Textile used for swimming suit and production method thereof

A production method and textile technology, applied in the field of swimwear textiles and its production, can solve the problems of low water-carrying performance maintenance, poor washing durability of polyester, etc., and achieve high safety, low wettability, and low water-carrying properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

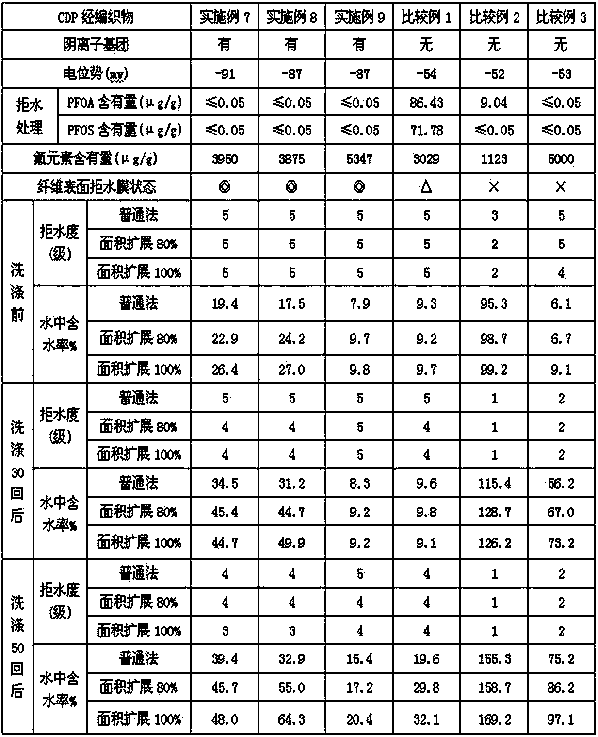

Examples

Embodiment 1

[0164] It includes dyeing warp knitted fabric formed by CDP (sulfonic acid modified polyester) / Lycra, and then processing it with a processing fluid composed of the following:

[0165] The pretreatment processing fluid consists of the following components:

[0166] Anionic pretreatment agent A 10 %o.w.f.

[0167] pH adjustment solution 3g / L

[0168] the rest is water

[0169] Water-repellent processing fluids consist of the following components:

[0170] Water repellent agent A 100g / L

[0171] Bridging agent A 3g / L

[0172] Bridging agent B 2g / L

[0173] Bridging agent J 10g / L

[0174] Penetrant 10g / L

[0175] The rest is soft water

[0176] Processing conditions: firstly treat in the bath of the pre-treatment processing liquid (bath ratio 1:20) for 30 minutes, the processing temperature is 90 degrees, and the processing pH value is 3-4; after drying, put it into the water-repellent processing liquid for padding, Then heat treatment for 1-20 minutes at a temperature...

Embodiment 2

[0178] It includes dyeing warp knitted fabrics formed by CDP (sulfonic acid modified polyester) / Lycra / PTT, and then processing with the following processing fluid:

[0179] The pretreatment processing fluid consists of the following components:

[0180] Anionic pretreatment agent A 10 %o.w.f.

[0181] pH adjustment solution 3g / L

[0182] the rest is water

[0183] Water-repellent processing fluids consist of the following components:

[0184] Water repellent B 60g / L

[0185] Water repellent D 45g / L

[0186] Bridging agent G 10g / L

[0187] Penetrant 10g / L

[0188] The rest is soft water

[0189] Processing conditions: firstly treat in the bath of the pre-treatment processing liquid (bath ratio 1:20) for 30 minutes, the processing temperature is 90 degrees, and the processing pH value is 3-4; after drying, put it into the water-repellent processing liquid for padding, Then heat treatment for 1-20 minutes at a temperature of 80-200°C or dry at a temperature of 80-150°...

Embodiment 3

[0191] It includes dyeing the warp knitted fabric formed by CDP (sulfonic acid modified polyester) / PBT, and then processing it with the following processing fluid:

[0192] The pretreatment processing fluid consists of the following components:

[0193] Anionic pretreatment agent B 5%o.w.f.

[0194] the rest is water

[0195] Water-repellent processing fluids consist of the following components:

[0196] Water repellent agent A 55g / L

[0197] Water repellent K 30g / L

[0198] Bridging agent B 10g / L

[0199] Bridging agent C 3g / L

[0200] Catalyst A (for bridging agent C) 2g / L

[0201] Penetrant 10g / L

[0202] The rest is soft water

[0203] Processing conditions: firstly treat in the bath of the pretreatment processing liquid (bath ratio 1:10) for 20 minutes, the processing temperature is 80 degrees, and the pH value of the processing is 2 to 3; after drying, put it into the processing liquid for water-repellent padding, Then heat treatment for 1-20 minutes at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com