Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213results about How to "High water repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

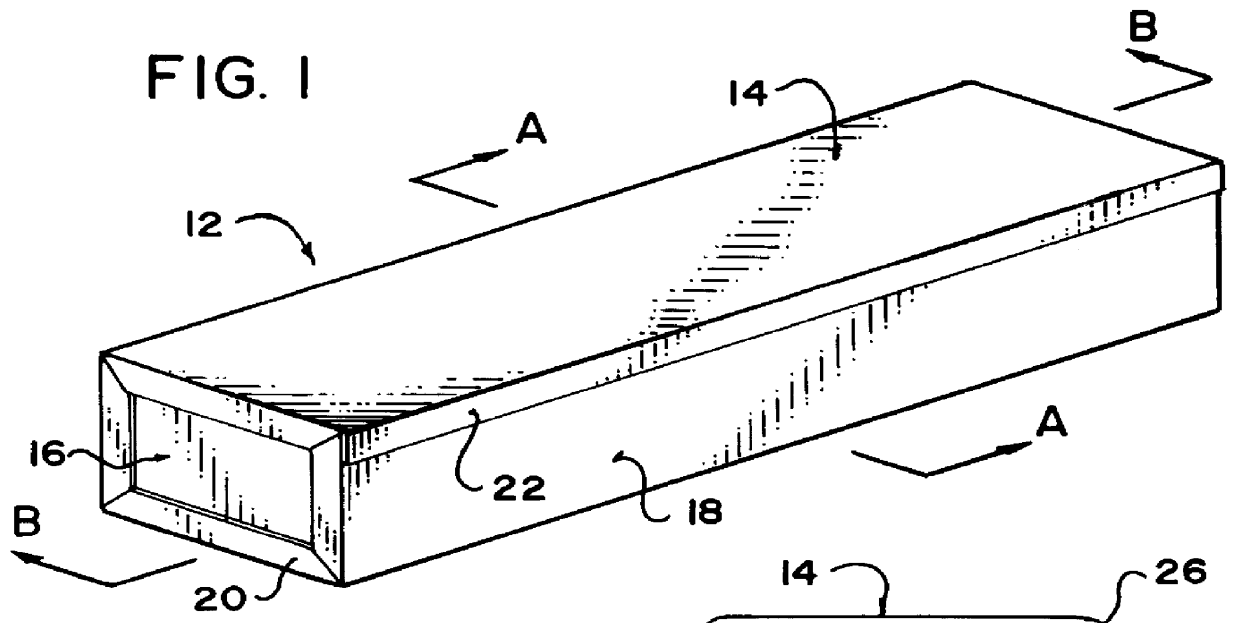

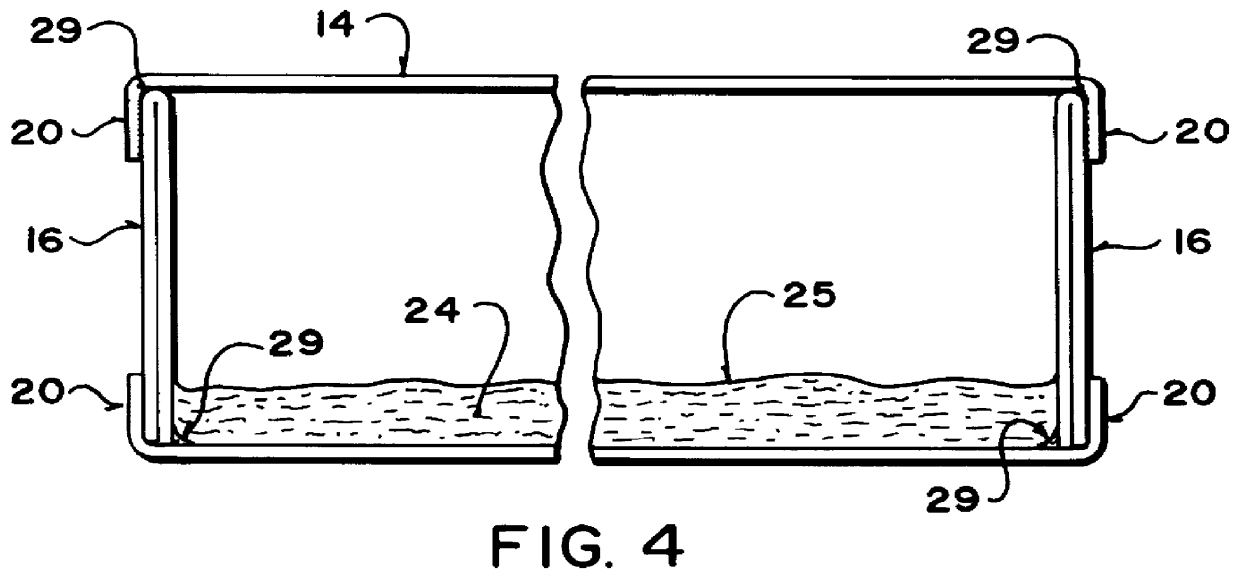

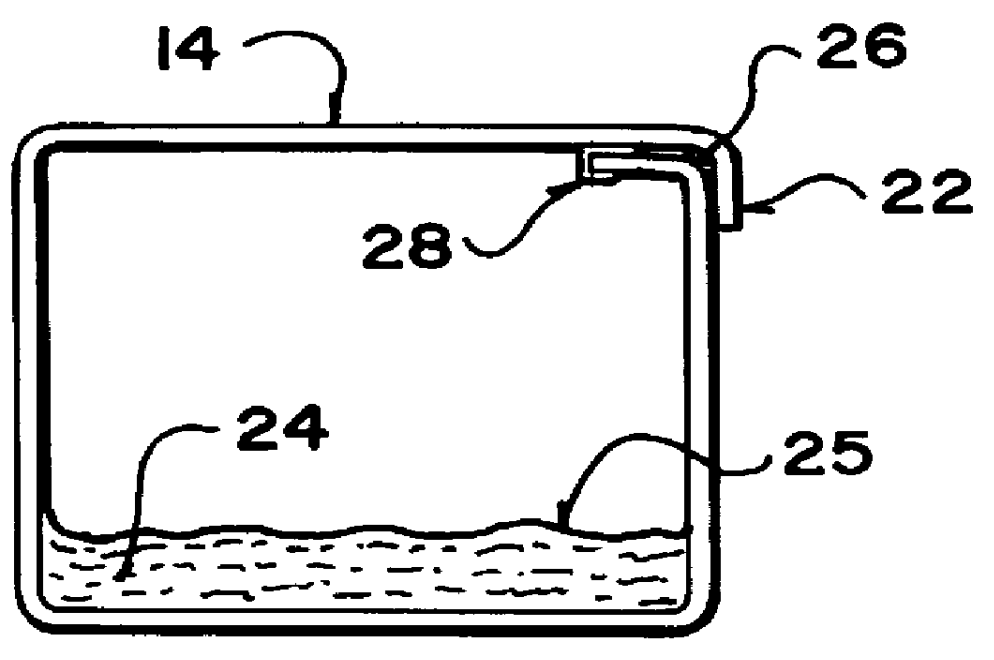

Method and apparatus for packaging and shipping horticultural products including cut flowers

InactiveUS6050412ASmall sizeAvoid spreadingFlexible coversLiving organism packagingCut flowersEngineering

This invention relates to a novel method and apparatus for packaging and shipping horticultural products including cut flowers. More particularly, this invention pertains to a novel method of and packaging for packaging cut flowers in a modified atmosphere package to prolong shelf life, shipping the packaged flowers to the destination, and then at the destination, opening the package and rehydrating the cut flowers in the package by saturating the stems of the flowers with water.

Owner:SUNBLUSH TECH CORP THE

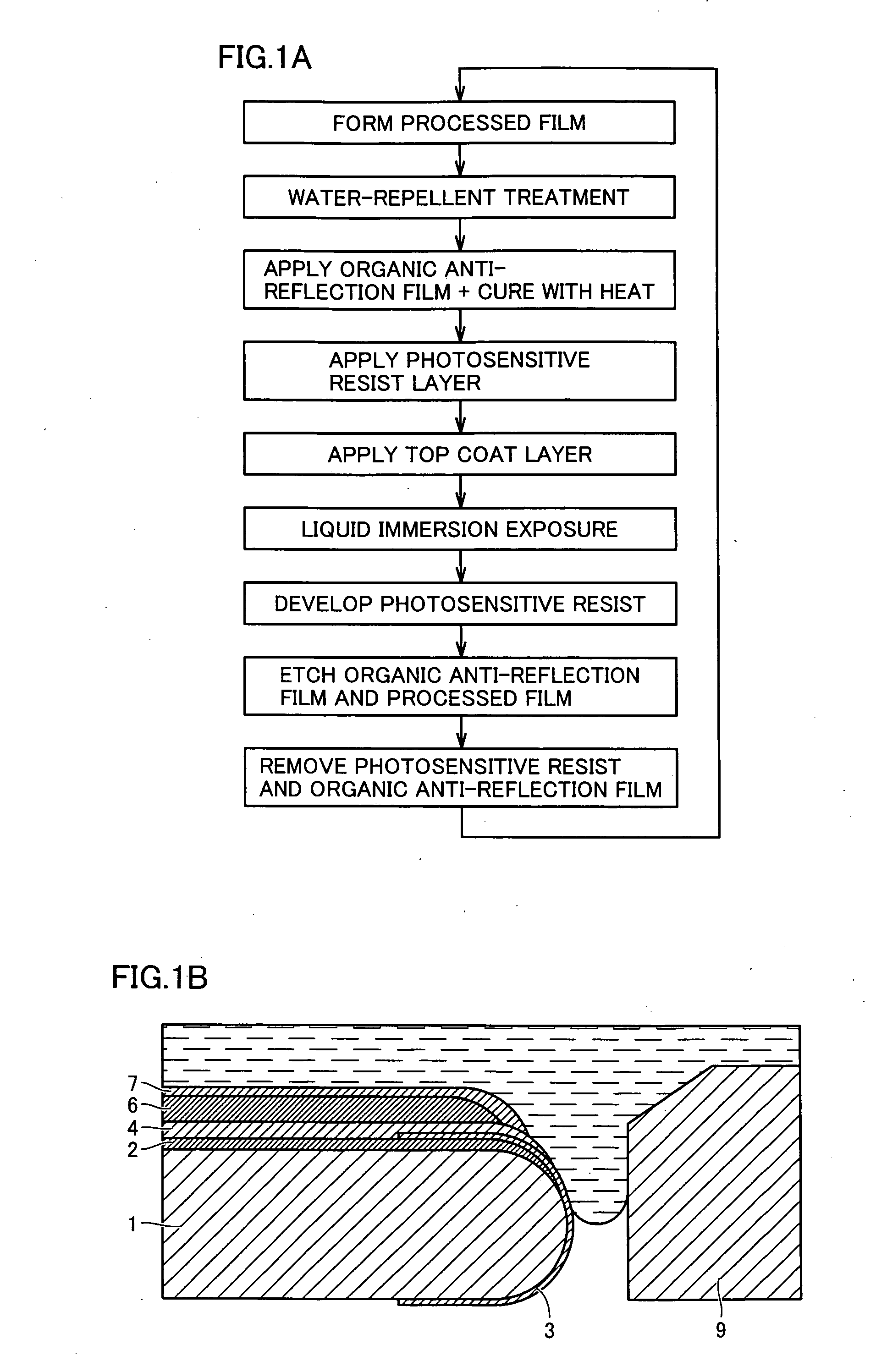

Method of forming resist pattern and semiconductor device manufactured with the same

InactiveUS20080241489A1High water-repellencyHigh film-peeling suppression effectNon-fibrous pulp additionLayered productsResistEngineering

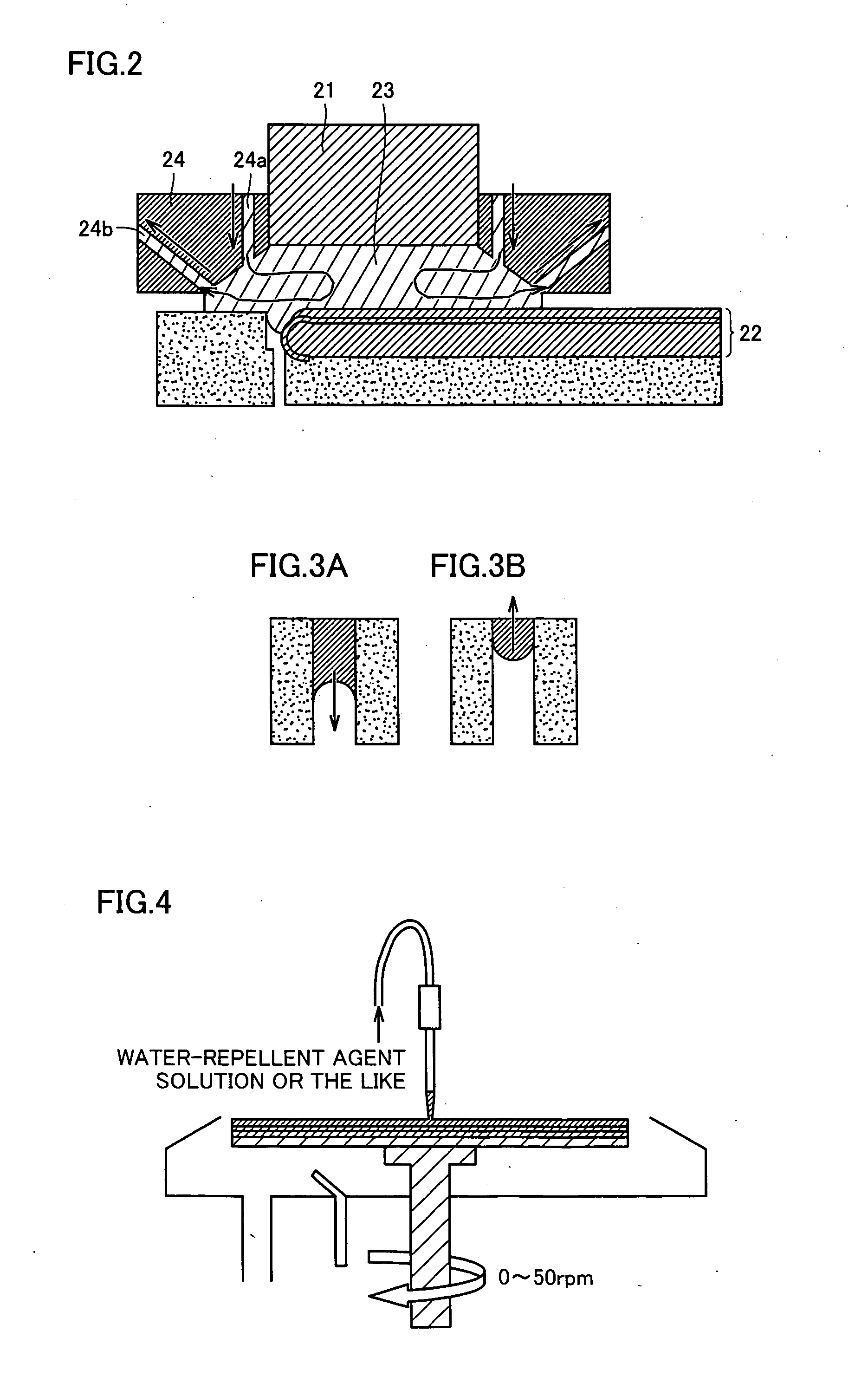

A method of forming a resist pattern through liquid immersion exposure in which exposure is performed such that a liquid film is formed between a substrate for a semiconductor device on which a processed film is formed and an objective lens arranged above the substrate is provided, and the substrate treated with a water-repellent agent solution composed of at least a water-repellent agent and a solvent is exposed to light.

Owner:RENESAS ELECTRONICS CORP

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN1884335AImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

Filter medium for air filter and method for its production

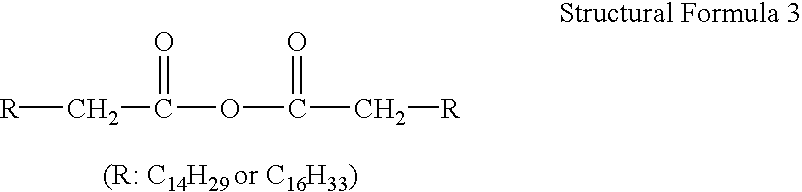

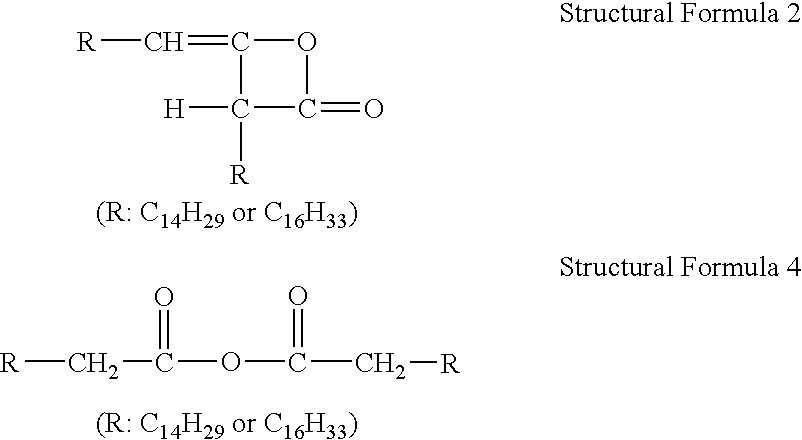

InactiveUS20030145569A1High water-repellencyHigh strengthSynthetic resin layered productsLoose filtering material filtersFiberAir filter

A filter medium for an air filter, characterized in that it comprises a filter material having a glass fiber as its primary component and an alkyl ketene dimer adhered to the surface of the glass fiber; and a method for producing the filter medium which comprises a step of subjecting a dispersed slurry of a raw material fiber to a wet papermaking to form a wet paper, a step of immersing the wet paper in an aqueous dispersion or solution of the dimer or a liquid mixture of the dimer and a binder resin, or applying or spraying any of the above-mentioned liquids to the wet paper, to thereby allow the dimer to adhere onto the surface of the glass fiber, and a step of drying the resultant wet paper having the dimer adhered thereto. The filter medium exhibits a reduced amount of an out gas generated when it is used with ventilation and also exhibits high water-repellency and satisfactory strength in various applications such as air conditioning of a building and semiconductor manufacturing.

Owner:HOKUETSU KK

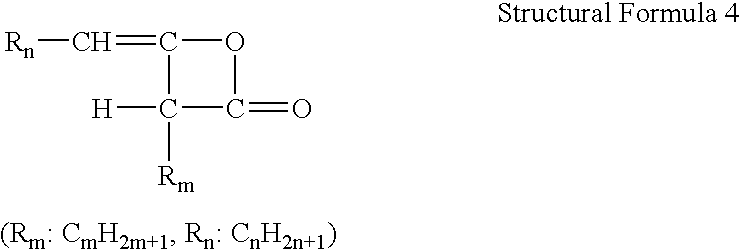

Filter medium for air filter and method for its production

InactiveUS6939386B2High water-repellencyAvoid componentsSynthetic resin layered productsLoose filtering material filtersFiberAir filter

A filter medium for an air filter, characterized in that it comprises a filter material having a glass fiber as its primary component and an alkyl ketene dimer adhered to the surface of the glass fiber; and a method for producing the filter medium which comprises a step of subjecting a dispersed slurry of a raw material fiber to a wet papermaking to form a wet paper, a step of immersing the wet paper in an aqueous dispersion or solution of the dimer or a liquid mixture of the dimer and a binder resin, or applying or spraying any of the above-mentioned liquids to the wet paper, to thereby allow the dimer to adhere onto the surface of the glass fiber, and a step of drying the resultant wet paper having the dimer adhered thereto. The filter medium exhibits a reduced amount of an out gas generated when it is used with ventilation and also exhibits high water-repellency and satisfactory strength in various applications such as air conditioning of a building and semiconductor manufacturing.

Owner:HOKUETSU KK

Fluorine-Containing Compound, Fluorine-Containing Polymer Compound, Resist Composition, Top Coat Composition And Pattern Formation Method

ActiveUS20120077126A1Improve waterproof performanceSufficient water repellencyOrganic chemistryOrganic compound preparationHigh energyDouble bond

A fluorine-containing polymer of the present invention contains a repeating unit (a) of the general formula (2) and has a mass-average molecular weight of 1,000 to 1,000,000. This polymer is suitably used in a resist composition for pattern formation by high energy ray radiation of 300 nm or less wavelength or electron beam radiation or a top coat composition for liquid immersion lithography and is characterized as having high water repellency, notably high receding contact angle.In the formula, R1 represents a polymerizable double bond-containing group; R2 represents a fluorine atom or a fluorine-containing alkyl group; R8 represents a substituted or unsubstituted alkyl group or the like; and W1 represents a single bond, a substituted or unsubstituted methylene group or the like.

Owner:CENT GLASS CO LTD

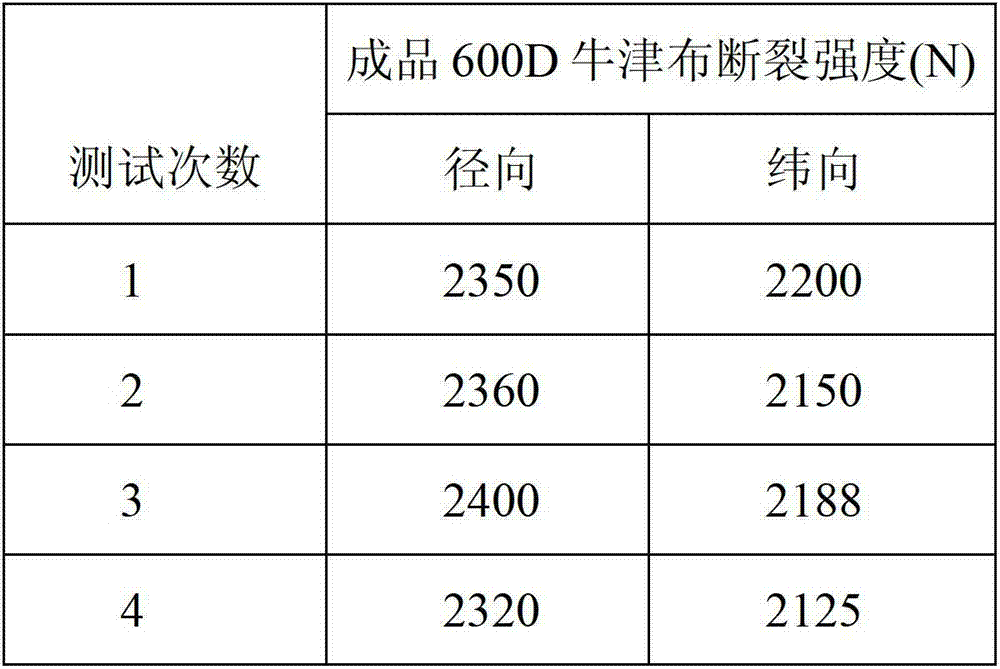

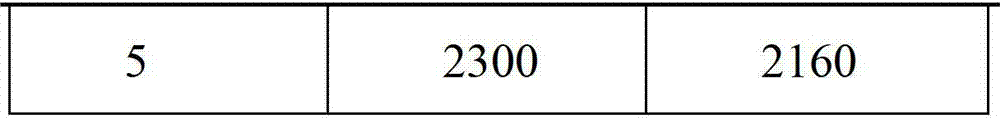

Preparation technology of camouflage cover cloth

ActiveCN102965974AHigh water repellencyReasonable workmanshipFibre typesTents/canopiesCamouflageCost (economic)

The invention provides a preparation technology of camouflage cover cloth, which comprises the following steps of: (I) performing pretreatment of base cloth for dyeing, printing, coating and sizing; (II) dyeing the base cloth by use of dyeing liquid including dyeing disperse dye with a near-infrared shielding function and an ultraviolet absorbent; (III) printing the dyed base cloth by use of printing slurry including printing disperse dye with a near-infrared shielding function; (IV) bottoming the printed base cloth by use of polyamide resin glue; (V) performing PVC (polyvinyl chloride) whitewashing of the bottomed base cloth by use of PVC coating slurry; (VI) performing PU (polyurethane) silver-surface coating of the base cloth after the PVC whitewashing by use of polyurethane silver slurry; and (VII) performing padding finishing of the base cloth after the PU silver-surface coating in water-repellent finishing liquid, and then drying and baking. According to the invention, fabric has a near-infrared green shielding function, color fastness to light and high resistance against hydrostatic pressure as well as high water sprinkling degree, the technology is reasonable, and the economic cost is low.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Core-shell type fluorinated acrylate fabric water repellent and preparation method thereof

ActiveCN103788303AExcellent water and oil repellencyDoes not affect breathabilityFibre treatmentEmulsionMoisture permeability

The invention relates to a core-shell type fluorinated acrylate fabric water repellent which comprises the components by weight percent: 25-50% of monomer, 50-75% of deionized water, an initiator and an emulsifying agent, wherein the weight of the initiator is 0.5-1.5% of the total weight of the monomer, and the weight of the emulsifying agent is 1.0-3.5% of total weight of the monomer. A preparation method of the water repellent comprises the steps of respectively preparing shell emulsion and core emulsion, and then dripping the shell emulsion and the initiator into the core emulsion for reaction to obtain the core-shell type fluorinated acrylate fabric water repellent. The core-shell type fluorinated acrylate fabric water repellent is applied to water and oil repellent finishing of the fabric, so that the fabric has excellent water and oil repellent property, and the problems that the existing water and oil repellent is poor in use durability, low in fastness and the like in the aspect of wearability can be solved; furthermore, the performances such as air permeability, moisture permeability and the like of the fabric are not influenced, and the environmental pollution is not caused.

Owner:广东奕美化工科技有限公司

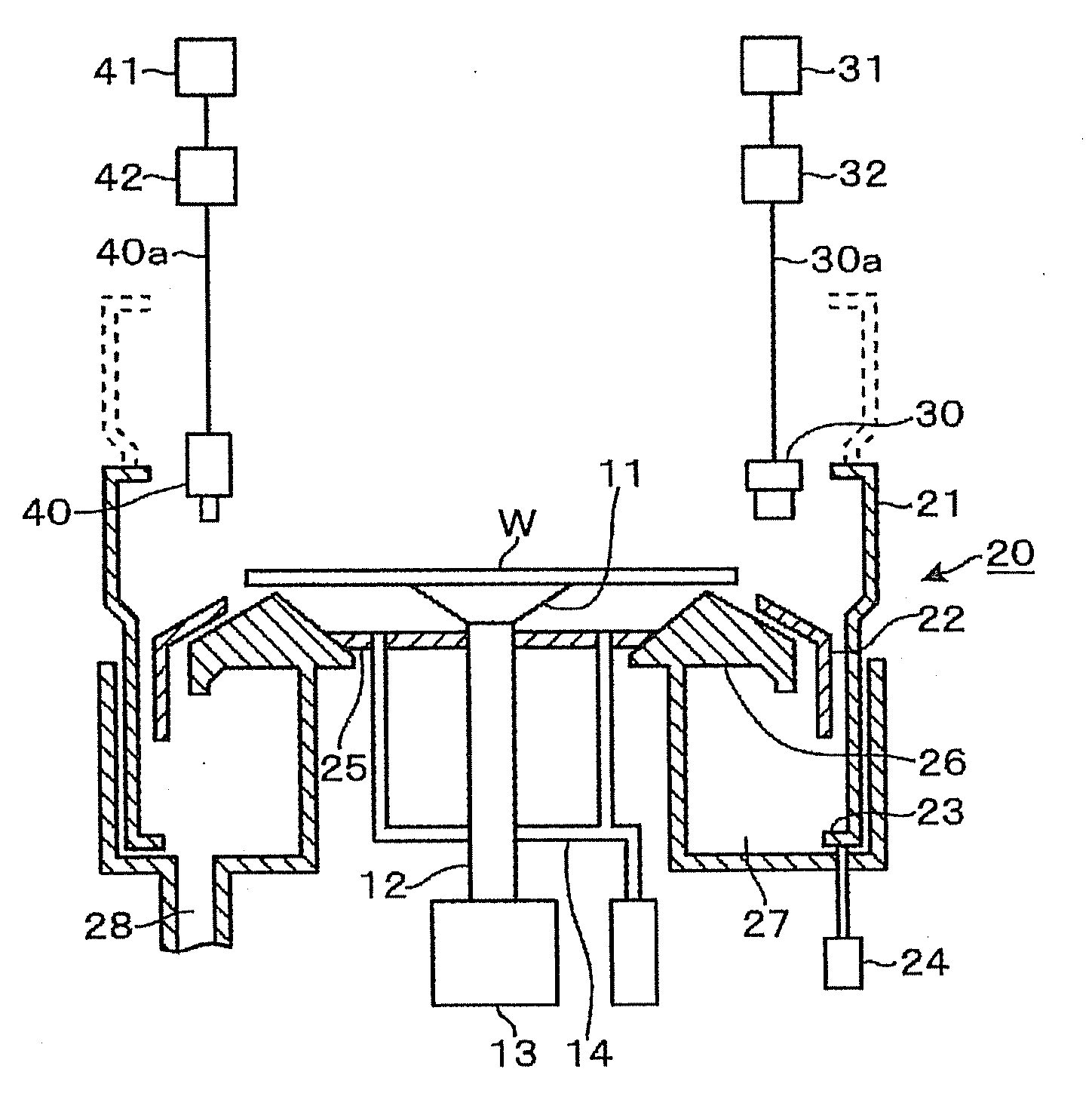

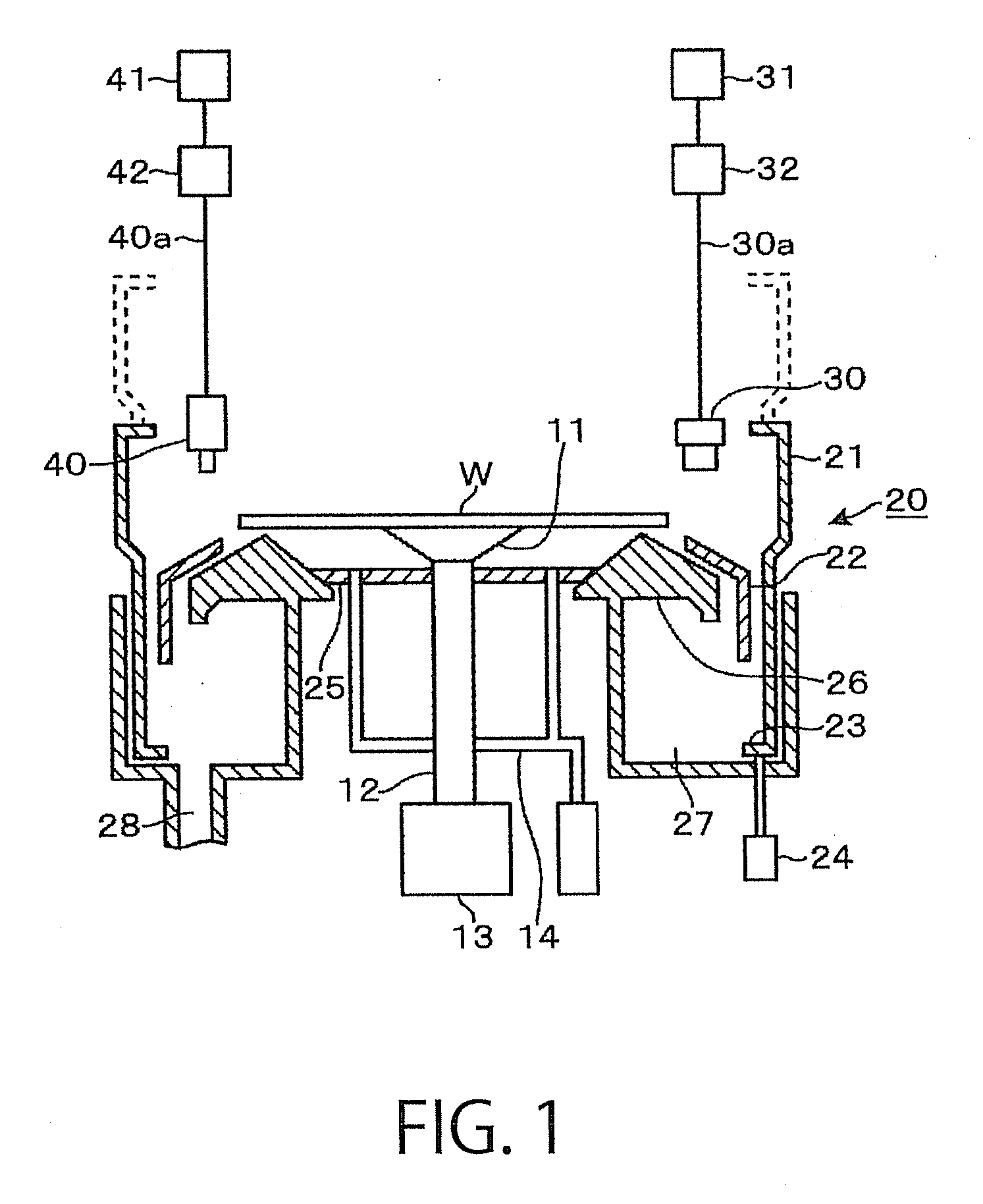

Developing apparatus, developing method and storage medium

ActiveUS20110096304A1Highly uniformly processing surfaceHigh water repellencyLiquid processingReversal processingResistWaste management

A pretreatment process, carried out prior to a developing process, spouts pure water, namely, a diffusion-assisting liquid for assisting the spread of a developer over the surface of a wafer, through a cleaning liquid spouting nozzle onto a central part of the wafer to form a puddle of pure water. The developer is spouted onto the central part of the wafer for prewetting while the wafer is rotated at a high rotating speed to spread the developer over the surface of the wafer. The developer dissolves the resist film partly and produces a solution. The rotation of the wafer is reversed, for example, within 7 s in which the solution is being produced to reduce the water-repellency of the wafer by spreading the solution over the entire surface of the wafer. Then, the developer is spouted onto the rotating wafer to spread the developer on the surface of the wafer.

Owner:TOKYO ELECTRON LTD

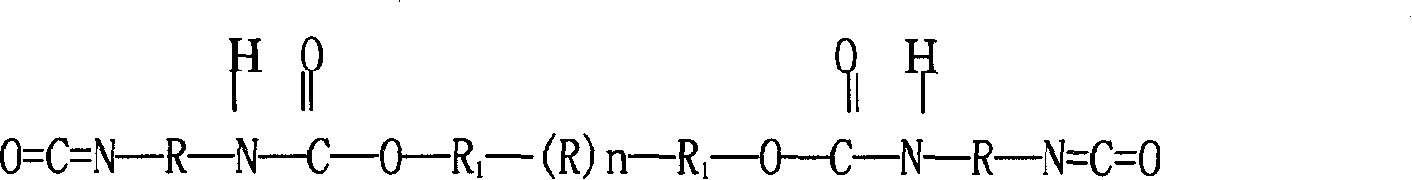

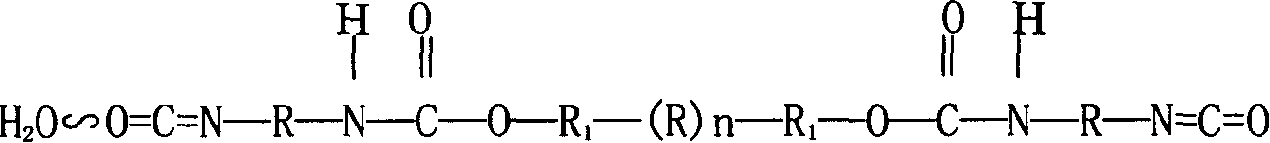

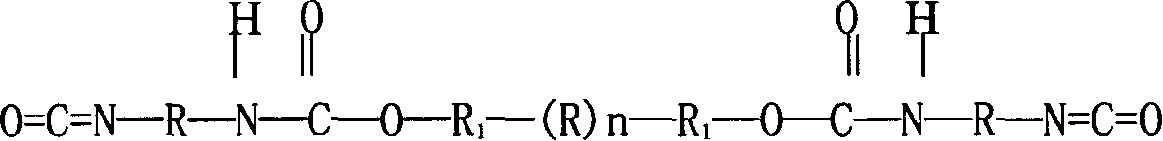

Drying agent for polyurethane synthetic leather and preparation method thereof

The invention provides a drying agent for polyurethane synthetic leather and a preparation method thereof. The drying agent has excellent drying performance, and the hydrolysis resistance of the products is effectively improved by adding the drying agent into the polyurethane synthetic leather. The drying agent is solution of fluorine-containing polyurethane resin, and the weight percentage concentration of the solution is 19.94 to 80 percent. The drying agent comprises the components of an effective solid matter A, a solvent B and an aid C, wherein A is fluorine-modified polyurethane resin and can be expressed by a general formula, namely PFm(PULink)nXk, wherein PF is a chain segment generated by reacting fluorine-containing alcohol with 2 to 18 carbon atoms with an isocyanate group; the PULink is a polyurethane molecule chain segment generated by reacting a polyol compound with diisocyanate and comprises 8 to 16 repetitive units of carbamate; X is a chain or cyclic group and has 2 to 20 carbon atoms; m is an integer from 2 to 8; n is an integer from 1 to 8; k is a number from 1 to 3; m and n can be equal or unequal; and the aid C is modified organosilicon and an addition amount of the aid C is 0.06 to 1.2 percent.

Owner:SHANGHAI HUIDE TECH CO LTD

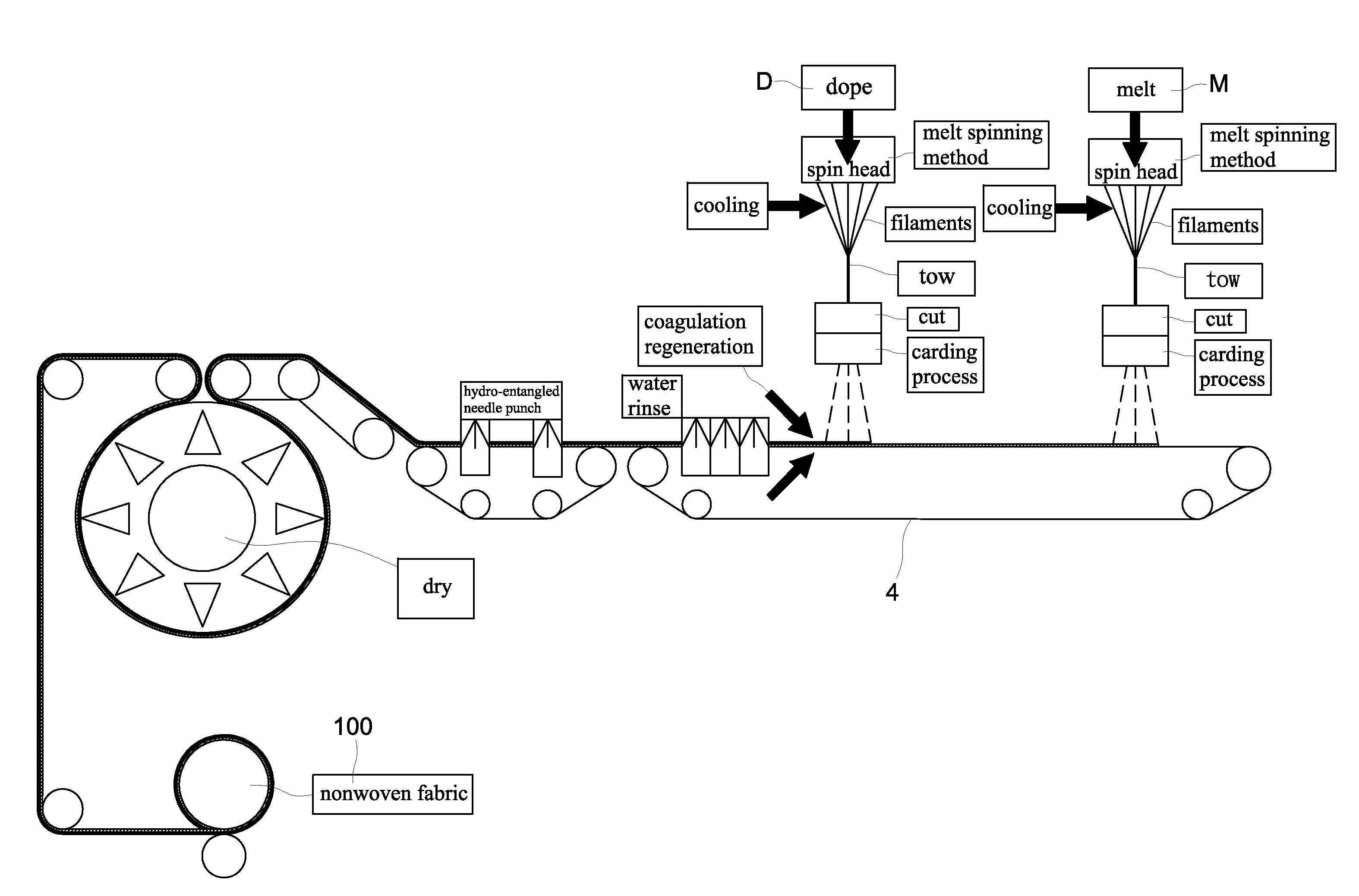

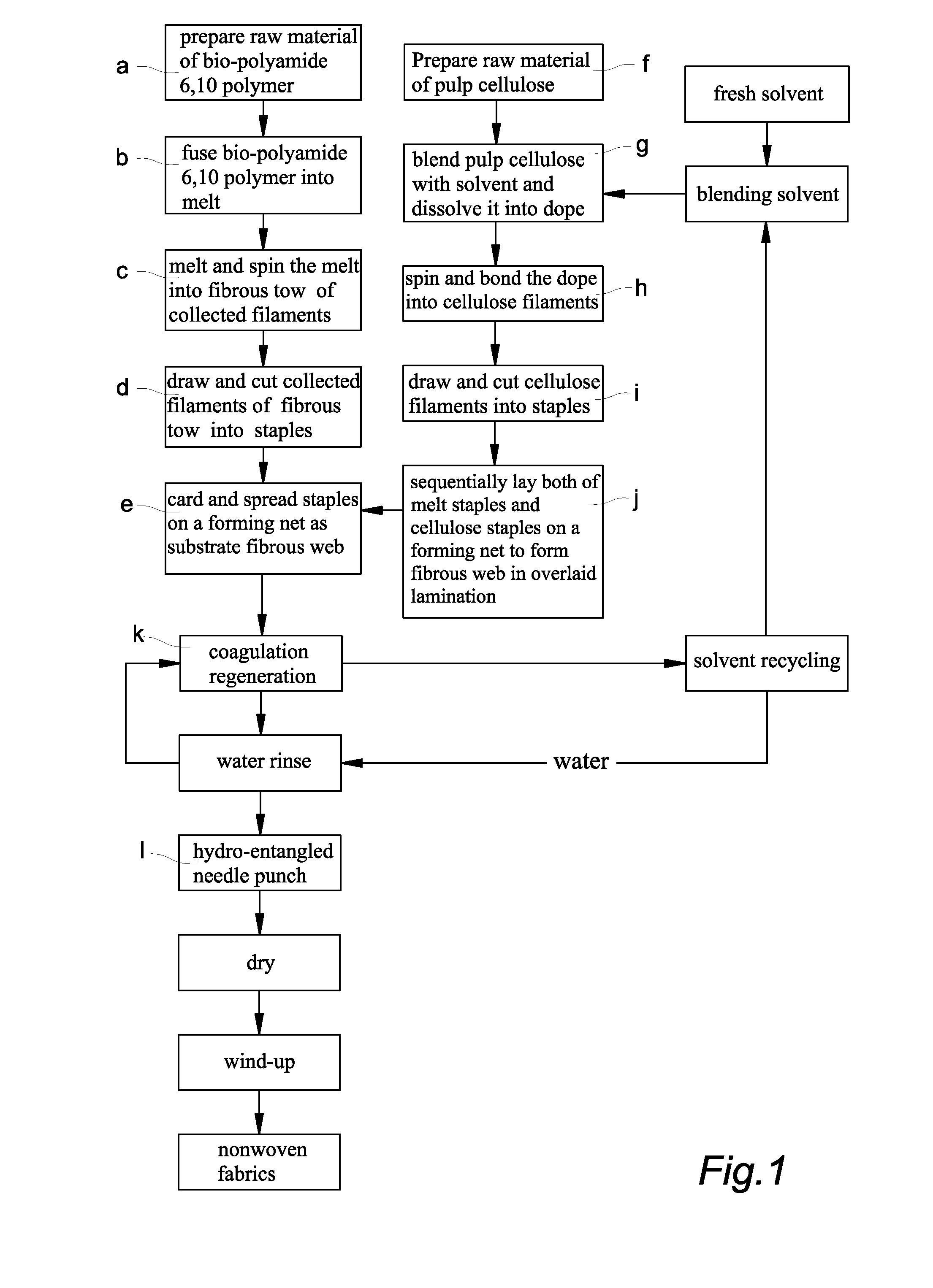

Stapled melt spinning method for producing non-woven fabrics with hygroscopic metastatic feature

ActiveUS20160145781A1Improve water absorptionReduce water contentPattern makingMonocomponent cellulose artificial filamentPunchingPolyamide

A stapled melt spinning method for producing nonwoven fabrics with hygroscopic metastatic feature. Firstly, fuse bio-polyamide 6,10 into melt, extrude and spin it out spin heads of extruder into filaments, cool, draw and collect filaments into tow, then extend, cut and card the filaments into the staples, and spread the staples on a conveyer to form fibrous web. Next, blend and dissolve pulp by N-methylmorpholine N-oxide (NMMO) dissolving solvent, dehydrate it to form dope, and extrude and spin it out spin heads of extruder into filaments, then cool, draw and collect filaments into tow, and extend, cut and card filaments into staples, then overlay the staples over existing fibrous web to form a composite fibrous web of bio-polyamide 6,10 and cellulose filaments. Finally, coagulate, regenerate and convert fibrous composite of bio-polyamide 6,10 and natural cellulose into nonwoven fabric with hygroscopic metastatic feature by hydro-entangled needle punching, drying, winding-up processes.

Owner:LIN CHIH HSIN

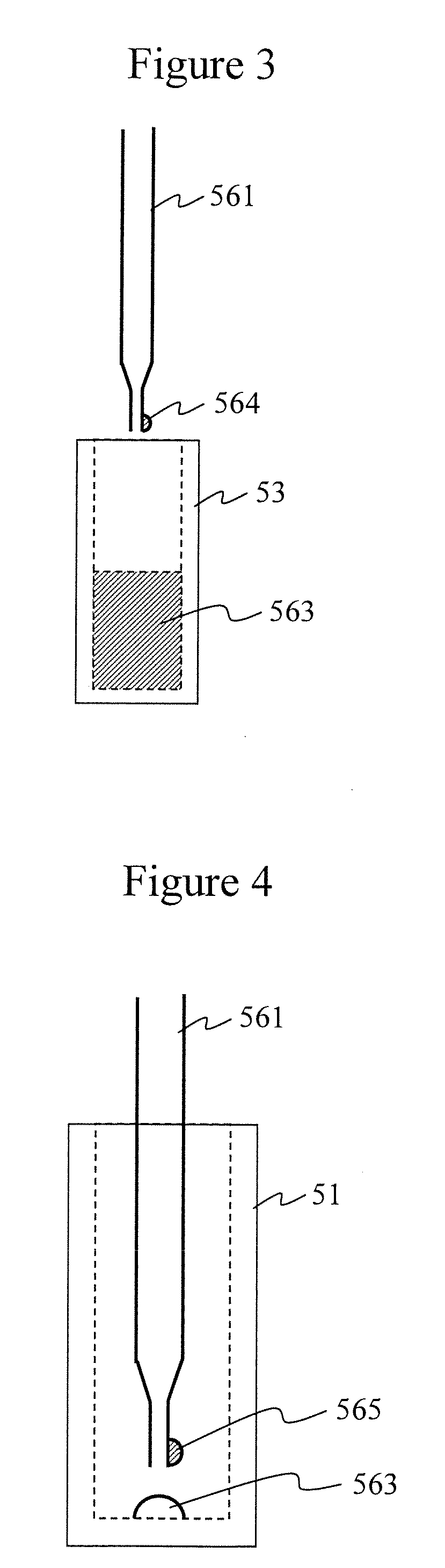

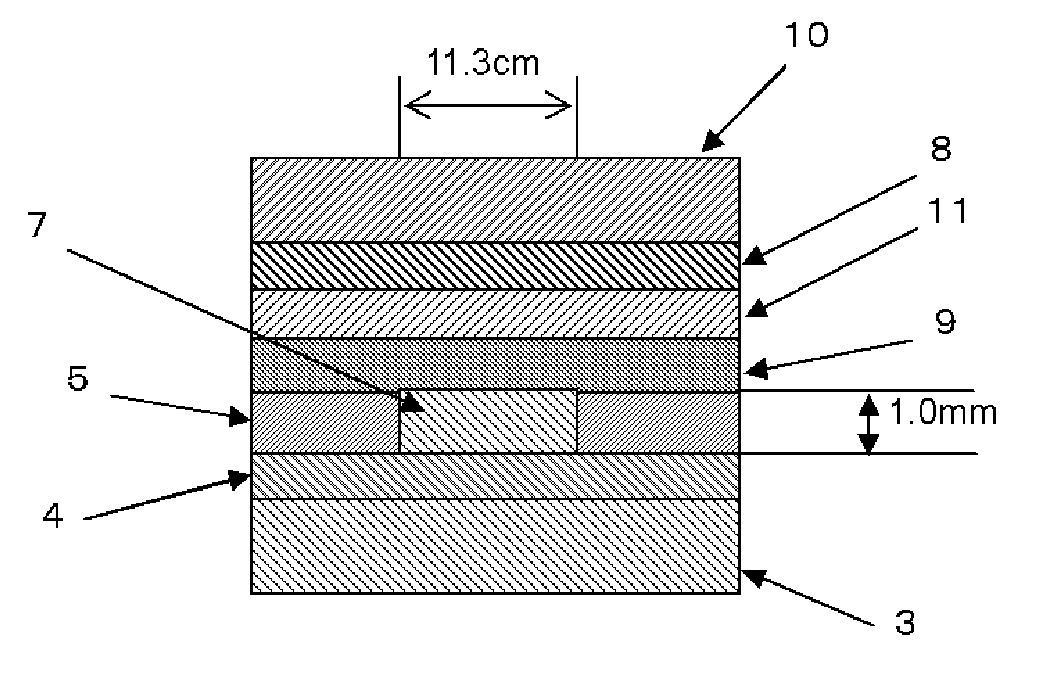

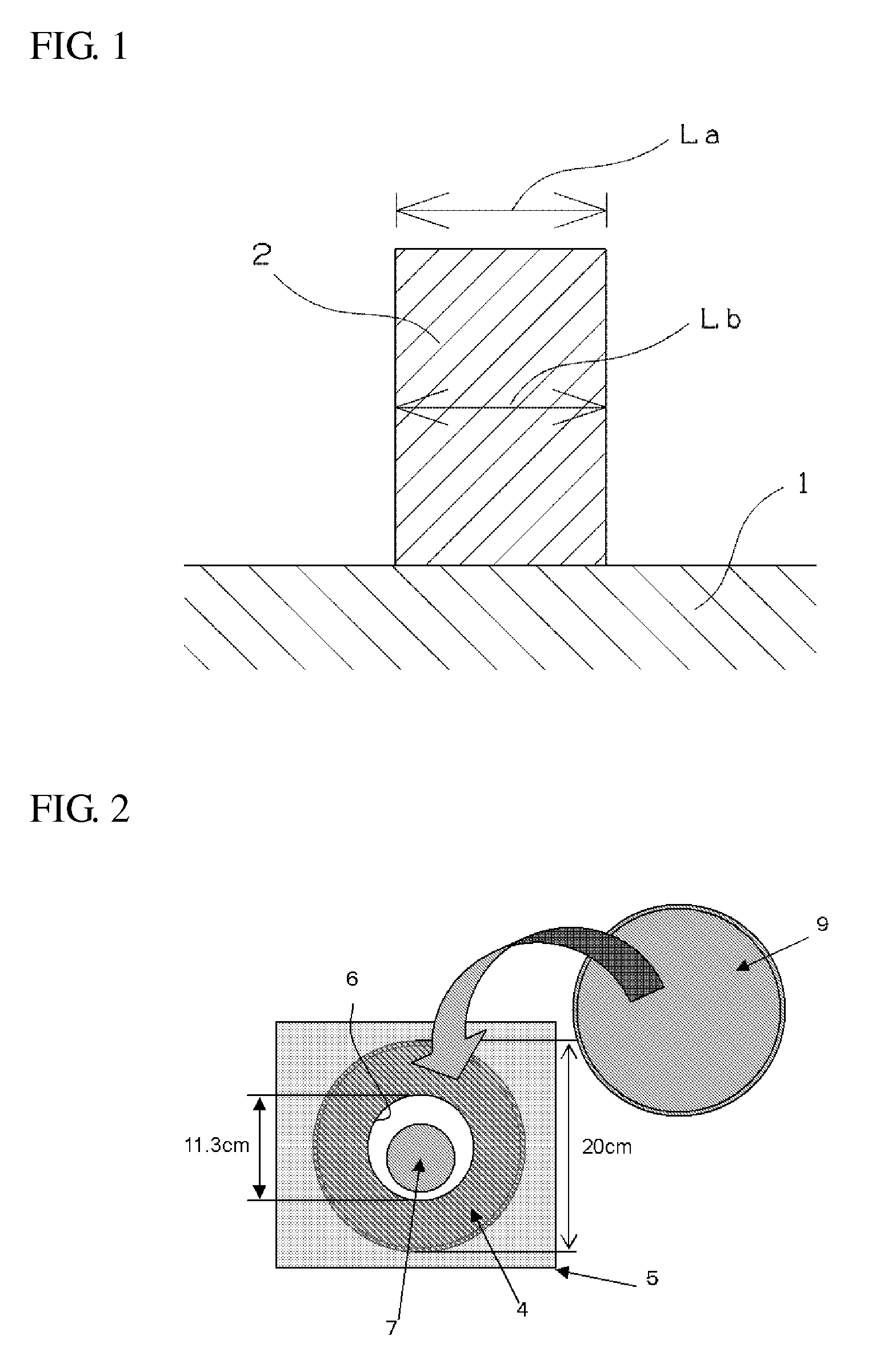

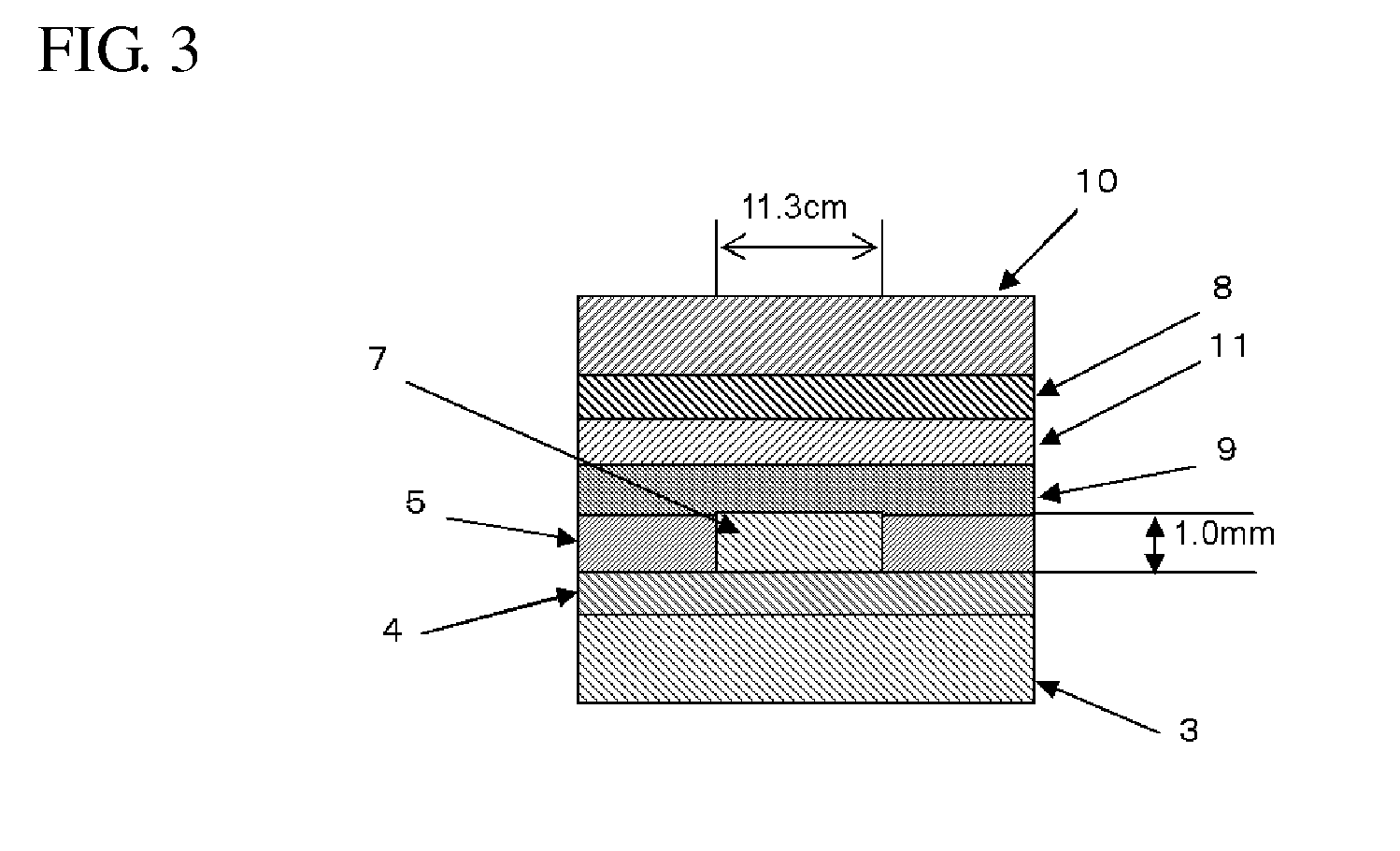

Autoanalyzer and pipetting nozzle for autoanalyzer

ActiveUS20110300035A1Superior in cutting off sample drippingLess liableMaterial analysis by optical meansBurettes/pipettesAutoAnalyzerContamination

There is provided a highly reliable autoanalyzer less liable to sample and reagent carry-over and capable of preventing contamination and precisely pipetting samples and reagents. Using a sample pipetting nozzle 27 having water-repellent surfaces, a sample is pipetted from a sample cell 25 to a reaction cell 4 having a hydrophilic bottom face.

Owner:HITACHI HIGH-TECH CORP

High-water-repellency and high-slidability coating member, fabrication method for same, and high-water-repellency and high-slidability product using same

InactiveCN101255237AHigh water repellencyEasy to slideCoatingsSpecial surfacesHeat resistanceHigh intensity

The invention provides a high-water-repellency and high-slidability coating member for endowing the base material with water repellency and abrasion resistance and the manufacture method and the product thereof. The high-water-repellency and high-slidability coating member of the invention simultaneous ebdows the base material with water repellency, thermal endurance and antifouling property. A silica coating film made of silica and silane hybrid modified fluororesin is applied to a surface of the base material.

Owner:HITACHI CABLE

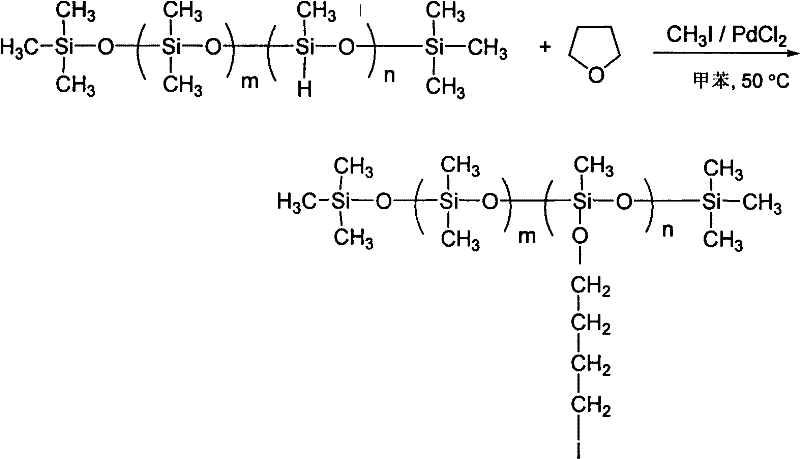

Preparation method of novel organic silicone oil water repellent agent used for cotton fabric

The invention relates to a preparation method of a novel organic silicone oil water repellent agent used for cotton fabric. The preparation method comprises the steps of: under the protection of nitrogen, adding 2 times of molar weight of toluene used as a solvent to a three-neck flask, then respectively adding hydrogen-containing silicone oil with 1 time of molar weight of active hydrogen, 3 times of molar weight of tetrahydrofuran and 4 times of molar weight of iodomethane to the three-neck flask, then adding 0.01 time of molar weight of palladium chloride catalyst, and reacting under the action of the palladium chloride catalyst to prepare the organic silicone oil water repellent agent with active group. The obtained organic silicone oil water repellent agent is mainly used for water repelling finishing of the cotton fabric, can improve water repellent property of the fabric as well as the water repellent durability and tearing resistance of the finished fabric, and is a novel printing and dyeing auxiliary agent.

Owner:金伦(苏州)织造有限公司

Preparation method of water-repellent hybrid fluorine-containing resin coating

The invention discloses a preparation method of a water-repellent hybrid fluorine-containing resin coating. The preparation method comprises the following steps: first, under the action of an initiator, carrying out solution copolymerization on perfluoroalkyl acrylate, other acrylates, styrene and a reactive styrene epoxy compound to synthesize an epoxy fluorostyrene-acrylic resin intermediate; second, carrying out hydrolytic polycondensation on aminoalkyl trialkoxy silane in an alcohol solution to prepare an aminoalkyl silsesquioxane oligomer in a topological structure; and third, hybridizing and cross-linking the epoxy fluorostyrene-acrylic resin by the aminoalkyl silsesquioxane oligomer, co-mixing with a nano-paint to prepare a coating; and leveling, surface-drying, roasting and curing to obtain the resin coating with a good water-repellent effect.

Owner:德施普(辽宁)新材料技术有限公司

Textile subjected to water repellency treatment and production method for textile

The invention discloses a textile subjected to water repellency treatment and a production method for the textile. The textile mainly comprises cationic dye-dyeable modified polyester fibers and / or nylon fibers; the single fiber surface of the textile is at least covered with a resin film formed by water-repellent C6 fluororesin and water-repellent non-fluororesin; the surfaces of the cationic dye-dyeable modified polyester fibers and / or nylon fibers have anionic groups. The textile has durable washability and high water repellency.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

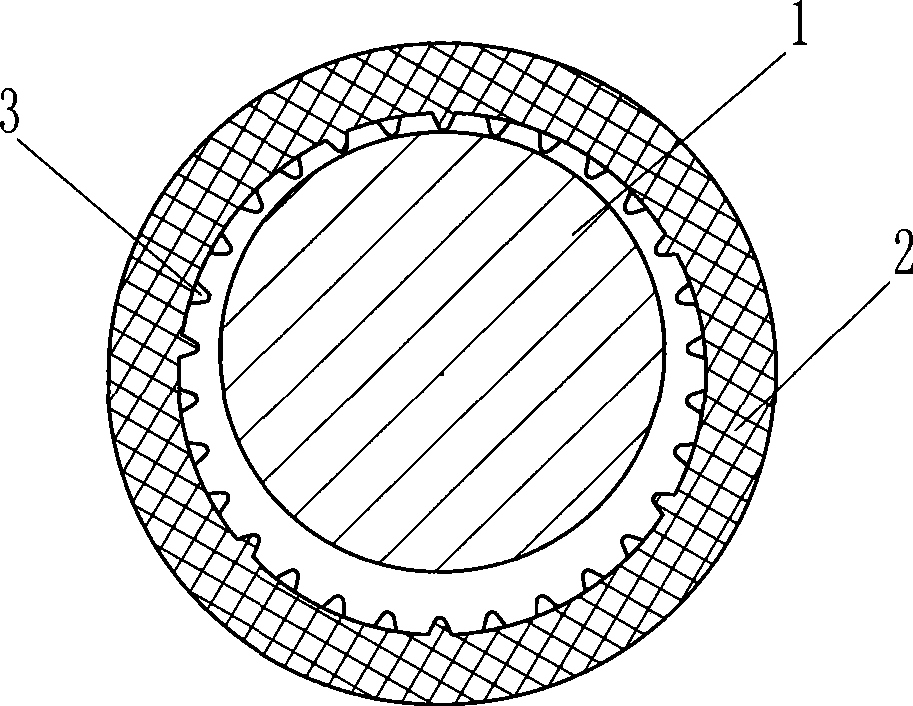

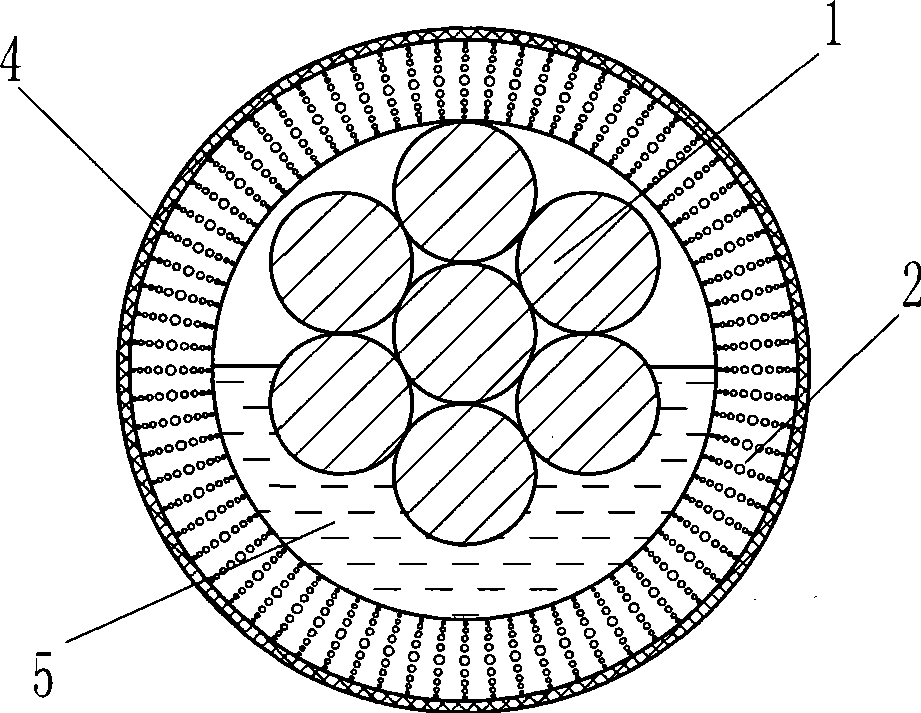

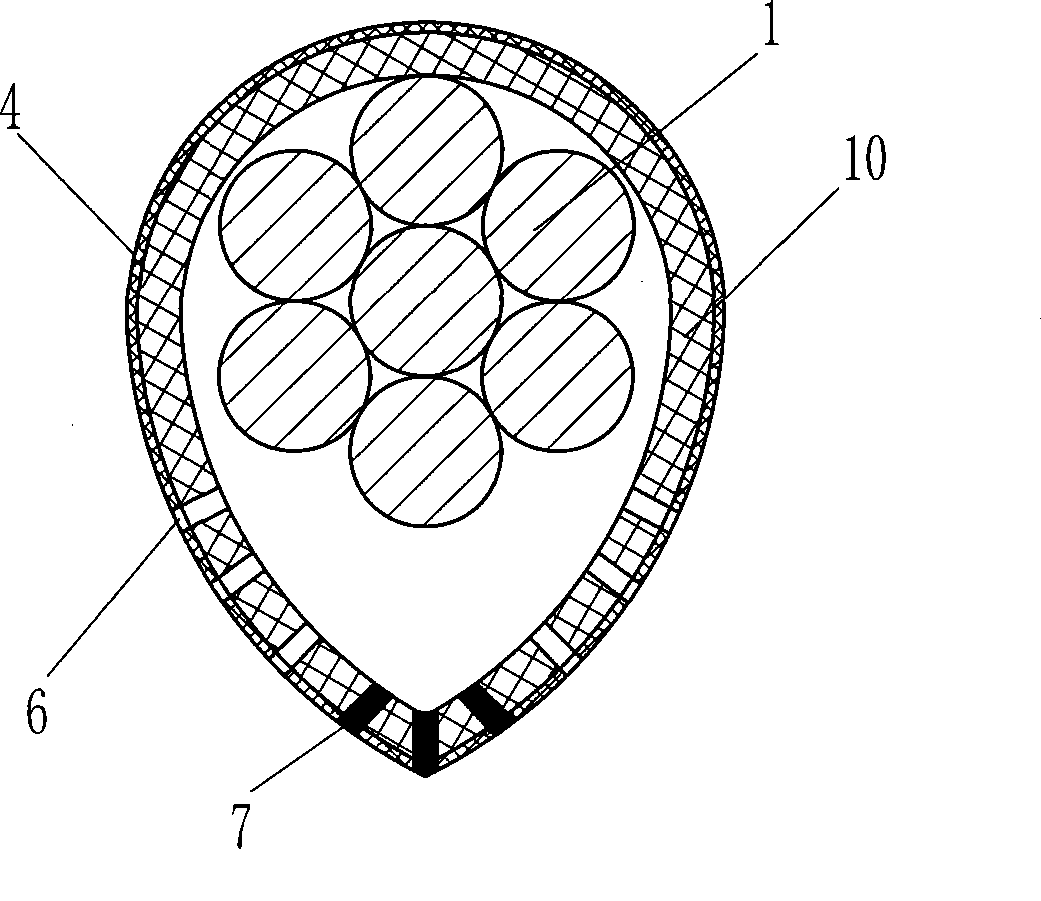

Ice coagulation preventing cable and auxiliary equipment

ActiveCN101504877AReduce gallopingImproved collision angleOverhead installationInsulated cablesEngineeringBottle

The invention relates to an anti-icing cable applicable to ice rain atrocious weather and matched auxiliary facilities with anti-icing property. The anti-icing cable of the invention is characterized in that the cable is sleeved with an anti-icing sleeve, a clearance is reserved between the inner surface of the anti-icing sleeve and the surface of the cable, and the anti-icing sleeve can rotate relative to the cable. An insulating bottle for field power transmission is characterized in that the easy-icing surface of the insulating bottle is provided with the anti-icing sleeve. An anti-icing field metal tower body is characterized in that the surface of an easy-icing part of the tower body is provided with an anti-icing element. A method for arranging the anti-icing sleeve or the anti-icing element on the easy-icing part of the cable, the insulating bottle or the tower body effectively prevents the surface from icing, greatly reduces the heat exchange with the outside, and effectively prevents the icing phenomenon caused by heat absorption after rainwater is directly contacted with the cable, the insulating bottle or the tower body.

Owner:尹学军

High water repellency artificial leather and its manufacturing method

InactiveCN1814906AHigh water repellencyWith anti-siphon effectTextiles and paperMaterials scienceWater washing

This invention relates to a manufacturing method for artificial leather including the following steps: providing a piece of basic cloth, forming a PUR resin impregnation layer with a water-driven agent in said cloth and a coated layer on said cloth to freeze, wash and dry said impregnation layer and the coated layer to form a kind of water-driven artificial leather and then process the fluorine water-driven agent to form a high water-driven artificial leather.

Owner:SAN FANG CHEM IND

Manufacturing method of acrylic fiber and bamboo fiber blended water-repellent shell fabric

InactiveCN104562387AGuaranteed to be clean and sterileGood physical and mechanical propertiesFibre treatmentLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses a manufacturing method of an acrylic fiber and bamboo fiber blended water-repellent shell fabric. The selected warp and weft materials comprise the following components in parts by mass: 40-90 parts of acrylic fibers, 20-45 parts of natural fibers, 6-12 parts of synthetic fibers, 8-15 parts of bamboo fibers, 60-95 parts of cotton fibers and 8-18 parts of super fine denier polyesters. According to the manufacturing method, water repellent finish is carried out between sizing operation and air injection by the following steps: padding a shell fabric in a water repellent finish liquid; taking out the shell fabric; and then carrying out electron radiation and drying treatment, wherein the water repellent finish liquid comprises 2-8% by mass of a water repellent; the drying treatment comprises first drying treatment and second drying treatment. According tothe manufacturing method of the acrylic fiber and bamboo fiber blended water-repellent shell fabric designed by the invention, the cohesive force between the fibers of the acrylic fiber and bamboo fiber blended water-repellent shell fabric can be enhanced, and the acrylic fiber and bamboo fiber blended water-repellent shell fabric has a good water-repellent antibacterial performance while having the advantages of high elasticity, high strength and heat and light resistance, and the washability and the softness of textile are improved.

Owner:SUZHOU CHENHENG WEAVING

Polyalkylsilsesquioxane particulates and a preparation method thereof

The present invention relates to polyalkylsilsesquioxane particulates and a method of preparing the same, and more particularly provides the polyalkylsilsesquioxane particulates, of which moisture content is low, water repellency is high, and hygroscopic property in storage is low, and a method of preparing the same by end-capping silanol groups (SiOH) on the surface of the polyalkylsilsesquioxane particulates with alkyl groups by adding an alkoxytrialkylsilane having a triorganosilyl group thereto.

Owner:KOLON IND INC

Plant fibre reinforced biodegradable film material and preparation thereof

The invention relates to a biodegradable thin-film material strengthened by plant fibers and a preparation method thereof. Raw materials and parts by weight thereof used are as follows: 20 parts to 45 parts of plant fibers, 30 parts to 50 parts of starch, 20 parts to 35 parts of vinyl monomers, 20 parts to 30 parts of biodegradable plastics, 10 parts to 15 parts of plasticizers, 3 parts to 5 parts of water and 0.5 part to 3 parts of heat stabilizers. The preparation method of the thin-film material comprises the steps: the plant fibers, starch, vinyl monomers and water of certain quantities are evenly mixed and radiated by a cobalt Gamma 60 source or an electron accelerator for 0.5kGy to 20kGy; the material after radiation is mixed with the biodegradable plastics, the plasticizers and the heat stabilizers; then a twin screw is used for preparing a thin-film special material; and finally the thin-film is formed by means of blow molding using a single screw. The completely biodegradable thin-film has good water resistance and heat combination performance and is applicable to producing farming terra films and packing films so as to solve the white pollution problem caused by the heavy use of oil-based plastic.

Owner:JILIN NORMAL UNIV

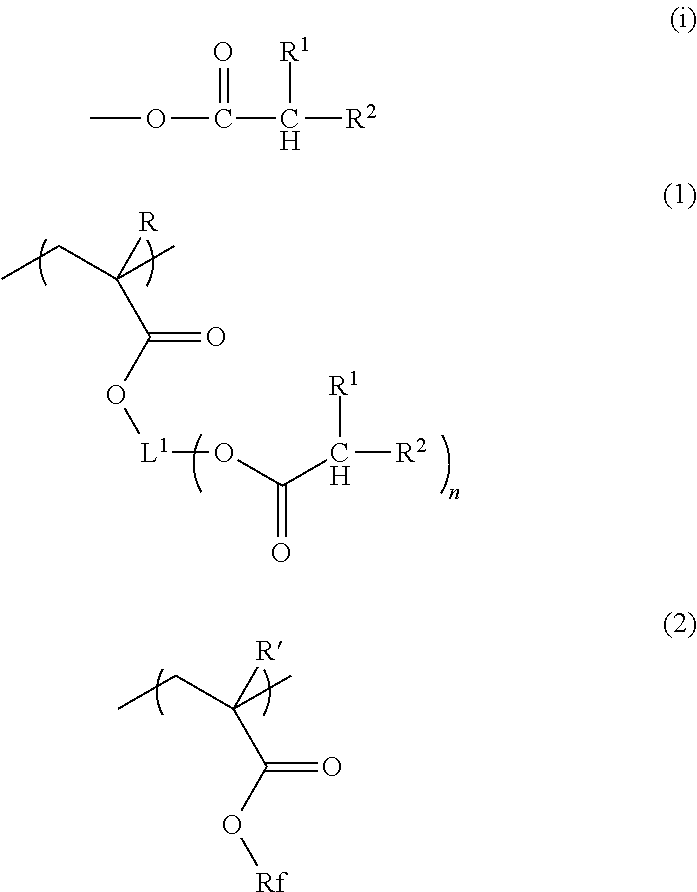

Composition for forming liquid immersion upper layer film, and polymer

ActiveUS20130217850A1Increase contentEasy to synthesizeSemiconductor/solid-state device manufacturingEmulsion paintsPolymer scienceSolvent

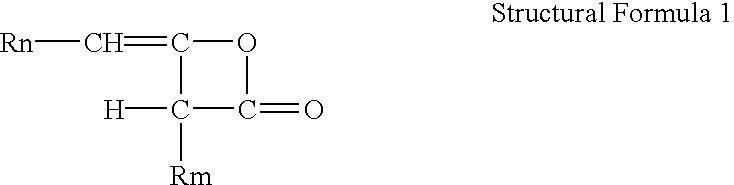

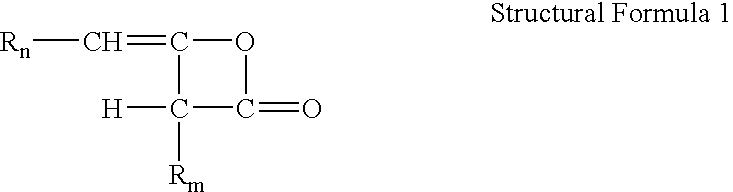

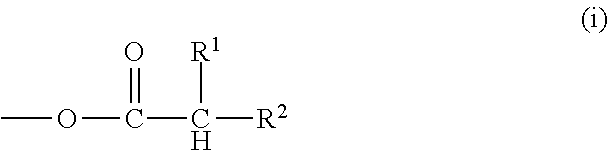

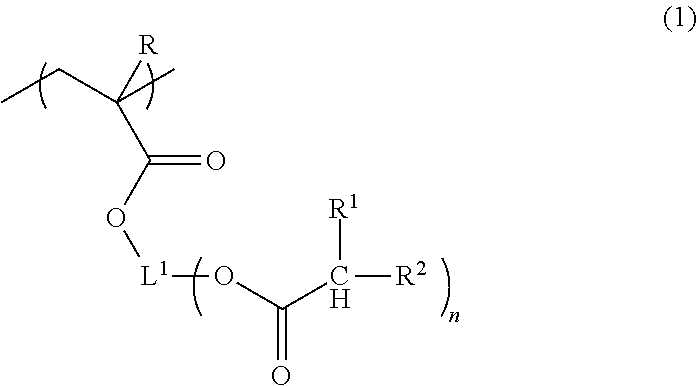

An immersion upper layer film-forming composition includes [A] a polymer component that includes a polymer (A1), and [B] a solvent, the polymer (A1) including a structural unit (I) that includes a group represented by the following formula (i). The structural unit (I) is preferably a structural unit (I-1) represented by the following formula (1). The polymer component [A] preferably further includes a structural unit (II-1) represented by the following formula (2), the structural unit (II-1) being included in the polymer (A1) or a polymer other than the polymer (A1). The polymer component [A] preferably further includes a structural unit (III) that includes a carboxyl group, the structural unit (III) being included in the polymer (A1) or a polymer other than the polymer (A1).

Owner:JSR CORPORATIOON

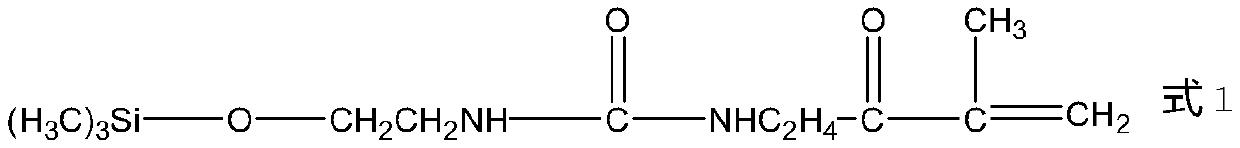

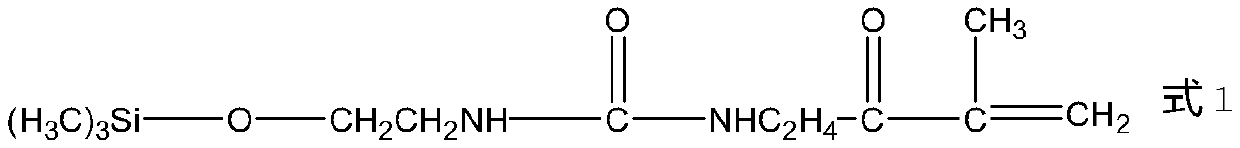

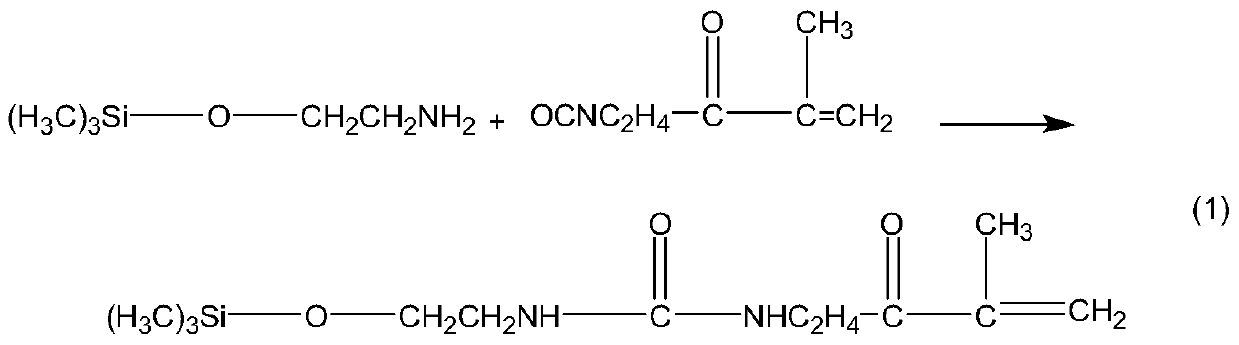

Preparation method of water repellent finishing agent

InactiveCN103726320AReduce usageHigh water repellencyFibre treatmentSilicon dioxideFluorine containing

The invention discloses a preparation method of a water repellent finishing agent, which comprises the following steps: adding ethanol in ammoniacal liquor for stirring, adding tetraethyl orthosilicate for reacting for a while to prepare transparent blue silica sol, adjusting the pH value of the nano silica sol by citric acid, and dissolving the nano silica sol and fluorine-containing acrylic acid ester according to certain mass ratio in water to prepare the finishing agent. According to the invention, the price of a fluorine-containing polymer is expensive, some fluorine-containing polymer contains pollutant of PFOS and PFOA, so that the application is limited, the silica sol is added in the fluorine-containing polyacrylate, water and oil repellent performance of the water repellent finishing agent is increased, and the usage of the fluorine-containing polymer can be reduced.

Owner:WUXI SHUNYE TECH

Stretchable film and method for forming the stretchable film

ActiveUS20180215876A1Easy to stretchHigh strengthPolyurea/polyurethane coatingsInsulatorsSide chainSilicon

The present invention provides a stretchable film that is excellent in stretch and strength and water repellency on the film surface, and a method for forming the stretchable film.The present invention was accomplished by a stretchable film including a resin having a branched siloxane bond having 3 to 11 silicon atoms on a side chain and having a urethane bond on a main chain.

Owner:SHIN ETSU CHEM IND CO LTD

Waterproofing agent of acrylic ester coat, and preparation method

ActiveCN101092532AWeather resistantWashableAntifouling/underwater paintsPaints with biocidesCold resistanceMaterials science

This invention discloses a method for preparing a waterproof acrylate coating agent. The object coated with the waterproof acrylate coating agent has such advantages as soft touching sense, high water resistance, high waterproof effect, and high film -forming performance, and high wind, rain, gigging and cold resistance. The generated waste gases can be incinerated in a catalytic incinerator, thus the waterproof acrylate coating agent is environmentally friendly.

Owner:ZHEJIANG SATELLITE PETRO CHEM CO LTD

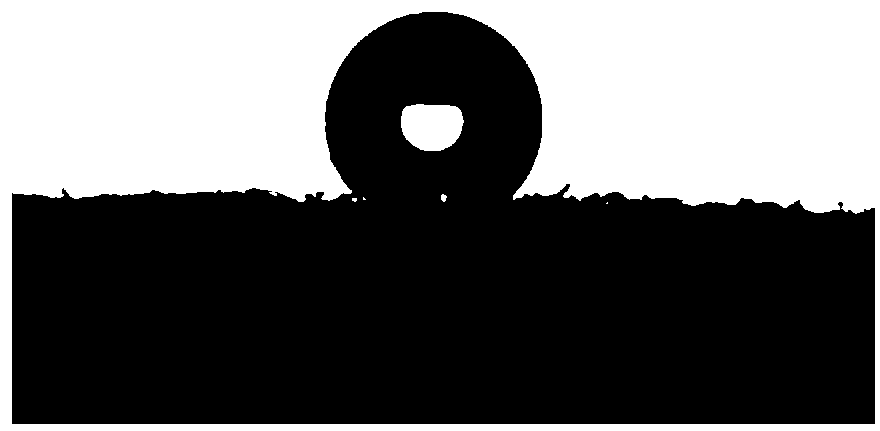

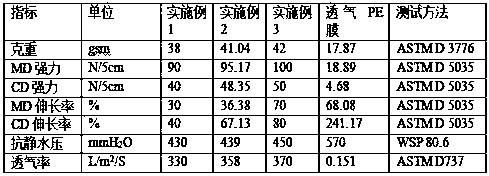

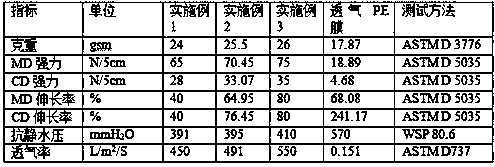

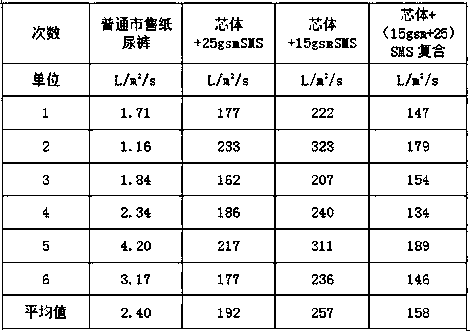

High-barrier spun and melted novel breathable material as well as preparation method and application thereof

ActiveCN109594200AReduce surface tensionStrong water repellencyNon-woven fabricsBandagesFill powerGram

The invention provides a high-barrier spun and melted novel breathable material. When the gram weight is 25 gsm, hydrostatic pressure resistance is 390-410 mmH2O, air permeability is 450-550 L / m<2> / S,MD strength is 65-75 N / 5 cm, CD strength is 28-35 N / 5 cm, MD elongation is 40%-80% and CD elongation is 40%-80%. The invention also provides a preparation method of the novel breathable material. Themethod comprises steps of material selection, melt extrusion, fiber drafting and hot rolling treatment. S-layer fine denier fiber with fineness of 1.5-1.8 denier is obtained through fiber drafting; M-layer fine denier fiber has fineness of 2-4 micrometers, and water repellency and filling power of fiber are kept. The invention also provides an application of the novel breathable material in diapers and the breathability of the diapers is substantially improved.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

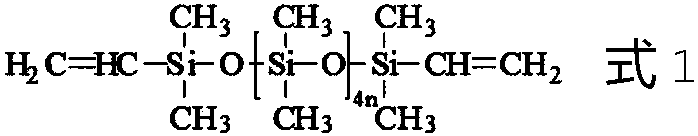

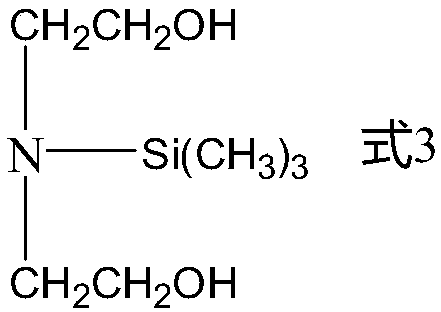

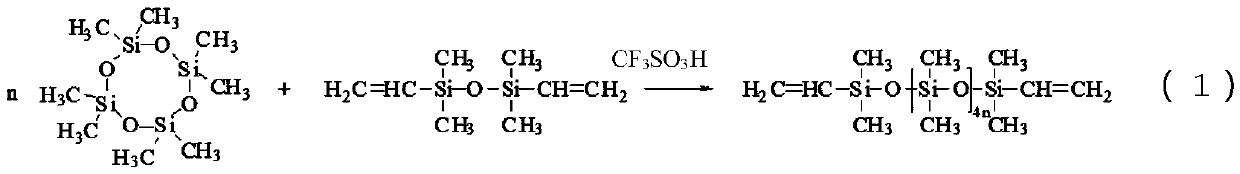

Nano-organosiliconorganosilicon and polyurethane composite waterproof emulsion

ActiveCN109679327AImprove stabilityHigh water repellencyLiquid repellent fibresEthylenediamineWater based

The invention discloses a nano-organosilicon and polyurethane composite waterproof emulsion. The emulsion is characterized by being composited from the components in percentage by mass as follows: 34%-47% of nano-organosilicon emulsion and 53%-66% of a waterborne polyurethane emulsion, wherein the nano-organosilicon emulsion is prepared from vinyl nano-SiO2 sol, a double-ended alkenyl organosilicon monomer, a monovinyl organosilicon monomer, an emulsifier, water and initiator by emulsion polymerization; the aqueous polyurethane emulsion is prepared from polyether glycol, diisocyanate, dimethylol propionic acid, dihydroxysilane monomer, triethylamine, ethylenediamine, a catalyst, an organic solvent and water. Hydrophobicity of the textile surface can be improved by increasing coarseness ormodifying the surface with low surface energy substances. Polysiloxane is used as a low surface energy material and nano-SiO2 is used for forming roughness to be combined with water-based polyurethane, and accordingly, good water repellency is achieved, and adhesion of organosilicon is improved.

Owner:浙江东进新材料有限公司

Coating technology for cover cloth

InactiveCN103643531AHigh light fastness functionHigh hydrostatic pressure resistanceTextiles and paperState of artSilver paste

A disclosed coating technology for cover cloth comprises the following steps: first step, priming fabric base cloth by employing PA glue; second step, performing PVC whitewashing on the primed fabric base cloth by PVC coating slurry; and third step, performing PU silver face coating on the fabric base cloth subjected to PVC whitewashing by PU silver paste. Compared with the prior art, the coating technology enables the fabric base cloth to have high color fastness to light and high hydrostatic-pressure resistance as well as relatively water sprinkling effect, and is reasonable in technology and low in economic cost.

Owner:青州市盛达蓬布厂

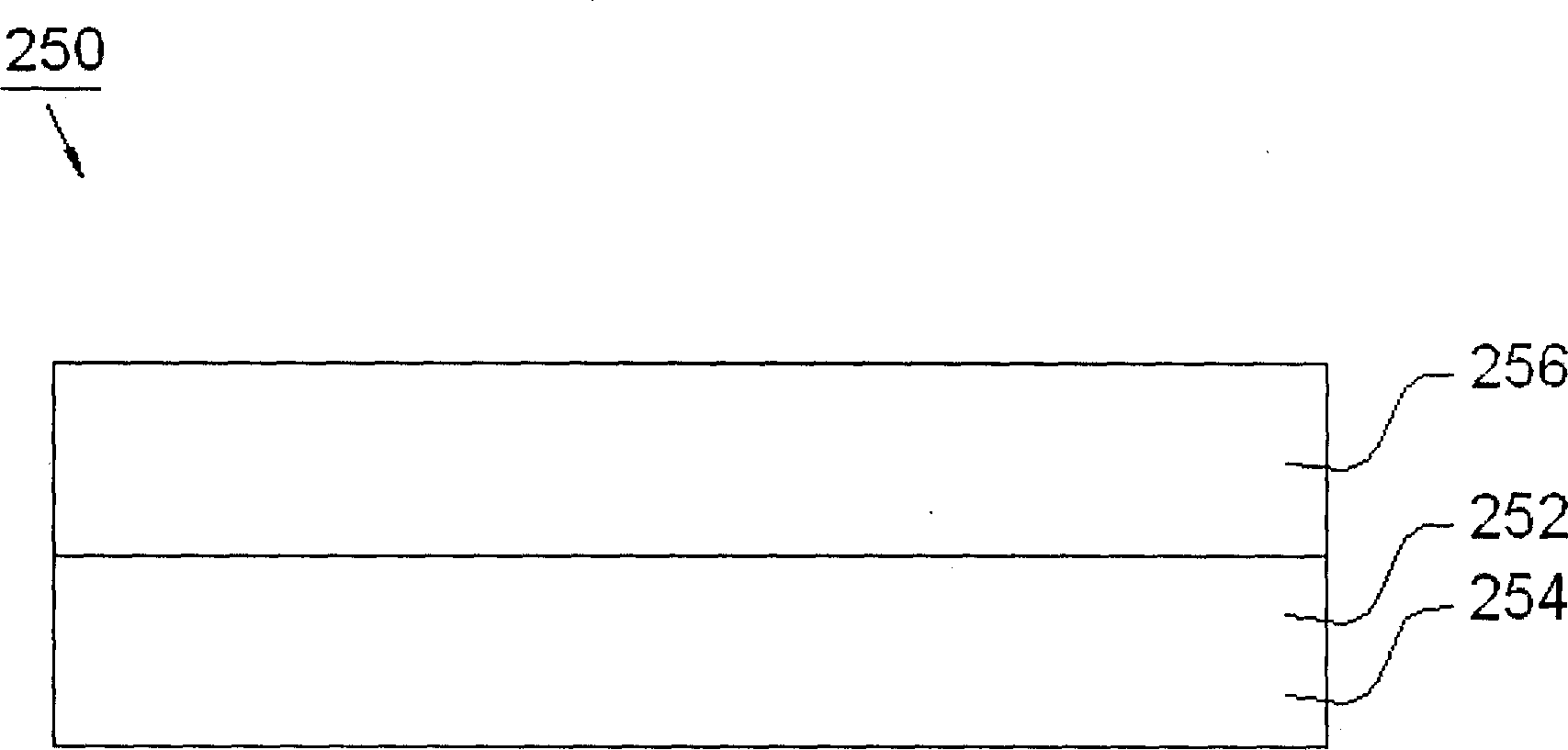

Composition for forming upper layer film for immersion exposure, upper layer film for immersion exposure, and method of forming photoresist pattern

ActiveUS20100255416A1Excellent solubilityDecrease solubilityPhotosensitive materialsSemiconductor/solid-state device manufacturingSolventPhotoresist

The object of the invention is to provide a composition for forming an upper layer film for immersion exposure capable of forming an upper layer film effectively inhibited from developing defects through an immersion exposure process, such as a watermark defect and dissolution residue defect. Also provided are an upper layer film for immersion exposure and a method of forming a resist pattern. The composition for forming an upper layer film includes a resin ingredient and a solvent. The resin ingredient includes a resin (A) having at least one kind of repeating units selected among those represented by the formulae (1-1) to (1-3) and at least either of the two kinds of repeating units represented by the formulae (2-1) and (2-2). (1-1) (1-2) (1-3) (2-1) (2-2) [In the formulae, R1 represents hydrogen or methyl; R2 and R3 each represents methylene, linear or branched C2-6 alkylene, or alicyclic C4-12 alkylene; R4 represents hydrogen or methyl; and R5 represents a single bond, methylene, or linear or branched C2-6 alkylene.].

Owner:JSR CORPORATIOON

Organosilicon acrylate compound waterproof finishing agent emulsion

The invention discloses an organosilicon acrylate compound waterproof finishing agent emulsion. The organosilicon acrylate compound waterproof finishing agent emulsion is prepared from in percentage by mass: 52-68% of an organosilicon emulsion and 32-48% of a silicon-contained acrylate emulsion in a blending mode; the organosilicon emulsion is mainly prepared from vinyl nano SiO2 sol, polymerizable organosilicon monomers, and a vinyl siloxane emulsion in a polymerized mode; and the silicon-contained acrylate emulsion is mainly prepared from acrylate monomers and vinyl siloxane monomers in a polymerized mode through an emulsion. The acrylate emulsion has good film formation, adhesion and weather resistance, and has the compatibility with polar polymers and non-polar polymers, and the acrylate emulsion is in composition with the organosilicon emulsion, the defects that a single-composition organosilicon emulsion has poor film formation fastness and poor washing resistance on the surfacesof fabrics can be overcome. The emulsion can form the organosilicon film with low surface energy, can also change the surface roughness, and enhance the water repellency of the surface synergistically.

Owner:浙江东进新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com