Finishing method of cotton-hydrophobic fabric based on BTCA-TEOS-OA combined treatment

A BTCA-TEOS-OA, combined processing technology, applied in fiber processing, textile material processing, liquid/gas/vapor textile processing and other directions, can solve environmental problems, application limitations and other issues, to avoid environmental problems, reduce Surface energy, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fabric: Cotton Woven (133×72 / 40S×40S)

[0033] 1) Prescription: BTCA: 1.5%

[0034] Sodium hypophosphite: 6%

[0035] Method: double dipping and rolling at room temperature, drying at 70°C for 4 minutes after rolling, and baking at 180°C for 2 minutes for later use.

[0036] 2) Prescription: tetraethyl orthosilicate 4%

[0037] Ethanol: water = 6:4

[0038] Ammonia: 3%

[0039] Method: Bath ratio: 1:30

[0040] Temperature: 80°C

[0041] Time: 2 hours

[0042] 3) Prescription: Methanol

[0043] Ammonia 1%

[0044] Octadecylamine 6%,

[0045] Method: Bath ratio: 1:30

[0046] Temperature: room temperature

[0047] Two dipping and two rolling, after rolling by rolling car, bake at 120°C for 5 minutes.

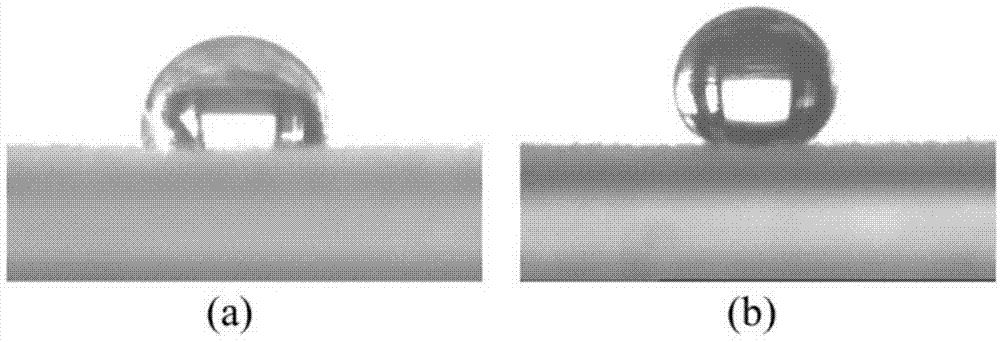

[0048] The obtained cotton fabric performance results are shown in Table 1. Figure 1-2 shown.

[0049] Hydrophobic property comparison: the cotton fabric hydrophobic property that the inventive method handles obtains is compared with contrast (only through O...

Embodiment 2

[0059] Treat cotton fabrics as follows:

[0060] (1) The fabric is first pretreated with 1,2,3,4-butanetetracarboxylic acid (BTCA): the cotton fabric is placed in a mixture with a mass fraction of BTCA of 1% and a catalyst sodium hypophosphite of 1%. Solution, padding at room temperature, drying at 100°C for 1 minute after rolling, baking at 160°C for 3 minutes, and set aside;

[0061] (2) Then treat with tetraethyl orthosilicate: the bath ratio is 1:10, the ratio of propanol to water is 5:5, the mass fraction of tetraethyl orthosilicate is 6%, and the mass fraction of catalyst (ammonia water) is 5 %, the reaction time at 85°C is 0.5 hours, take it out and dry it, and set it aside;

[0062] (3) Finally, it is treated with octadecylamine: according to the bath ratio of 1:10, ethanol is added, the mass fraction of ammonia water is 2%, and the mass fraction of octadecylamine is 1%. After the fabric is impregnated, it is rolled by rolling, Bake at 100°C for 4 minutes.

[0063] ...

Embodiment 3

[0065] Treat cotton fabrics as follows:

[0066] (1) The fabric is first pretreated with 1,2,3,4-butanetetracarboxylic acid (BTCA): the cotton fabric is placed in a mixture with a mass fraction of BTCA of 5% and a catalyst sodium hypophosphite of 4%. Solution, padding at room temperature, drying at 85°C for 5 minutes after rolling, baking at 170°C for 1 minute, and set aside;

[0067] (2) Then treat with tetraethyl orthosilicate: the bath ratio is 1:40, the ratio of butanol to water is 9:1, the mass fraction of tetraethyl orthosilicate is 1%, and the mass fraction of catalyst (ammonia water) is 1 %, the reaction time at 50°C is 4 hours, take it out and dry it, and set it aside;

[0068] (3) Finally, it is treated with octadecylamine: according to the bath ratio of 1:40, isopropanol is added as the OA solvent, the mass fraction of ammonia water is 5%, and the mass fraction of octadecylamine is 8%. After the fabric is impregnated, After rolling, bake at 150°C for 1 minute.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com