Electrode member and device

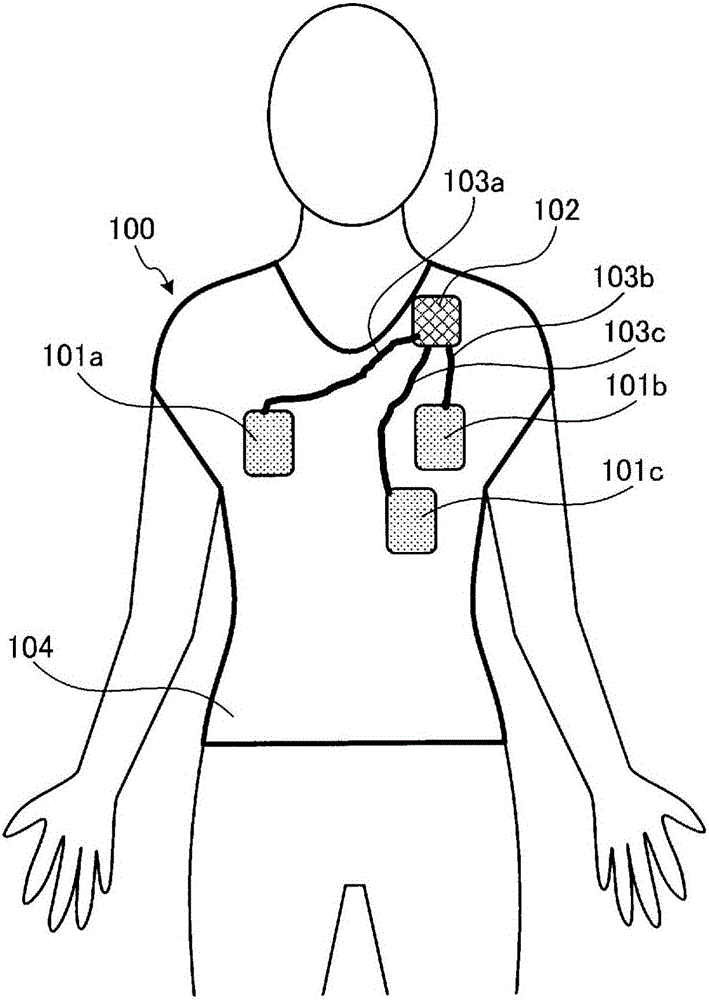

An electrode element and conductivity technology, applied in the field of fabric electrode elements, can solve the problems of poor practical durability such as fabric electrode washing durability, and achieve the effect of excellent washing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Using 100T-136F polyester nanofiber blended yarn to weave circular fabric with double rib weave, the polyester nanofiber blended yarn will use polyethylene terephthalate as island component Alkaline hot water soluble polyester made of a copolymer of terephthalic acid and isophthalic acid-5-sodium sulfonate as the acid component of the ester 75T-112F as the sea component (the sea-island ratio is 30%:70%, The number of islands is 127 islands / F) and nanofibers are blended with 22T-24F high-shrinkage yarns. Next, the fabric was immersed in a 3% by mass sodium hydroxide aqueous solution (75° C., bath ratio: 1:30) to remove easily soluble components to obtain a knitted fabric using mixed yarns of nanofibers and high-shrinkage yarns. By a known gravure coating method, 1.0 wt% of conductive polymer dispersed in a mixed solvent of water and ethanol (44 wt% of water, 50 wt% of ethanol) was coated on the knitted fabric as the obtained fiber structure. Dispersion of PEDOT / PSS and ...

Embodiment 2

[0097] Change the high-shrinkage yarn from 22T-24F to 33T-6F, and use 110T-118F polyester fiber blended with nanofibers and 75T-112F (sea-island ratio: 30%:70%, and the number of islands is 127 islands / F). Except for the ester nanofiber mixed yarn, the same treatment as in Example 1 was performed to manufacture an electrode. Table 1 and Table 2 show the properties of the materials used and the electrodes obtained.

Embodiment 3

[0099] Except for changing the fabric structure from the knitted fabric to the plain weave fabric, the same treatment as in Example 1 was performed to manufacture an electrode. Table 1 and Table 2 show the properties of the materials used and the electrodes obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com