Antistatic water permeability resistant coated fabric

A coated fabric, waterproof and moisture-permeable technology, applied in the direction of layered products, textiles and papermaking, synthetic resin layered products, etc., can solve the problems of high cost, increased scraping adhesive process, high operation requirements, etc., to achieve large Economic and social benefits, excellent water resistance and moisture permeability, good washing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

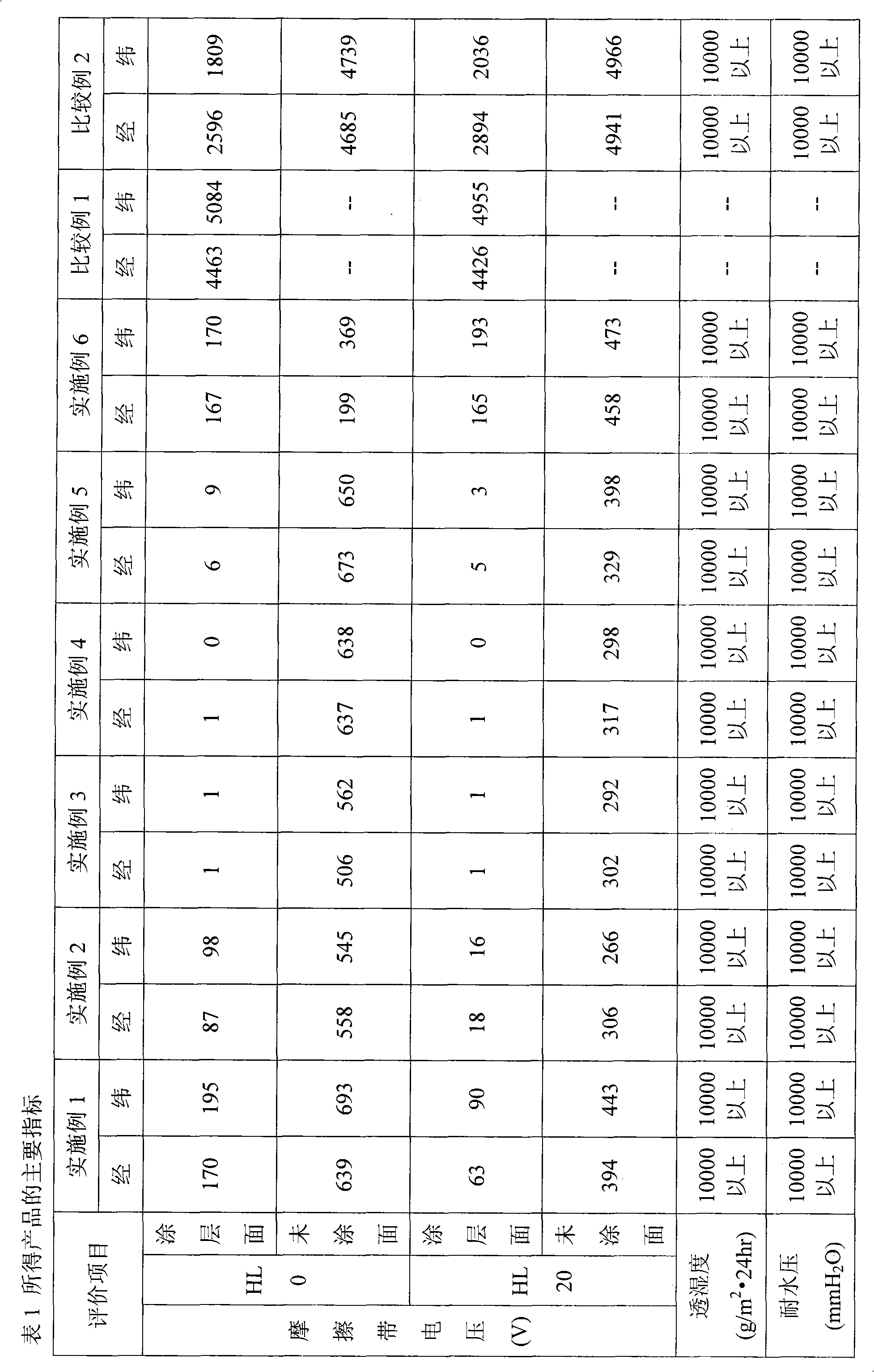

Examples

Embodiment 1

[0018] First, the following components by weight are uniformly mixed into a fabric coating primer:

[0019] Hydrophilic polyester polyurethane resin 100 parts

[0020] Isocyanate type bridging agent 1.5 parts

[0021] Acid bridging accelerator 1.2 parts

[0022] 30 parts of toluene

[0023] Butanone 5 parts

[0024] The above-mentioned fabric coating primer is evenly coated on the surface of the pure polyester fabric that has been treated with water in a dry coating method to form a coating; before the coating is dry, it is heated and dried. The heating and drying steps are divided into two steps: low-temperature pre-baking and high-temperature baking. The low-temperature pre-baking temperature is 70°C, and the pre-baking time is 1min; the high-temperature baking temperature is 120°C, and the baking time is 1min. After drying, a coated fabric comprising a non-porous layer of polyurethane is obtained.

[0025] Secondly, the following components by weight are uniformly mixe...

Embodiment 2

[0031] The weight part that is mixed into fabric coating primer is:

[0032] Hydrophilic polyester polyurethane resin 100 parts

[0033] Isocyanate type bridging agent 1.5 parts

[0034] Acid bridging accelerator 1.2 parts

[0035] Conductive mica powder 10 parts

[0036] 30 parts of toluene

[0037] Butanone 10 parts

[0038] The weight part that is mixed into fabric coating top glue is:

[0039] Hydrophilic polyether polyurethane resin (7% swelling rate) 100 parts

[0040] 20 parts of white paint

[0041] Conductive mica powder 15 parts

[0042] 25 parts of toluene

[0043] Butanone 5 parts

[0044] Wherein, the conductive mica powder is flake particles with an average particle diameter of 5.0-9.0 μm.

[0045] All the other are with embodiment 1. After drying, an antistatic waterproof and moisture-permeable coated fabric comprising two polyurethane non-porous layers with a swelling rate of 7% is obtained, and the weight percentage of the conductive mica powder in th...

Embodiment 3

[0047] The weight part that is mixed into fabric coating primer is:

[0048] Hydrophilic polyester polyurethane resin 100 parts

[0049] Isocyanate type bridging agent 1.5 parts

[0050] Acid bridging accelerator 1.2 parts

[0051] Conductive titanium dioxide powder 8 parts

[0052] 30 parts of toluene

[0053] Butanone 10 parts

[0054] The weight part that is mixed into fabric coating top glue is:

[0055] Hydrophilic polyether polyurethane resin (12% swelling rate) 100 parts

[0056] 20 parts of white paint

[0057] Conductive titanium dioxide powder 7 parts

[0058] 25 parts of toluene

[0059] Butanone 5 parts

[0060] Among them, the conductive titanium dioxide powder is needle-shaped particles with an average particle diameter of 0.27 μm and an average length of 5.15 μm.

[0061] All the other are with embodiment 1. After drying, an antistatic waterproof and moisture-permeable coated fabric comprising two polyurethane non-porous layers with a swelling rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com