Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "High washing durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing yarns and fabrics having a wash-durable non-electrically conductive topically applied metal-based finish

Durable non-electrically conductive metal treatments (such as coatings or finishes) for yarns and textile fabrics. Such treatments preferably comprise silver and / or silver ions; however, other metals, such as zinc, iron, copper, nickel, cobalt, aluminum, gold, manganese, magnesium, and the like, may also be present or alternatively utilized. Such a treatment provides, as one example, an antimicrobial fiber and / or textile fabric which remains on the surface and does not permit electrical conductivity over the surface. The treatment is extremely durable on such substrates; after a substantial number of standard launderings and dryings, the treatment does not wear away in any appreciable amount and thus the substrate retains its antimicrobial activity (or other property). The method of adherence to the target yarn and / or fabric may be performed any number of ways, most preferably through the utilization of a binder system or through a transfer method from a donor fabric to a target textile fabric in the presence of moisture and upon exposure to heat. The particular methods of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

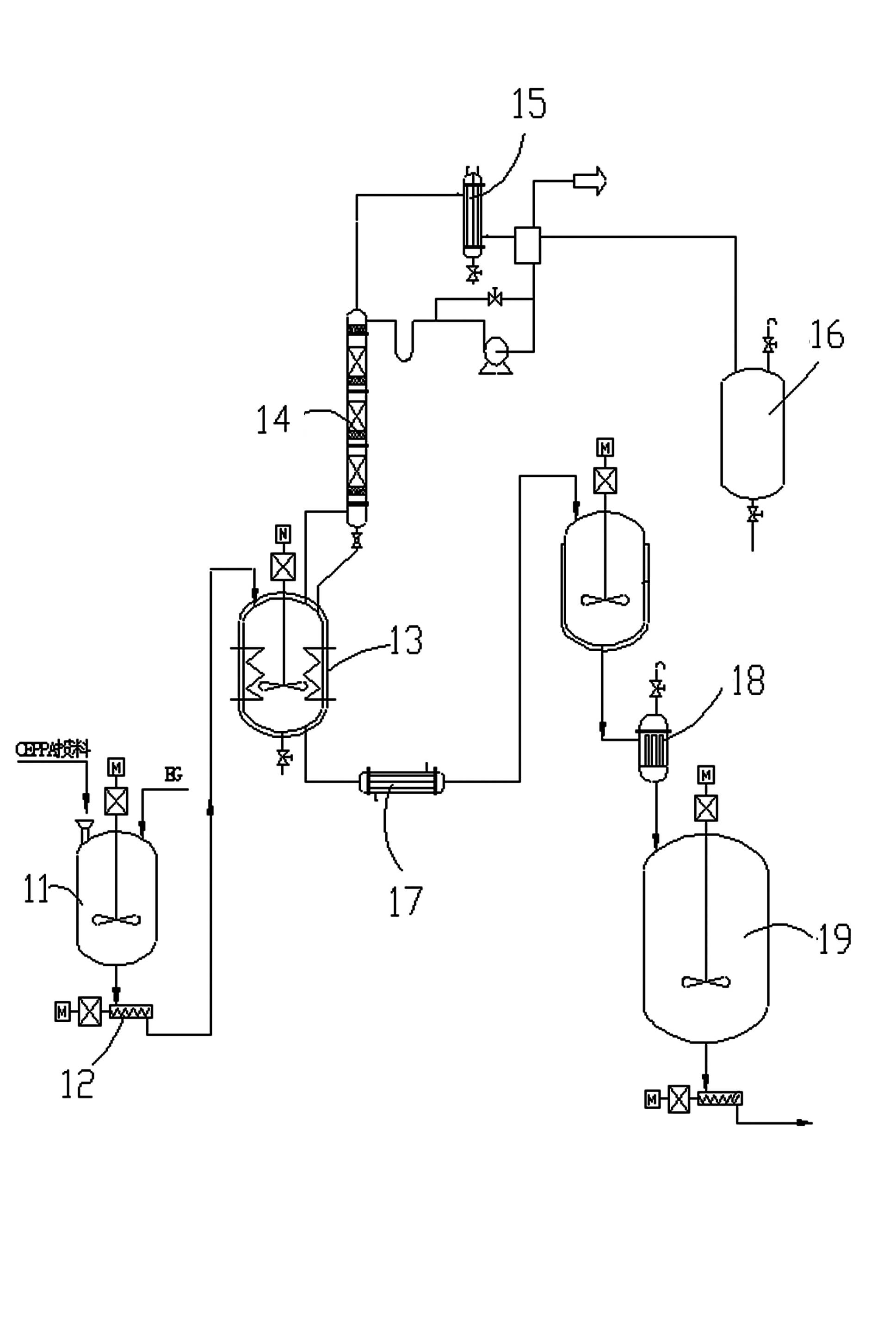

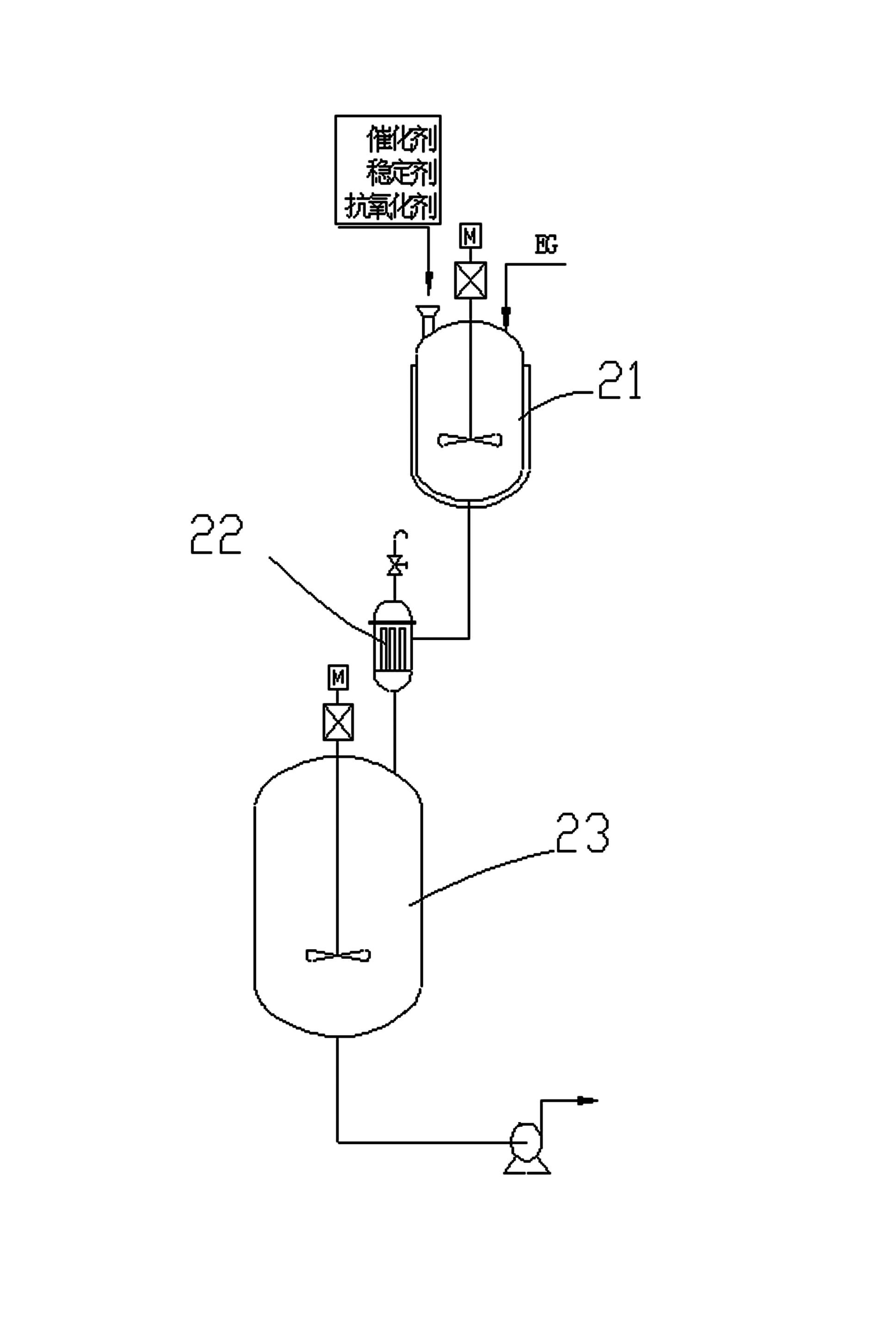

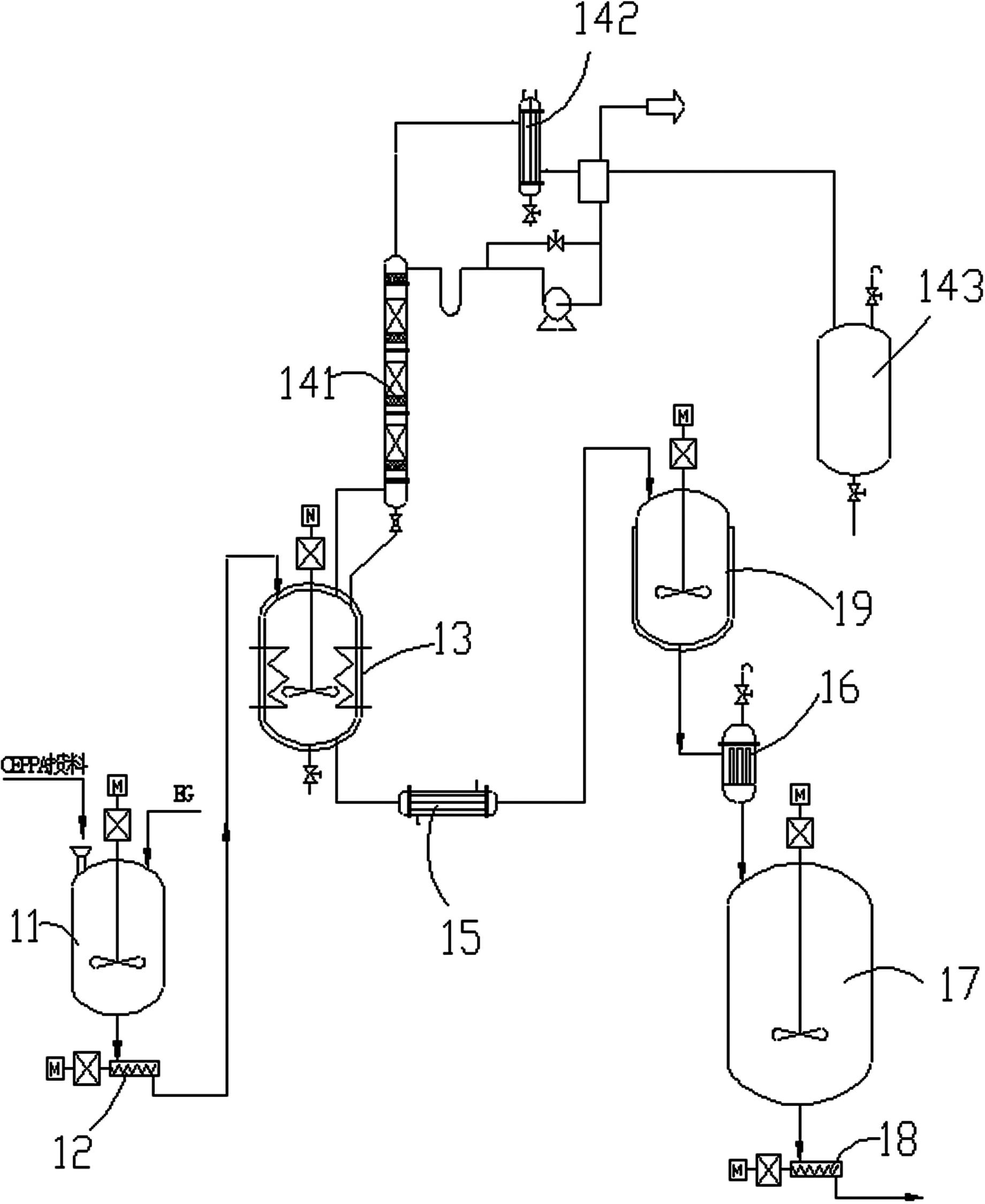

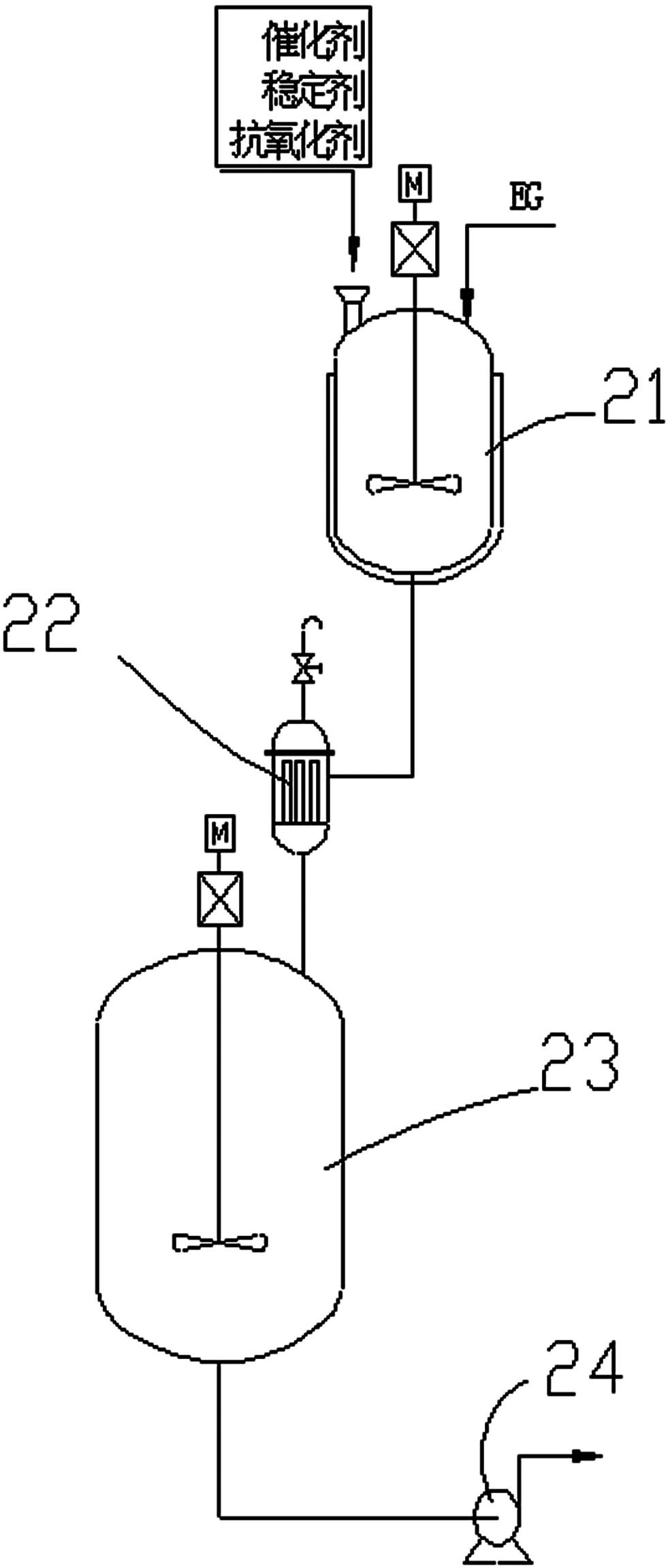

Process for manufacturing fire-retardant polyester fiber

ActiveCN102691130AIncrease productivityReduce consumptionFlame-proof filament manufactureSpinning head liquid feederFiberPolyester

The invention provides a process for manufacturing fire-retardant polyester fiber. The process comprises the steps of: fire retardant preparation, catalyst and promoter preparation, size preparation, two grading esterification reactions, two pre-polycondensation reactions, pre-polymer conveying and filtering, final polycondensation reactions, final polymer conveying and filtering, spinning melt conveying and distributing, spinning and drafting. According to the invention, phosphorus-based non-toxic fire retardant 2-carboxyethyl (phenyl) phosphinic acid-ethylene glycol (CEPPA-EG) esterifying liquid is adopted to ensure that the heat resistance is better; compared with a conventional generally-adopted two-step fiber producing process of firstly producing chips through batch or semicontinuous polymerization and then carrying out chip spinning, the process adopts an one-step fiber producing process of a continuous polymerization melt direct spinning method and therefore has the advantages of high production efficiency, low consumption and loss and low production cost; the manufactured fire-retardant polyester fiber has the advantages of excellent spinnability and fiber physical property and excellent fire retardation of polymer per se; and the fabric manufactured by adopting the fire-retardant polyester fiber has the advantages of more excellent and lasting fire retardation, high limit oxygen index (LOI) which is more than 34, excellent washing durability and safety and no harm to human body.

Owner:福建经纬新纤科技实业有限公司

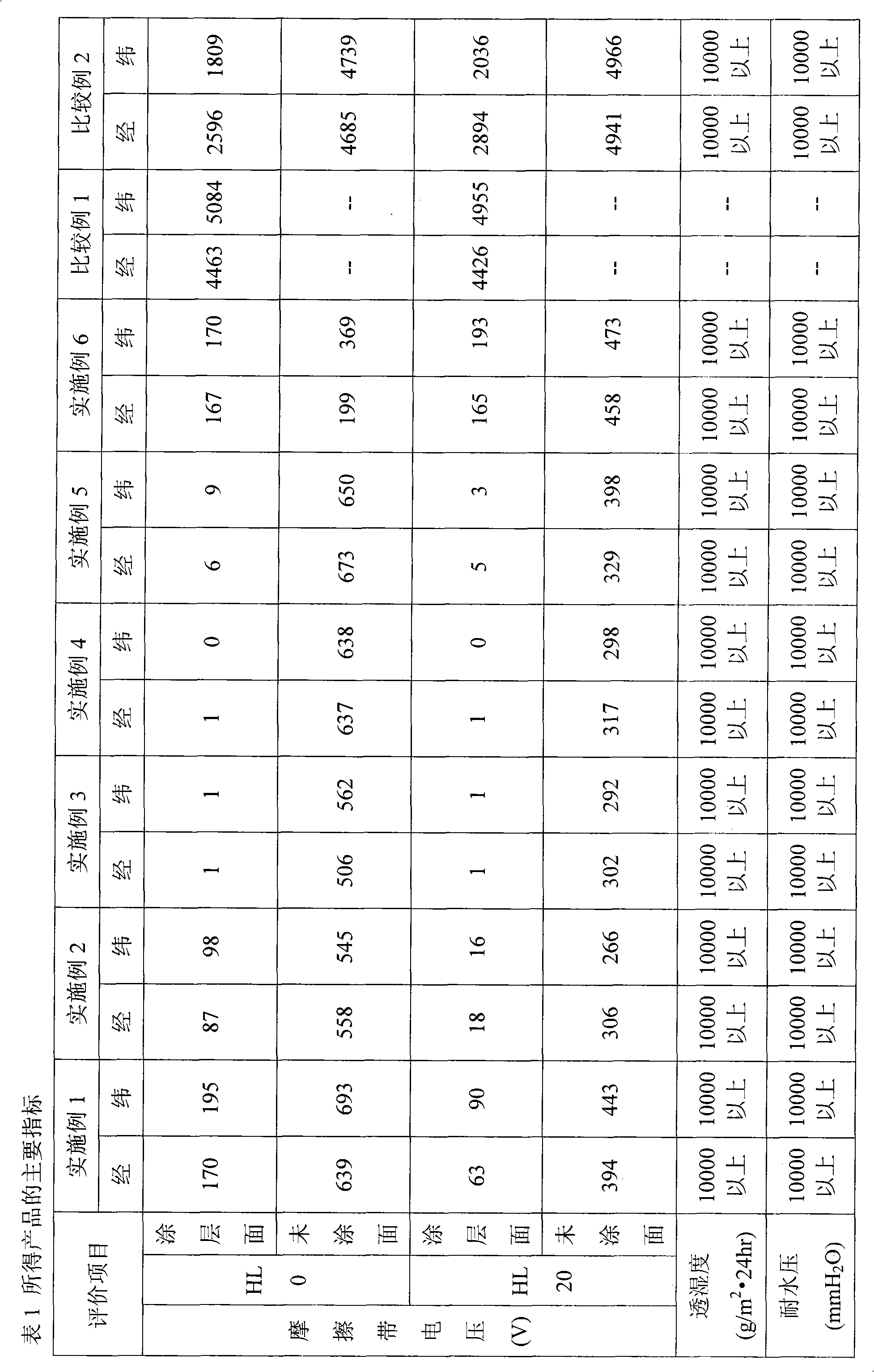

Antistatic water permeability resistant coated fabric

InactiveCN101929080AImprove waterproof performanceGood moisture permeabilitySynthetic resin layered productsTextiles and paperSocial benefitsEconomic benefits

The invention discloses an antistatic water permeability resistant coated fabric comprising base cloth and a coating layer, wherein the coating layer has the antistatic water permeability resistant function, is a single-layer or multi-layer polyurethane imporous layer of which the swelling rate is 15-30% or a single-layer or multi-layer polyurethane imporous layer of which the swelling rate is less than 15%, wherein the single-layer or multi-layer polyurethane imporous layer of which the swelling rate is less than 15% contains 10-40 wt% of conductive powder. The fabric of the invention has excellent waterproofness, moisture-penetrability, antistatic behaviour and washing durability, can be applied on work clothes of departments, such as metallurgy, petroleum, coal, national defense and the like, can be used for work clothes, gym suits and the like in the harsh external environment such as dry and cold occasions and has great economic benefit and social benefit.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

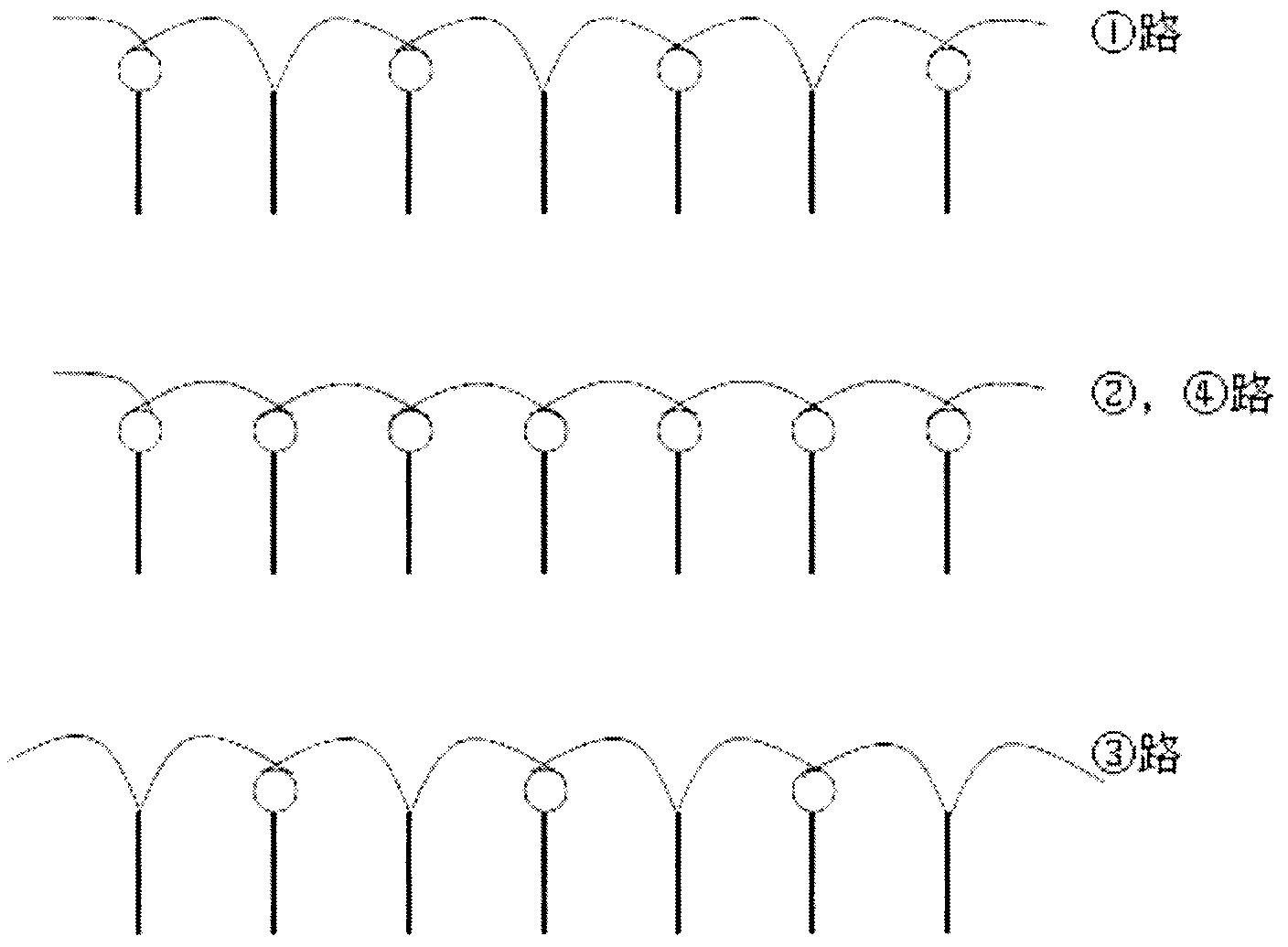

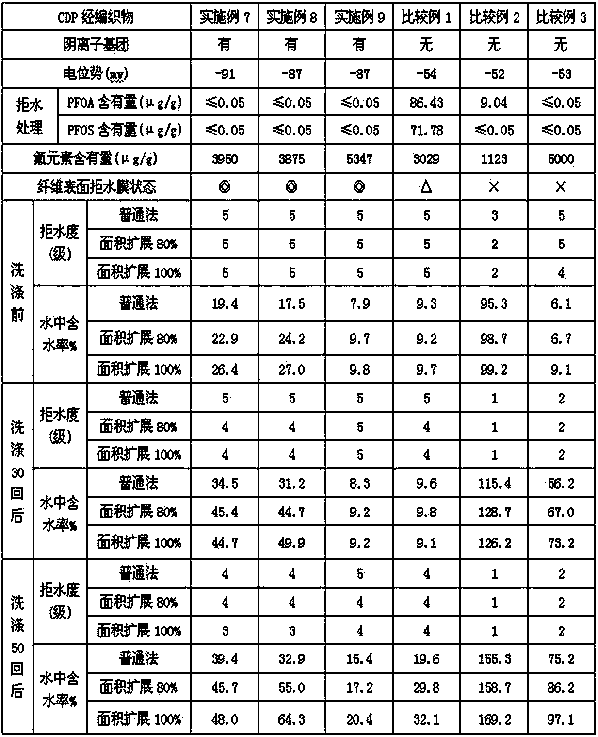

Textile subjected to water repellency treatment and production method for textile

The invention discloses a textile subjected to water repellency treatment and a production method for the textile. The textile mainly comprises cationic dye-dyeable modified polyester fibers and / or nylon fibers; the single fiber surface of the textile is at least covered with a resin film formed by water-repellent C6 fluororesin and water-repellent non-fluororesin; the surfaces of the cationic dye-dyeable modified polyester fibers and / or nylon fibers have anionic groups. The textile has durable washability and high water repellency.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

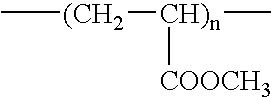

Silk fabric darkening agent copolymer emulsion and preparation method thereof

The invention discloses a silk fabric darkening agent copolymer emulsion and a preparation method thereof. The silk fabric darkening agent copolymer emulsion comprises the following raw materials by weight percent: 2-8% of methyl acrylate monomers, 6-16% of butyl acrylate monomers, 0.1-1.5% of an anionic surfactant, 0.1-1.5% of a non-ionic emulsifier, 0.01-0.1% of an initiator, 0.8-5% of a mono-amino-containing silane coupling agent, 5-15% of a vinyl-containing silane coupling agent, 0-1% of a silane hydrolysis inhibitor and 50-70% of deionized water. The silk fabric darkening agent copolymer emulsion disclosed by the invention is small in particle size, low in emulsifier dosage, and easy to control in the reaction process and causes no pollution to environment, the darkening rate of a thin and light silk fabric processed by the copolymer emulsion is close to 10% and the hydrophily is basically unchanged, while the darkening rate of a thick and heavy fabric is close to 16% and the hydrophily is slightly reduced. The silk fabric darkening agent copolymer emulsion has the characteristics of darkening and brightening, good washing durability, smooth handfeel and the like.

Owner:SUZHOU UNIV

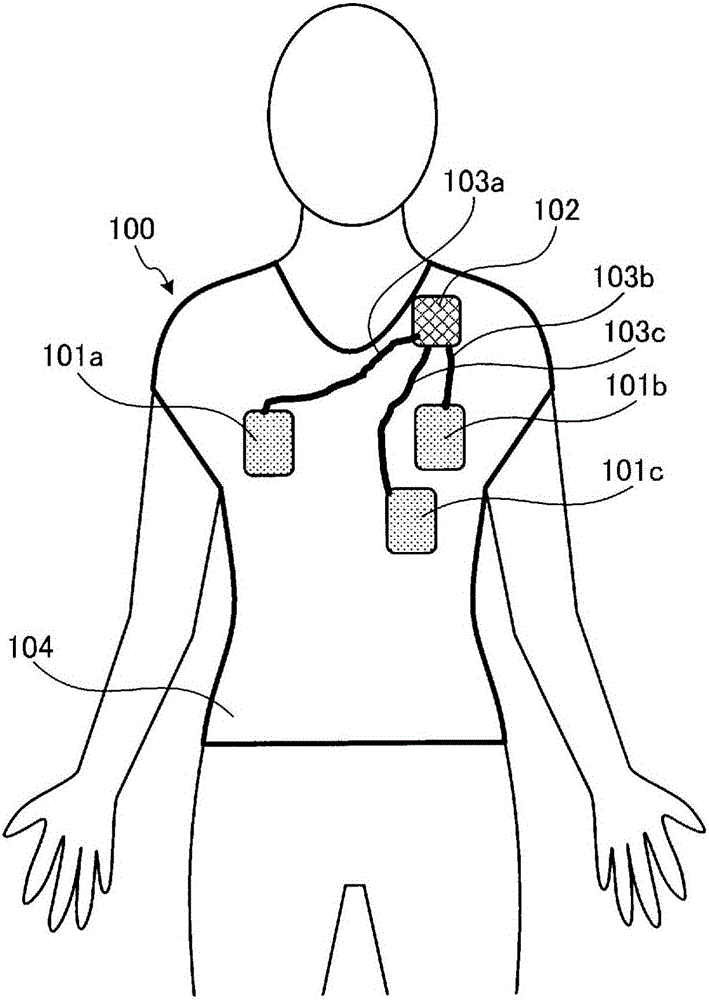

Electrode member and device

ActiveCN105939659AImprove conductivityHighly conductive textureDiagnostic recording/measuringSensorsBiological bodyPolymer science

Provided are an electrode member and a device capable of maintaining high electrical conductivity even after repeated washing, and of also being applied as an electrode for an organism. This electrode member is characterized by being a fiber structure configured from a textile or the like including an electroconductive polymer, wherein an electroconductive polymer such as a polythiophene-based electroconductive polymer is supported on the surfaces of single fibers and / or in spaces between single fibers constituting a multifilament used in the fiber structure.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP +1

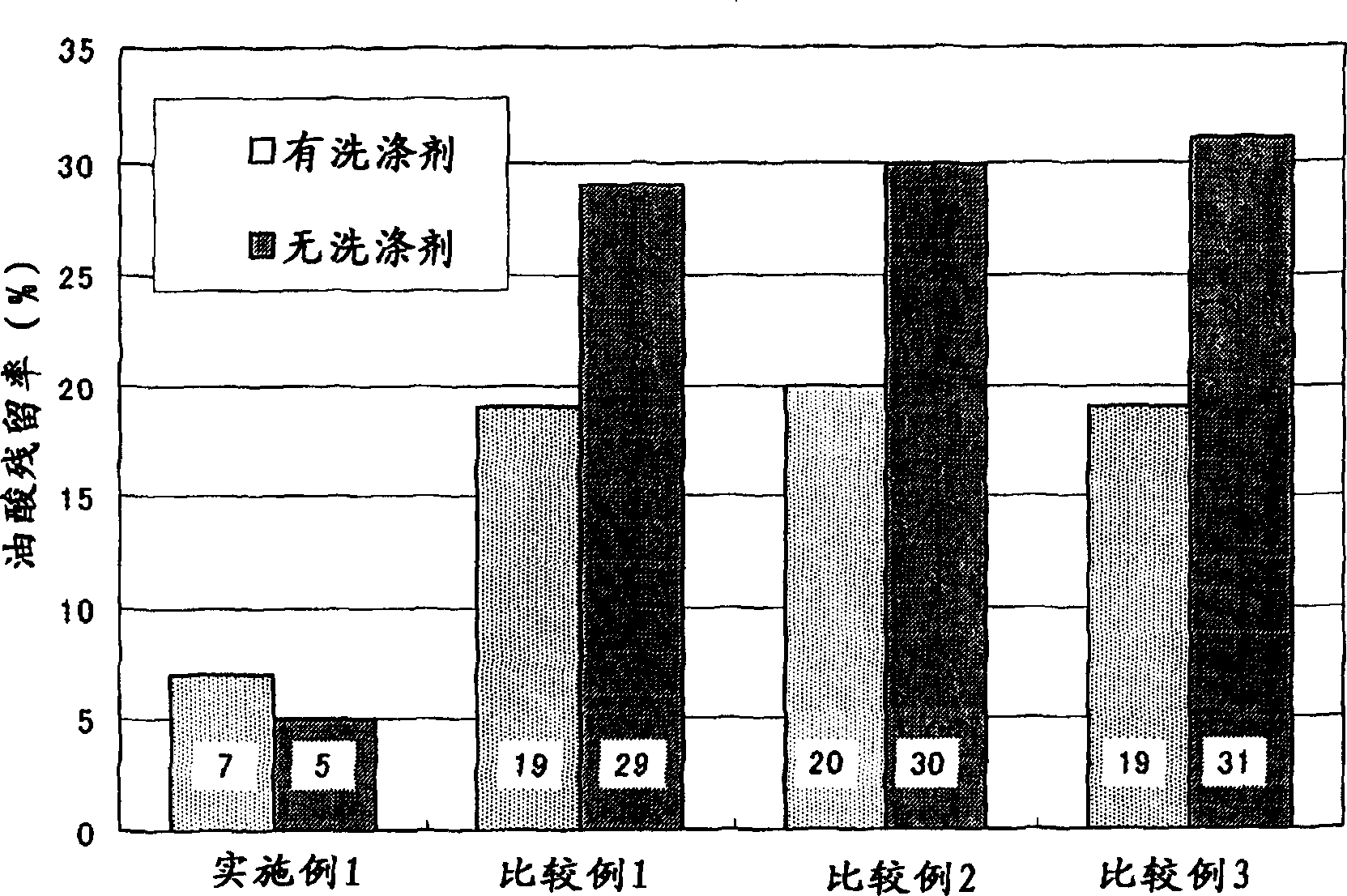

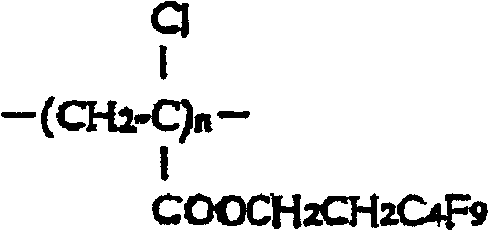

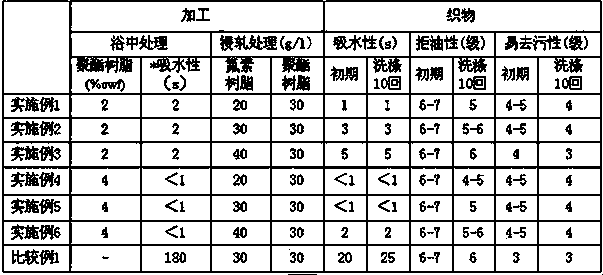

Anti-pollution fiber structure and its processing method

InactiveCN1782219AHigh washing durabilityDifficult to adhereFibre treatmentPolymer scienceAqueous solution

The invention discloses an antifouling fiber structure, which is obtained by applying a treatment liquid containing a hydrophilic and oil-repellent processing agent and a softener to the fiber structure, and then performing heat treatment. The hydrophilic and oil-repellent processing agent is composed of a fluorine-based A vinyl monomer, a copolymer of a hydrophilic vinyl monomer containing polyalkylene glycol and a non-polyalkylene glycol-based vinyl monomer, and the softener is composed of a nonionic surfactant aqueous solution constitute. Thereby, cloth with good washing durability can be provided. The method of the present invention can be combined with various processing such as anti-wrinkle processing, skin care processing, antibacterial processing, and softening processing.

Owner:NISSHINBO IND INC

Deodorant fiber structure

InactiveCN102822411AHigh washing durabilityFeel goodBiochemical fibre treatmentLiquid repellent fibresPolyesterAcid derivative

Disclosed is a polyester-based fiber structure, which exerts excellent washing durability and deodorizing properties and which is characterized by being attached with a substance comprising a hydroxy acid derivative and / or hydroxy acid.

Owner:TORAY IND INC

Quick-acting antibacterial functional master batch for polyolefin filamentous material as well as preparation method and application of master batch

ActiveCN109594139AHigh bactericidal/bacteriostatic activityGood adhesionMonocomponent polyolefin artificial filamentMonocomponent halogenated hydrocarbon artificial filamentPolyolefinPolymer science

The invention relates to quick-acting antibacterial functional master batch for a polyolefin filamentous material as well as a preparation method and an application of the master batch. According to the method, nano-silver inorganic antibacterial master batch in ZL201310571129.3, a guanidine salt polymer, polyolefin carrier resin, a stabilizer and a dispersant are mixed, double-screw melt extrusion and granulation are performed, and the quick-acting antibacterial functional master batch is prepared. The prepared quick-acting antibacterial functional master batch has good drawing or spinning performance in the processing process of the polyolefin filamentous material and has longer net change period and spinning assembly change period than those of other similar antibacterial master batch.The antibacterial polyolefin filamentous material prepared with the method contains nano-silver and guanidine salt polymer binary compound synergistic antibacterial components and thus has high antibacterial quick-acting performance, good washing durability and good whiteness and is applicable to production and processing of antibacterial products such as non-woven fabric of disposable medical health supplies, bath balls / bath towel for bathing, artificial turf filaments and carpets.

Owner:SANHE JINGNA ENVIRONMENTAL PROTECTION TECH CO LTD

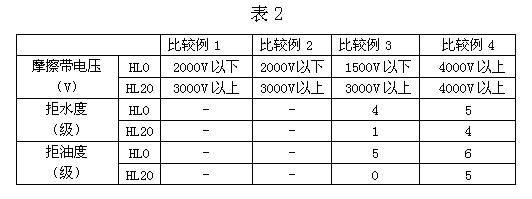

Antistatic nylon textile

ActiveCN103174025ASolve the problem of water and oil repellencySimple processing methodFibre typesNylon materialCross-link

The invention discloses an antistatic nylon textile. A coating resin layer is covered on the single-fiber surface of the textile, and the coating resin layer is formed by polyether type polyurethane resin and fluorine-based resin, which perform cross-linking reaction with a terminal group of nylon fiber. The initial friction-charged electrostatic potential of the textile is below 2000V, the water repellent degree is above grade 4, and the oil repellent degree is above grade 4; and the friction-charged electrostatic potential after 20 times of family washing is below 2500V, the water repellent degree is above grade 3, and the oil repellent degree is above grade 3. The antistatic nylon textile disclosed by the invention fills in the blank that the nylon textile can not integrate the antistatic performance and the water-repellent and oil-repellent performance simultaneously.

Owner:TORAY IND INC

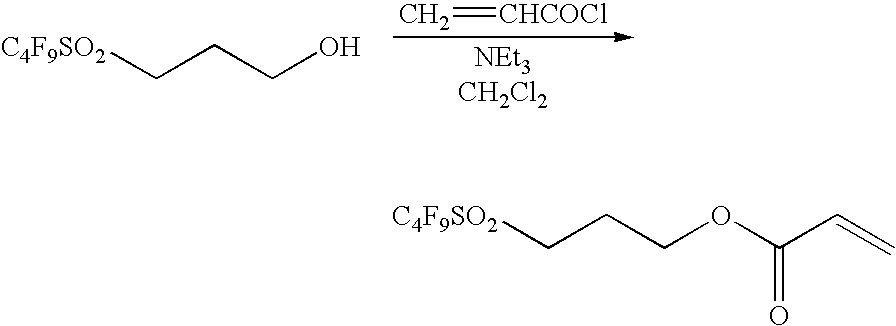

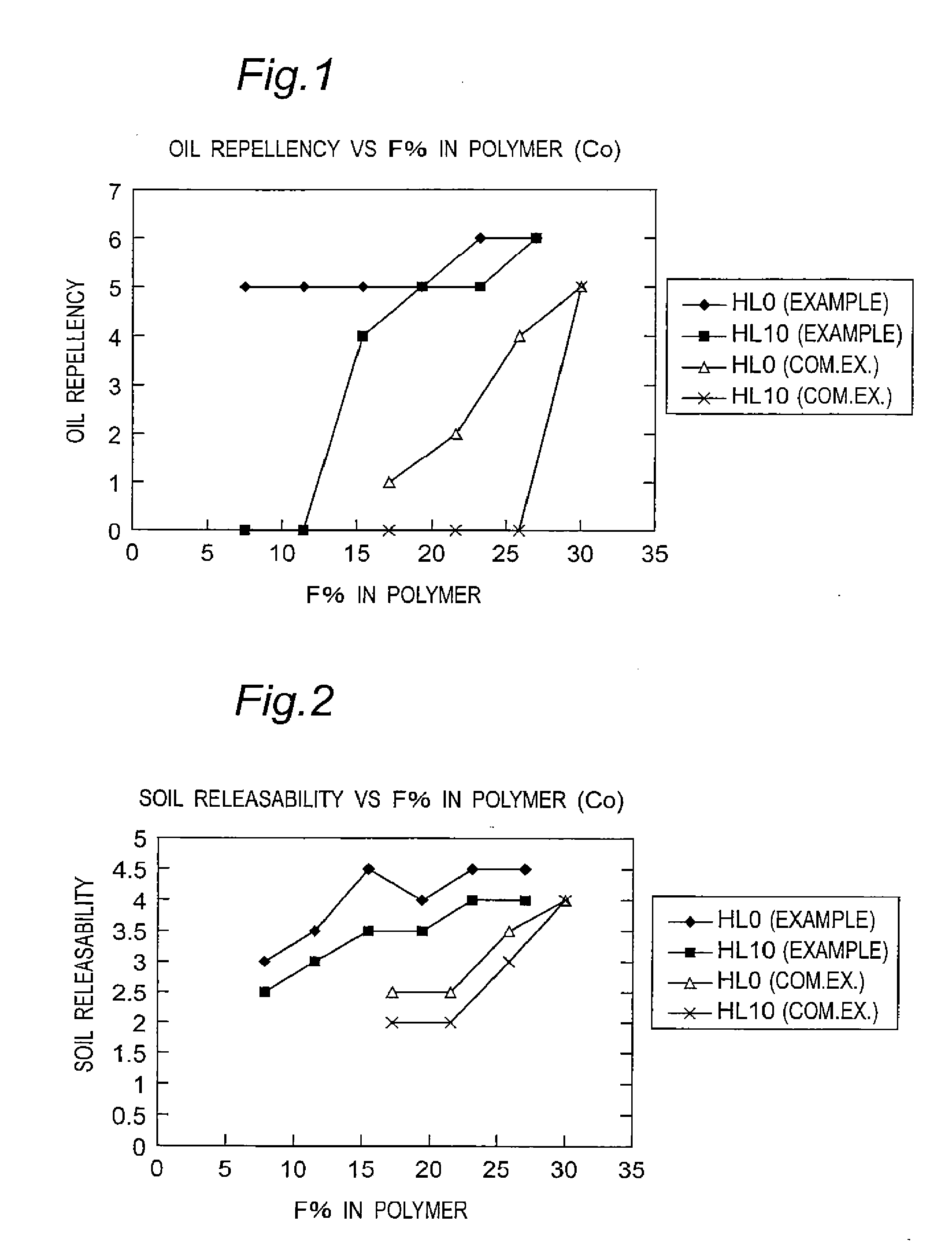

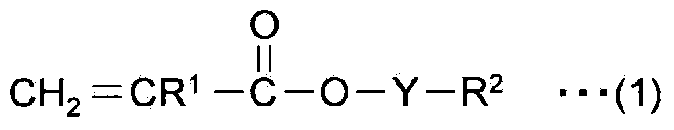

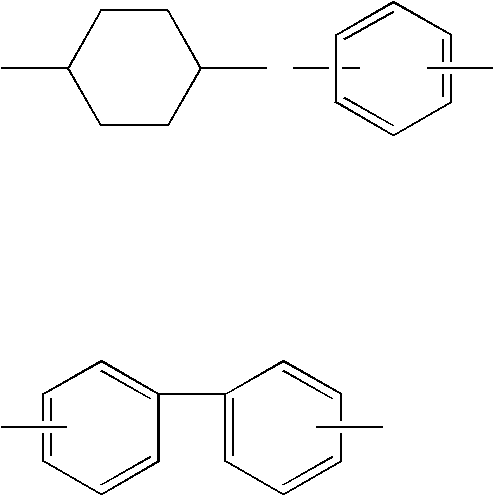

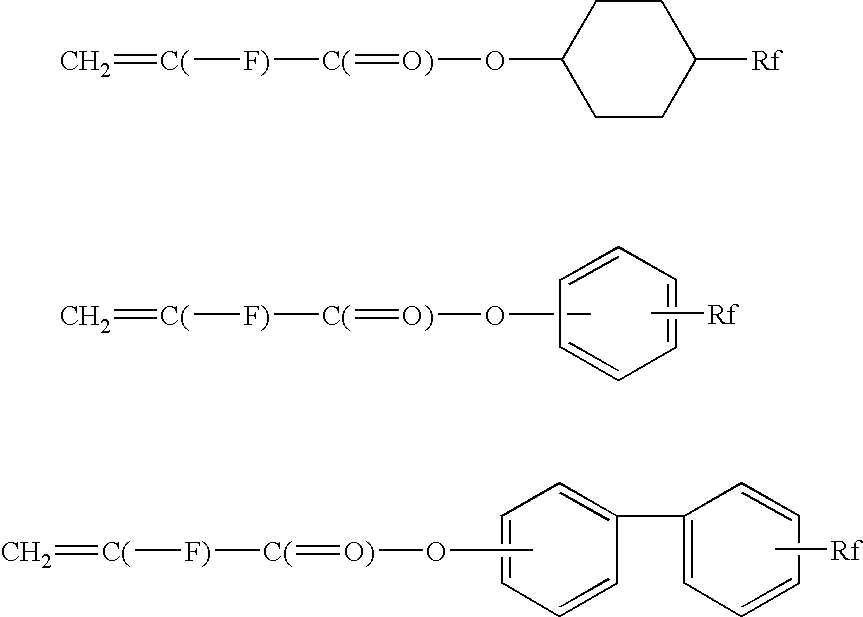

Fluoropolymer and soil remover

InactiveUS20090256102A1Excellent washing durabilityHigh flip-flop propertyFibre treatmentBromineChemistry

A fluorocopolymer formed from, as essential ingredients,(a) a fluoromonomer represented by the general formula:CH2═C(—X)—C(—O)—Y—[—(CH2)m-Z-]p-(CH2)n—Rf (1)[wherein X is hydrogen, C1-21 linear or branched alkyl, fluorine, chlorine, bromine, iodine, —CFX1X2 (wherein X1 and X2 each is hydrogen, fluorine, chlorine, bromine, or iodine), cyano, C1-21 linear or branched fluoroalkyl, (un)substituted benzyl, or (un)substituted phenyl; Y is —O— or —NH—; Z is —S— or —SO2—; Rf is C1-21 fluoroalkyl; m is 1-10; n is 0-10; and p is 0 or 1] and(b) a polyalkylene glycol (meth)acrylate. A soil remover containing this fluorocopolymer imparts to a woven fabric, etc. excellent oil repellency, unsusceptibility to fouling, and the property of releasing stains therefrom, while maintaining durability in washing.

Owner:DAIKIN IND LTD

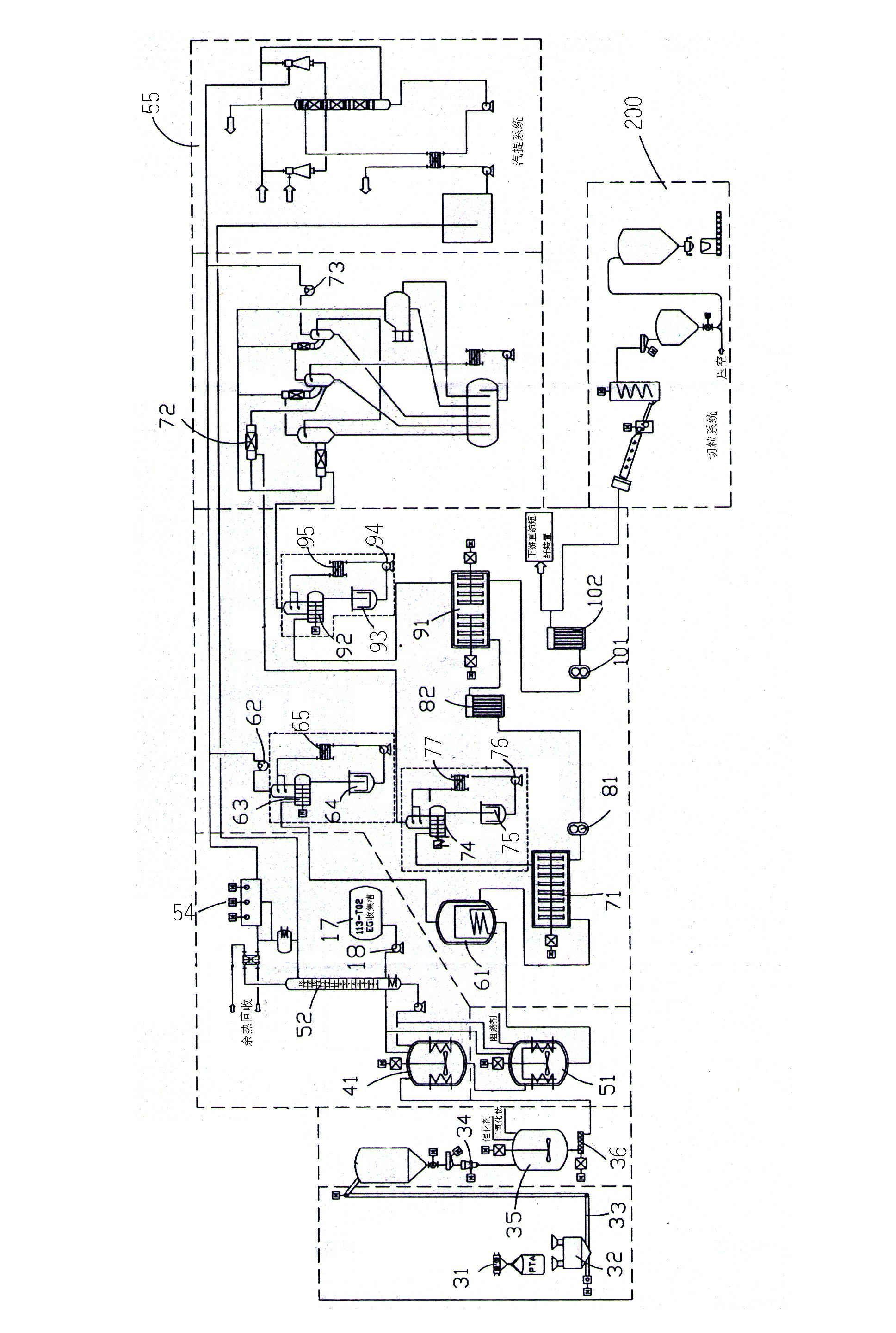

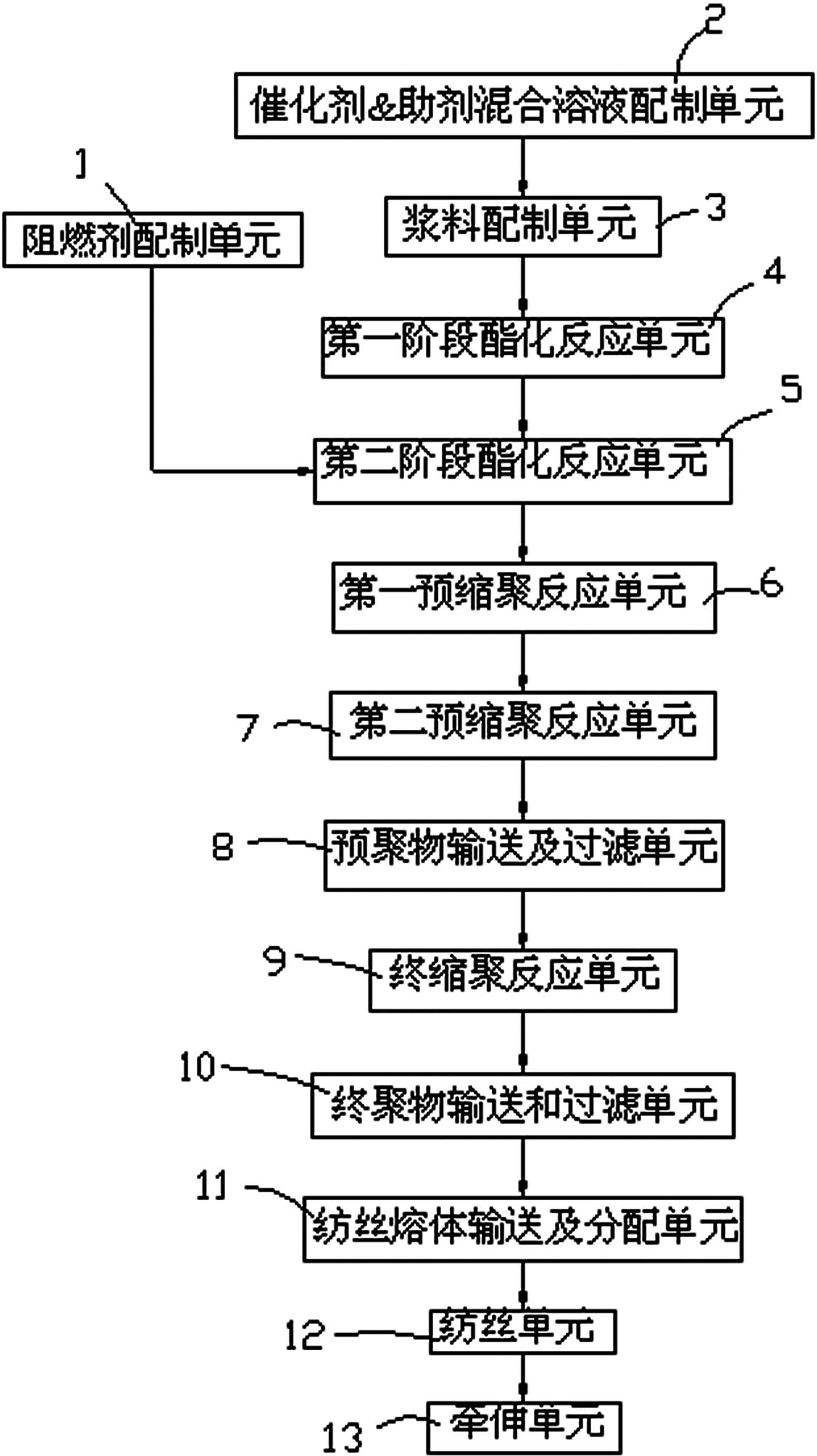

Manufacturing equipment system of flame-retardant polyester fiber

InactiveCN102691131AIncrease productivityReduce consumptionFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention provides a manufacturing equipment system of flame-retardant polyester fiber. The system comprises a flame retardant preparation unit, a catalyst and auxiliary mixed solution preparation unit, a slurry preparation unit, a first-stage esterification unit, a second-stage esterification unit, a first pre-polycondensation unit, a second pre-polycondensation unit, a prepolymer conveying and filtering unit, a final polycondensation unit, a final polymer conveying and filtering unit, a spinning melt conveying and distribution unit, a spinning unit and a drafting unit. The manufacturing equipment system of flame-retardant polyester fiber, provided by the invention, is applied to the continuous polymerization direct spinning technology, so that the synthetic fiber has lasting flame retardance, is nontoxic and environment-friendly and has the advantages of high production efficiency, low consumption and loss and low production cost; the synthetic fiber has excellent spinnability and fiber physical properties and excellent polymer flame retardance; the flame retardance of the textile is better and lasting; the limit oxygen index (LOI) is greater than 34; and the synthetic fiber has perfect washing durability and is safe and harmless to human bodies.

Owner:福建经纬新纤科技实业有限公司

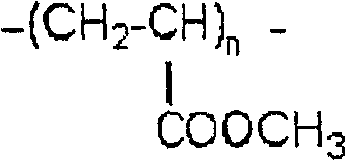

Fluorine-containing polymer and soil release agent

InactiveUS20080194450A1Improve washabilityHigh flip-flop propertyOrganic detergent compounding agentsOrganic chemistryMeth-Macromonomer

Owner:DAIKIN IND LTD

Easy-to-clean textile and applications thereof

ActiveCN103174033AGood removal effectImprove hydrophilicityVegetal fibresCarboxymethyl celluloseFiber

The invention discloses an easy-to-clean textile and applications of the easy-to-clean textile. The easy-to-clean textile is formed by 30-90% by weight of cotton staple fiber and 70-10% by weight of polyester staple fiber, a grafting reactant of N-hydroxymethyl dihydroxy ethylene urea and carboxymethyl cellulose sodium is at least attached on the cotton staple fiber, and hydrophilic polyester resin is at least attached on the polyester staple fiber. The collar dirt removal ability and the hydrophilic property of the obtained textile are excellent and the laundering durability is excellent.

Owner:TORAY IND INC

Detergent with

InactiveCN101289525AHigh washing durabilityExcellent oil repellencyOrganic detergent compounding agentsOrganic chemistryArylOligomer

The invention relates to a fluorine-containing copolymer, which takes: (A) repeating units derived from a fluorine-containing macromonomer of the general formula: CH2=C(-X)-COO-(Y)1-Z-MmMn-H (I) and (B) repeating units derived from poly alkylene glycol (meth) acrylic ester as necessary ingredients, in the formula (I), X is hydrogen atom or methyl, Y is -CH2CH(OH)CH2- or R<1>-NHCO-; l is 0 or 1; Z is -L1-L2-S-(wherein L1 is direct bonding, -O-, -COO- or -NH-, L2 is alkylidene group or aryl, S represents sulphur atom); MmMn is a fluorine-containing oligomer composed by m units derived from fluorine-containing monomers (M) and n units derived from fluorine-non-containing monomers (M). The fluorine-containing copolymer provides durability for maintenance of washing, and has the decontaminant with excellent oil removing property, antifouling property and decontamination property.

Owner:DAIKIN IND LTD

Production method of grape polyphenol modified hydrophobic cotton fabric

ActiveCN110528269ARaw material environmental protectionSimple methodLiquid repellent fibresVegetal fibresSurface energyChemistry

The invention relates to a production method of a grape polyphenol modified hydrophobic cotton fabric. The production method comprises the steps of taking grape polyphenol extracted from waste grape skin as a main reagent, taking nano columnar particles self-assembled by folic acid as a template, grafting the template onto a cotton fabric through oxidative polymerization to form a specific nano structure, and then grafting a low-surface energy substance octadecylamine onto the nano particles through Michael addition to endow the cotton fabric with superhydrophobic performance. The raw materials are environmentally friendly, the process is rapid and simple, and the conditions are mild. The superhydrophobic fabric has high hydrophobic property, has a water contact angle of 150-160 degrees, has good washing durability and can be used in the fields of oil-water separation and the like.

Owner:SUZHOU UNIV

Aqueous emulsion surface treatment agent

ActiveCN105745272AExcellent water and oil repellencyIncreased durabilityOther chemical processesLiquid repellent fibresLiquid mediumMethyl group

Provided is a surface treatment agent that does not use a fluorine-containing monomer, and in particular does not use a monomer containing a fluoroalkyl group. Disclosed are (1) a non-fluorinated polymer that comprises a repeating unit that is derived from a long-chain (meth)acrylate ester monomer indicated by formula (a), CH2=CA11-C(=O)-O-A12 (wherein A11 is a hydrogen atom or a methyl group, and A12 is a straight chain or branched aliphatic hydrocarbon group that has 18-30 carbons), (2) a surfactant that contains a surface-active compound that has either or both an amide group and an amino group, and (3) a surface treatment agent that is an aqueous emulsion that contains a liquid medium that contains water.

Owner:DAIKIN IND LTD

Preparation method of green light-cured durable one-way moisture-diversion finishing agent

InactiveCN103276585AAchieve chemical modificationExcellent unidirectional moisture transfer performancePhysical treatmentPotassiumCarbon chain

The invention relates to a preparation method of a green light-cured durable one-way moisture-diversion finishing agent. The preparation method comprises the following steps of 1, adding 3 to 20wt% of sodium or potash water glass into a mixture of water and ethanol, adding greater than or equal to 4wt% of an ammonium salt aqueous solution into the mixed solution, adjusting a pH value, and carrying out stirring at a room temperature, 2, orderly adding 0.5 to 1wt% of gamma-azidopropyltriethoxysilane and 2 to 4wt% of a hydrophobic long-carbon chain alkyl siloxane into the mixed solution obtained by the step 1 with stirring, and sequentially carrying out stirring to obtain a modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and 3, sequentially adding 0.5 to 15wt% of a thickener into the modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and carrying out stirring to obtain the green light-cured durable one-way moisture-diversion finishing agent. The preparation method adopts the raw materials having wide sources and has a low cost. The green light-cured durable one-way moisture-diversion finishing agent has stable properties. A fabric treated by the green light-cured durable one-way moisture-diversion finishing agent has excellent one-way moisture-diversion performance and washing endurance and has wide market application prospects and good social benefits.

Owner:DONGHUA UNIV +1

Fluorine-containing copolymer having excellent washing resistance and soil release agent

ActiveCN101595142AExcellent oil repellencyImprove antifouling performanceOther chemical processesLiquid repellent fibresFiberHydrogen atom

Disclosed is a soil release agent composition essentially containing a fluorine-containing copolymer, which is essentially composed of (a) a fluorine-containing monomer having a fluoroalkyl group, (b) a polyalkyleneglycol(meth)acrylate, (c) a monomer having an acetoacetyl group and (d) a monomer having a cation-donating group, and a crosslinking agent. This soil release agent composition imparts a base material such as a fiber fabric with excellent oil repellency, antifouling property and soil releasing property, while maintaining washing resistance of the base material. The monomer (a) is preferably represented by the following formula: CH2=C(-X)-C(=O)-Y-Z-Rf (1). In the formula, X represents a hydrogen atom, a linear or branched alkyl group having 1-21 carbon atoms, a fluorine atom, a chlorine atom or the like; Y represents -O- or -NH-; Z represents an aliphatic group having 1-10 carbon atoms, an aromatic group having 6-18 carbon atoms, an alicyclic group or the like; and Rf represents a linear or branched fluoroalkyl group having 1-21 carbon atoms.

Owner:DAIKIN IND LTD

Three-proofing finishing method for elastic tencel blended fabrics

ActiveCN103409959AImprove performanceGood decontamination performanceSucessive textile treatmentsSolvent-treatmentTextile technologyOrganic chemistry

The invention belongs to the textile technical field and particularly relates to a production method for elastic tencel blended fabrics. A three-proofing finishing method for elastic tencel blended fabrics is characterized by adding 5-20g / L of softening agents 3305, 20-40g / L of chlorine washing resistant improvers, 10-30g / L of finishing agents CP-SLA, 10-30g / L of finishing agents 7713, 10-30g / L of soil release finishing agents CP-R and 1-20g / L of improvers LK-30. When elastic tencel blended fabrics are subjected to three-proofing finishing through the method, the three-proofing finishing and soil release amount is adjusted in the pretreatment process of tencel to improve the performance of the tencel; the tencel treated by the method has a good soil release property, the good soil release property is provided for heavy oil difficult to be washed away, and the soil release property is good after washing for 50 times, so that the washing durability is outstanding.

Owner:HUAFANG

Fluorine-containing copolymer, method for producing same, and water repellent/oil repellent agent composition

InactiveCN104093757AReduce environmental loadFully water repellent and oil repellentOther chemical processesLiquid repellent fibresPolymer scienceMeth-

Provided are a fluorine-containing copolymer and a water repellent / oil repellent agent composition having adequate water / oil repellency, excellent washing durability, and low environmental impact. The fluorine-containing copolymer comprises units (A) derived from a macromonomer (a) having an average of two or more units derived from 2-perfluorohexylethyl(meth)acrylate or the like; units (B) derived from a monomer (b) not having a fluoroalkyl group or a cross-linkable functional group and having a glass transition temperature of 50-150 DEG C when used to form a homopolymer; and units (C) derived from a monomer (c) having a cross-linkable functional group and not having a fluoroalkyl group. Also, a water repellent / oil repellent agent composition including the fluorine-containing copolymer is provided.

Owner:ASAHI GLASS CO LTD

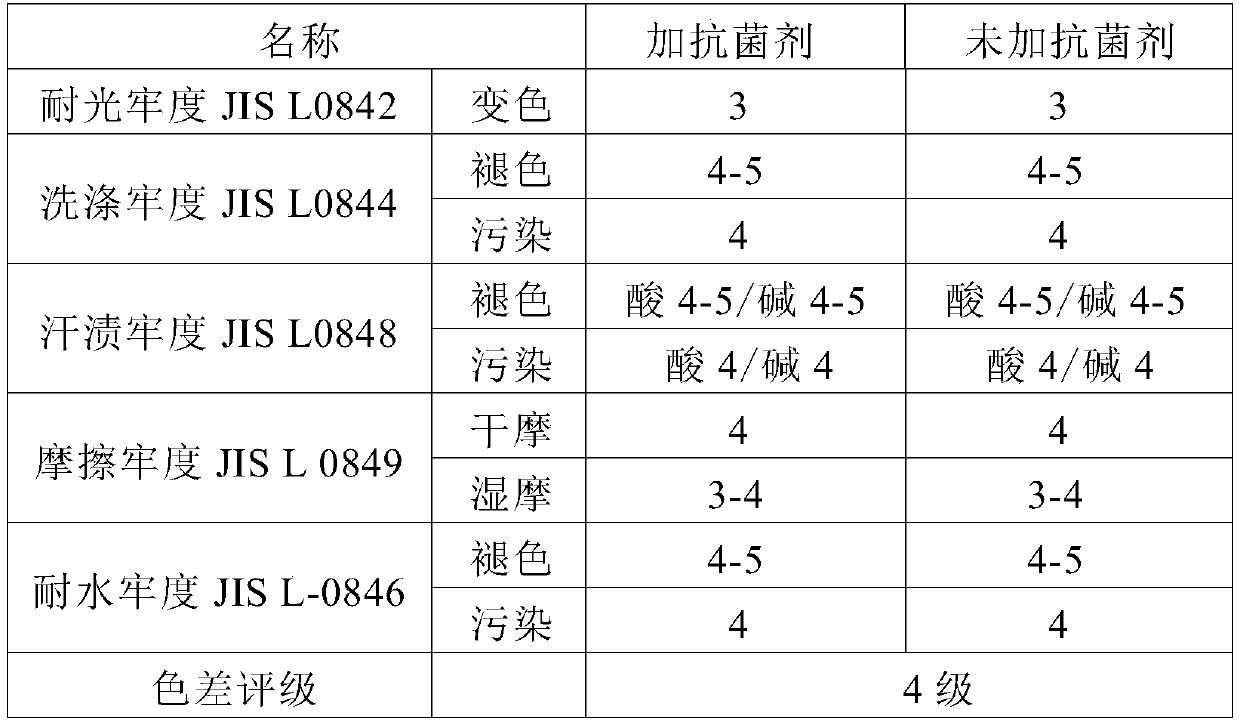

Application of organic-metal ion composite antibacterial agent

InactiveCN110130127AAvoid lossShort production processBiochemical fibre treatmentDyeing processSilver ionTemperature resistance

The invention discloses an application of an organic-metal ion composite antibacterial agent, and relates to the field of textile bacteria resistance. The organic-metal ion composite antibacterial agent has good stability and high temperature resistance and can be processed in the same bath with dye, and finish dyeing and antibacterial processing of fabric simultaneously by heating dyeing in a cylinder. The organic-metal ion composite antibacterial agent comprises organic components and metal ions, wherein the organic components comprise pyridine, quaternary ammonium salt, isothiazolinone, imidazole or biguanide; the metal ions comprise silver ions, copper ions or zinc ion and are combined with the organic components through coordination bonds. The invention aims to provide an antibacterial finishing technology with simple processing technology, shortened production process flow and reduced cost, and the fabric prepared with the antibacterial finishing technology can have the characteristics of good antibacterial property and high safety.

Owner:LERUNE QINGDAO TEXILE TECH

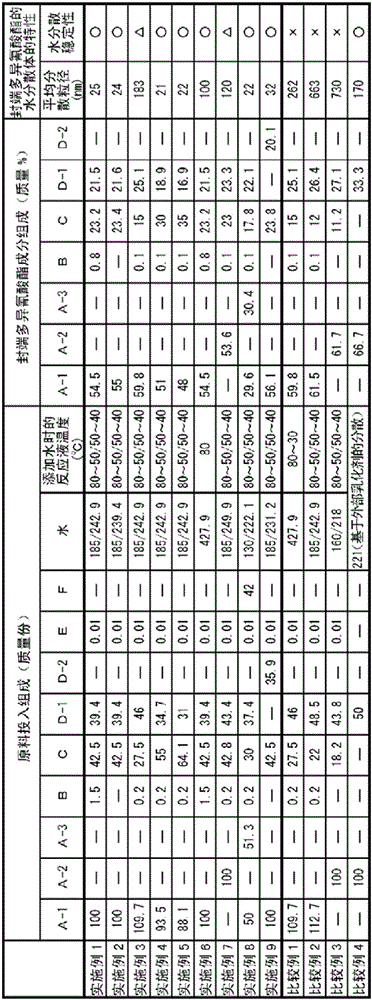

Blocked polyisocyanate water dispersion, fiber processing agent composition, and fabric

InactiveCN106008904AGood water dispersion stabilityHigh film strengthLiquid repellent fibresPolyurea/polyurethane coatingsDispersion stabilityFiber

The invention provides a blocked polyisocyanate water dispersion, a fiber processing agent composition, and fabric. The purpose of the present invention is to provide: a blocked polyisocyanate water dispersion having favorable water dispersion stability, capable of achieving high coating strength, exhibiting excellent mechanical stability as a fluorine-doped fiber processing agent, and capable of producing a fabric having high washability; and a fiber processing agent composition containing the same. The blocked polyisocyanate water dispersion contains water and a blocked polyisocyanate at least having component units (1-3), and has an average dispersed particle diameter of the blocked polyisocyanate of phi=1-250nm, wherein the component units (1-3) are a polyisocyanate unit having at least one type of diisocyanate monomer unit selected from a group consisting of aliphatic diisocyanate monomers and alicyclic diisocyanate monomers, 2) a polyethylene oxide unit having a hydroxyl group on one end, and 3) a blocking agent unit.

Owner:ASAHI KASEI KK

Textile subjected to water repellency treatment and production method thereof

The invention discloses a textile subjected to water repellency treatment and a production method thereof. The textile is a woven fabric or a knitted fabric formed from polyester fibers and / or cellulose fibers. Single fiber surfaces of the polyester fibers and / or cellulose fibers are covered with resin films. The resin film at least comprises a non-fluorinated compound containing -CH2- as a main chain with the carbon atom number greater than or equal to 8, and one or more of -Si-H, -NO2, -NO and -COOR (wherein R is shown the description and n is greater than or equal to 3) and a C-H bond as branched chains, or at least comprises a non-fluorinated compound containing a main chain -Si-O- and branched chains of -COOR (wherein R is shown the description and n is greater than or equal to 3) and / or a C-H bond. The textile has excellent washing endurance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

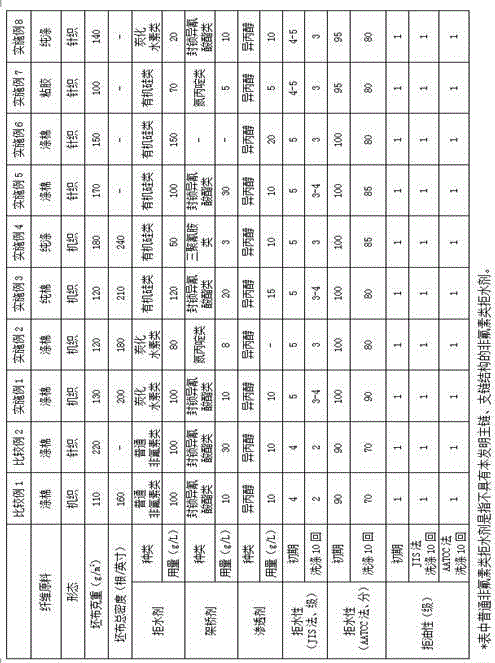

Water-absorbing oil-repellent fabric and production method

InactiveCN104047174AStrong water absorptionExcellent water absorption and oil repellencyVegetal fibresEngineeringPolyester resin

The invention discloses a water-absorbing oil-repellent fabric and its production method. The surface of single filaments of the fabric is attached with a resin layer which is mainly composed of polyester resin and fluoroplast. Positive and negative surfaces of the fabric have characteristics as follows: in the initial stage, water absorption is less than 5 seconds, oil repellency is above level 6, and easy decontamination performance is above level 4. The production method is simple and easy to operate. Base cloth firstly undergoes hydrophilic resin bath treatment, and then, oil-repellent easy-decontamination resin padding treatment is carried out. The obtained fabric has oil-repellent easy-decontamination functions, has excellent water absorption, has excellent washing endurance, and can be widely used in production of shirts, working clothes and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Fluorine-containing fiber processing agent having alcohol repellency and soil release properties

InactiveUS20100216363A1Improve washabilityGood effectStain/soil resistant fibresSynthetic resin layered productsFiberSoil science

Disclosed is a fluorine-containing copolymer having, as an essential component, a repeating unit derived from (a) a monomer having a fluoroalkyl group or a fluoroalkenyl group, (b) a monomer having an alkylene oxide group, (c) a monomer having an acetoacetyl group, (d) a monomer having a —CH(OH)—CH2—Cl group, and (e) a monomer having a —CH(OH)—CH2—OH group. In this fluorine-containing copolymer, the amounts of the monomer (a), the monomer (b), the monomer (c), the monomer (d) and the monomer (e) are 30-80 parts by weight, 1-30 parts by weight, 0.5-20 parts by weight, 0.5-20 parts by weight and 0.5-20 parts by weight, respectively. This fluorine-containing copolymer provides a base material such as a fiber product with excellent alcohol repellency, oil repellency, antifouling properties and soil release properties, while maintaining washing durability. This fluorine-containing copolymer serves as an active ingredient for a fluorine-containing fiber processing agent having soil release properties.

Owner:DAIKIN IND LTD

Knitted fabric and application thereof

The invention discloses a knitted fabric and application thereof. The knitted fabric is 100% polyester fiber knitted fabric, wherein thirty weight percents to seventy weigh percents yarns are high shrinkage polyester yarns. Longitudinal direction washing dimensional change rate and latitudinal direction washing dimensional change rate of the knitted fabric all are in -0.3%-1.0%. Longitudinal direction rigidity and latitudinal direction rigidity are greater than 0.02gf.cm 2 / cm. Anti-pilling capacity achieves above a three grade. The knitted fabric is suitable for making shirts and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Novel multifunctional fabric and preparation method thereof

The invention discloses a novel multifunctional fabric and a preparation method thereof. The novel multifunctional fabric sequentially comprises a moisture conducting layer (1) and a rough layer (2) from top to bottom. The moisture conducting layer (1) is composed of surface yarn and plays a moisture conducting role, the rough layer (2) is composed of bottom yarn, the diameter of the bottom yarn is 6-12 times that of the surface yarn, and the skin-friendly side of the rough layer (2) has an antibacterial function. The size of the yarn gap of the moisture conducting layer is far smaller than that of the yarn gap of the rough layer, the surface yarn is thinner than the bottom yarn, so that the surface yarn gap is smaller than the bottom yarn gap, and the wicking effect of the surface yarn isdominant. When people do sports and sweat, sweat is discharged to the surface yarn from the bottom yarn through the wicking effect and spreads on the surface yarn, and the sweat can be rapidly evaporated on the surface yarn while the skin is kept dry and comfortable.

Owner:LERUNE QINGDAO TEXILE TECH

Textile used for swimming suit and production method thereof

InactiveCN103572595AHigh washing durabilityImprove securityFibre typesGarmentsChemistryPerfluorooctane

The invention discloses a textile used for a swimming suit and a production method thereof. The textile is mainly formed by elastic fiber, and polyester fiber surface of which is provided with anionic groups. The surface of single fiber in the textile is coated with a water-repellent resin film, wherein a fluorine element content of the water-repellent resin film is not less than 0 [mu]g / g and less than 6000 [mu]g / g; a residual amount of ammonium perfluorocaprylate is not more than 0.05 [mu]g / g, and a residual amount of perfluorooctane sulfonate is not more than 0.05 [mu]g / g. The textile is suitable for manufacturing functional swimming suit textile fabrics, and has excellent water repellency functions of low wettability, low water volume and durable rinsibility.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

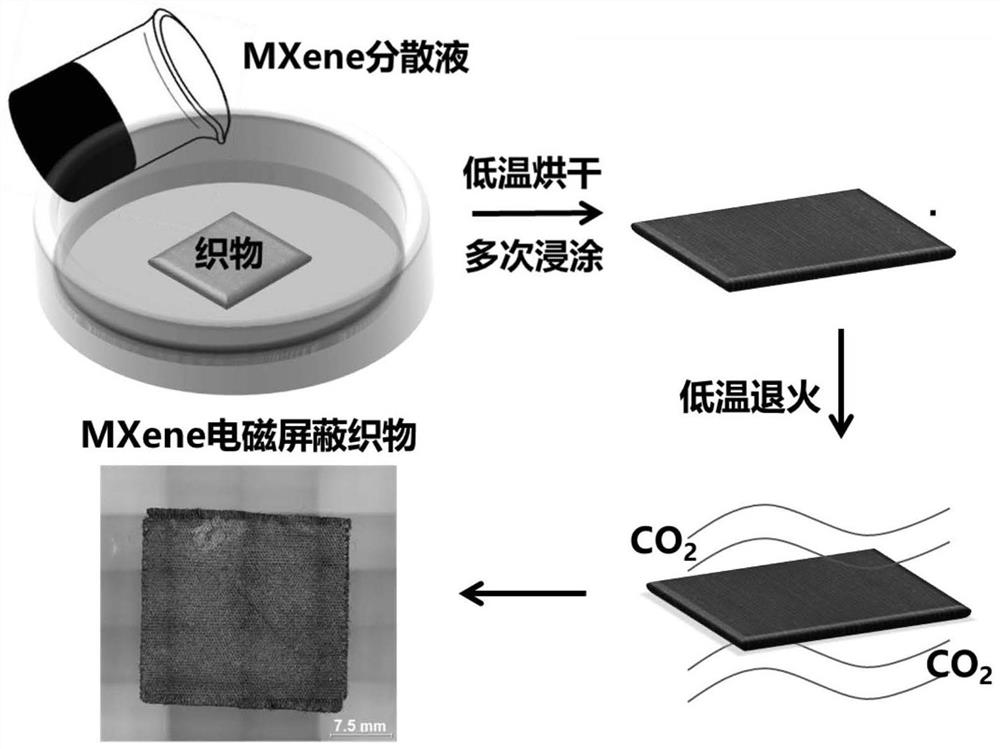

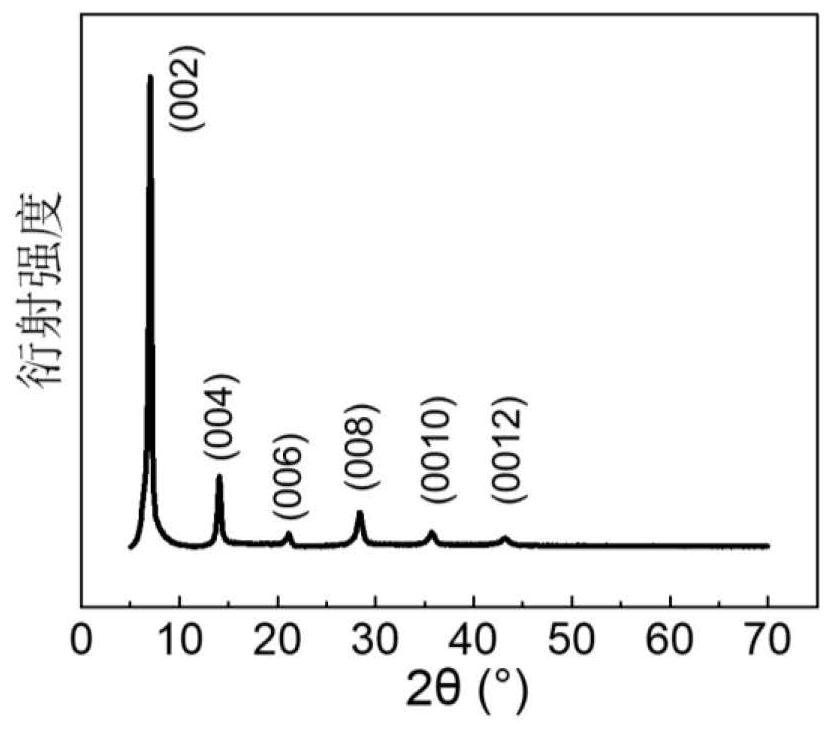

MXene electromagnetic shielding fabric as well as preparation method and application thereof

ActiveCN112663323AHigh strengthStrong adhesionUltrasonic/sonic fibre treatmentElectromagnetic shieldingMechanical engineering

The invention relates to an MXene electromagnetic shielding fabric as well as a preparation method and application thereof. The method comprises the following steps of carrying out plasma pretreatment on a flexible fabric substrate, dipping in an MXene dispersion liquid, taking out, drying, and carrying out low-temperature annealing treatment under a CO2 condition. The electromagnetic shielding fabric has good flexibility, washing resistance and electromagnetic shielding characteristics.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com