting-point polymer fiber membrane and the electrostatic spinning low-melting-point polymer fiber membrane undergo composite hot pressing, or the melt-blowing spinning low-melting-point polymer fiber membrane and the electrostatic spinning high-melting-point polymer fiber membrane undergo composite hot pressing, and thus the nanofiber composite membrane is obtained. The nanofiber composite membrane has high tensile strength which reaches up to 22 MPa-32 MPa.

Owner:ZHEJIANG WEIXING IND DEV

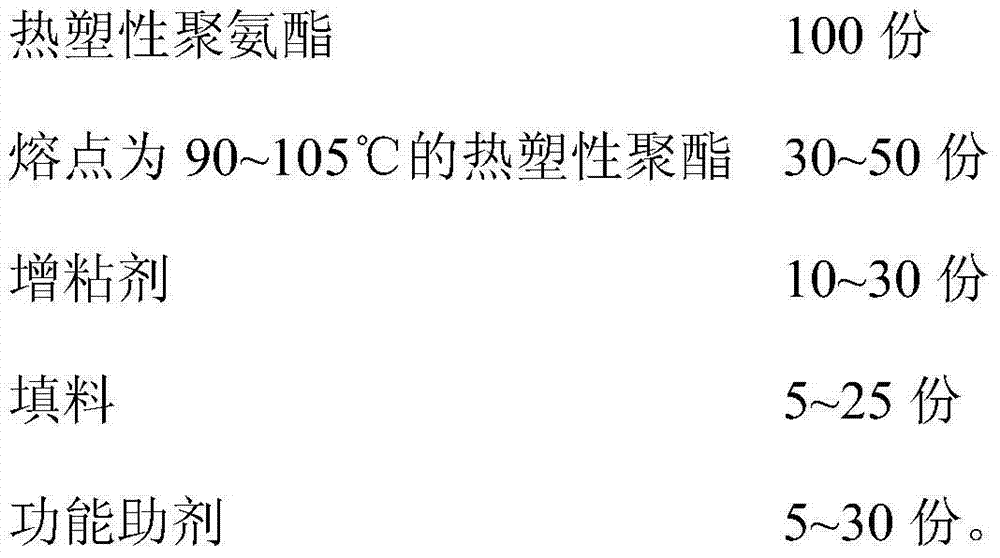

Low-melting-point and high-bonding-strength TPU (thermoplastic polyurethane) hot melt adhesive membrane and preparation method thereof

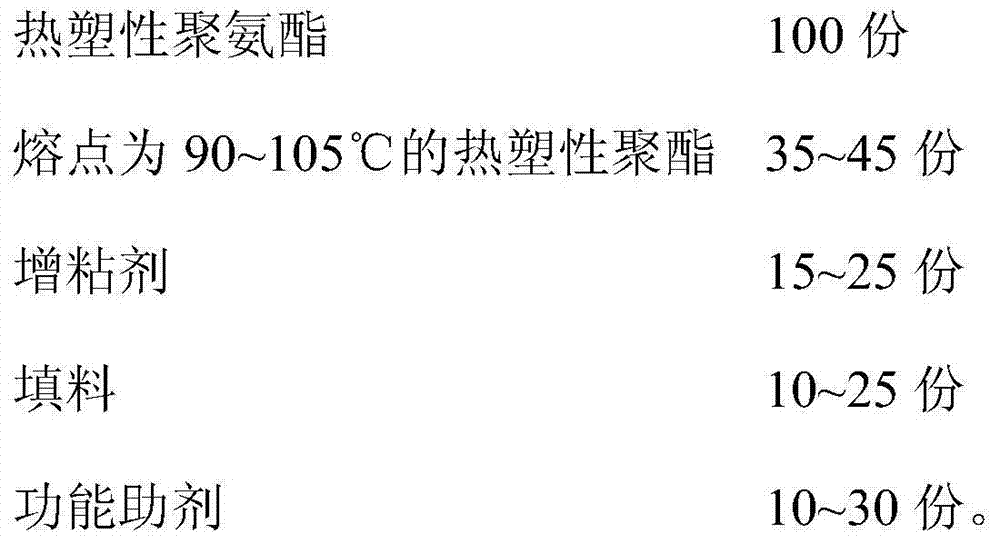

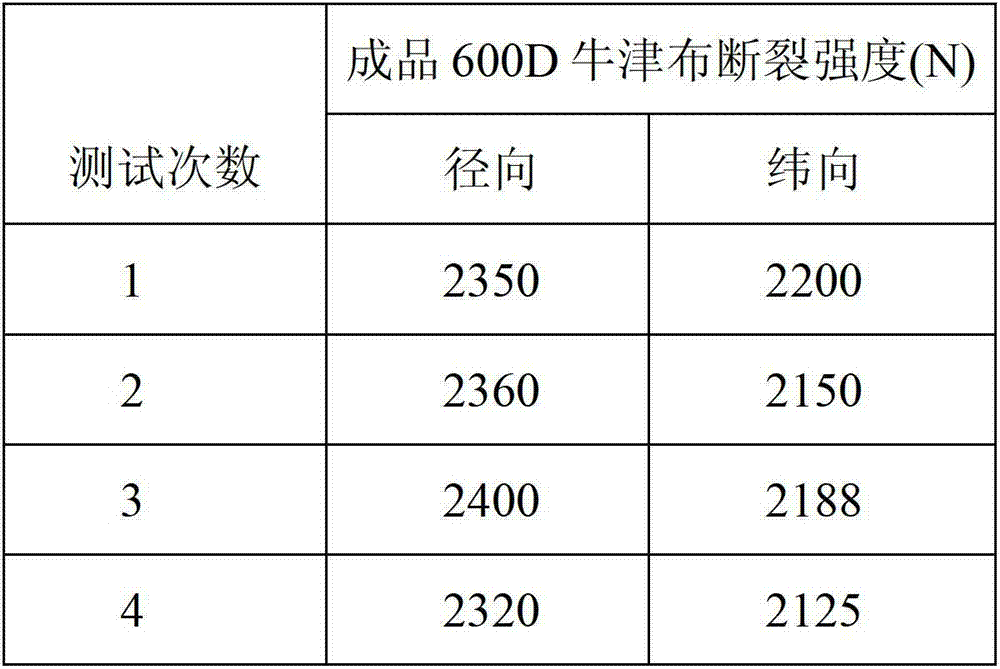

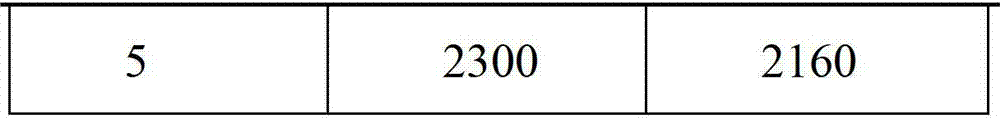

ActiveCN104263259AUniform thicknessSimple bonding processNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyester

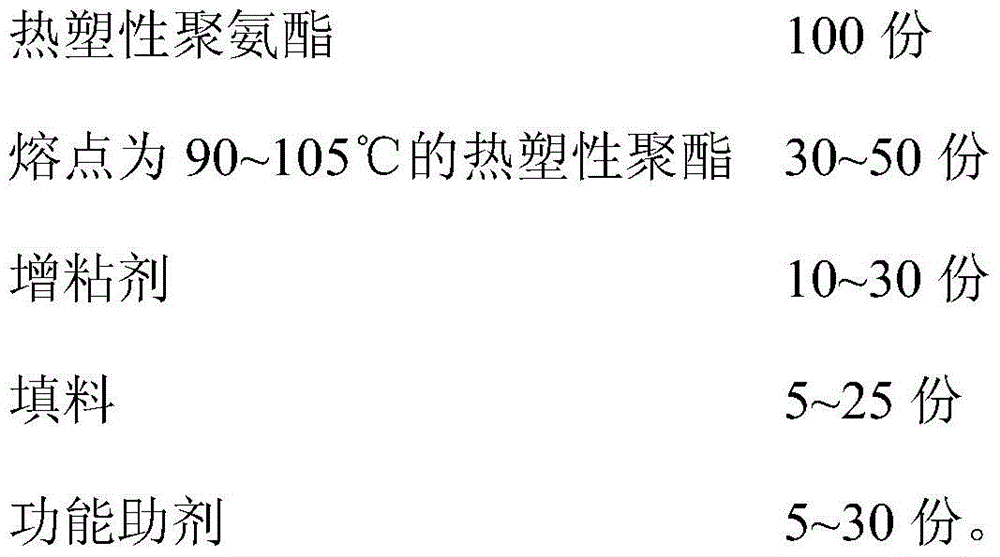

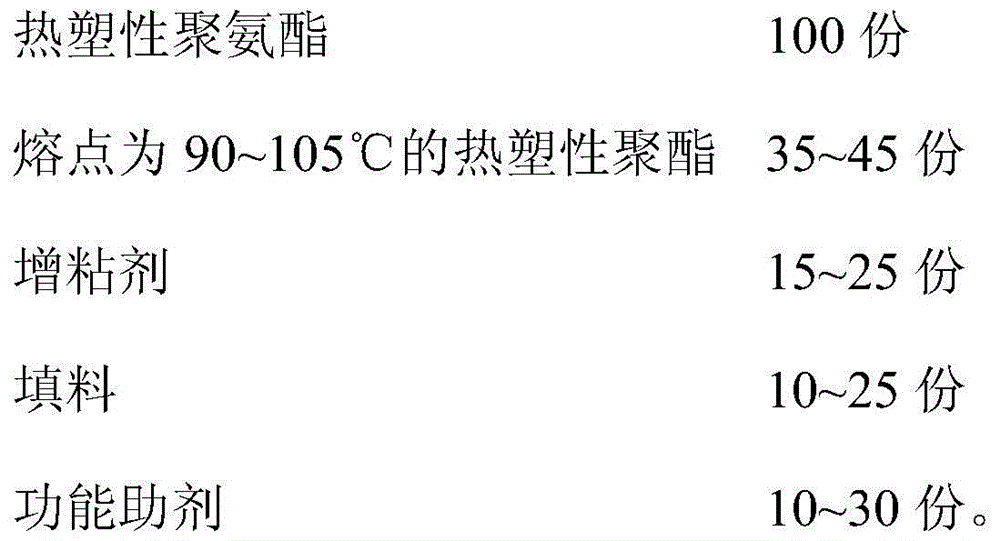

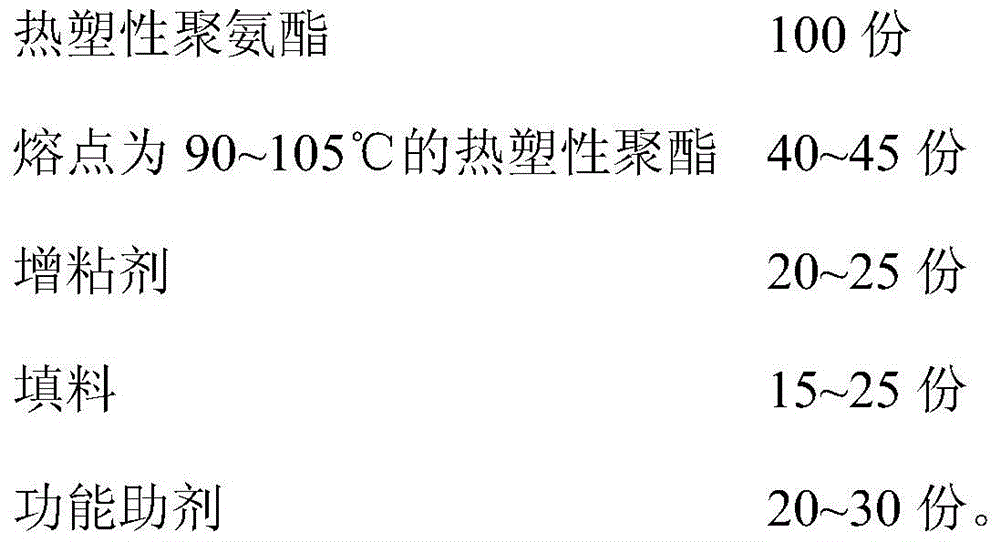

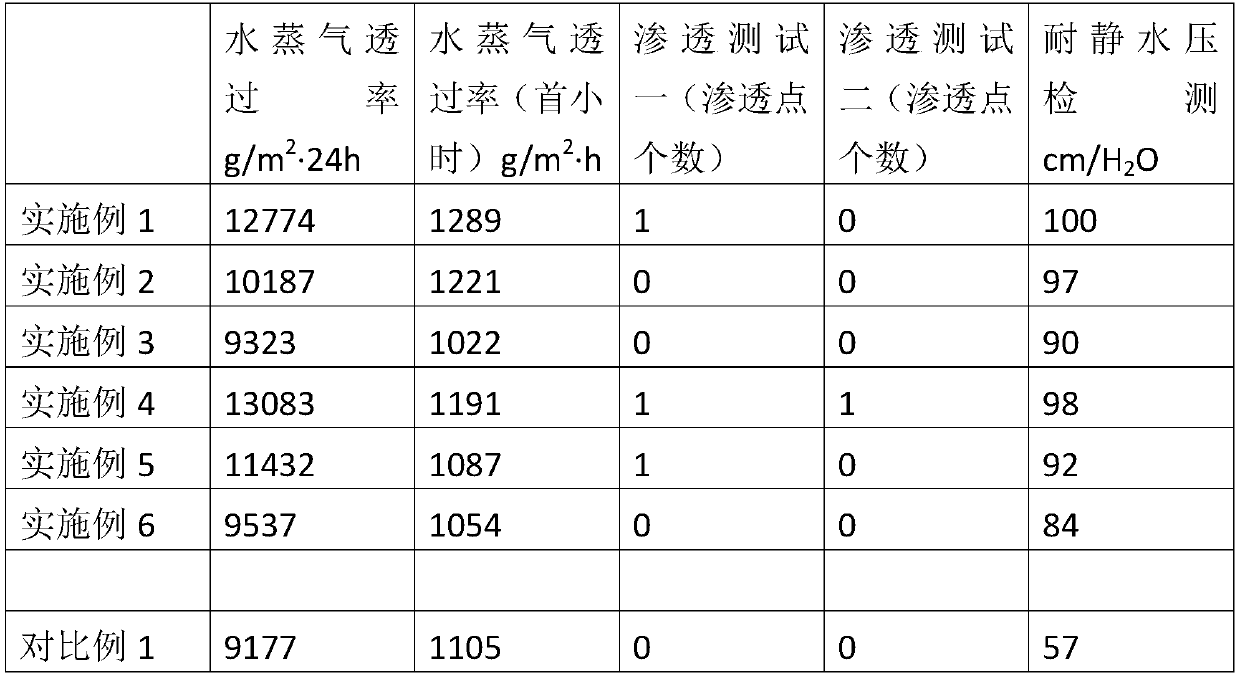

The invention provides a TPU (thermoplastic polyurethane) hot melt adhesive membrane. The TPU hot melt adhesive membrane is mainly prepared from the following raw materials in parts by weight: 100 parts of TPU, 30-50 parts of thermoplastic polyester of which the melting point is 90-105 DEG C, 10-30 parts of a tackifier, 5-25 parts of a filling material and 5-30 parts of a functional auxiliary agent. The hot melt adhesive membrane prepared by using the method provided by the invention is of a thermoplastic adhesive, is uniform in thickness and simple in bonding process, is suitable for bonding by adopting an automatic production line, is high in production efficiency and large in peeling strength after bonding, can resist water, heat and salt fog aging in an outdoor harsh environment, is durable in bonding, and can be used for significantly improving the bonding strength of the hot melt adhesive membrane adhered to fabrics.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Preparation technology of camouflage cover cloth

ActiveCN102965974AHigh water repellencyReasonable workmanshipFibre typesTents/canopiesCamouflageCost (economic)

The invention provides a preparation technology of camouflage cover cloth, which comprises the following steps of: (I) performing pretreatment of base cloth for dyeing, printing, coating and sizing; (II) dyeing the base cloth by use of dyeing liquid including dyeing disperse dye with a near-infrared shielding function and an ultraviolet absorbent; (III) printing the dyed base cloth by use of printing slurry including printing disperse dye with a near-infrared shielding function; (IV) bottoming the printed base cloth by use of polyamide resin glue; (V) performing PVC (polyvinyl chloride) whitewashing of the bottomed base cloth by use of PVC coating slurry; (VI) performing PU (polyurethane) silver-surface coating of the base cloth after the PVC whitewashing by use of polyurethane silver slurry; and (VII) performing padding finishing of the base cloth after the PU silver-surface coating in water-repellent finishing liquid, and then drying and baking. According to the invention, fabric has a near-infrared green shielding function, color fastness to light and high resistance against hydrostatic pressure as well as high water sprinkling degree, the technology is reasonable, and the economic cost is low.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

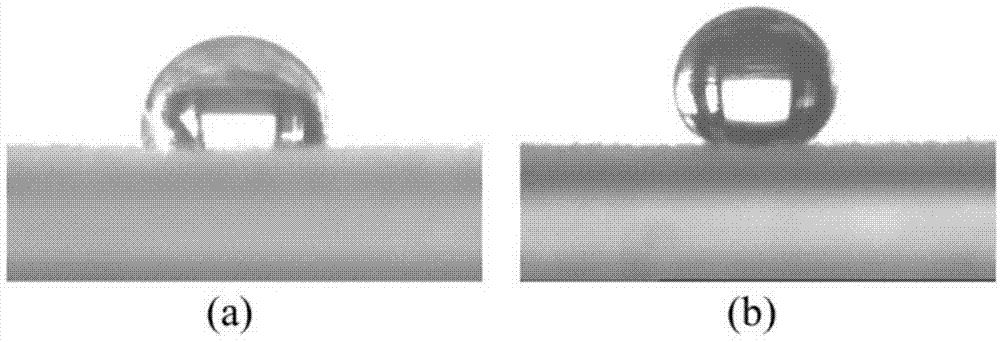

Finishing method of cotton-hydrophobic fabric based on BTCA-TEOS-OA combined treatment

ActiveCN104711852ALower surface energyAvoid environmental problemsLiquid/gas/vapor removalVegetal fibresSurface energyPre treatment

The invention discloses a finishing method of a cotton-hydrophobic fabric based on BTCA-TEOS-OA combined treatment and belongs to the technical field of functional textiles. The finishing method is characterized in that 1,2,3,4-butanetetracarboxylic acid is adopted for pretreating the fabric so as to increase the capability of reaction between the fabric and a following chemical reagent and function as a bridge; tetraethoxysilane is hydrolyzed and condensated under the acidic or alkali condition so as to form particulate matters on the surface of the fabric and play a role in roughening the fabric; due to long-chained alkane type octadecylamine, the surface energy of the fabric can be effectively reduced, and further the environmental problem caused by total-fluoride energy is avoided. The finishing method disclosed by the invention has the advantages that the traditional processes of soaking, rolling, drying and baking are adopted, and a product is good in uniformity and repeatability and low in cost. BTCA, TEOS and OA adopted in the finishing process need to be carried out under the condition of weak acid and weak alkaline, the baking temperature is low and the damage on the fabric is less. The finishing method can be used for finishing the hydrophobic function of the cotton fabrics.

Owner:高青如意纺织有限公司

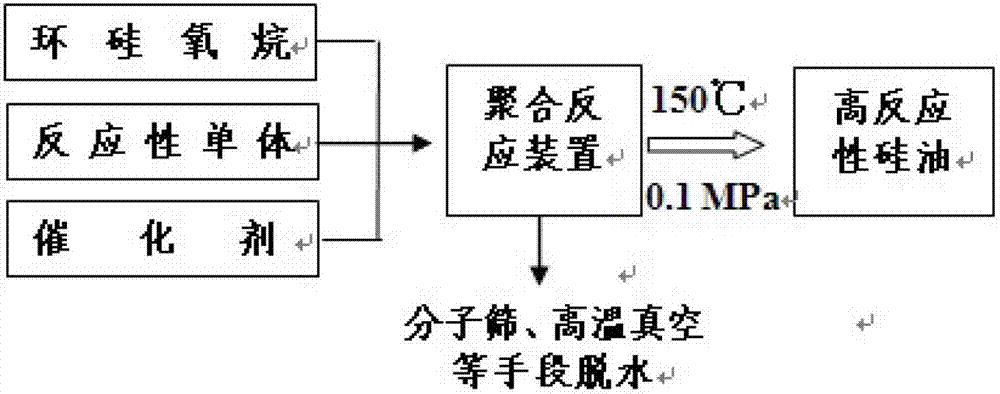

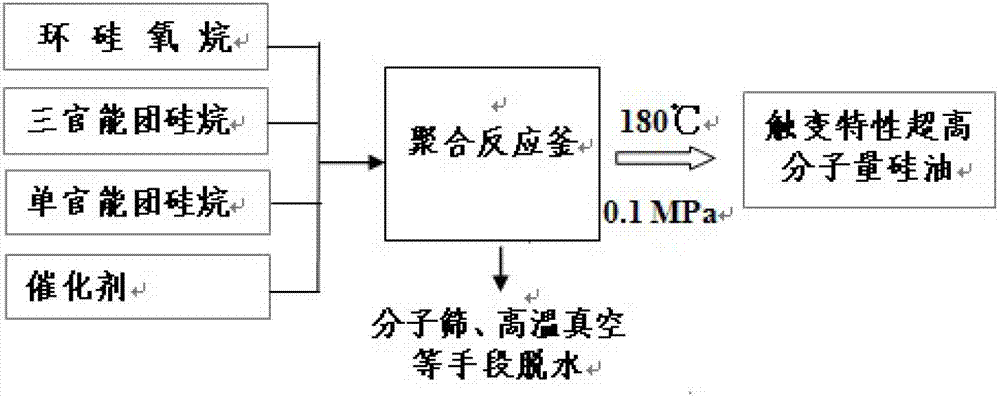

Organic/inorganic nanometer function particle modified organosilicon fabric coating agent preparation method

ActiveCN102898652ADoes not affect softness and comfortHigh strengthVegetal fibresChemical industryPolymer science

The present invention belongs to the technical field of chemical industry, and specifically relates to an organic / inorganic nanometer function particle modified organosilicon fabric coating agent preparation method. The preparation method comprises: adopting an anion ring opening polymerization process to synthesize hyperreactivity silicone oil, a special cross-linking agent, and silicone oil having thixotropy and ultra-high molecule weight; carrying out molecule penetration melting of the hyperreactivity silicone oil, the special cross-linking agent, and the silicone oil having thixotropy and ultra-high molecule weight to synthesize an organosilicon coating agent base gum; and finally adopting a high energy dispersing device to uniformly wrapping nanometer hollow silica microspheres and polymer hollow microspheres into the organosilicon coating agent base gum under a strong shear condition to obtain the organic / inorganic nanometer function particle modified organicsilicon fabric coating agent. With the organic / inorganic nanometer function particle modified organicsilicon fabric coating agent, good crisp hand feeling and slick feeling can be provided for the coated fabric coating, and strength, hydrostatic pressure resistance and waterproof moisture permeation performance of the fabric coating can be significantly improved without influence on softening and comfort of the fabric.

Owner:ZHEJIANG CHANGE ORGANIC SILICON MATERIAL

Raw material composition for preparing blown breathable film, blown breathable film and preparation of blown breathable film

The invention provides a raw material composition for preparing a blown breathable film, a blown breathable film and preparation of the blown breathable film. The raw material composition comprises the following ingredients in percentage by weight (100% in total): 50-70% of inorganic filler coated with a coupling agent on the surface, 25-50% of linear low density polyethylene and 0.2-1.0% of antioxidant, wherein linear low density polyethylene comprises 1-3 kinds of linear low density polyethylene in different densities; density distribution of linear low density polyethylene in the differentdensities is 0.910-0.935g / cm<3>; and melting index distribution at 190 DEG C is 2.5-0.5g / 10min. The invention further provides a masterbatch of the blown breathable film, which is prepared from the raw material composition. The invention further provides a blown breathable film which is prepared by blowing the masterbatch to form a film by a film blowing method and then performing unilateral stretching on the film. The blown breathable film is excellent in comprehensive performance and lower in cost.

Owner:RENOLIT PLASTICS TECH BEIJING CO LTD

Coating technology for cover cloth

InactiveCN103643531AHigh light fastness functionHigh hydrostatic pressure resistanceTextiles and paperState of artSilver paste

A disclosed coating technology for cover cloth comprises the following steps: first step, priming fabric base cloth by employing PA glue; second step, performing PVC whitewashing on the primed fabric base cloth by PVC coating slurry; and third step, performing PU silver face coating on the fabric base cloth subjected to PVC whitewashing by PU silver paste. Compared with the prior art, the coating technology enables the fabric base cloth to have high color fastness to light and high hydrostatic-pressure resistance as well as relatively water sprinkling effect, and is reasonable in technology and low in economic cost.

Owner:青州市盛达蓬布厂

Anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process

ActiveCN107988799AGood adhesionGood tensile tear strengthHeat resistant fibresLiquid repellent fibresChemistrySynthetic fiber

The invention discloses an anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process. The anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process solves a problem that the prior art can not find a good flame-retardant dyeing and finishing mode for synthetic fiber fabrics such as polyamide fibers. The anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process comprises the steps that (1) grey fabric is turned, cold-rolled, scoured, shaped, dyed and printed; (2) drying is conducted after printing; and then baking is conducted at a temperature of 160 DEG C and a vehicle speed of 50m / min; then steaming is conducted in the speed of 15 to 18m / min, temperature of 101 to 103DEG C; and then drying operation is conducted after steaming; (3) soaping is conducted, and then fixation treatment is conducted; (4) a finished product is prepared after reverse gluing is conducted,processes of the reverse gluing stentering are: using a coating squeegee to perform a gluing operation. An adhesive adopts fire-retardant adhesive TF-680B, and the flame-retardant adhesive TF-680B isalso provided with a paint yellow G-24, paint blue G-31, paint black G-51, smooth resin TF-399, cross-linking agent TF-694B, and thickener DM-5299. The anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process has the advantages of high strength, good waterproof and flame retardant effects and the like.

Owner:MIANYANG GANLION PRINTING & DYEING +1

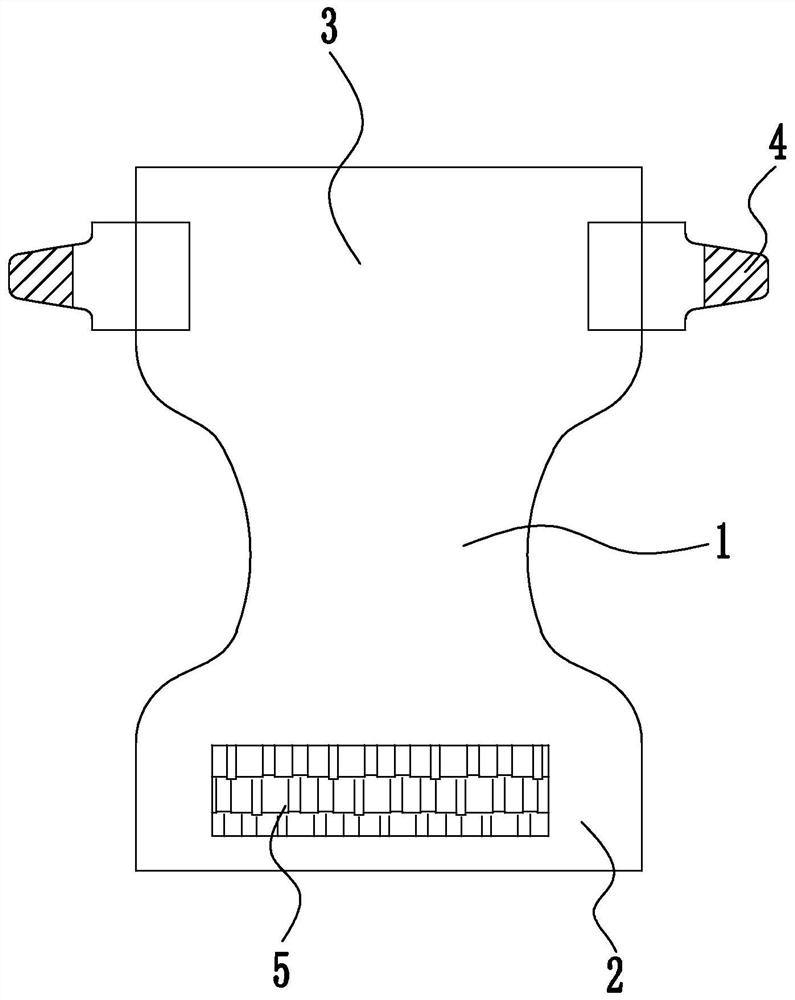

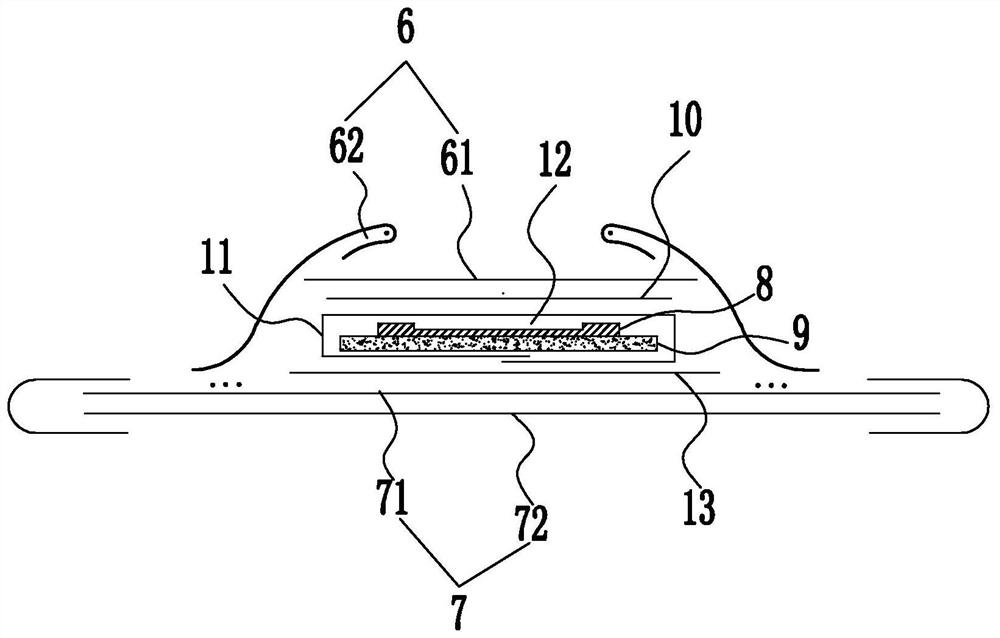

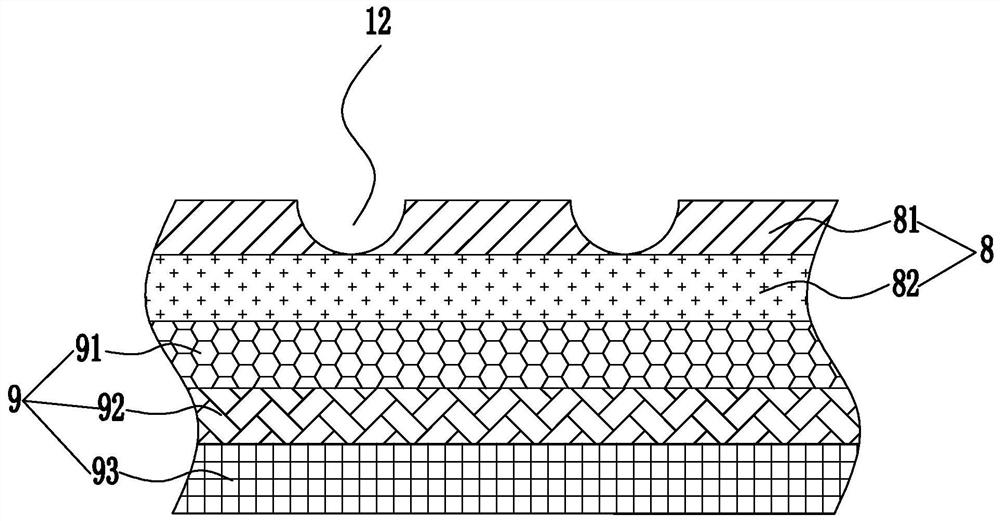

Degradable baby paper diaper

PendingCN112155858AImprove water absorptionPoor water absorptionAbsorbent padsBandagesPolymer scienceNonwoven fabric

The invention relates to the technical field of disposable hygienic products, and provides a degradable baby paper diaper which comprises a paper diaper, the paper diaper comprises a liquid permeablesurface layer, an acquisition layer, an absorption layer and a waterproof bottom layer which are sequentially stacked from top to bottom, the liquid permeable surface layer is composed of polylactic acid non-woven fabric and hydrophobic non-woven fabric, and the absorption layer is composed of polylactic acid non-woven fabric and hydrophobic non-woven fabric. The absorption layer is composed of anabsorption core and a wrapping layer, the absorption core comprises an upper absorption core and a lower absorption core, and the upper absorption core comprises a first macromolecule resin layer anda first fluffy non-woven fabric layer. The lower absorption core is composed of a second fluffy non-woven fabric, a second macromolecule resin layer and a third fluffy non-woven fabric layer which are sequentially stacked from top to bottom, and the waterproof bottom layer is composed of a degradable casting film and a hydrophobic non-woven fabric arranged at the bottom of the degradable castingfilm. The paper diaper solves the problems that paper diapers of the prior art are difficult to be degraded after being used, and affects the health of the ecological environment, and has the advantages of large absorbing capacity and rapid absorbing speed.

Owner:ZHONGTIAN CHINA IND

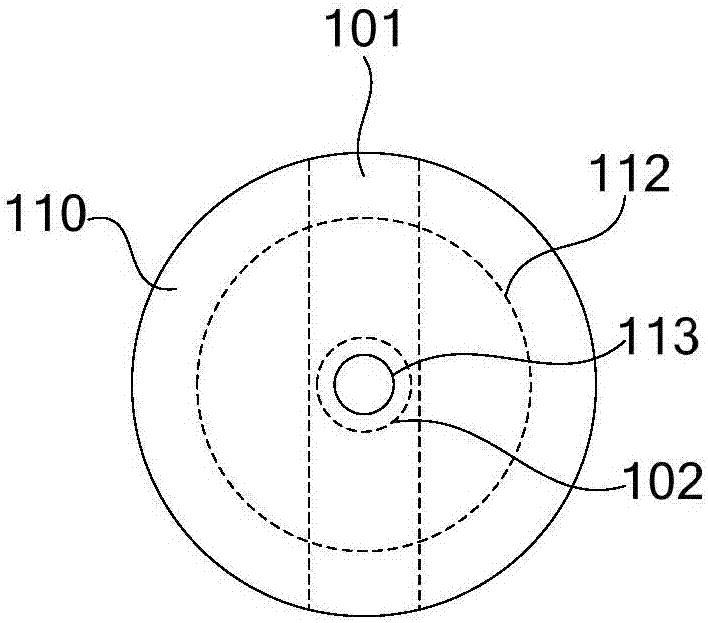

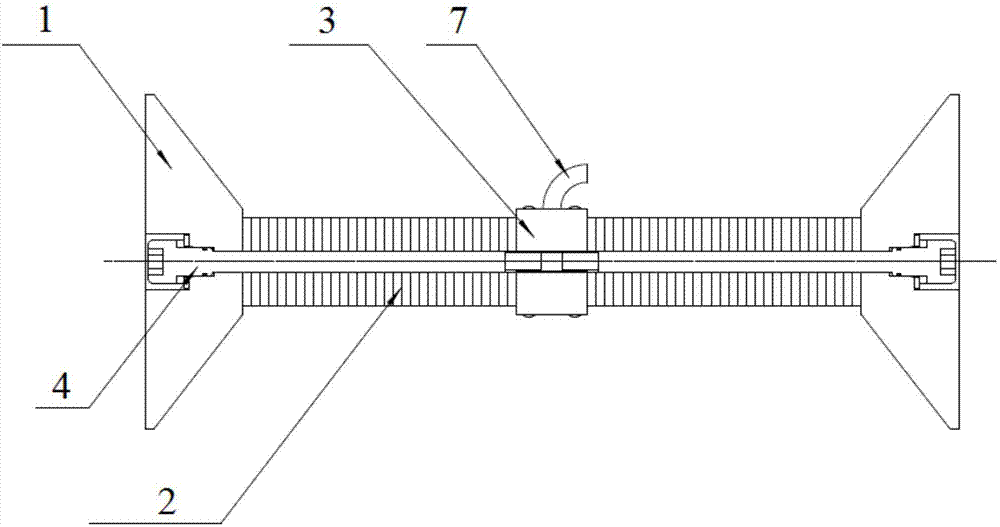

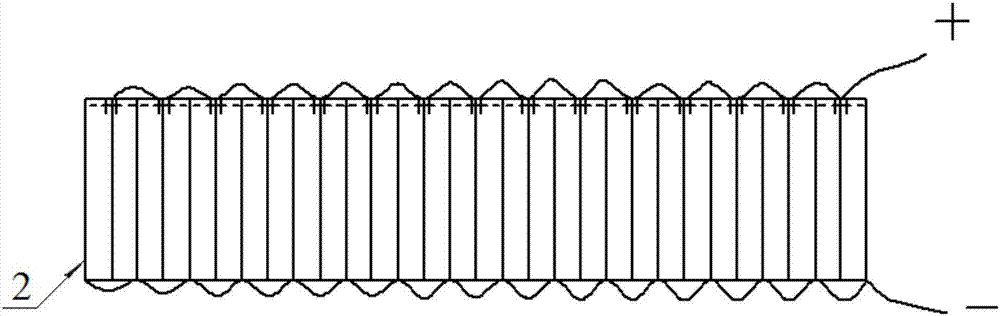

Fiber grating hydrophone and sound pressure sensing system

ActiveCN107167226AMiniaturizationIncreased frequency measurement rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansHydrophoneGrating

The invention provides a fiber grating hydrophone and a sound pressure sensing system, and belongs to the technical field of fiber sensors. The fiber grating hydrophone comprises a substrate, a sound sensitive cylinder, a balancing pipe and a fiber grating. A communication hole is arranged in the substrate. The first end of the sound sensitive cylinder is connected with the substrate, thereby forming a cavity body. The balancing pipe is arranged in the cavity body. The first opening of the balancing pipe communicates with the communication hole. The second opening of the balancing pipe communicates with the cavity body. The fiber grating is arranged in the cavity body and used for measuring axial deformation of the sound sensitive cylinder under the functions of to-be-measured sound pressure signals and outputting signal light carrying the to-be-measured sound pressure signals. According to the invention, the fiber grating hydrophone is small in size, and simple in structure; miniaturization of the fiber grating hydrophone is facilitated; static water pressure is effectively balanced; static water pressure resisting ability is improved; and the frequency measurement range of the sound pressure signals is enlarged.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Coating technology for tent cloth

InactiveCN105421077AHigh light fastness functionHigh hydrostatic pressure resistanceFibre treatmentCost (economic)Adhesive

The invention discloses a coating technology for a tent cloth. The coating technology comprises the following steps that 1, bottoming is performed on a fabric base cloth by adopting a PA adhesive; 2, PVC whitening is performed on the bottomed fabric base cloth by adopting PVC coating slurry; 3, PU silver surface coating is performed on the PVC-whitened fabric base cloth by adopting PU silver slurry. Compared with the prior art, a fabric base cloth fabric not only has the functions of the high color fastness to light and the high resistance to the static water pressure, but also has the higher water splashing degree effect, the technology is reasonable, and the economic cost is low.

Owner:马延军

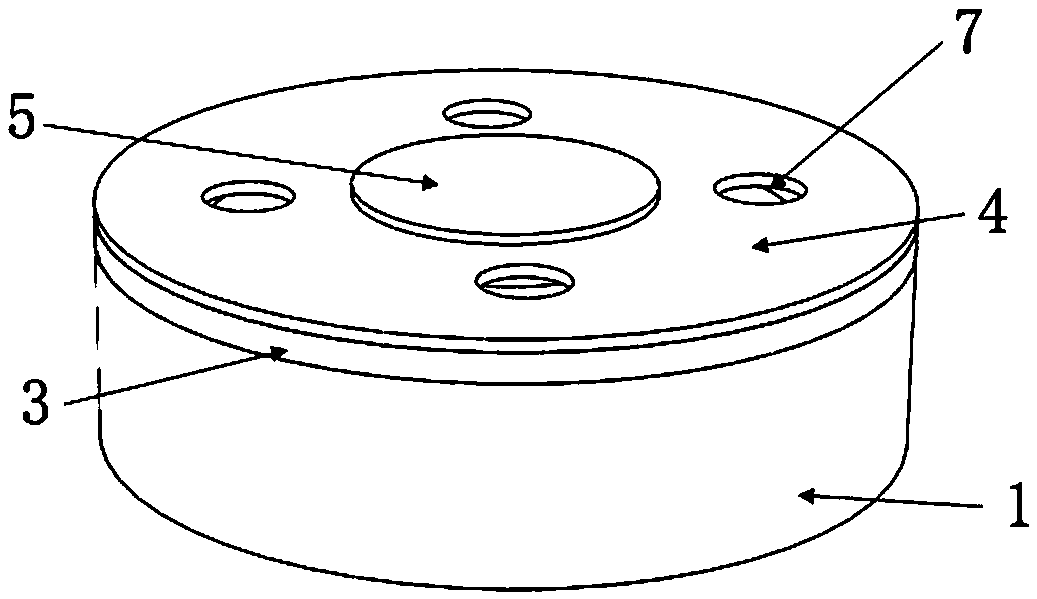

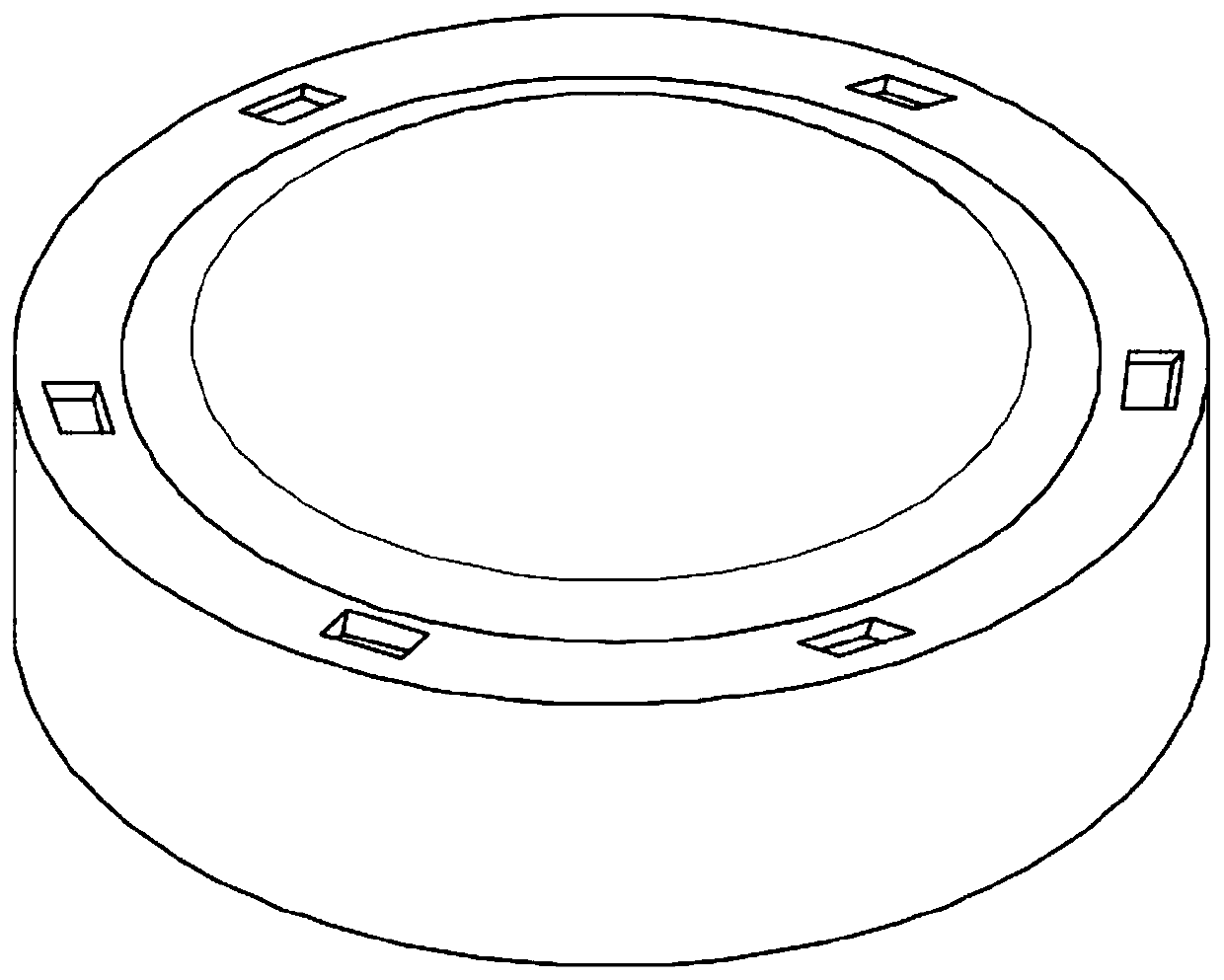

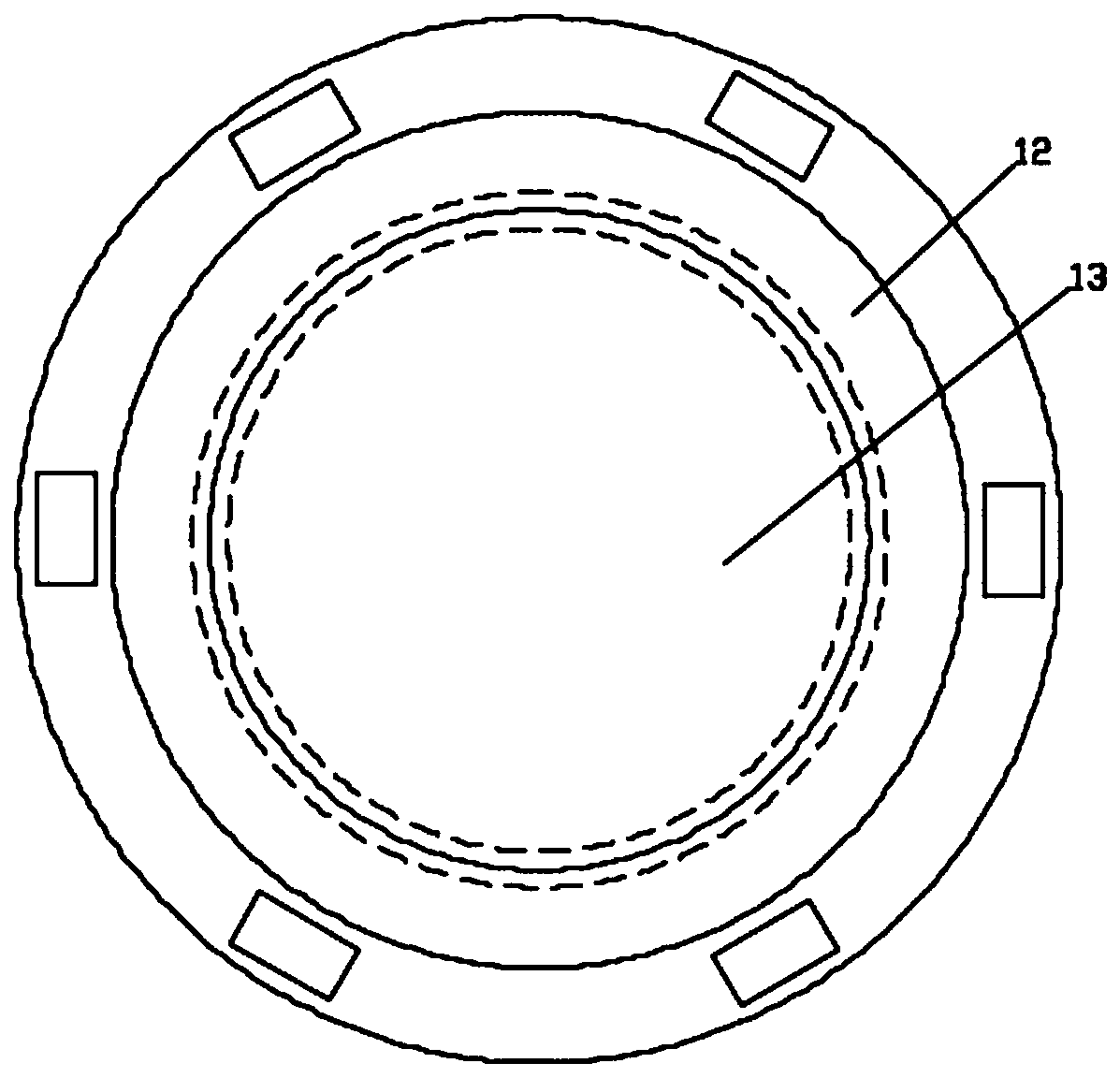

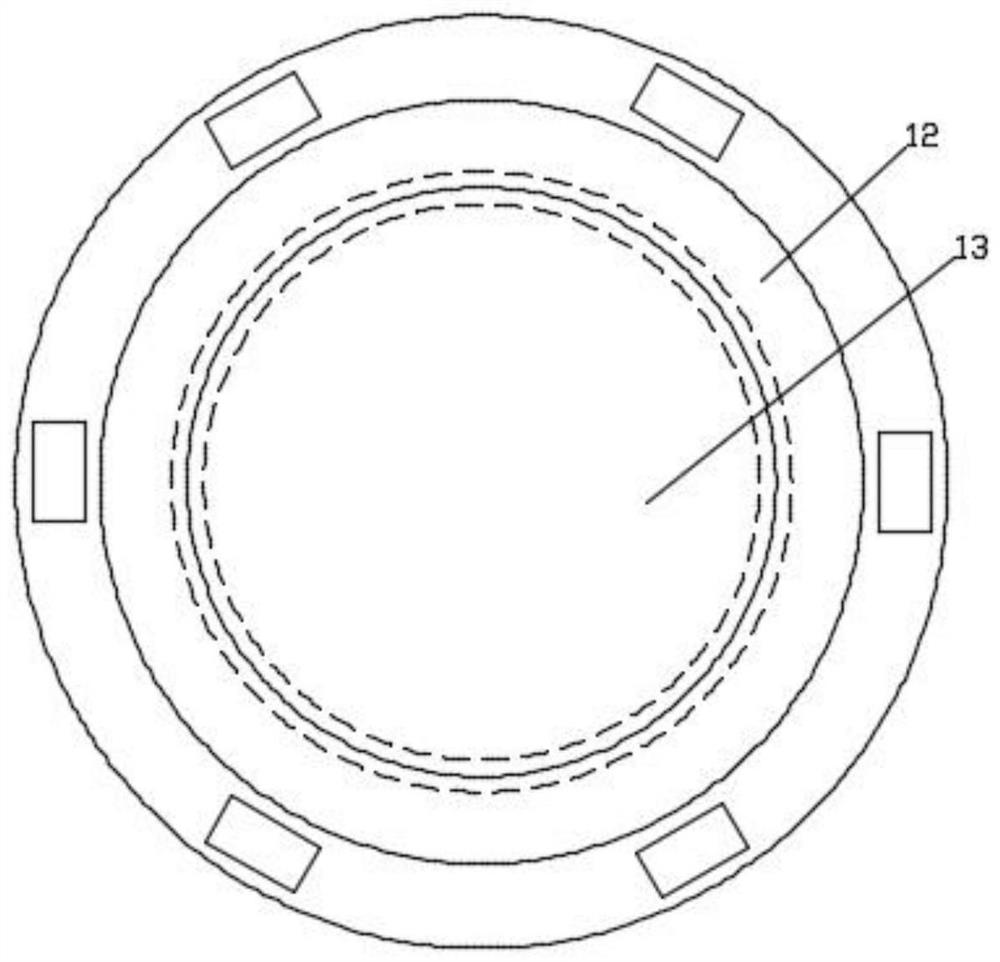

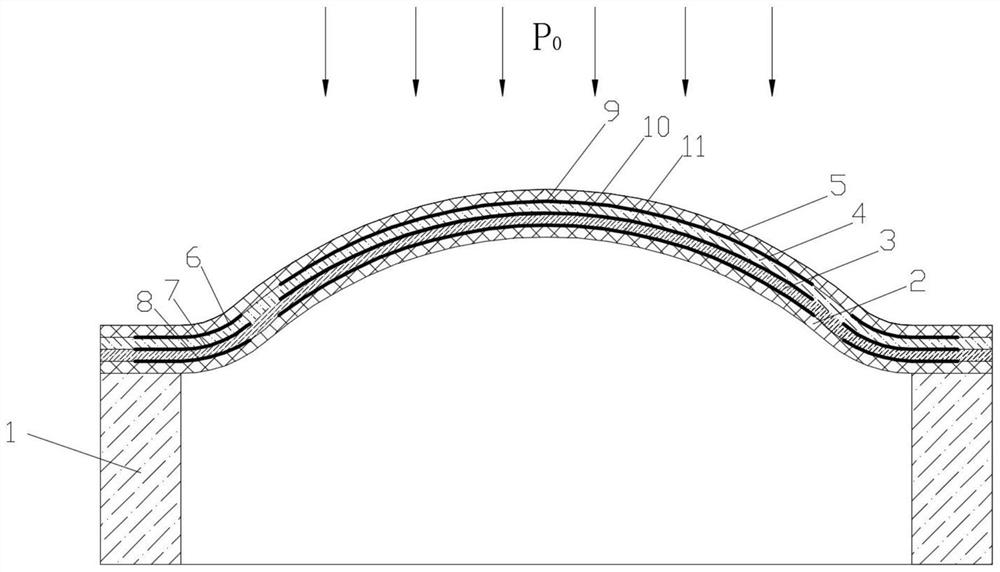

Capacitive sound pressure hydrophone based on MEMS technology and preparation method thereof

InactiveCN109855721AHigh sensitivitySmall sizeTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceSilicon dioxide

The invention relates to a capacitive sound pressure hydrophone based on the MEMS technology and a preparation method thereof. The hydrophone comprises a glass substrate, a ring-shaped silicon supportand a silicon dioxide vibration film. A capacitor cavity is encircled by the silicon dioxide vibration film, the ring-shaped silicon support and the glass substrate. A disk-shaped metal aluminum lower electrode is arranged on the top surface of the glass substrate; and a disk-shaped metal aluminum upper electrode is arranged on the top surface of the silicon dioxide vibration film. Four circularoil injection holes communicated with the capacitor cavity are distributed in the silicon dioxide vibration film uniformly around the disk-shaped metal aluminum upper electrode; and the capacitor cavity is filled with silicone oil through the circular oil injection holes. According to the invention, the capacitive sound pressure hydrophone has advantages of small size, high sensitivity, and good hydrostatic-pressure-resistant capability; the process flow is simplified; production in batches is realized; and the cost is lowered. With the hydrophone, the underwater sound pressure measurement under the conditions of the frequency response range of 5Hz to 2kHz, the hydrostatic-pressure-resistant capability of over 20MPa and the sensitivity of over -160dB is realized.

Owner:ZHONGBEI UNIV

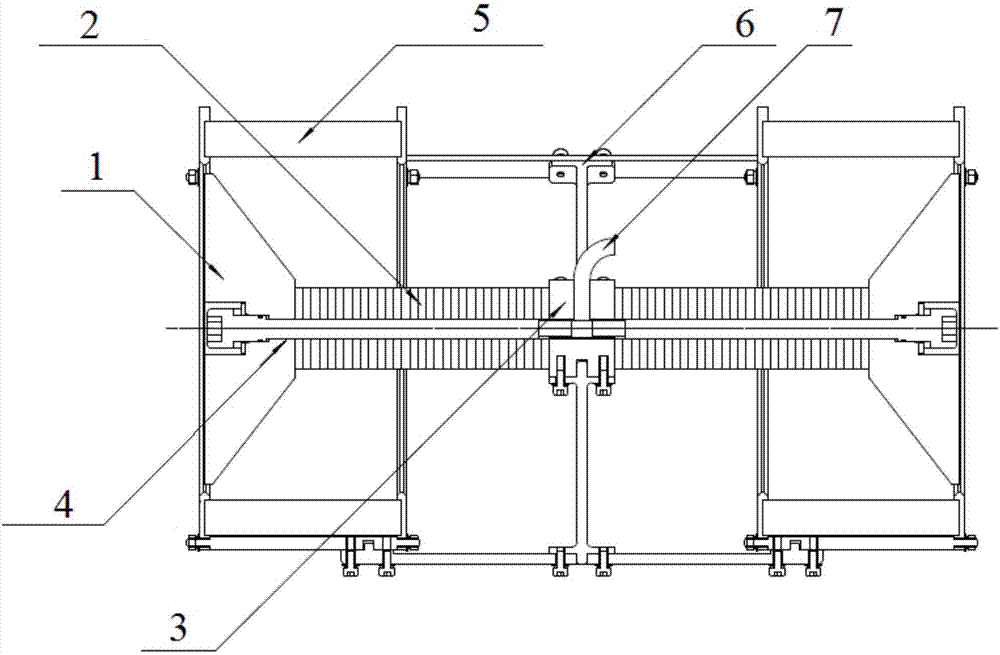

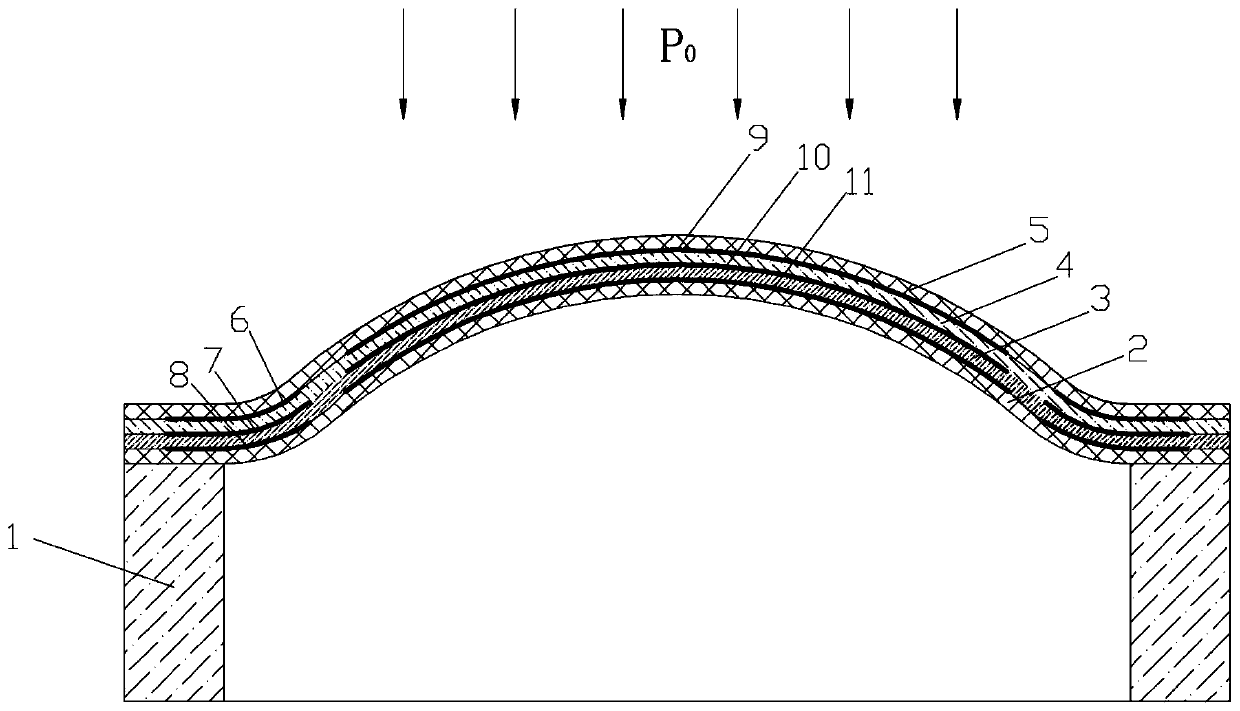

Thermoplastic polyolefin earthwork composite material and preparation method thereof

ActiveCN106891593AGood flexibilityGood extensibilitySynthetic resin layered productsLaminationExtensibilityBursting strength

The invention provides a thermoplastic polyolefin earthwork composite material and a preparation method thereof and belongs to the technical field of water-power engineering. The thermoplastic polyolefin earthwork composite material is used for solving the problem that the present impermeable material cannot be applied to the water-power engineering for a long time. The thermoplastic polyolefin earthwork composite material includes a thermoplastic polyolefin layer and a geo-fabric layer which are compounded with each other. The composite material has high flexibility, extensibility and durability of rubbers and excellent fusing processing characteristics of thermoplastic plastics, contains no plasticizer, has excellent ultraviolet light aging resistance, high anti-puncturing strength, high anti-burst strength, high hydrostatic pressure resistance and excellent thermal welding performance, is capable of bearing water pressure impact 200m or above, can be directly exposed and applied to the newly constructed and repaired hydraulic and hydro-power engineering for preventing seepage, such as dams, reservoirs, embankments, cofferdams, water channels, tunnels and nuclear power plants, and has the service life as same as the service life of the constructions.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Camouflage tent cloth coating technology

InactiveCN102978963AHigh light fastness functionHigh hydrostatic pressure resistanceTextiles and paperSilver pasteHydrostatic pressure

The invention provides a camouflage tent cloth coating technology. The technology comprises the following steps: 1, priming a fabric base cloth by PA glue; 2, carrying out PVC whitening of the primed fabric base cloth by a PVC coat; and 3, carrying out PU silver surface coating of the PVC-whitened fabric base cloth by a PU silver paste. The technology enables the fabric base cloth fabric to have a high light color fastness function, a high hydrostatic pressure resistance function and a high water repellency, and has the advantages of reasonableness and low economic cost.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Thermoplastic polyolefin impermeable composite material and preparation method thereof

InactiveCN106945371AGood high and low temperature resistanceImprove puncture resistanceSynthetic resin layered productsLaminationRubber materialBursting strength

The invention provides a thermoplastic polyolefin impermeable composite material, belonging to the technical field of impermeable materials. The invention can solve the problems of inadequate flexibility and incapable application to seepage control of a dam under direct exposure for a conventional impermeable material. The thermoplastic polyolefin impermeable composite material provided by the invention comprises a cross-laminated polyolefin layer, a thermoplastic polyolefin layer compounded thermoplastic polyolefin composite layer and a geotextile layer. The composite material has excellent puncture resistance, high burst strength, strong hydrostatic pressure resistance and excellent thermal weldability, can bear impact with hydraulic pressure of 200 m or above, and meets the application of high impermeable water head water-power engineering. The composite material provided by the invention is free of any plasticizers, has flexibility similar to the flexibility of a rubber material, can be used under direct exposure, and has long service life.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Whitewashing process of camouflage cover cloth

ActiveCN102965935AHigh light fastness functionHigh hydrostatic pressure resistanceFibre typesHigh resistanceHydrostatic pressure

The invention provides a whitewashing process of camouflage cover cloth. Before coating, fabric is subjected to PVC (polyvinyl chloride) whitewashing by use of PVC coating slurry. According to the invention, fabric has high color fastness to light and high resistance against hydrostatic pressure and high water sprinkling degree, the technology is reasonable, and the economic cost is low.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

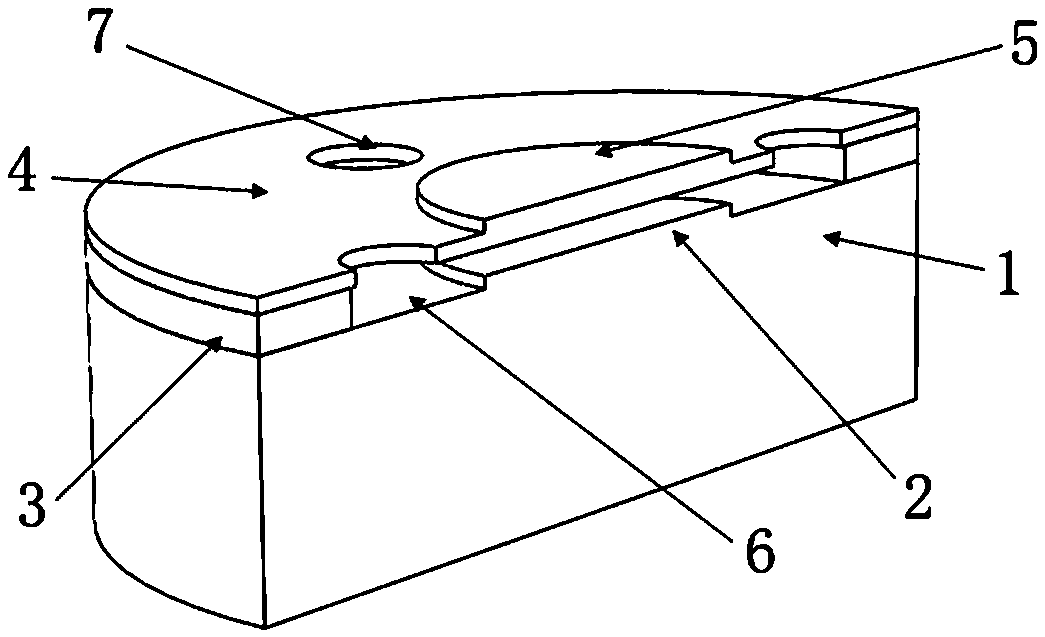

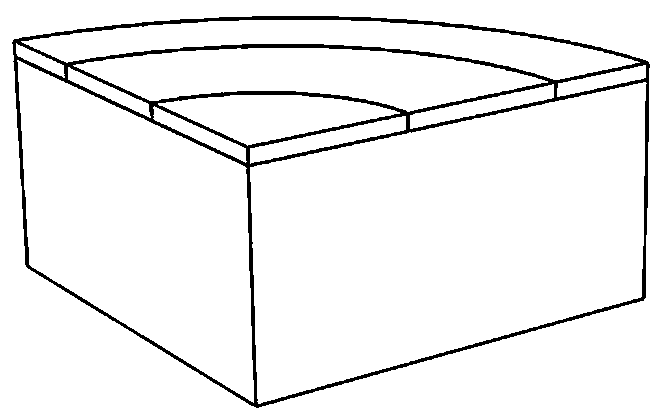

High-power deep water broadband transducer

ActiveCN107465982AIncrease the emission voltage response valueLarge power capacityPiezoelectric/electrostrictive transducersMagnetostrictive transducersElectricityBroadband transmission

The invention relates to a high-power deep water broadband transducer, and belongs to the technical field of underwater acoustic transducers. In the transducer: a screw hole is formed in the middle of a middle mass block, a screw with threads on two ends penetrate through the screw hole, and horn heads and a piezoelectric ceramic crystal pile are connected with the middle mass block; the middle mass block is located at the middle of the screw, an even number of piezoelectric ceramic wafers are symmetrically distributed on the left and right sides, the two horn heads are symmetrically distributed on the left and right sides of the piezoelectric ceramic crystal pile and are located on the two ends of the screw, the tails of the horn heads are in threaded connection with the end parts of the screw, and the opening is outward; a cable is connected from the middle mass block; a piezoelectric ceramic circular ring transducer is respectively embedded at each horn head and is connected with the horn head, the piezoelectric ceramic crystal pile and the middle mass block through connecting pieces. The transducer expands the working bandwidth of the transducer while increasing the transmitting power, and realizes high-power deep water broadband transmission.

Owner:BEIJING GREAT WALL ELECTRONICS EQUIP CO LTD

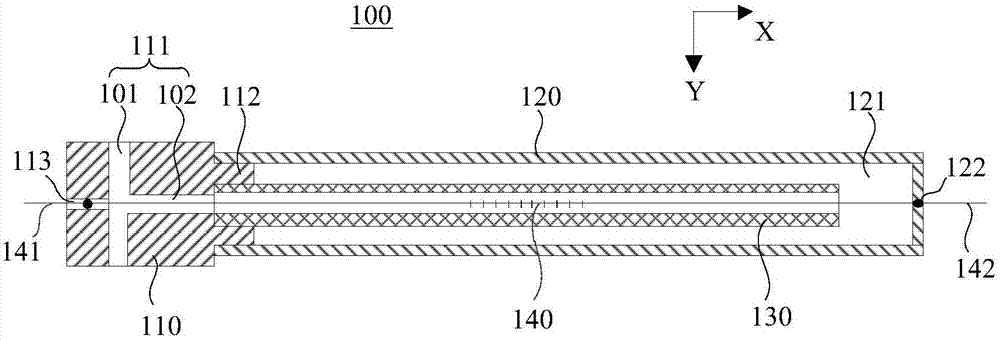

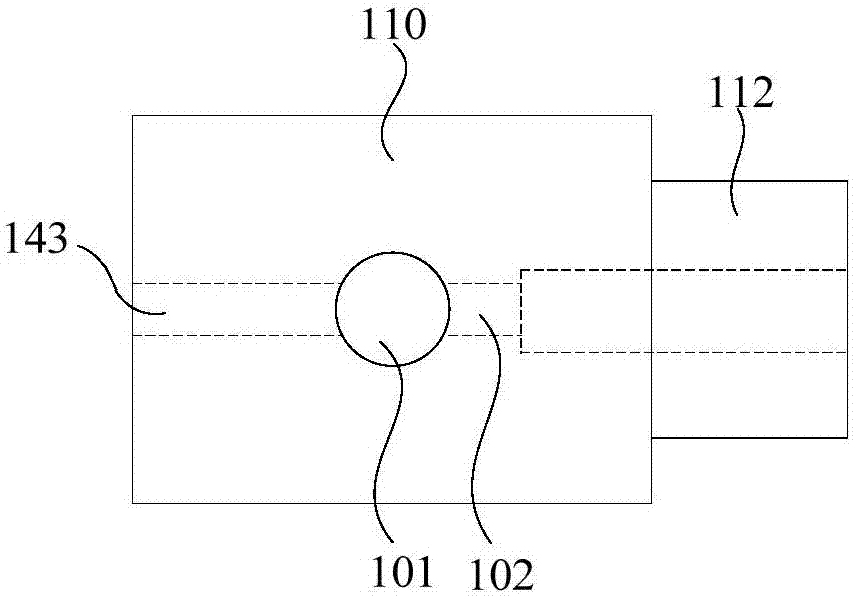

Piezoelectric MEMS acoustic sensor

ActiveCN110793708AIncreasing the thicknessHigh hydrostatic pressure resistanceFluid pressure measurement using piezo-electric devicesFlexible microstructural devicesPiezoelectric memsEngineering

The invention provides a piezoelectric MEMS acoustic sensor, which comprises a substrate, an internal electrode area and an external electrode area. The external electrode area is arranged at the periphery of the internal electrode area. Each of the internal electrode area and the external electrode area includes a top electrode, an upper piezoelectric layer, an intermediate electrode, a lower piezoelectric layer and a bottom electrode which are stacked from top to bottom. The top electrode, the intermediate electrode and the bottom electrode in the internal electrode area are spaced apart from the top electrode, the intermediate electrode and the bottom electrode in the external electrode area. A lower supporting layer is arranged at the top of the substrate; the internal electrode area and the external electrode area are both arranged on the lower supporting layer; and upper supporting layers made of silicon-based materials are arranged on the top face of the internal electrode areaand the top face of the external electrode area. The piezoelectric MEMS acoustic sensor has advantages of high sensitivity and enhanced hydrostatic pressure resistance; and the MEMS acoustic sensor can meet the application requirements of different pressure resistance and working water depths.

Owner:UNITED MICROELECTRONICS CENT CO LTD

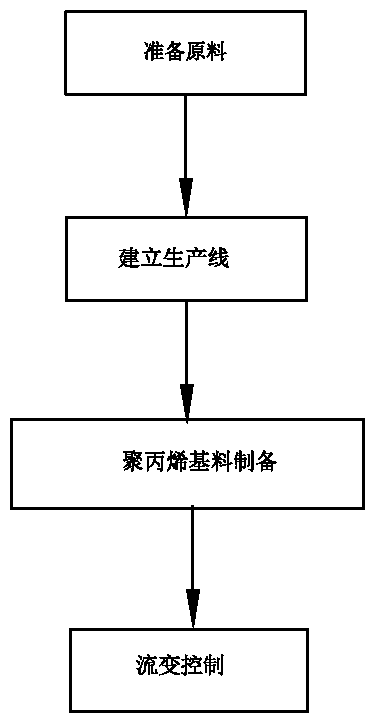

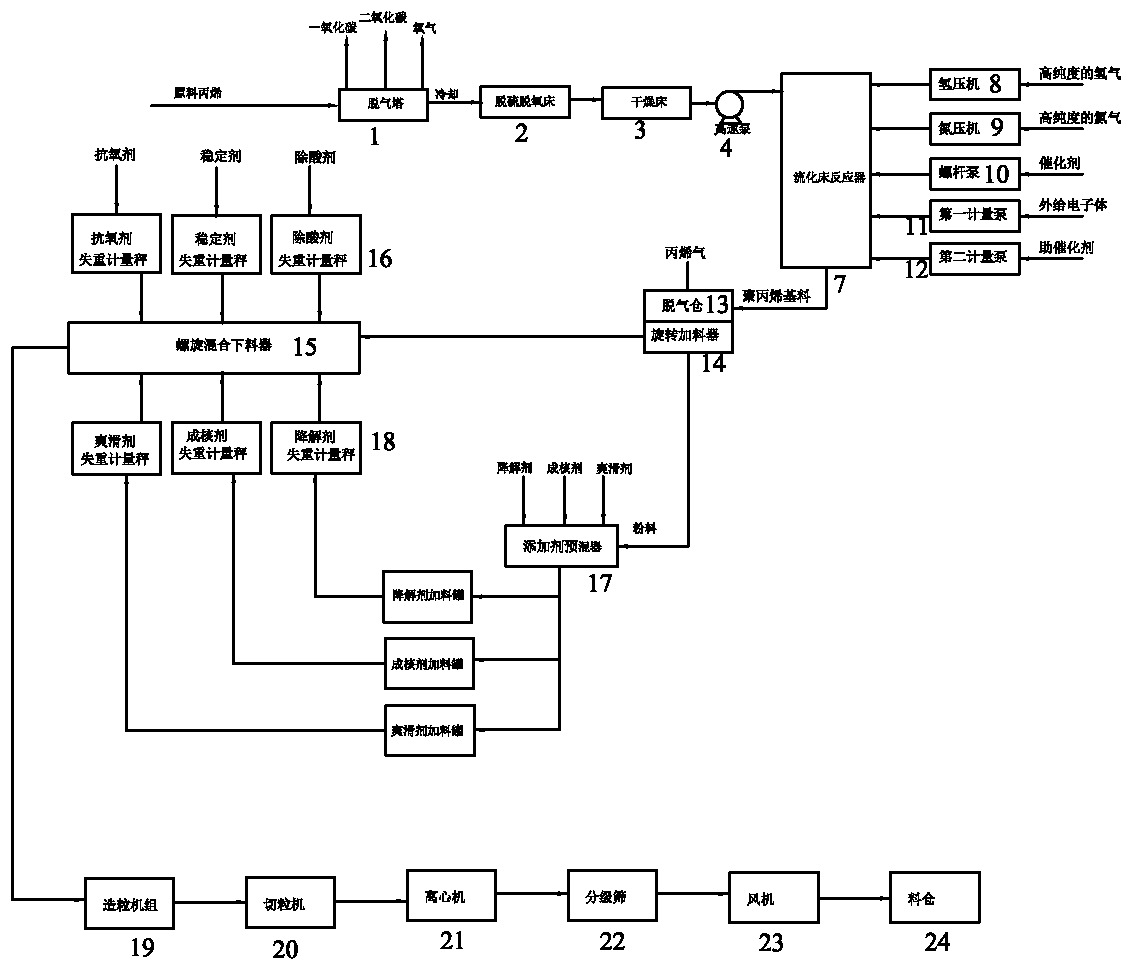

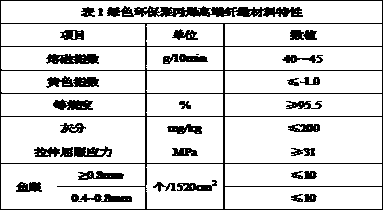

Method for producing environment-friendly polypropylene high-end fiber material

InactiveCN111499781AAvoid defectsSolve the prone to discolorationMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberMelt flow index

The invention discloses a method for producing an environment-friendly polypropylene high-end fiber material. The preparation method comprises the following four steps: preparing raw materials, establishing a production line, preparing a polypropylene base material and performing rheology control. The melt index of the material is 40-45 g / 10 min, the yellow index of the material is smaller than orequal to -1.0, the isotacticity of the material is larger than or equal to 95.5%, the ash content of the material is smaller than or equal to 200 mg / kg, and the tensile yield stress of the material is larger than or equal to 31 MPa. The number of fish eyes is less than or equal to 10 / 1520 cm <2>. The production material disclosed by the invention does not contain phthalate, and a brand-new non-peroxide degradation agent is added in rheological process control, so that the defects of a traditional peroxide degradation agent are avoided, and the problems of color change, peculiar smell and thelike of a product are solved. In order to further improve the product performance, through optimization of additives and optimization of compatibility, the material is clearer, the fiber thickness ismore uniform, and the hand feeling and the impression are better. The material prepared by the production method can be used as a melt-blown fabric raw material for preparing masks, and can greatly relieve the situation of shortage of raw materials for producing medical protective articles at present.

Owner:东莞巨正源科技有限公司

A kind of TPU hot-melt adhesive film with low melting point and high adhesive strength and preparation method thereof

ActiveCN104263259BUniform thicknessSimplify the bonding processNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterProduction line

The invention provides a TPU hot-melt adhesive film, which is mainly prepared from the following raw materials in parts by weight: 100 parts of thermoplastic polyurethane, 30-50 parts of thermoplastic polyester with a melting point of 90-105°C, and 10-30 parts of tackifier 5-25 parts of fillers and 5-30 parts of functional additives. The hot-melt adhesive film prepared by the invention is a thermoplastic adhesive with uniform thickness and simple bonding process, which is suitable for automatic production line bonding and high production efficiency; the peeling strength after bonding is large, and it can withstand water in harsh outdoor environments. , heat resistance, salt spray aging resistance, long-lasting bonding, which significantly improves the bonding strength attached to the fabric.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Waterproof finishing solution for polyamide fiber fabric and padding method of polyamide fiber fabric

The invention discloses a waterproof finishing solution for a polyamide fiber fabric and a padding method of the polyamide fiber fabric. According to the waterproof finishing solution, the problem that a good waterproof way targeted for the polyamide fiber fabric is not available in the prior art is solved. The waterproof finishing solution is prepared from a waterproof agent DM-3680K, a waterproof agent DM-3665, a waterproof agent DM-1000 and a waterproof agent DTM648-2 of which the mass ratio is (1 to 2):(2 to 4):(1 to 2):(1 to 2); and the waterproof finishing solution is also prepared froma pH neutralizer and magnesium chloride, wherein the addition volume of the magnesium chloride is 4.5 to 5.5 g / L and the pH value of the waterproof finishing solution is 6 to 8. The waterproof finishing solution disclosed by the invention has the characteristics that fading after dyeing is avoided, and a flame-retardant coating can be better attached to the polyamide fiber fabric, so that the service life of the polyamide fiber fabric is prolonged; and the waterproof finishing solution has the advantages of improving waterproof effects, strength, durability and the like.

Owner:MIANYANG GANLION PRINTING & DYEING +1

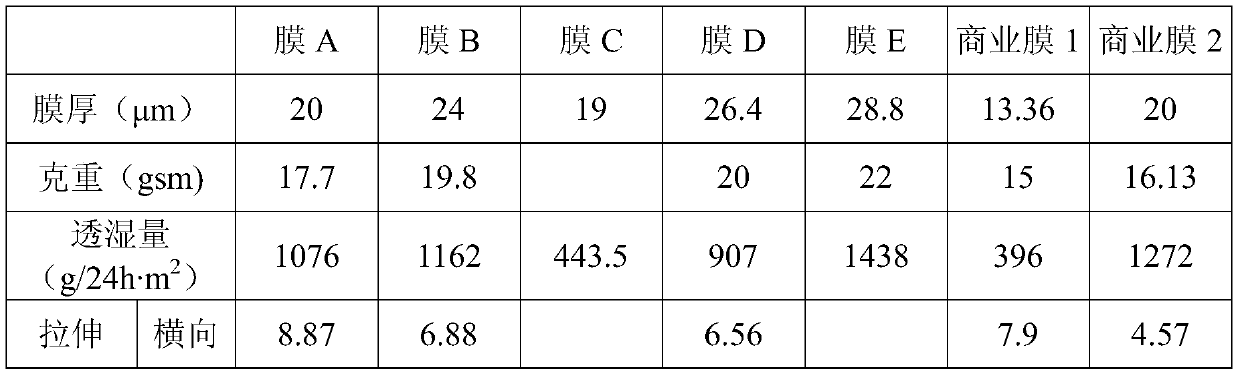

Preparation method of polyolefin microporous breathable film

The invention relates to a preparation method of a polyolefin microporous breathable film. According to the method, process improvement is conducted on the basis of the prior art, a tape casting process is changed into a film blowing process, and it is accidentally found that when a polyolefin base material of a specific formula is adopted and specific parameters are adopted in the film blowing process, the microporous breathable film which is lower in basis weight and still keeps excellent high moisture permeability can be obtained; moreover, it is also accidentally found that the hydrostaticpressure resistance of the polyolefin microporous breathable film is further improved, the anti-leakage performance is better, and the use safety of hygienic products can be more effectively guaranteed.

Owner:上海紫华薄膜科技有限公司

A pu silver surface coating process of camouflage tent cloth

ActiveCN102953267BHigh light fastness functionHigh hydrostatic pressure resistanceFibre typesKetoneMoisture permeation

The present invention provides a PU silver surface coating process of camouflage tent cloth. According to the process, during coating, a polyurethane silver paste is adopted to carry out PU silver surface coating on a fabric, wherein the polyurethane silver paste comprises single-component polyurethane, an aluminum silver paste, methyl ethyl ketone and dimethylformamide, and a weight ratio of the single-component polyurethane to the aluminum silver paste to the methyl ethyl ketone to the dimethylformamide is 50:10:25-30:5-10. According to the present invention, the process is reasonable, economic cost is low, and the fabric can have characteristics of high color fastness to light, high hydrostatic pressure resistance, good gas permeation, and good moisture permeation.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

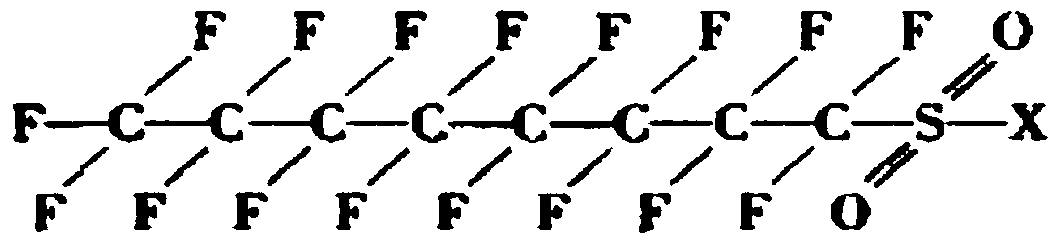

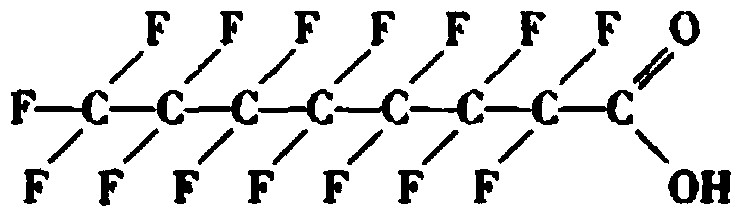

Shaping technology for cover cloth

InactiveCN103643478AReasonable workmanshipHigh hydrostatic pressure resistanceFibre typesState of artHydrostatic pressure

A disclosed shaping technology for cover cloth comprises: performing padding shaping on fabric in a water repellent agent, and then drying and baking the shaped fabric, wherein the water repellent agent is a fluorine containing water repellent agent, and has the concentration of 5-65 g / L and the pH value of 4-6, and the pH value of the water repellent agent is adjusted by acetate acid gracial. Compared with the prior art, the shaping technology enables the fabric to have both high hydrostatic-pressure resistance and relatively high water-sprinkling degree, and is reasonable in technology and low in economic cost.

Owner:青州市盛达蓬布厂

Novel high barrier spunbond ventilating material, preparation method and application

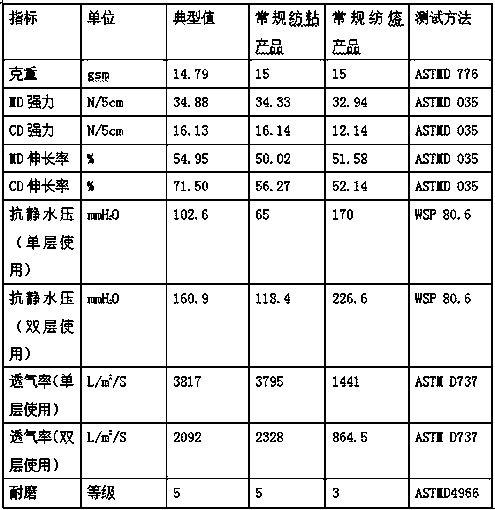

ActiveCN111501208AHigh hydrostatic pressure resistanceImprove breathabilityAbsorbent padsNon-woven fabricsFiberDiaper rash

The invention provides a novel high barrier spunbond ventilating material. When the gram weight of the material is 15 gsm, the anti-hydrostatic pressure is 100-105 mmH2O, the air permeability is 3810-3820 L / m<2>, the MD strength is 30-35 N / 5 cm, the CD strength is 15-17 N / 5 cm, the MD elongation is 48-58% and the CD elongation is 65-75%. The invention further provides a preparation method of the novel ventilating material. The preparation method comprises material selection, fiber traction and hot rolling treatment. In the fiber traction step, the traction air pressure is 3000-4000 pa, the process air temperature is 16-30 DEG C, the slit width is 20-24 mm and the fineness of the obtained fine denier fibers is 1.5-1.8 denier. The invention further provides application of the novel high barrier spunbond ventilating material in paper diapers. The dehumidifying property is improved and the problems of reddening of skin of babies and induction of diaper rash when the paper diapers are usedare solved while the ventilating property is improved.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

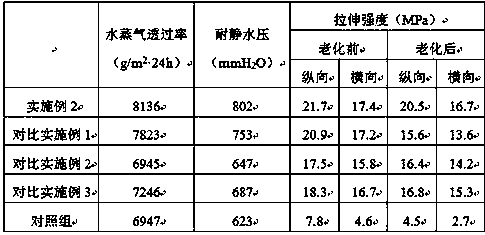

Preparation method for ultraviolet aging-resistant breathable film

InactiveCN110294908AIncrease water vapor permeabilityHigh tensile strengthFlat articlesAging resistanceWater vapor

The invention discloses a preparation method for an ultraviolet aging-resistant breathable film, and belongs to the technical field of preparation of breathable films. The preparation method comprisesthe following steps of 1, preparation of a modified composite filler; 2, preparation of a melt body; 3, cover treatment; 4, cold plasma treatment; 5, melting and stretching; 6, setting. By means of the preparation method for the ultraviolet aging-resistant breathable film, the water steam permeating rate, tensile strength and hydrostatic pressure resistance of the breathable film are effectivelyimproved, the ultraviolet aging resistance of the breathable film is improved and enhanced, and the application range of the breathable film is widened.

Owner:含山县金中环装饰材料有限公司

A kind of thermoplastic polyolefin geotechnical composite material and preparation method thereof

ActiveCN106891593BGood flexibilityGood extensibilitySynthetic resin layered productsLaminationThermoplasticPolymer science

The invention provides a thermoplastic polyolefin geotechnical composite material and a preparation method thereof, which belong to the technical field of hydropower engineering and can solve the problem that existing anti-seepage materials cannot be used in hydropower engineering for a long time. The thermoplastic polyolefin geotechnical composite material of the present invention includes a composite thermoplastic polyolefin layer and a geotextile layer, and the composite material has both the high flexibility, extensibility and durability of rubber and the excellent melt processing characteristics of thermoplastics, and the composite material It does not contain any plasticizers, it has excellent UV aging resistance, high puncture resistance, high burst strength, high hydrostatic pressure resistance, excellent thermal welding performance, and can withstand water pressure impact of more than 200m. It can be directly exposed Applied to dams, reservoirs, embankments, cofferdams, canals, tunnels, nuclear power plants and other new and repaired hydropower and water conservancy projects for anti-seepage, and the application life is the same as that of buildings.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

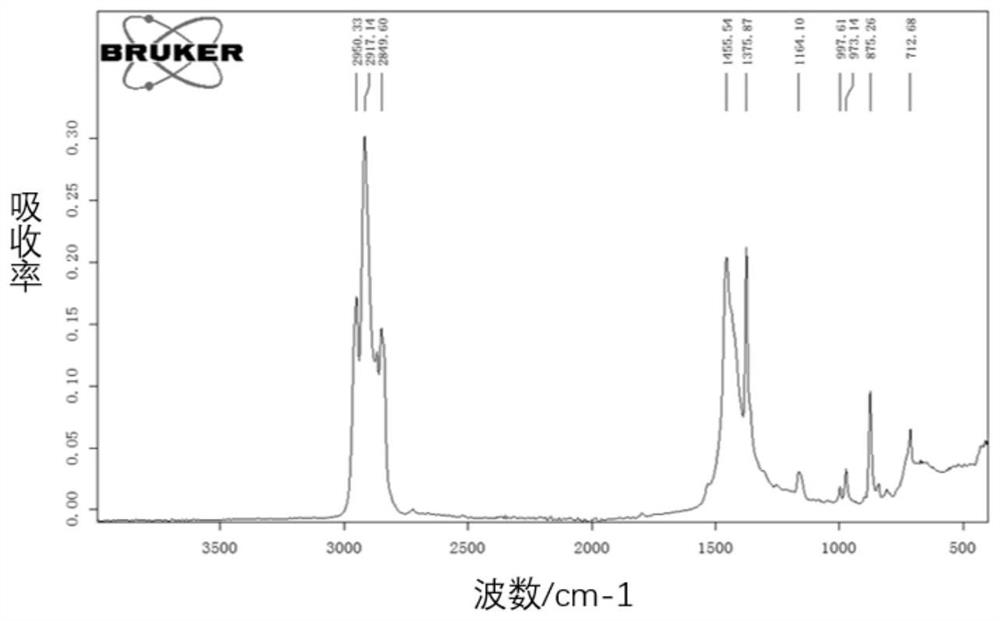

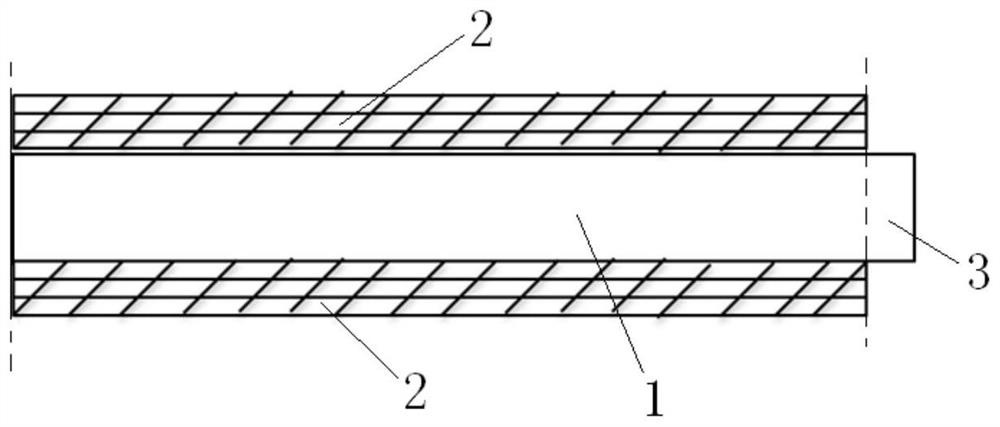

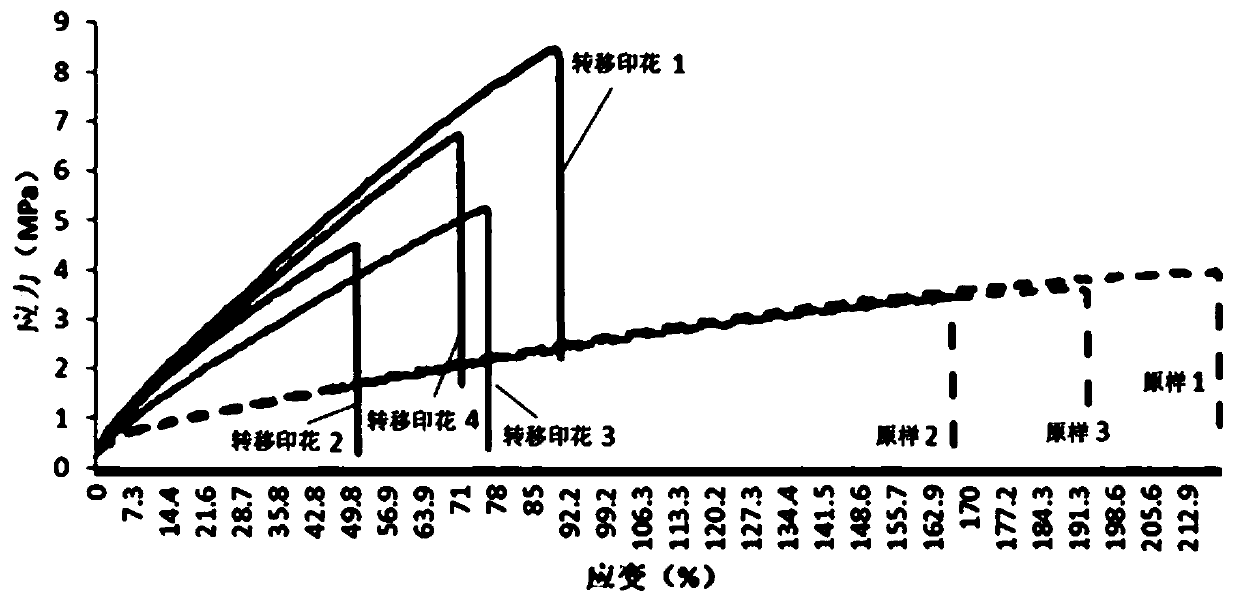

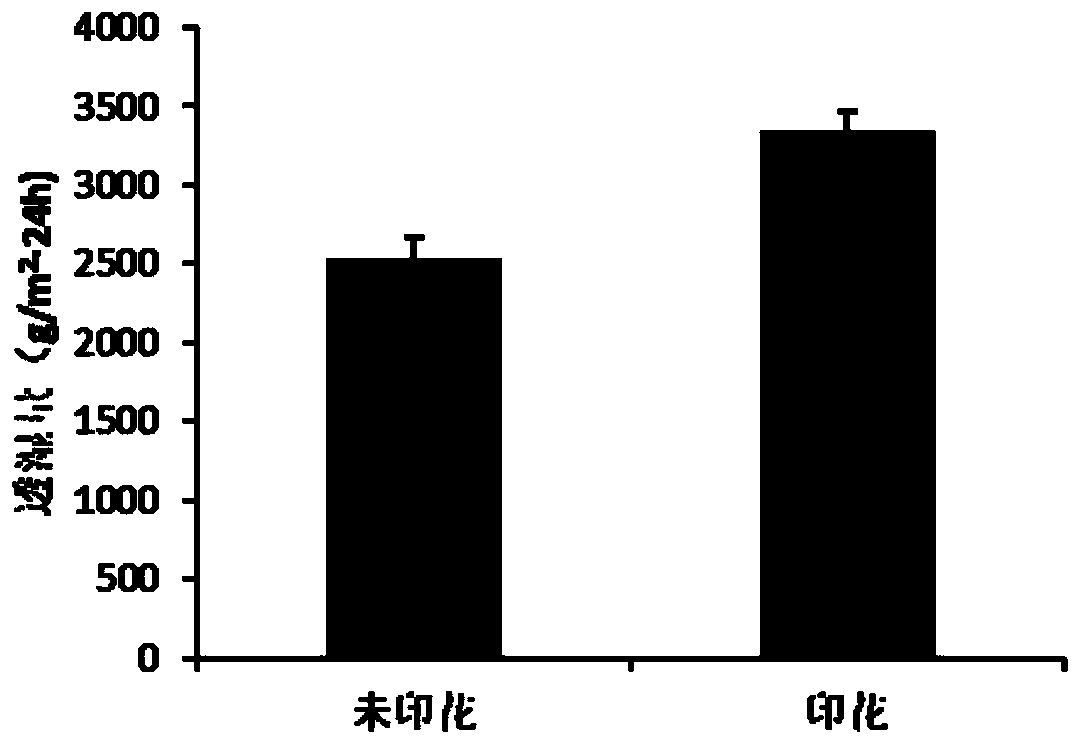

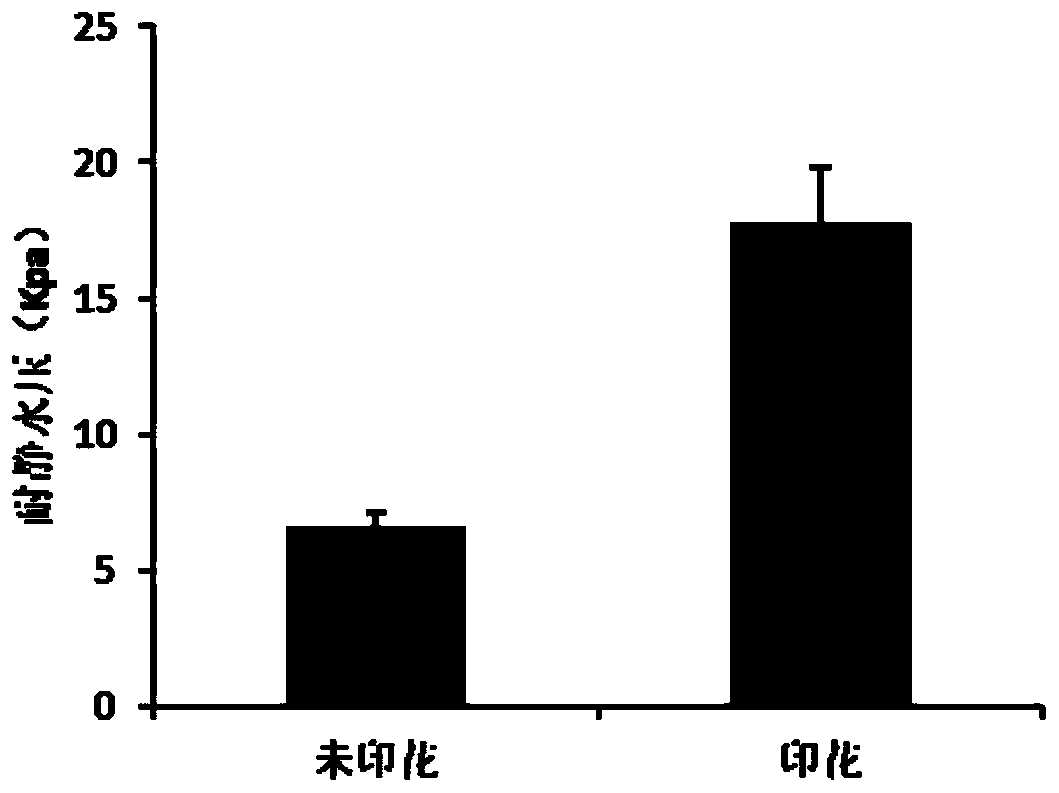

Thermal transfer printing method for waterproof moisture-permeable nanofiber membrane

ActiveCN110804887AVariety of colorsBright colorTransfer printing processDyeing processTextile printerPolymer science

The invention discloses a thermal transfer printing method for a waterproof moisture-permeable nanofiber membrane, which comprises the steps: printing patterns on a transfer printing medium; transferring the patterns from the transfer medium to a waterproof moisture-permeable nanofiber membrane; and separating the transfer printing medium and the waterproof moisture-permeable nanofiber membrane after printing the patterns. The nanofiber membrane subjected to transfer printing has good light fastness, water fastness and dry-wet rubbing fastness, as well as good mechanical properties, air permeability, moisture permeability, water resistance and the like. At the premise that waterproof and moisture-permeable performances of the waterproof moisture-permeable nanofiber membrane are not greatlychanged, the dry rubbing fastness of the waterproof moisture-permeable nanofiber membrane after transfer printing reaches grade 3-4, with wet rubbing fastness reaching grade 3-4, water fastness reaching grade 5, and light fastness reaching grade 4-5. The tensile strength is increased by 56.6% on average; the hydrostatic pressure resistance is increased by 32% on average; and the moisture permeability is increased by 167.4% on average.

Owner:ZHONGYUAN ENGINEERING COLLEGE

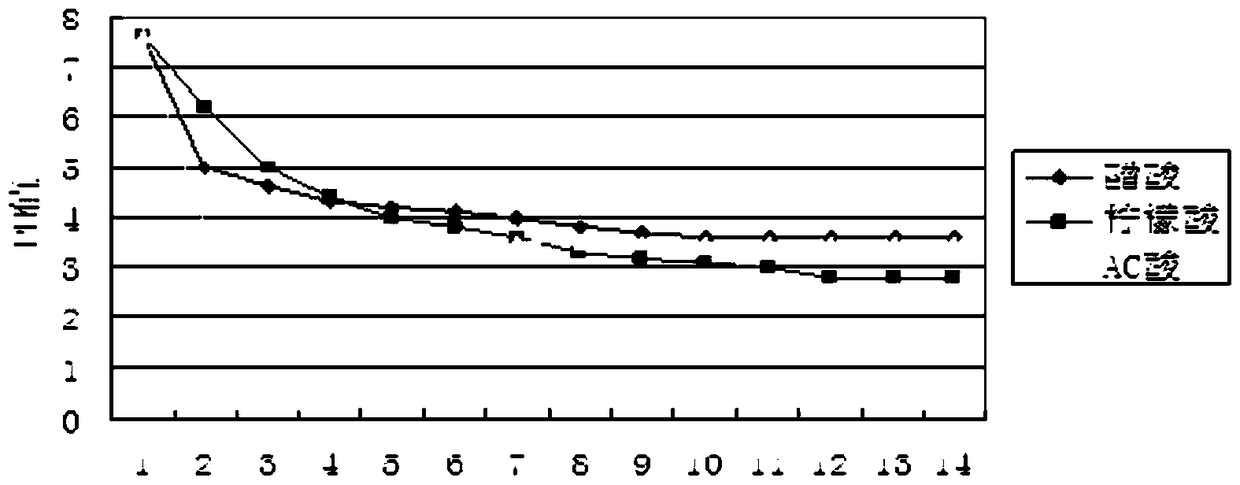

A processing method of fluorine-free hydrostatic pressure durable waterproof pure cotton canvas

ActiveCN105506992BHigh hydrostatic pressure resistanceImprove waterproof performanceDyeing processVegetal fibresAcetic acidHydrostatic pressure

Provided is a method for processing fluoride-free hydrostatic-pressure-resisting durable waterproof pure cotton canvas. According to the method, pure cotton gray fabric is adopted, and the fluoride-free hydrostatic-pressure-resisting durable waterproof pure cotton canvas is obtained after fabric detection, seam turning, singeing, cold batching-short steaming washing, dyeing, full-width washing, tentering, fluoride-free waterproof treatment and preshrinking. According to operation of fluoride-free waterproof finishing, fluoride-free waterproof finishing liquid is prepared firstly, and is formed by blending 180 g / L to 240 g / L of a fluoride-free water-proofing agent RSH-NF, 18 g / L to 24 g / L of synergist and 0.3 g / L to 1.0 g / L of acetic acid; then, the gray fabric is soaked and rolled with the fluoride-free waterproof finishing liquid, and the rolling-over rate ranges from 60% to 70%; then, baking is carried out at the temperature of 110 DEG C to 130 DEG C. The processed fabric has the high hydrostatic-pressure-resisting effect and the lasting waterproof effect.

Owner:HEBEI NINGFANG GRP

A piezoelectric mems acoustic sensor

ActiveCN110793708BIncreasing the thicknessHigh hydrostatic pressure resistanceFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostrictive microphonesPiezoelectric memsEngineering

A piezoelectric MEMS acoustic sensor provided by the present invention includes a substrate, an internal electrode area and an external electrode area, and the external electrode area is located on the periphery of the internal electrode area, and the internal electrode area and the external electrode area both include a top-to-bottom stack The top electrode, the upper piezoelectric layer, the middle electrode, the lower piezoelectric layer and the bottom electrode; the top electrode, the middle electrode and the bottom electrode in the inner electrode area and the top electrode, the middle electrode and the bottom electrode in the outer electrode area are spaced from each other; A lower supporting layer is arranged on the top of the base, the inner electrode area and the outer electrode area are located on the lower supporting layer, and the upper supporting layer made of silicon-based material is arranged on the top surfaces of the inner electrode area and the outer electrode area. The invention has high sensitivity and enhanced ability to withstand hydrostatic pressure: the MEMS acoustic sensor can meet the application requirements of different pressure resistance and working water depth.

Owner:UNITED MICROELECTRONICS CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com