Preparation method of novel organic silicone oil water repellent agent used for cotton fabric

A technology of silicone oil and water repellent, which is applied in the fields of plant fiber, textiles, papermaking, fiber treatment, etc., and can solve the problems of rough fabric feel, poor washability, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

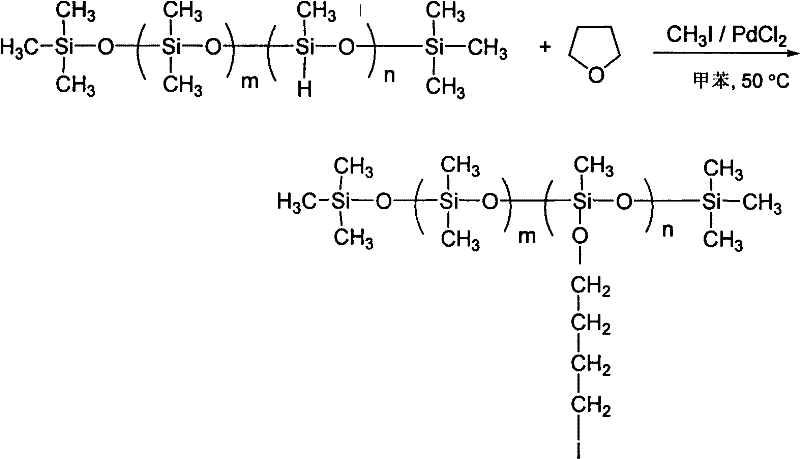

Image

Examples

Embodiment 1

[0013] (1) In a constant temperature heating magnetic stirrer, fix a dry three-necked flask with an iron stand, add 18.4g (0.2mol) toluene as a reaction solvent, and then use a syringe to take 22.2g of 0.45% hydrogen-containing silicone oil (active 0.1 mol of hydrogen, 21.6 g (0.3 mol) of tetrahydrofuran, and 56.8 g (0.4 mol) of methyl iodide were put into a three-necked flask. Add 0.176g (0.001mol) of palladium chloride catalyst, and adjust the rotating speed of the magnet to make it mix evenly. The reaction temperature was controlled at 50° C., nitrogen was used for protection during the reaction, a serpentine condenser was used to reflux, and the reaction time was 10 h. After the reaction, the product was filtered to remove the catalyst palladium chloride, and then rotary evaporated under a rotary evaporator to obtain a light yellow liquid product, a new type of silicone oil water repellent agent, with a yield of 71.3%.

[0014] (2) Take 10g of zirconium oxychloride in a 1...

Embodiment 2

[0020] (1) In a constant temperature heating magnetic stirrer, fix a dry three-necked flask with an iron stand, add 18.4g (0.2mol) toluene as a reaction solvent, and then use a syringe to take 22.2g of 0.45% hydrogen-containing silicone oil (active 0.1 mol of hydrogen, 21.6 g (0.3 mol) of tetrahydrofuran, and 56.8 g (0.4 mol) of methyl iodide were put into a three-necked flask. Add 0.176g (0.001mol) of palladium chloride catalyst, and adjust the rotating speed of the magnet to make it mix evenly. The reaction temperature was controlled at 50° C., nitrogen was used for protection during the reaction, a serpentine condenser was used to reflux, and the reaction time was 12 hours. After the reaction, the product was filtered to remove the catalyst palladium chloride, and then rotary evaporated under a rotary evaporator to obtain a light yellow liquid product, a new type of silicone oil water repellent agent, with a yield of 80.2%.

[0021] (2) Take 10g of zirconium oxychloride in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com