Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about "Reversal processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

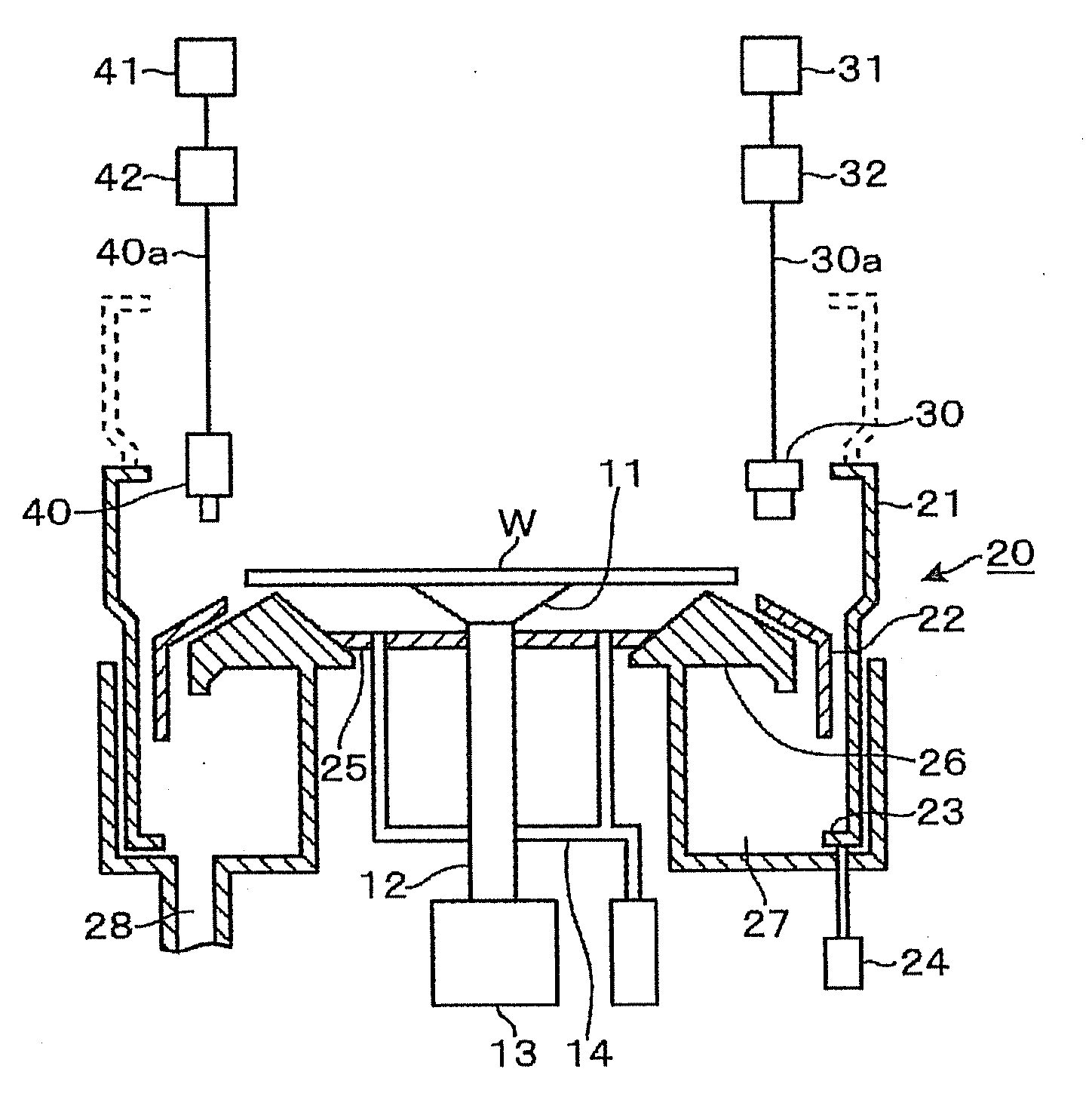

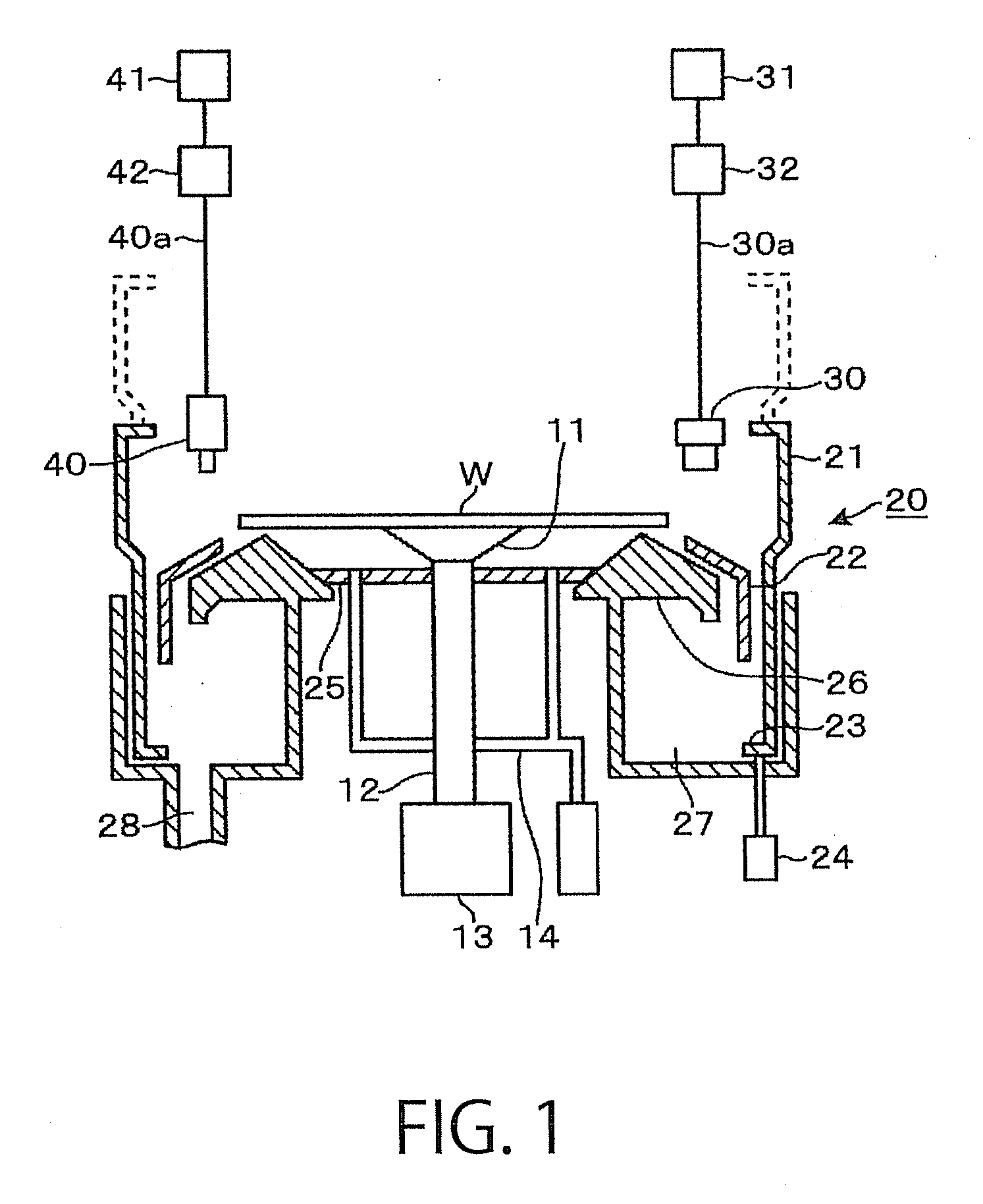

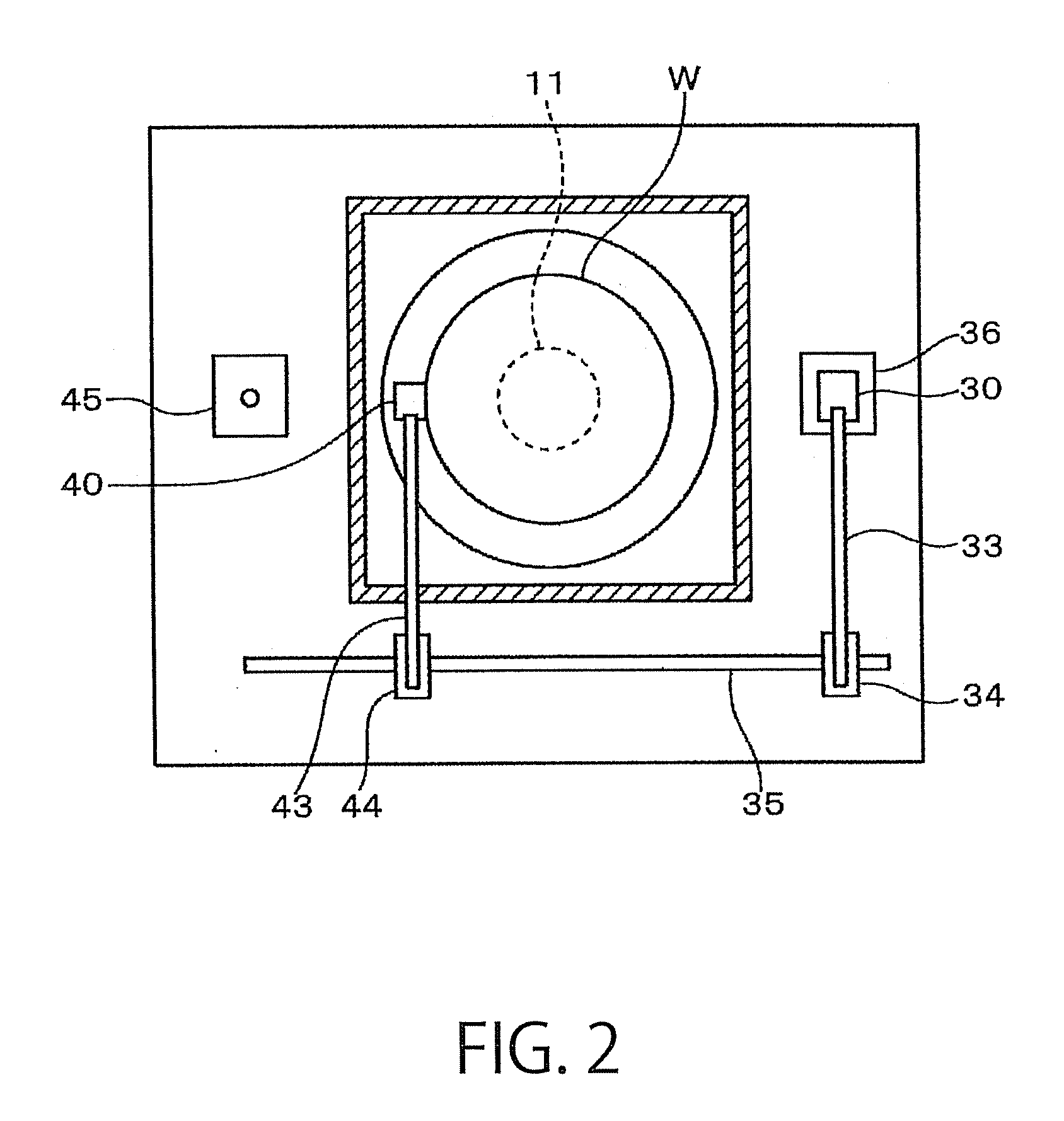

Substrate processing apparatus and processing method by use of the apparatus

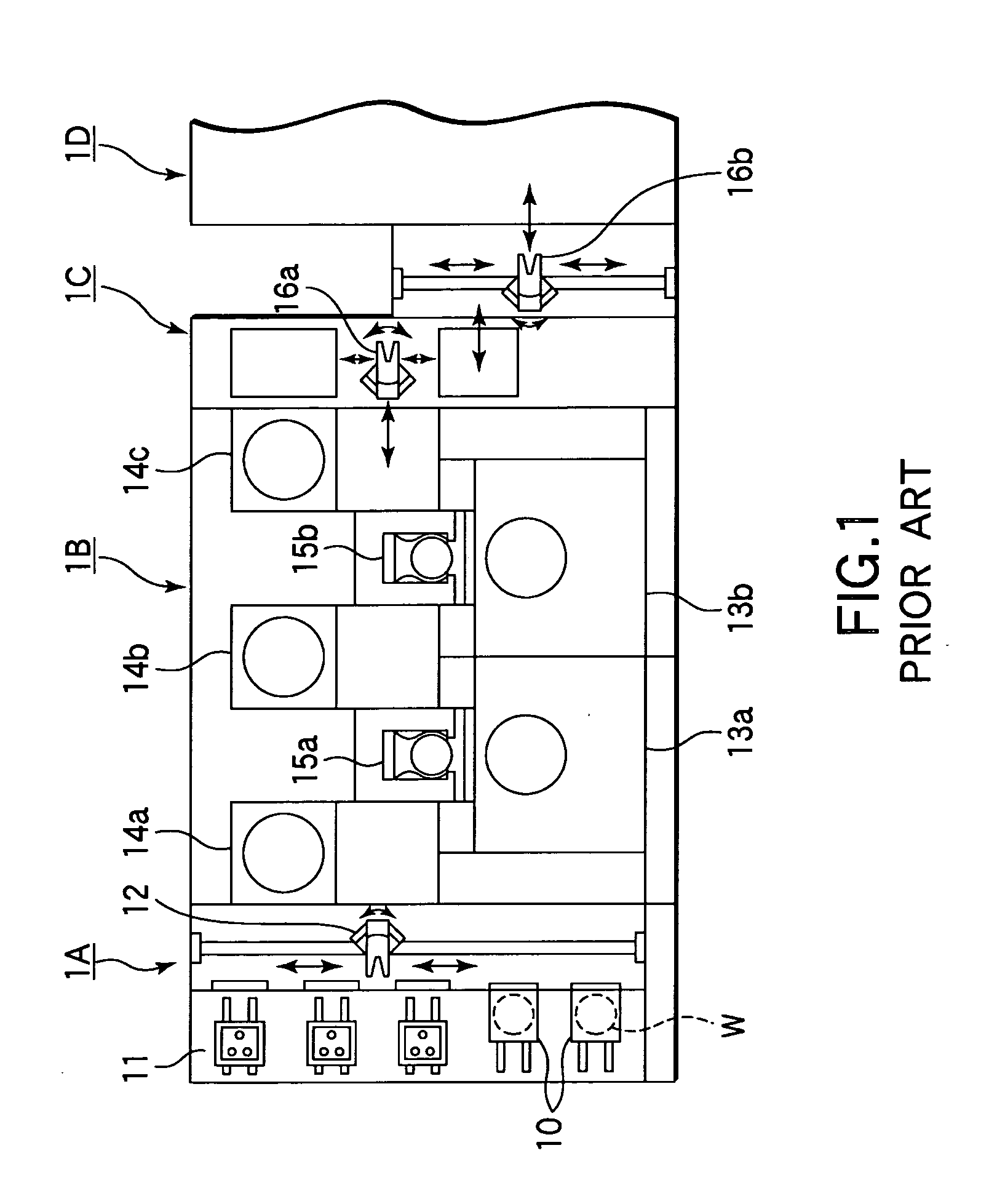

InactiveUS6550990B2Liquid surface applicatorsReversal processingChemical solutionAnalytical chemistry

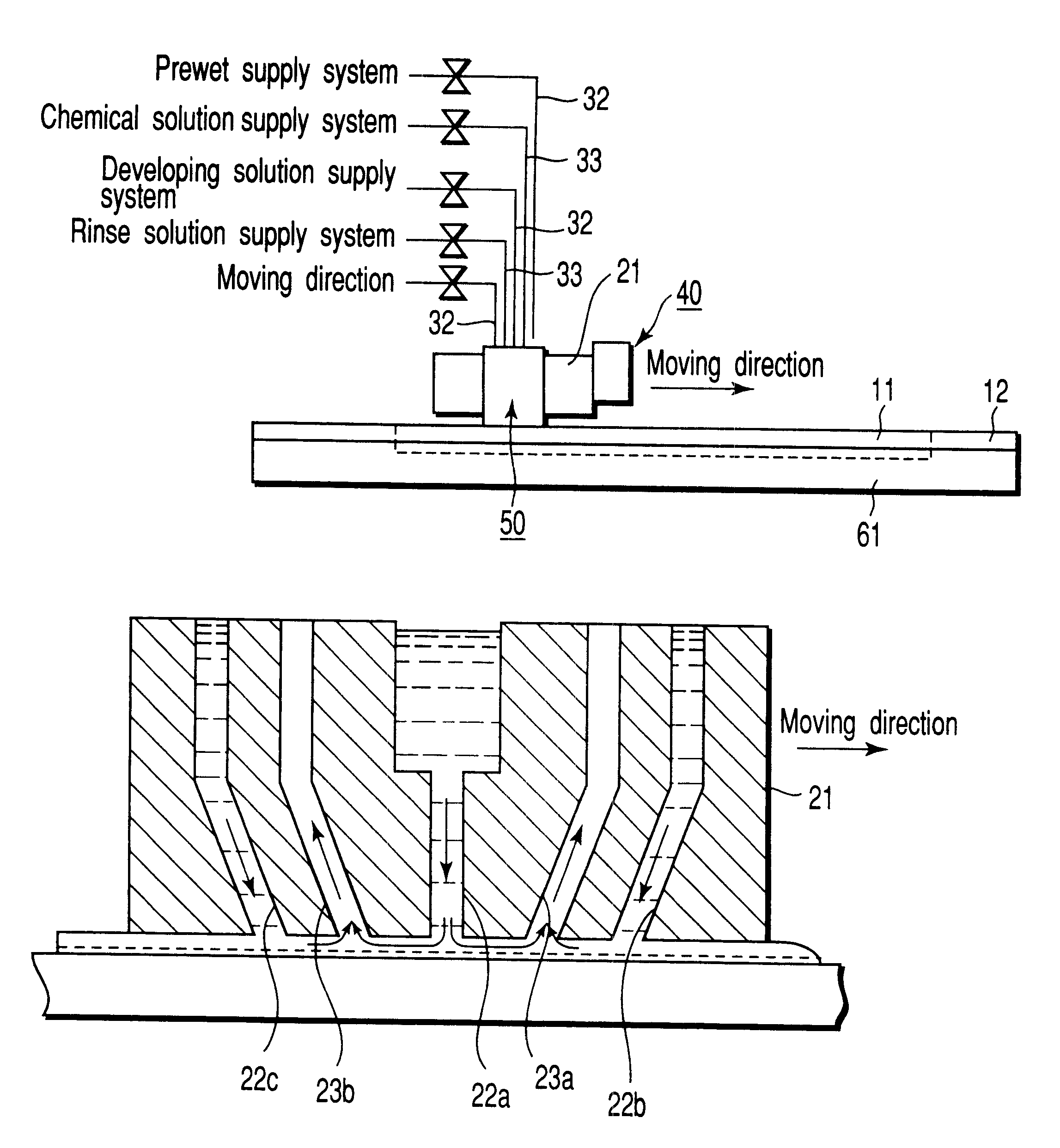

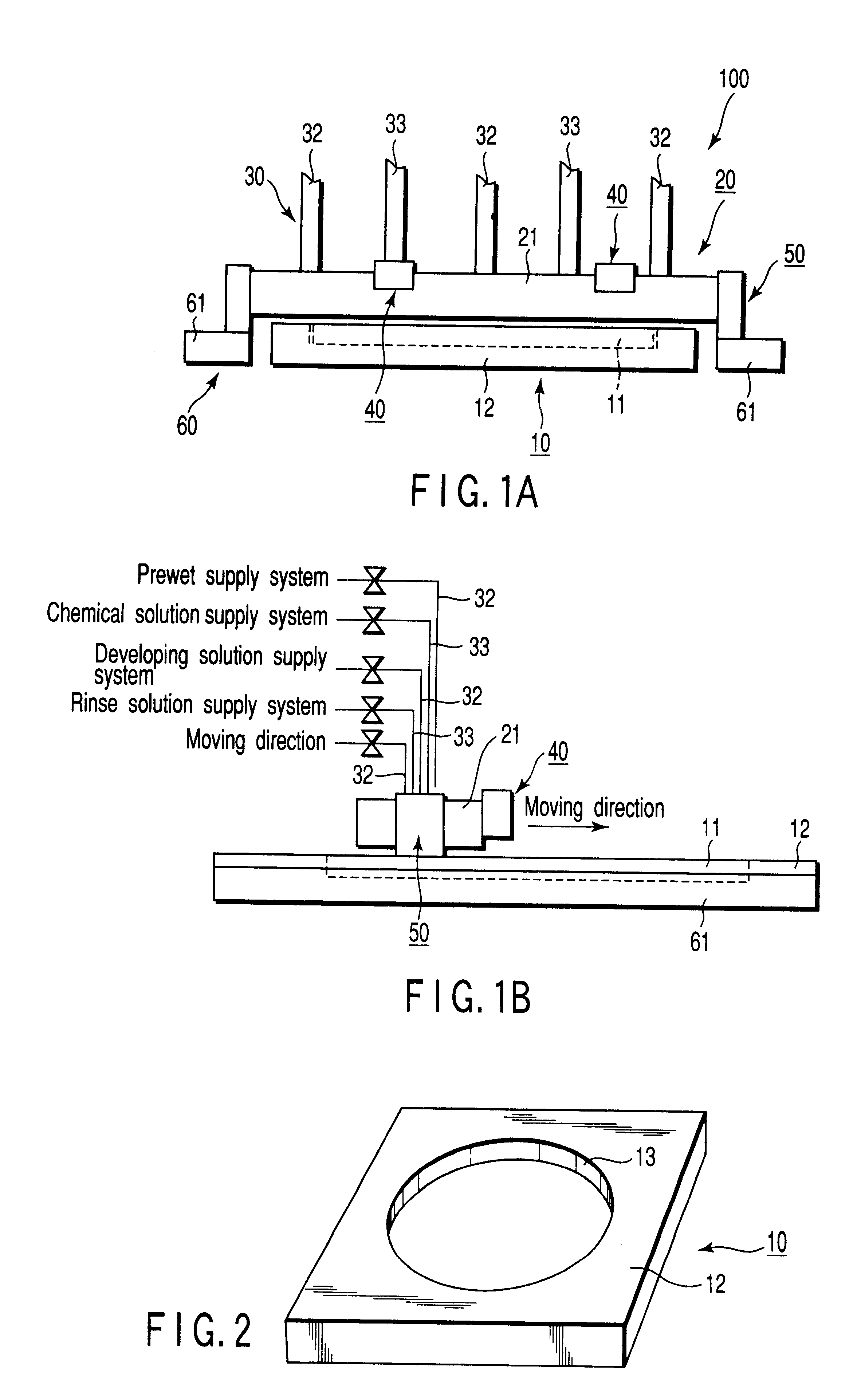

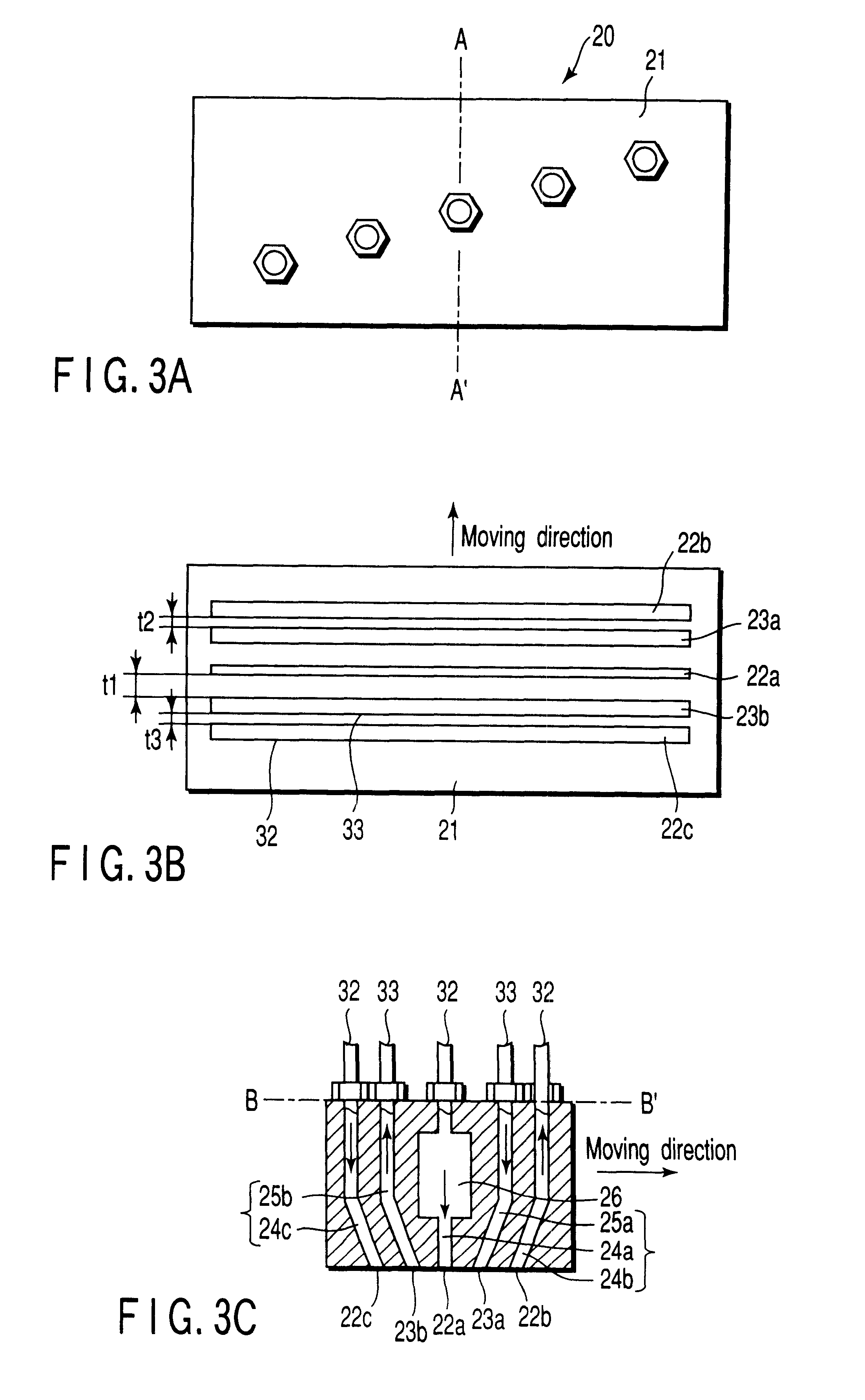

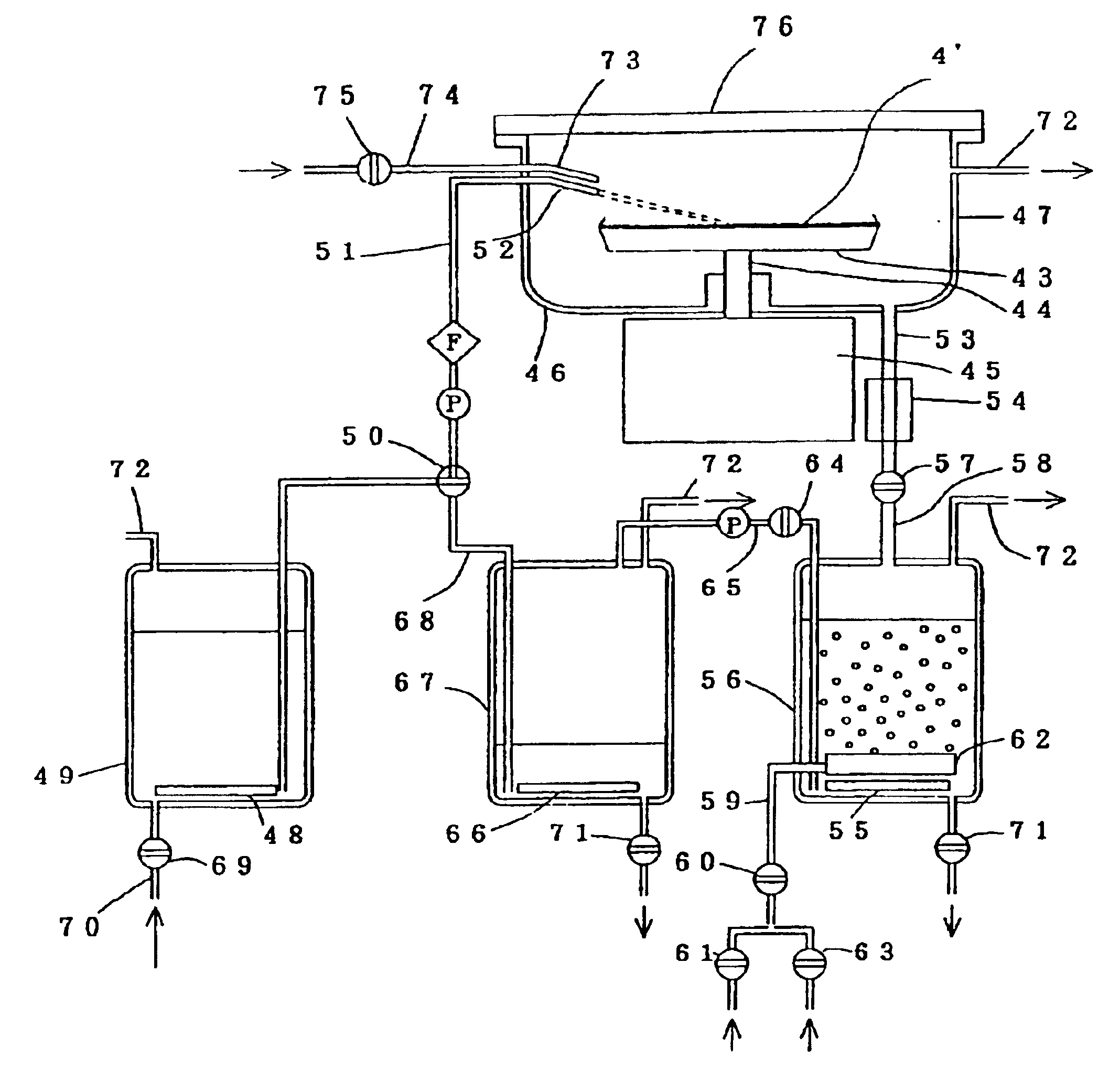

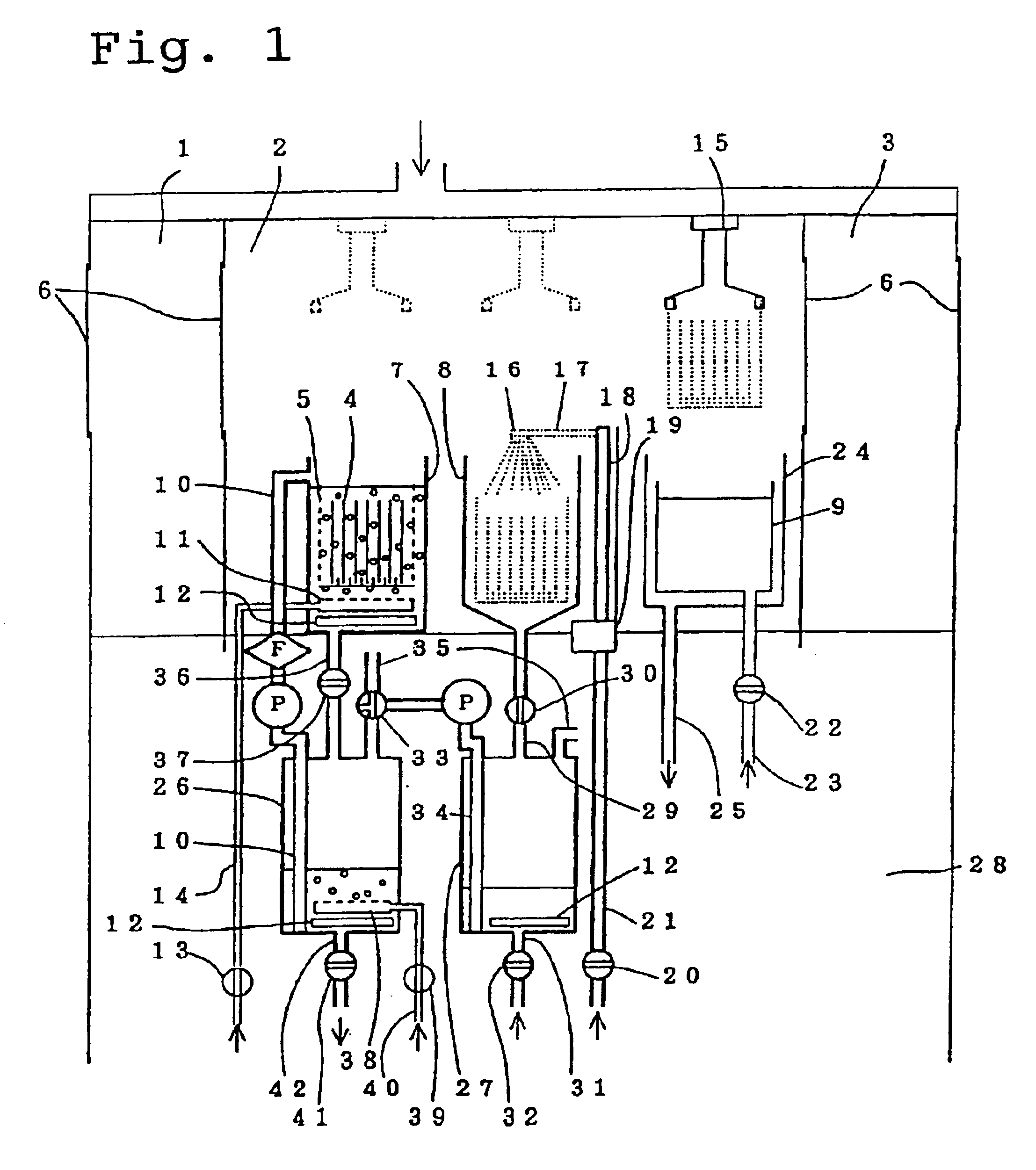

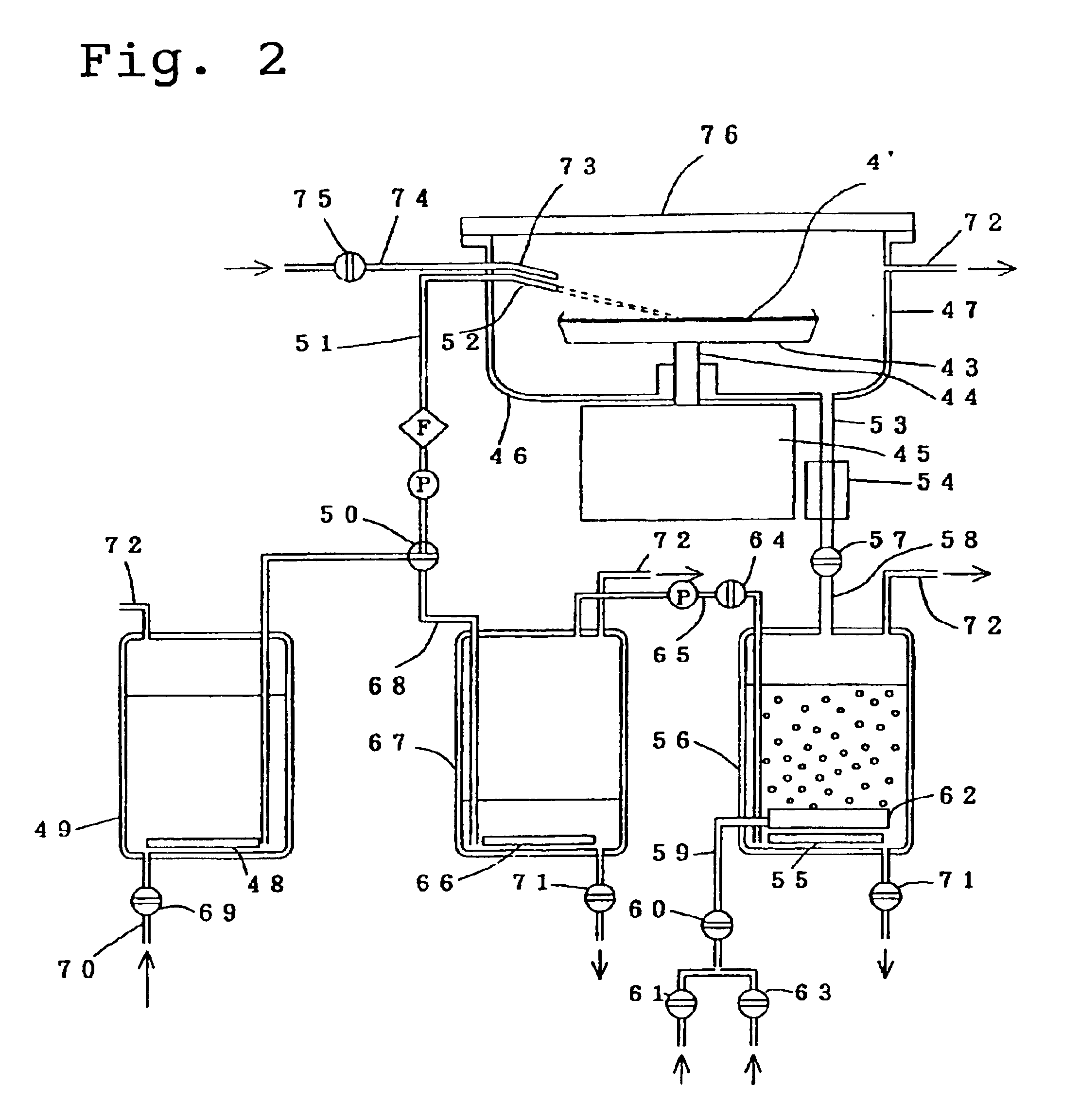

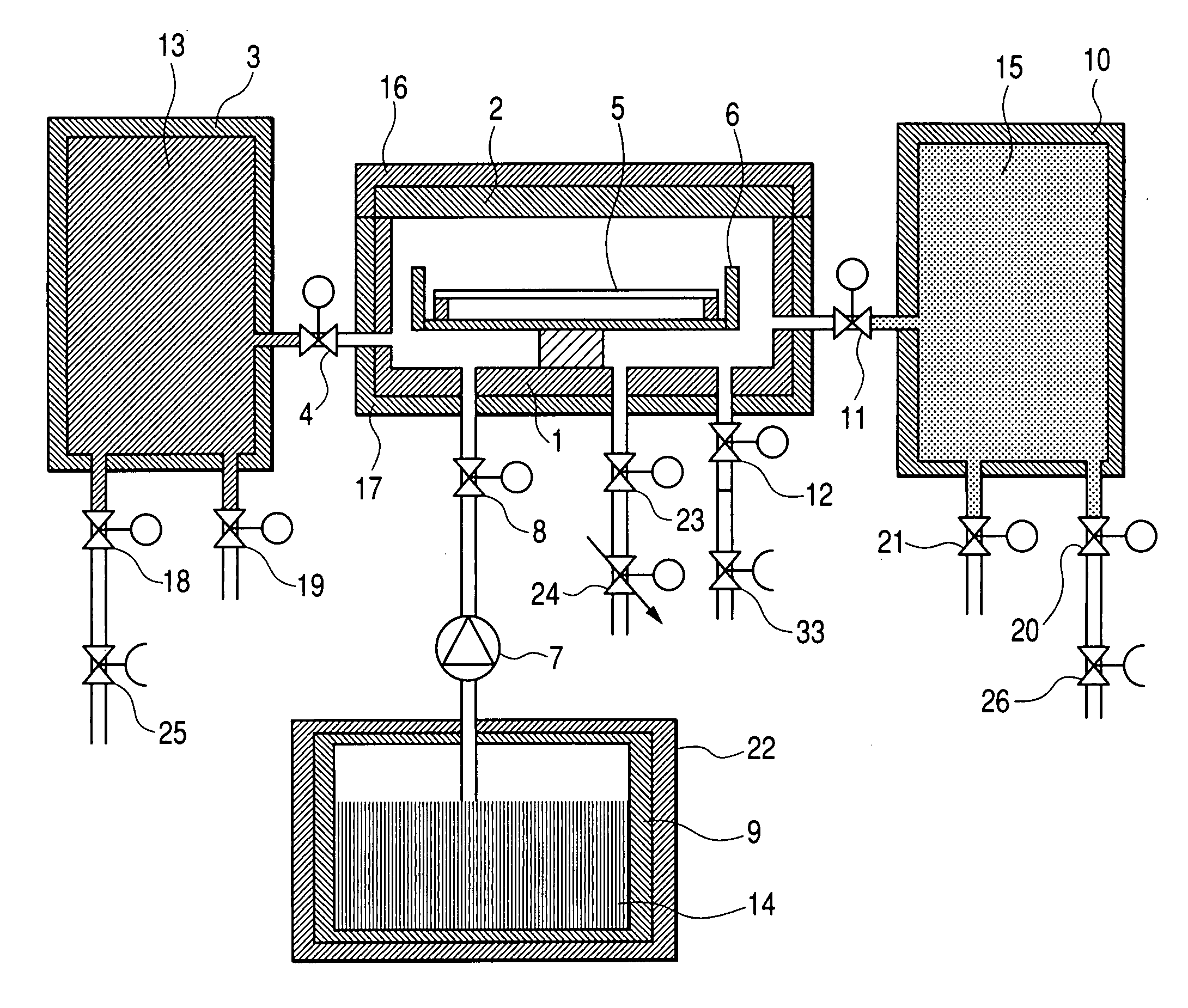

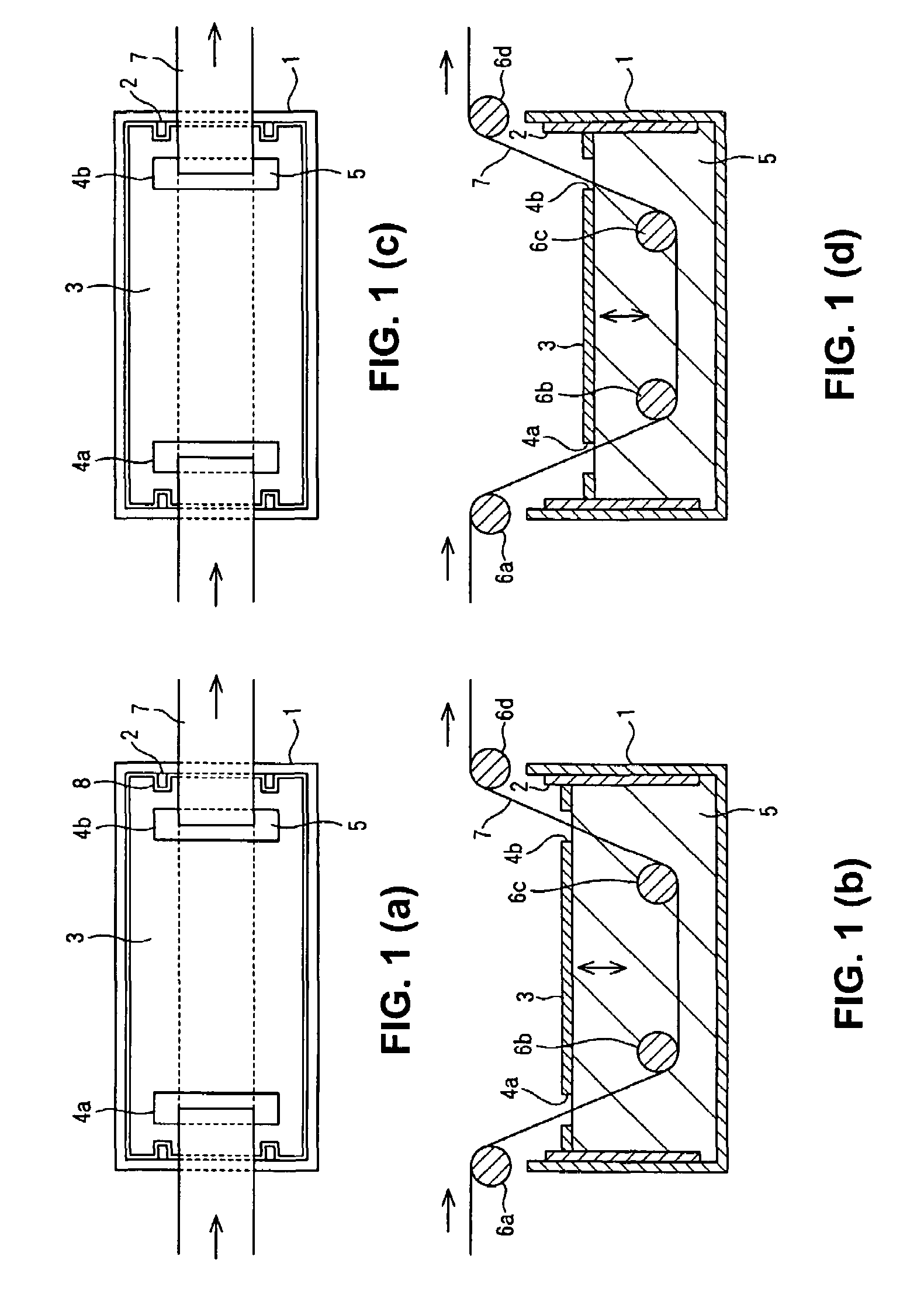

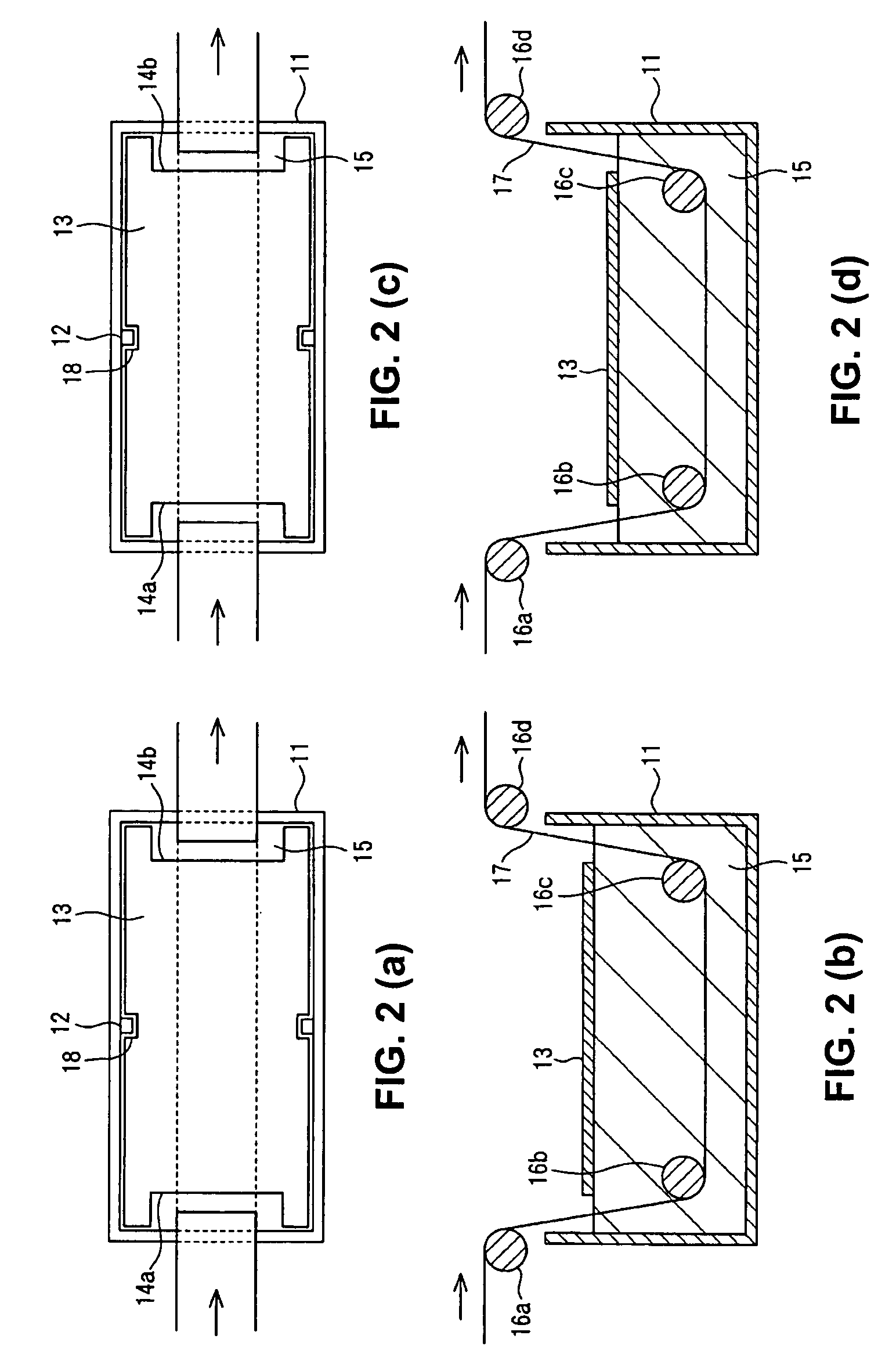

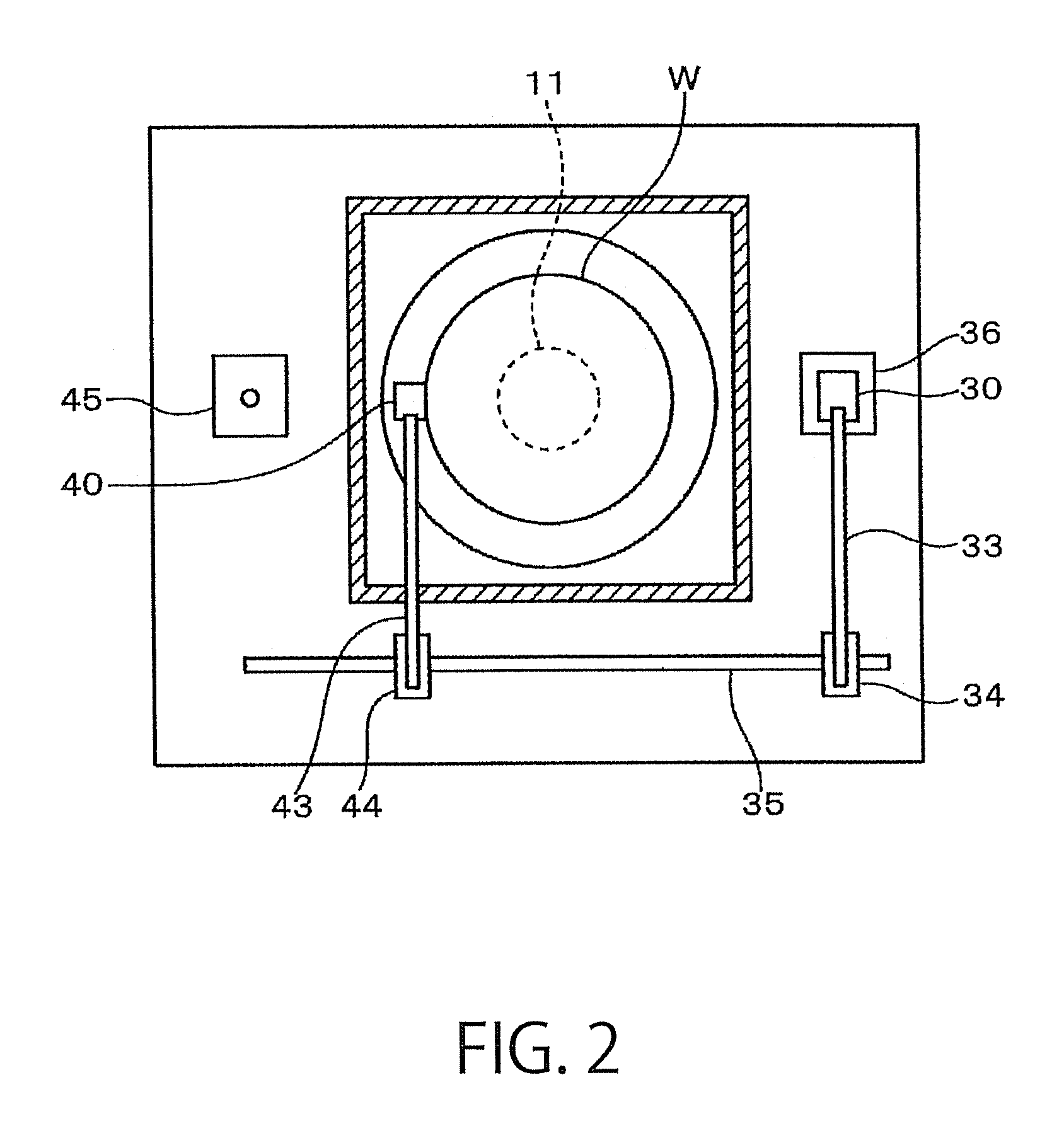

An apparatus for processing a substrate comprising a substrate holding mechanism for holding the substrate substantially horizontally, a chemical solution discharge / suction mechanism having a chemical solution discharge / suction portion which has a chemical solution outlet for discharging a chemical solution onto the substrate and chemical solution inlets for sucking up the chemical solution present on the substrate, and a chemical solution supply / suction system for supplying the chemical solution to the chemical solution discharge / suction mechanism simultaneously with sucking the chemical solution by the chemical solution supply / suction mechanism.

Owner:TOSHIBA MEMORY CORP

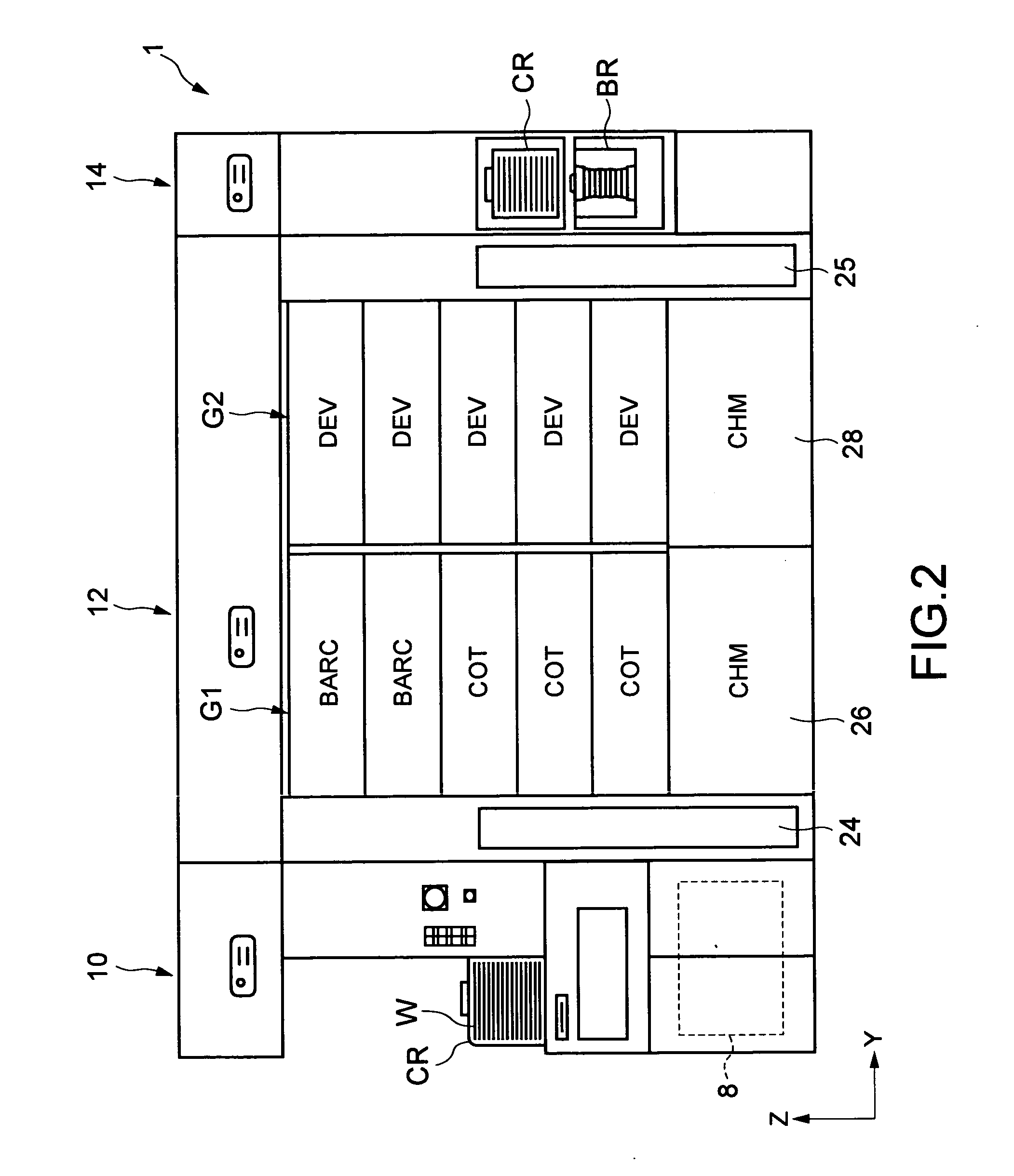

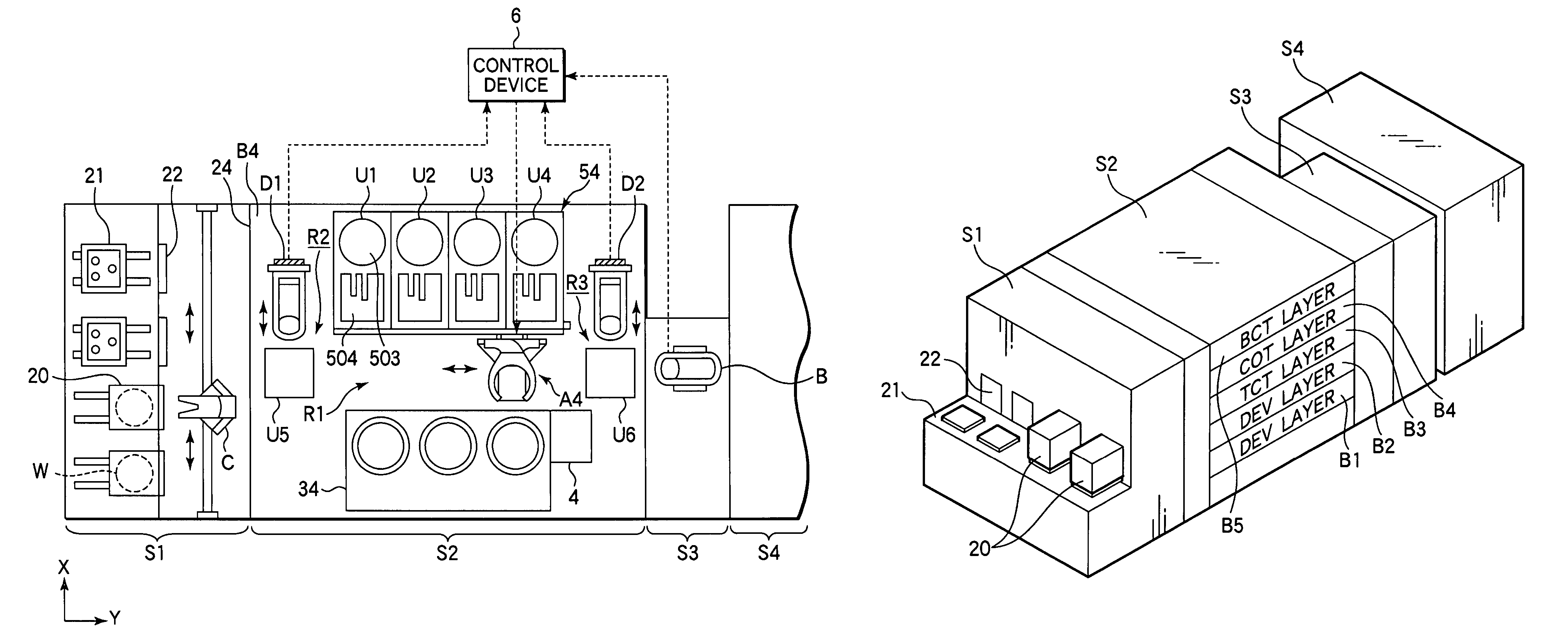

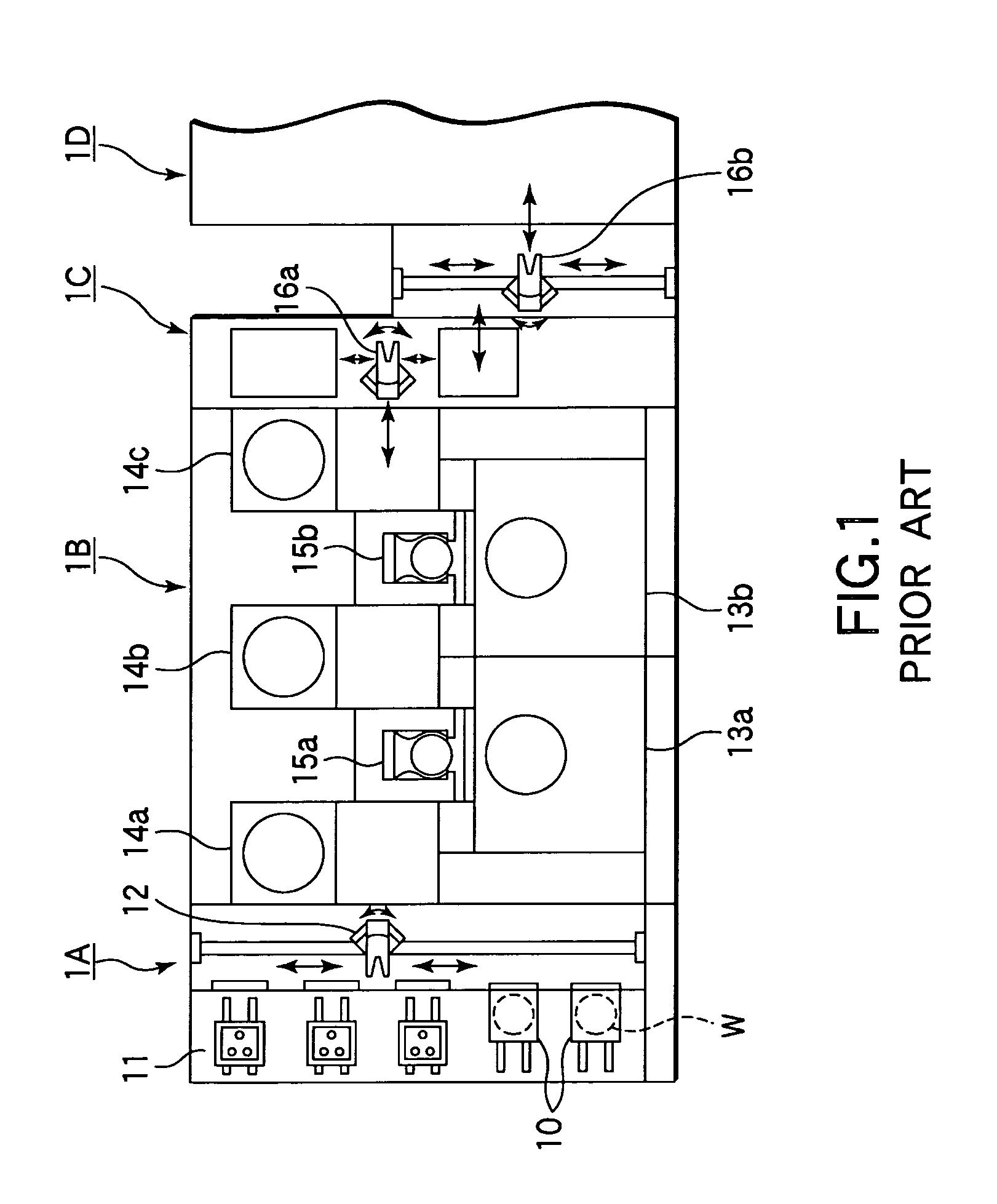

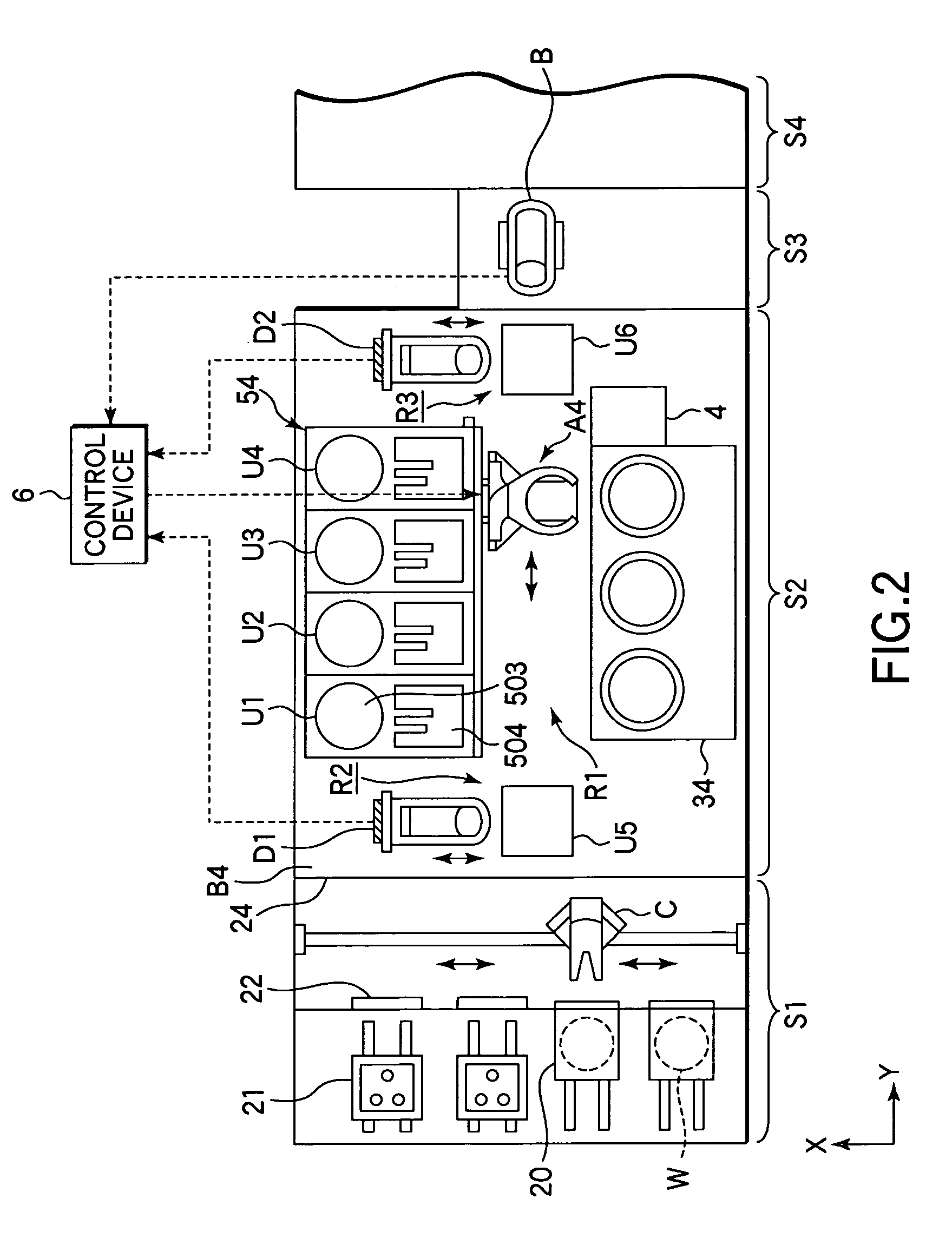

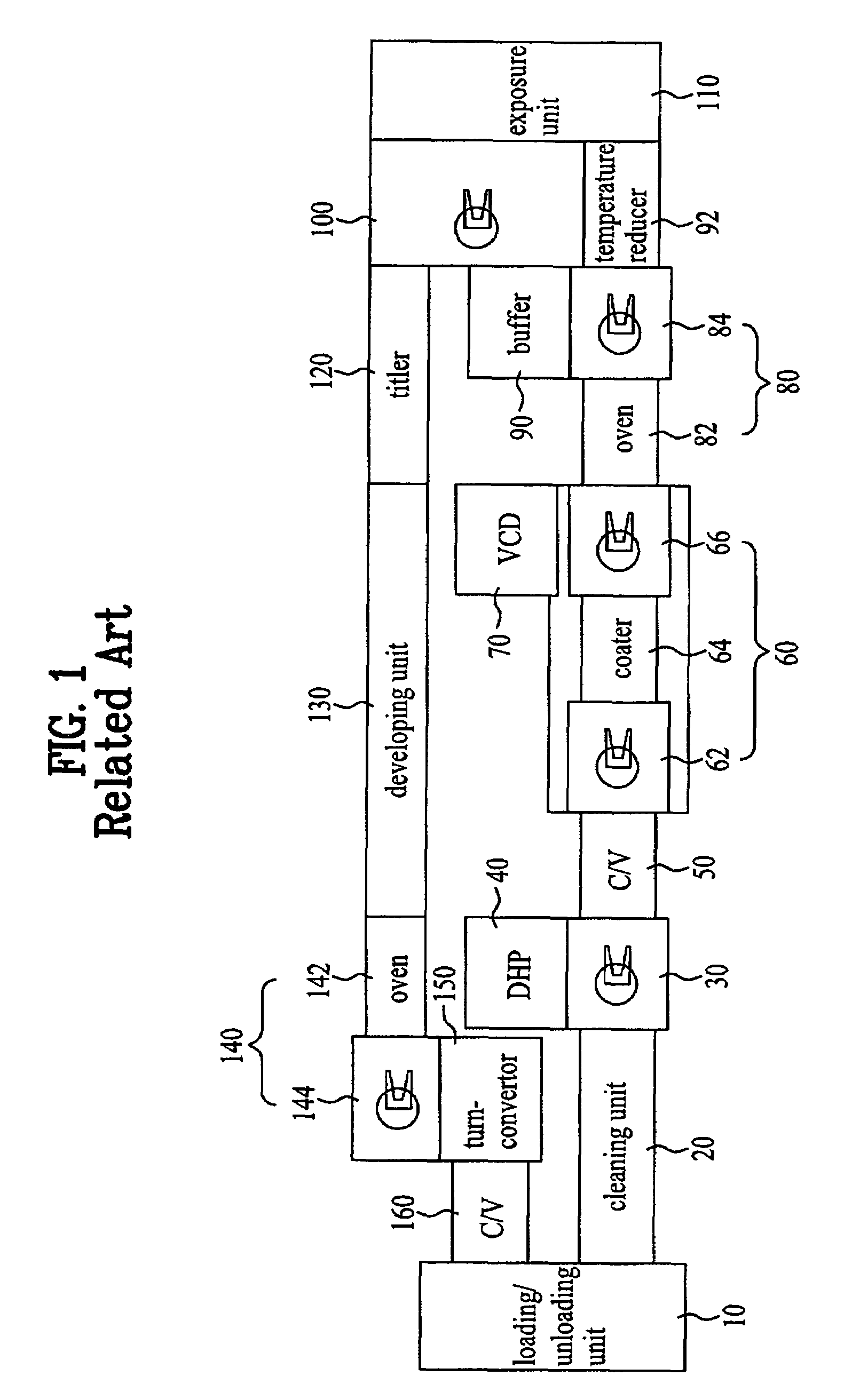

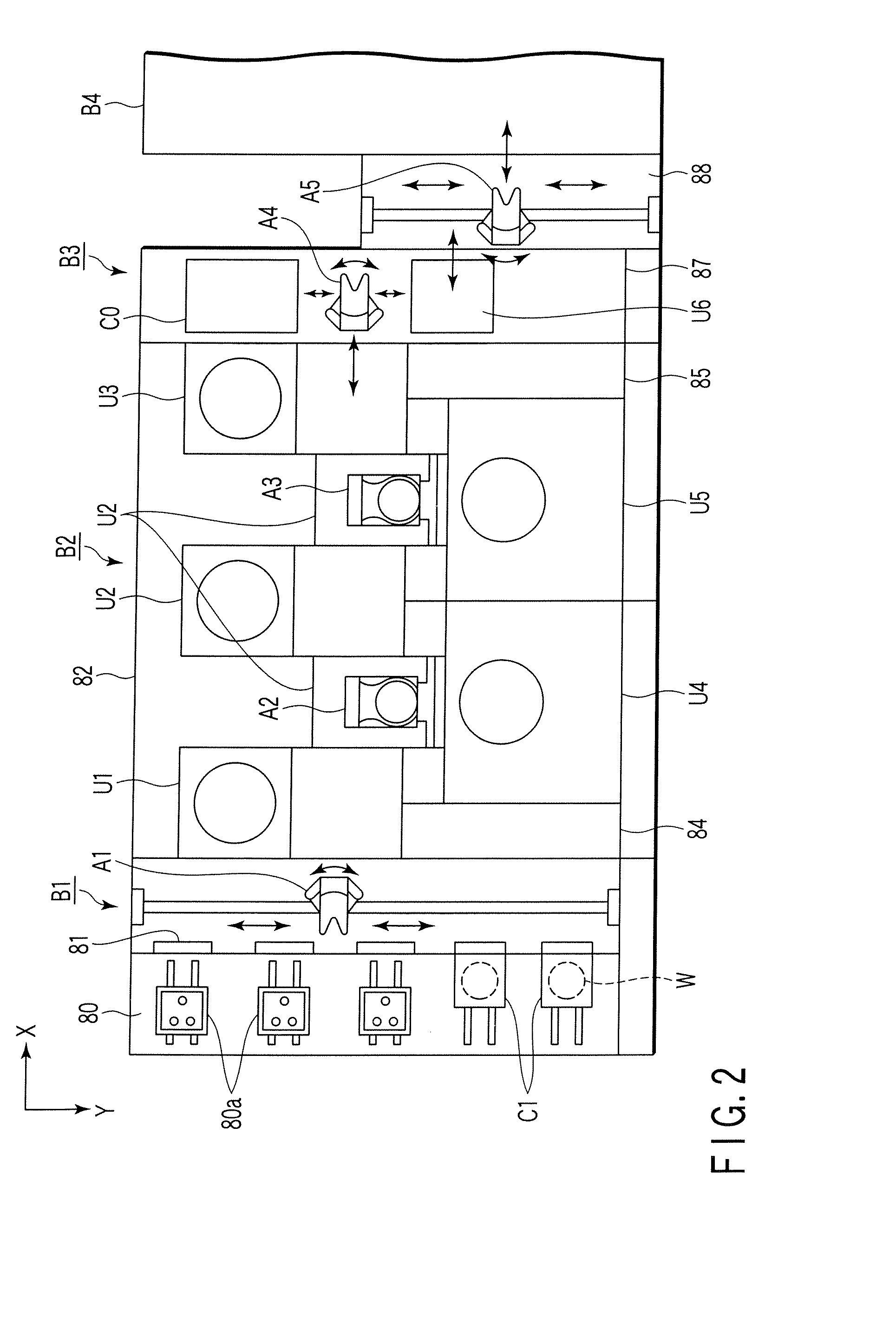

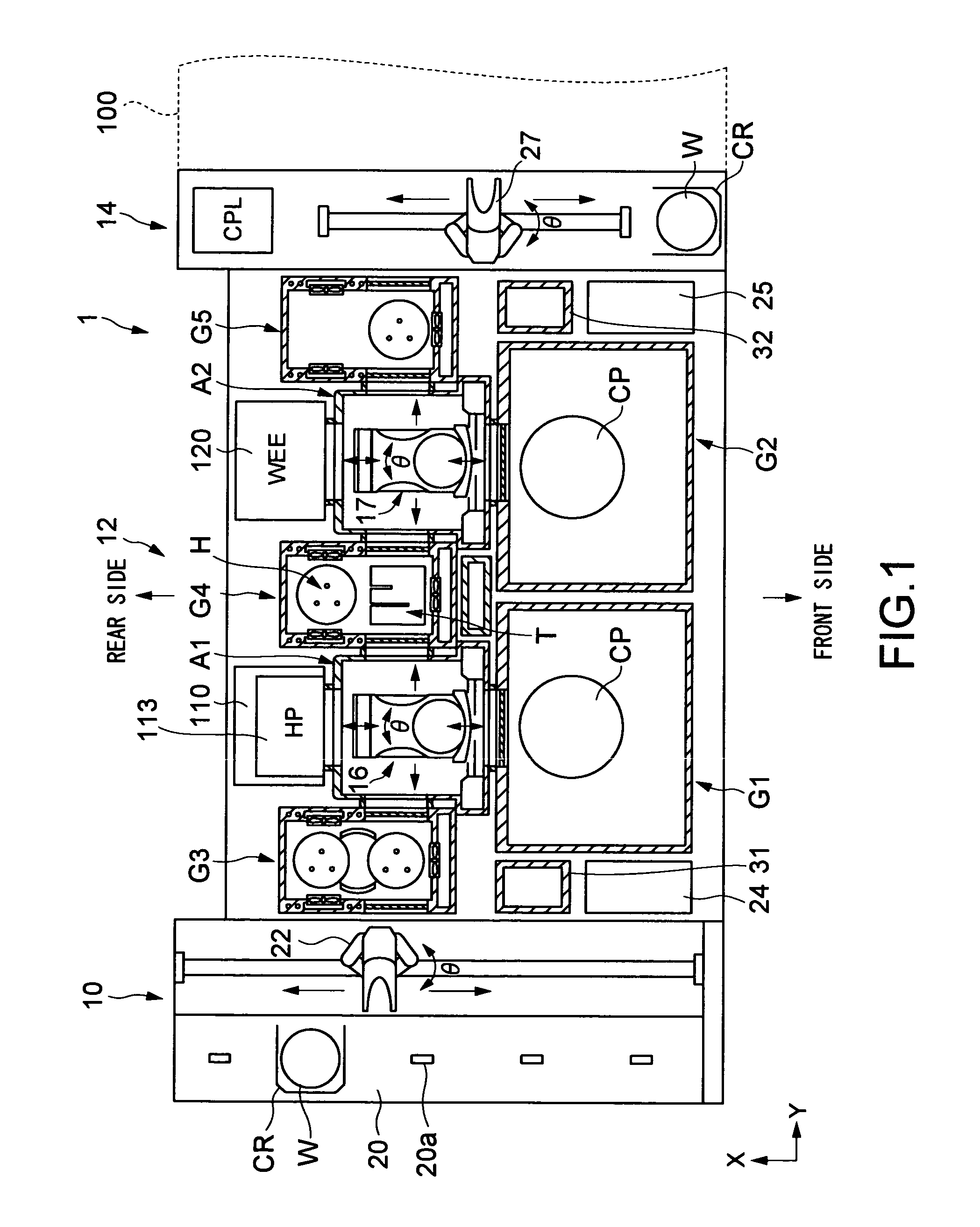

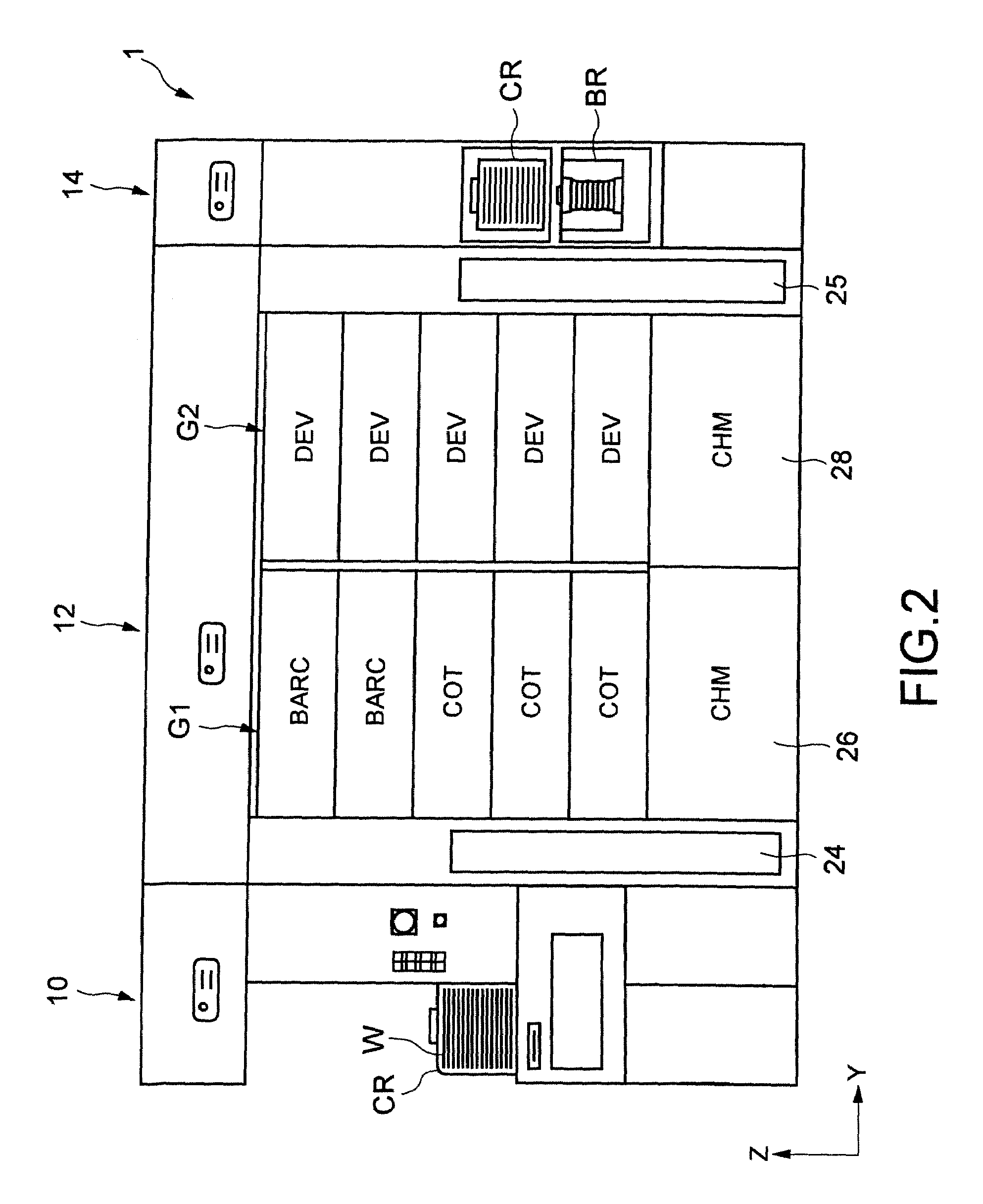

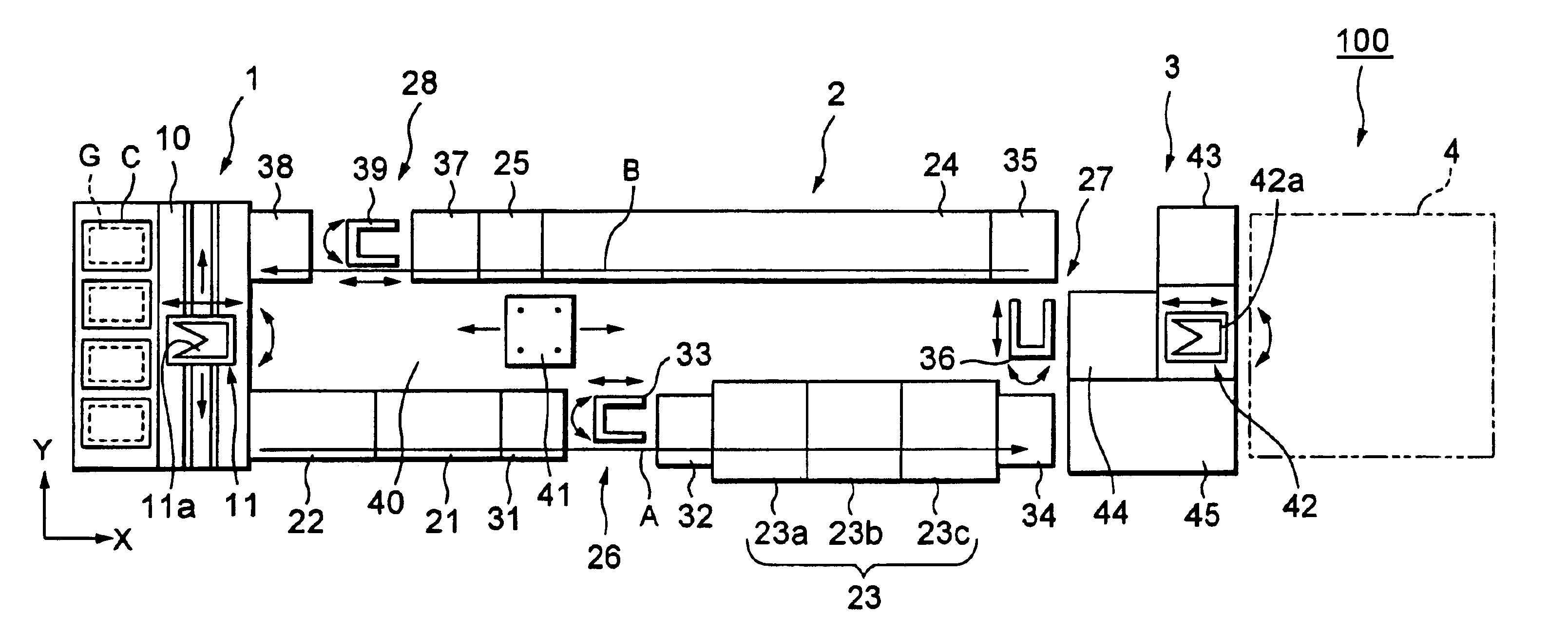

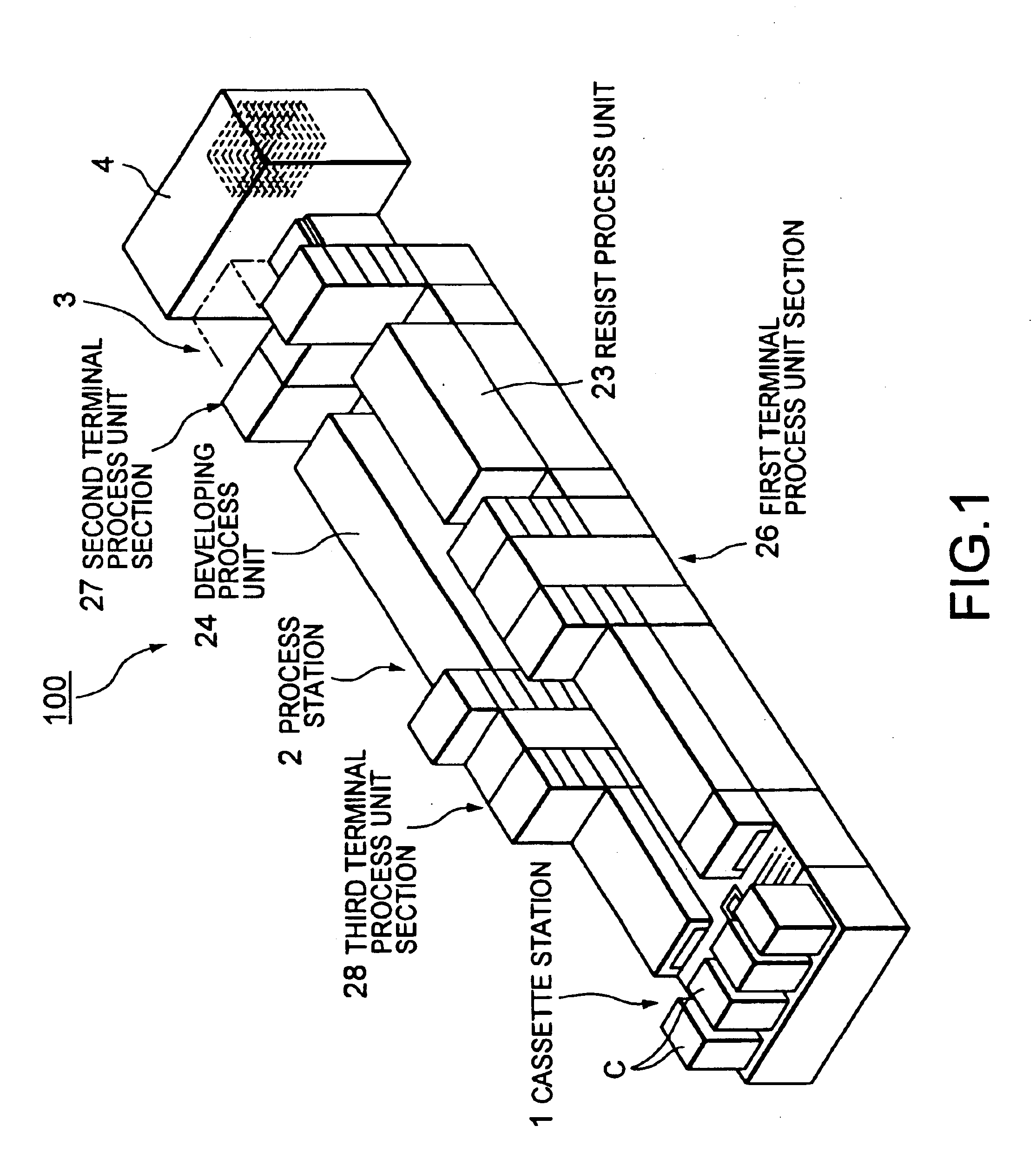

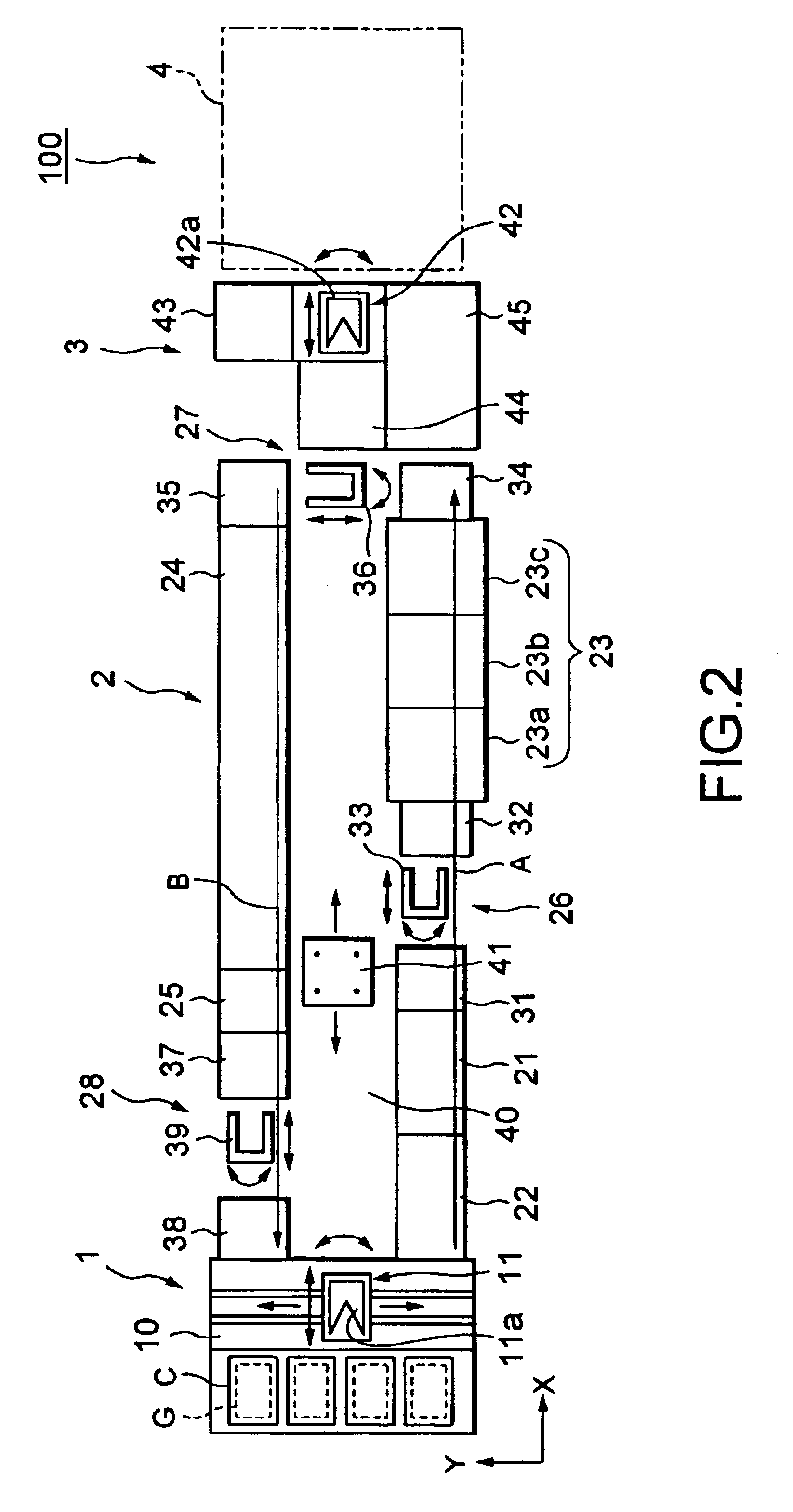

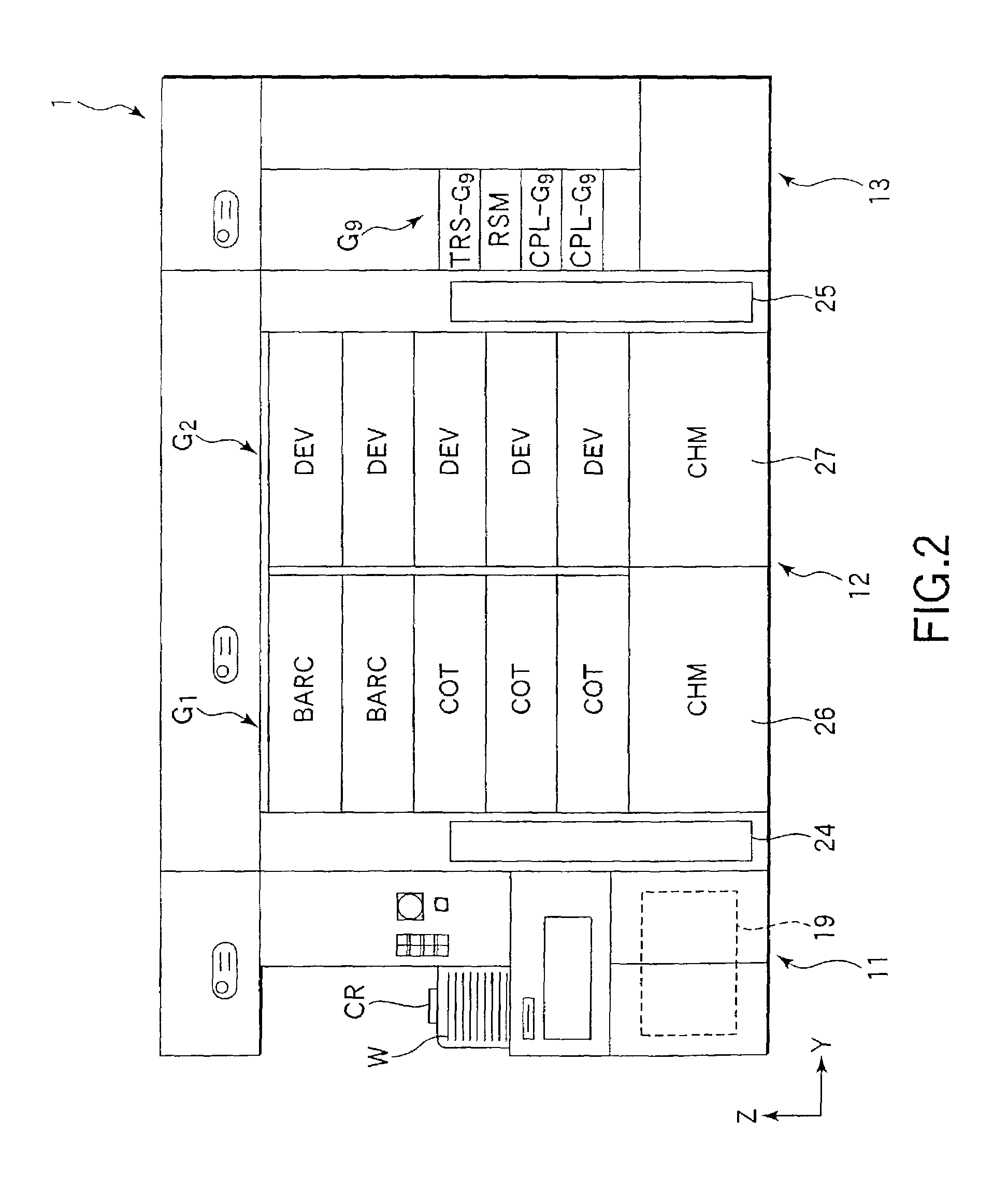

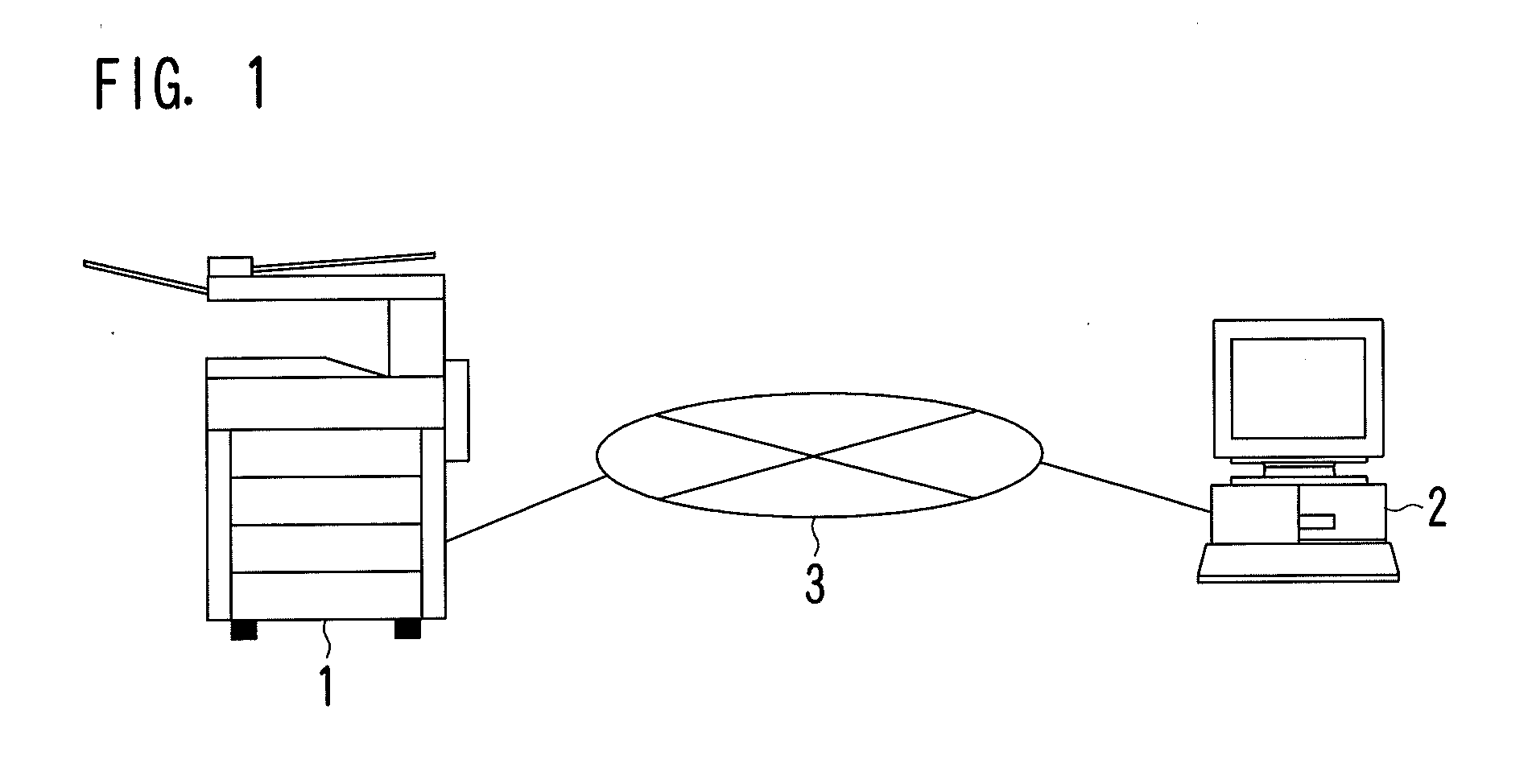

Coating and developing apparatus and coating and developing method

ActiveUS20060165408A1Reduce yieldQuality improvementLiquid processingReversal processingEngineeringTransfer mechanism

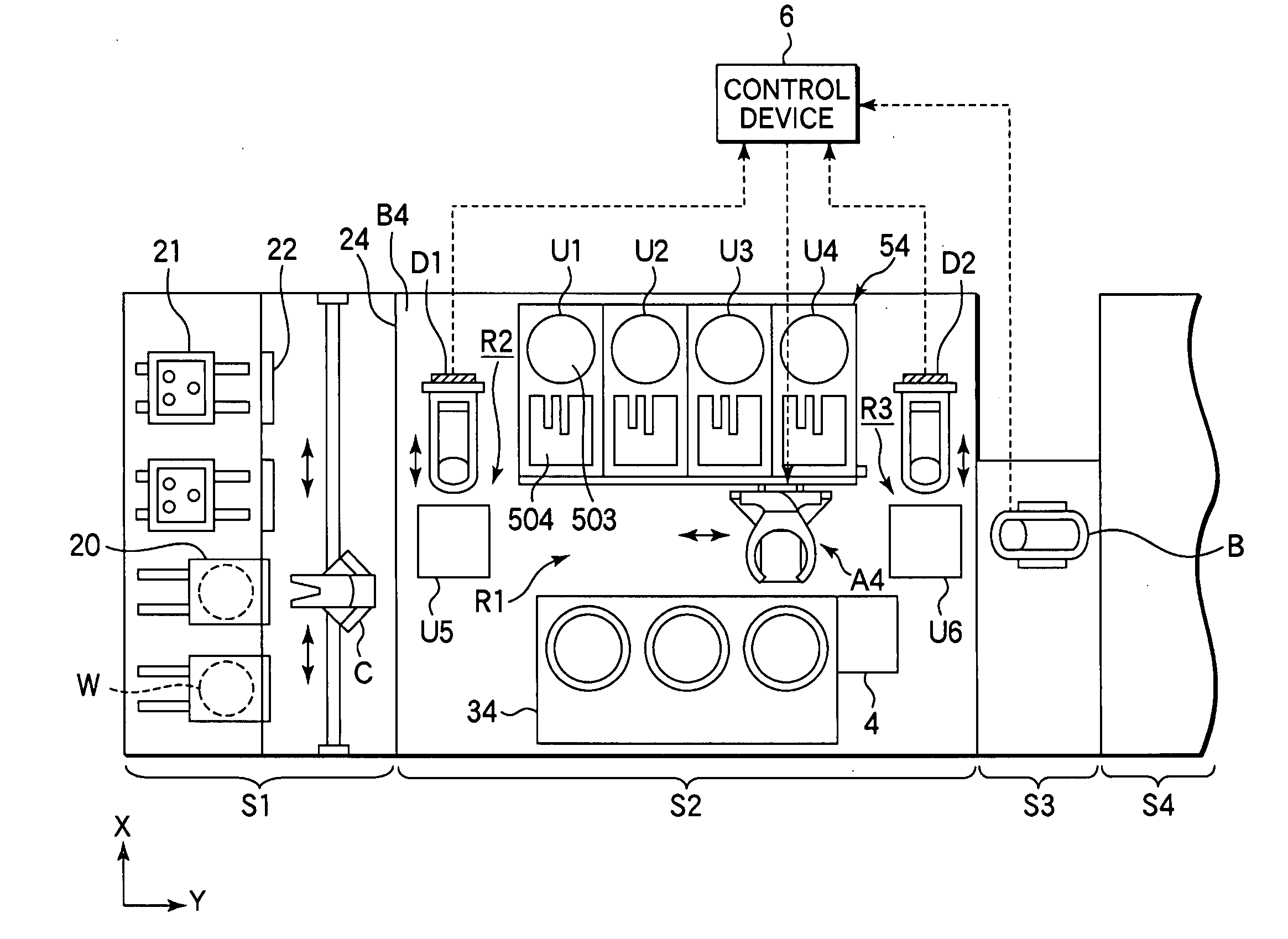

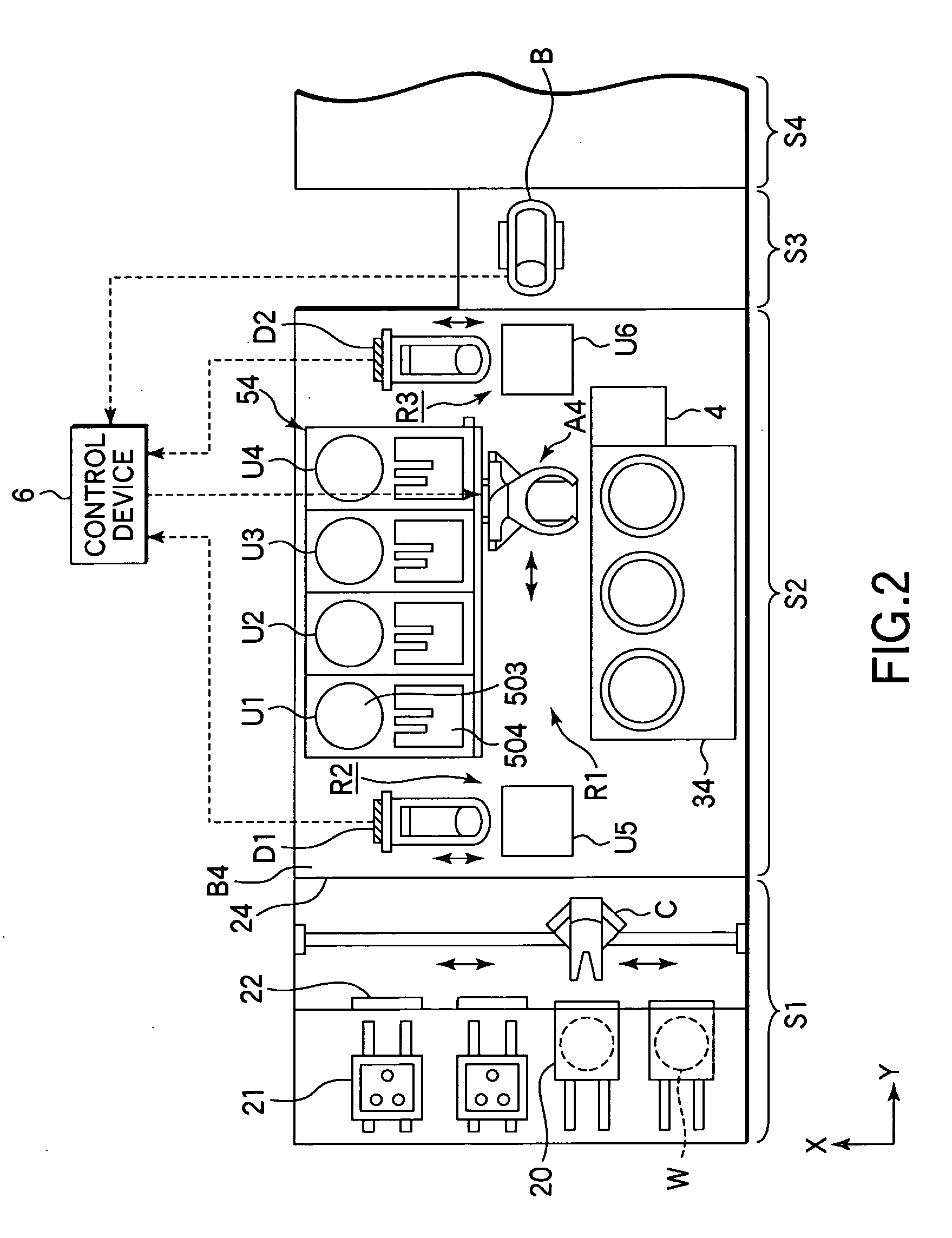

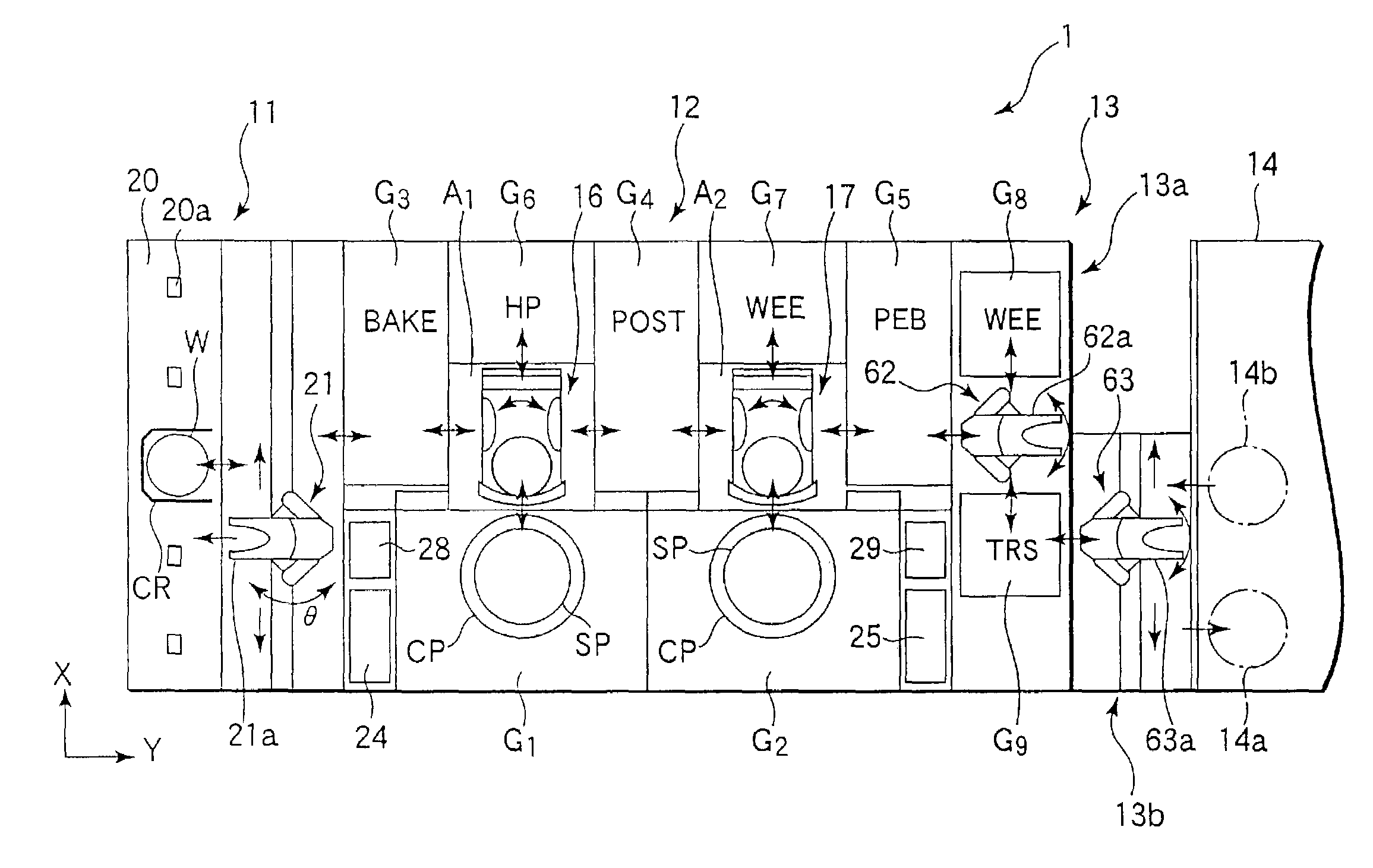

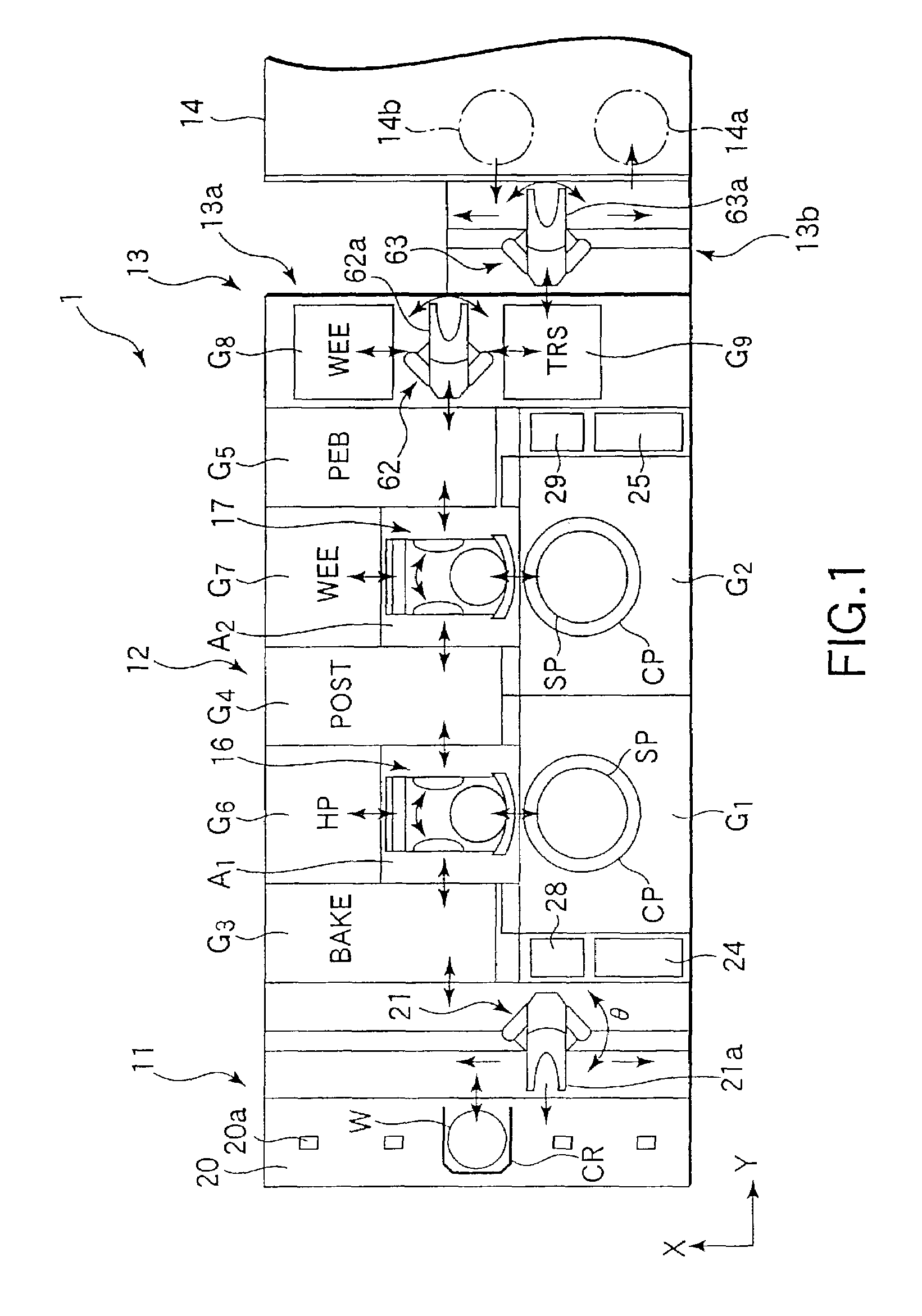

A coating and developing apparatus comprises a process block which forms a resist film on a wafer, then transfers the wafer to an exposure apparatus, and performs a developing process on the wafer after exposure, and an interface transfer mechanism provided between the process block and the exposure apparatus. The process block includes unit blocks for coating-film formation and unit blocks for development laid out in a stacked manner. When an abnormality occurs in the interface transfer mechanism, an ordinary process in the unit block for coating-film formation is performed on those substrates which are present in that unit block for coating-film formation, after which processed wafers are retreated to a retaining unit and transfer of any wafer into the unit block for coating-film formation is inhibited.

Owner:TOKYO ELECTRON LTD

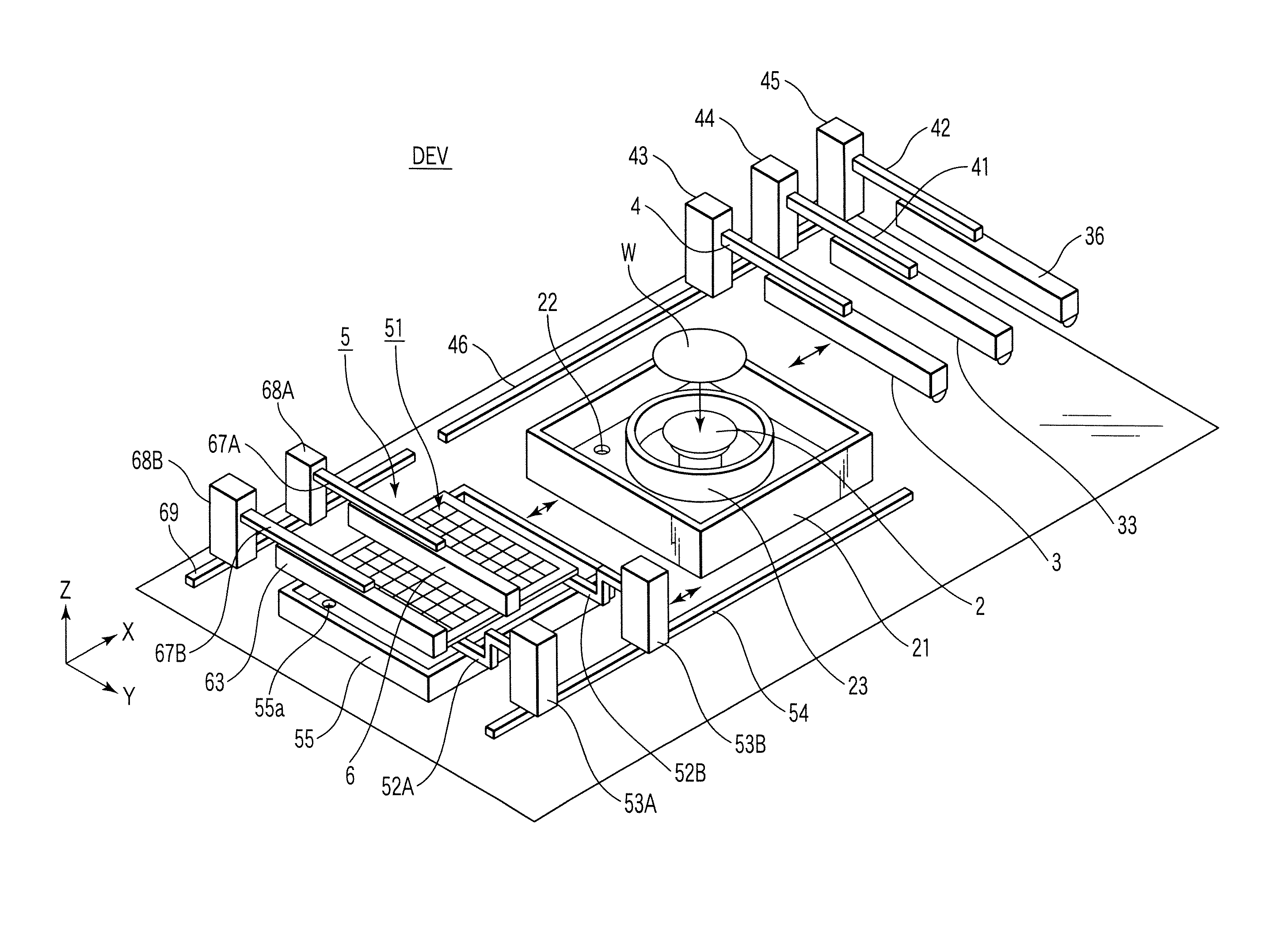

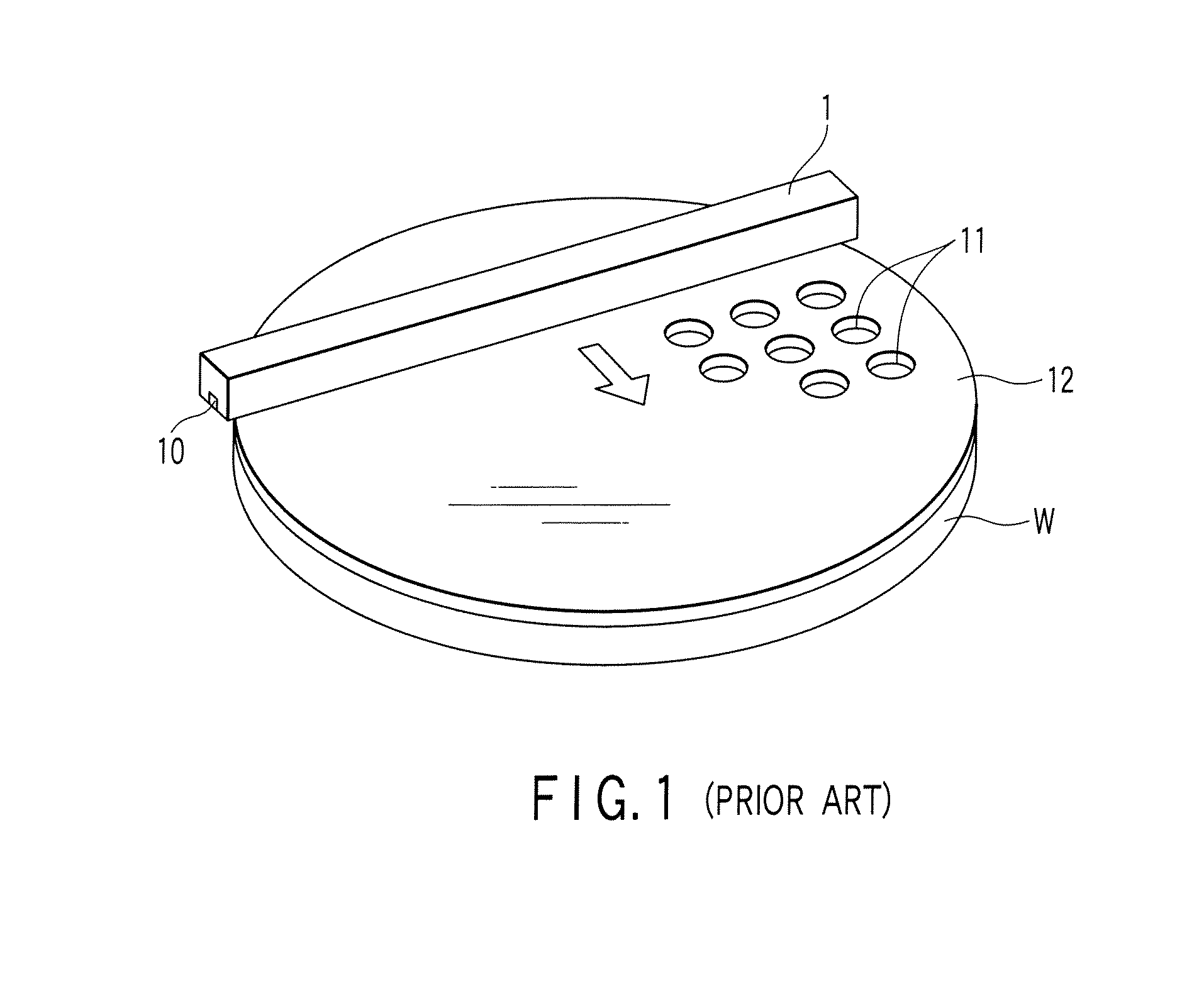

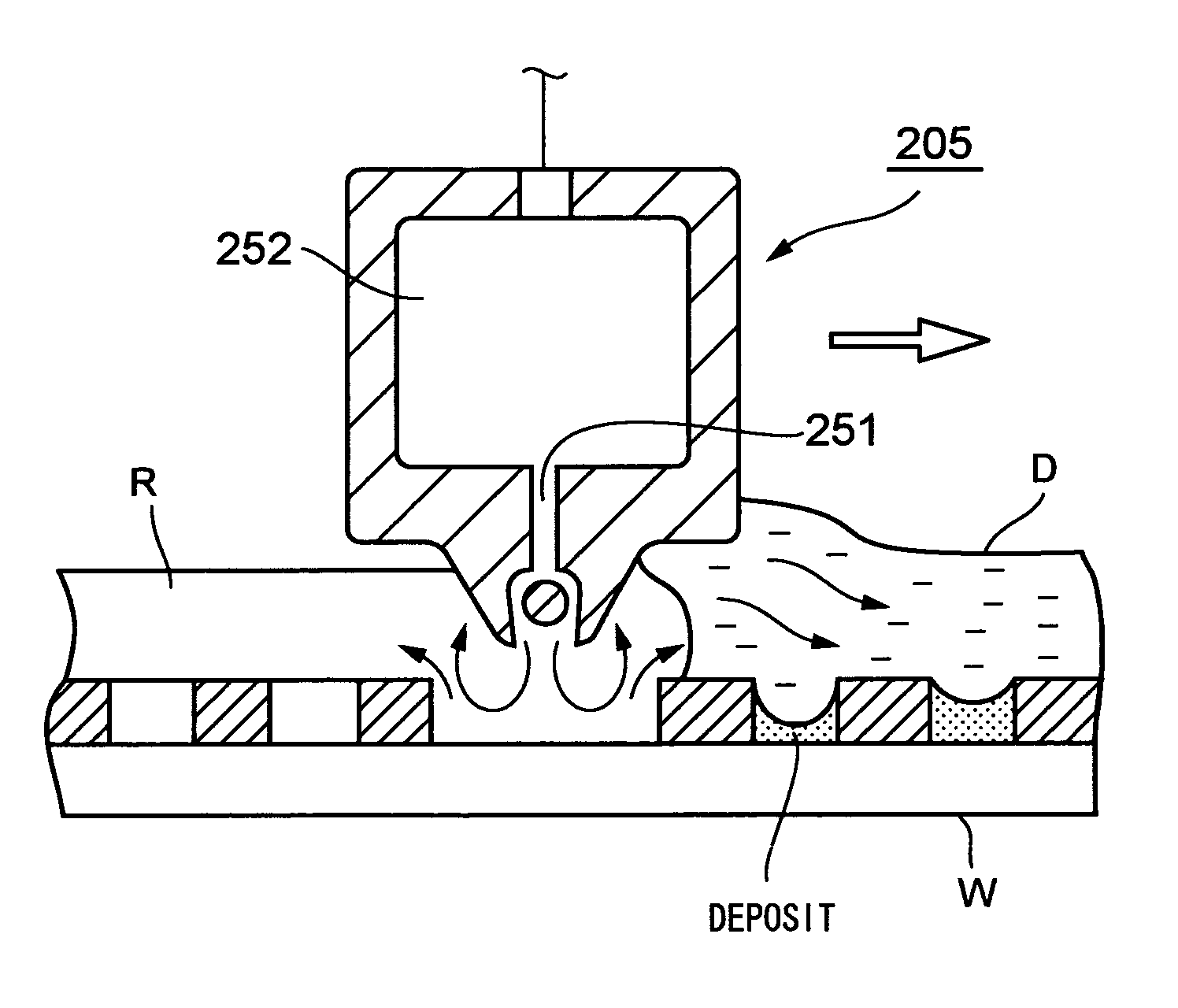

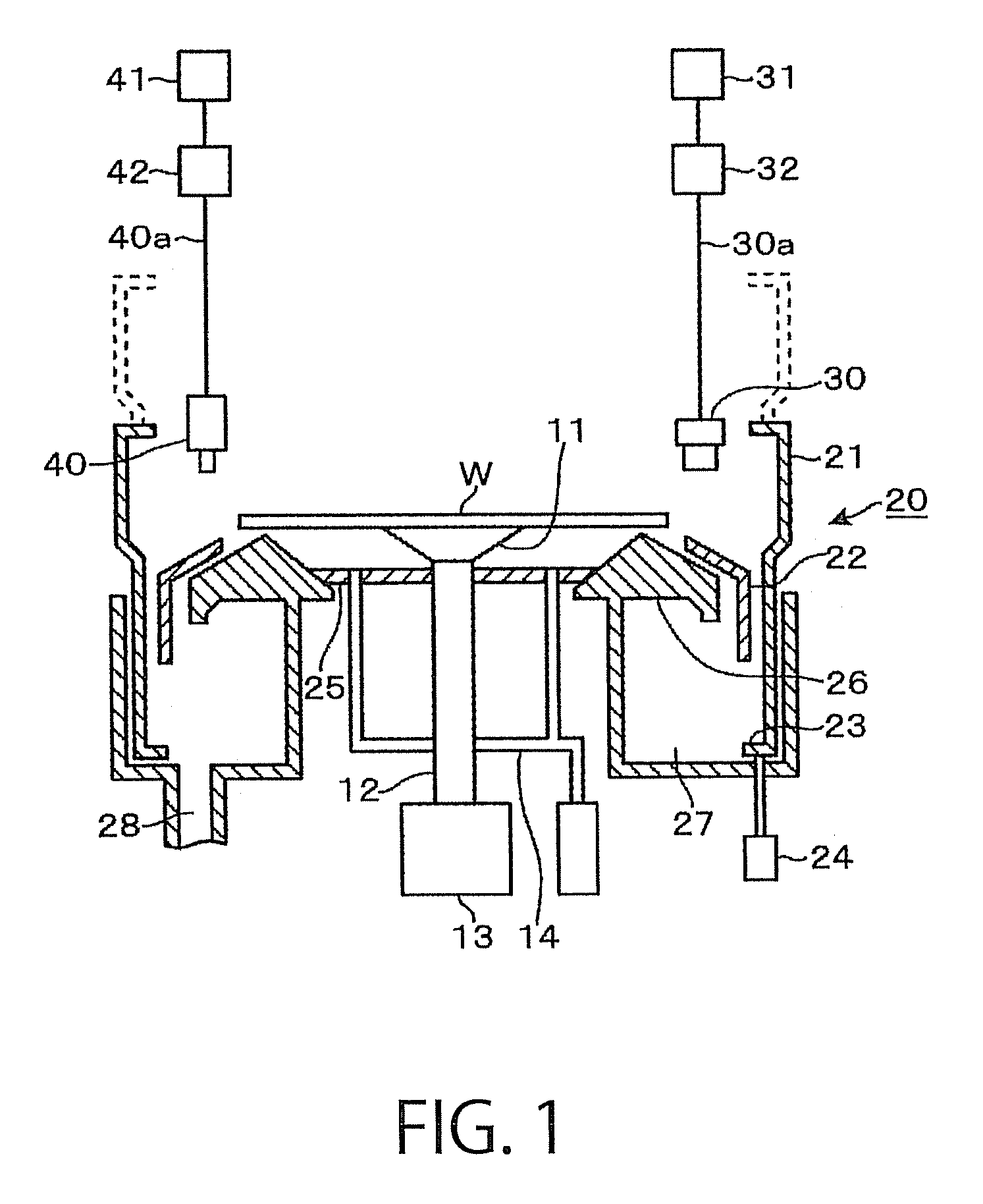

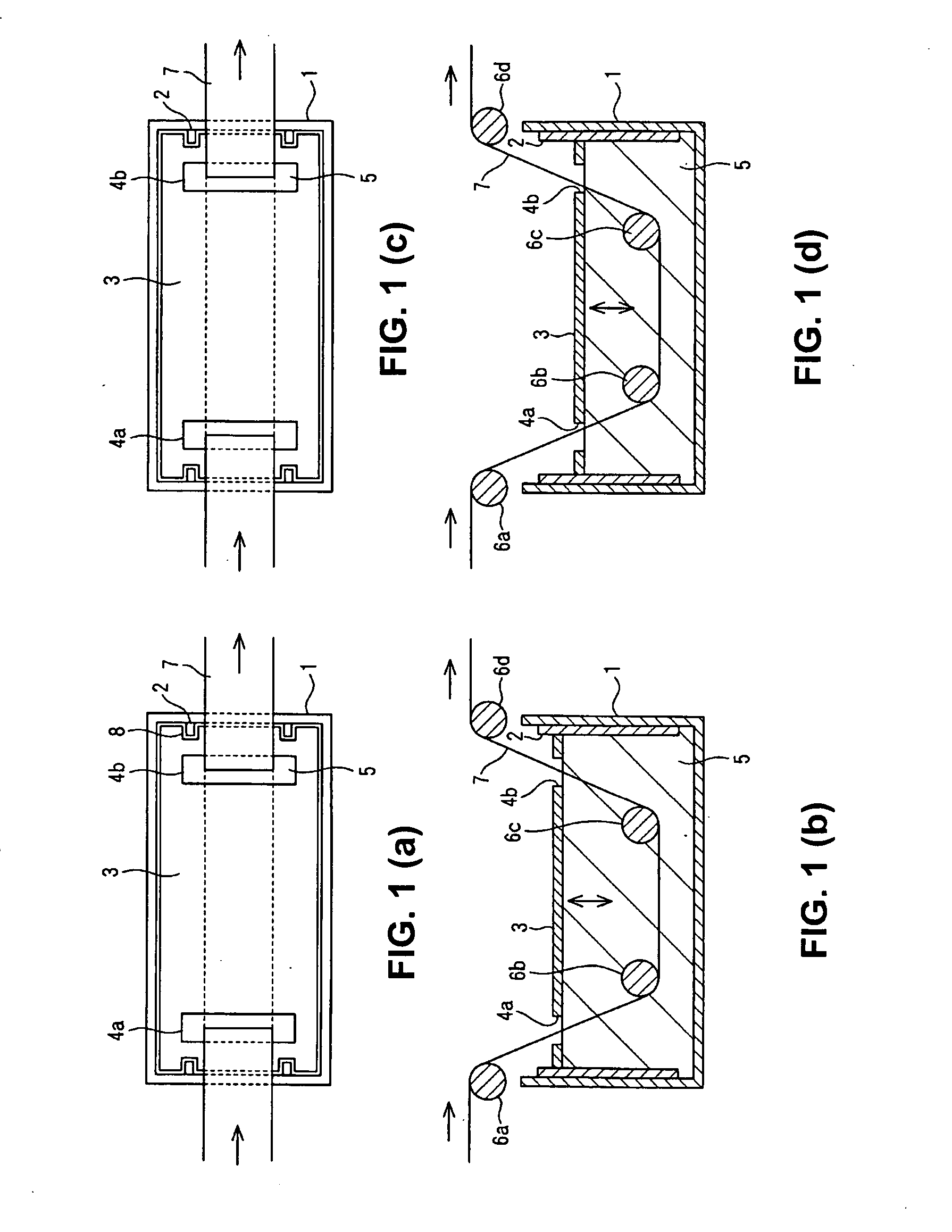

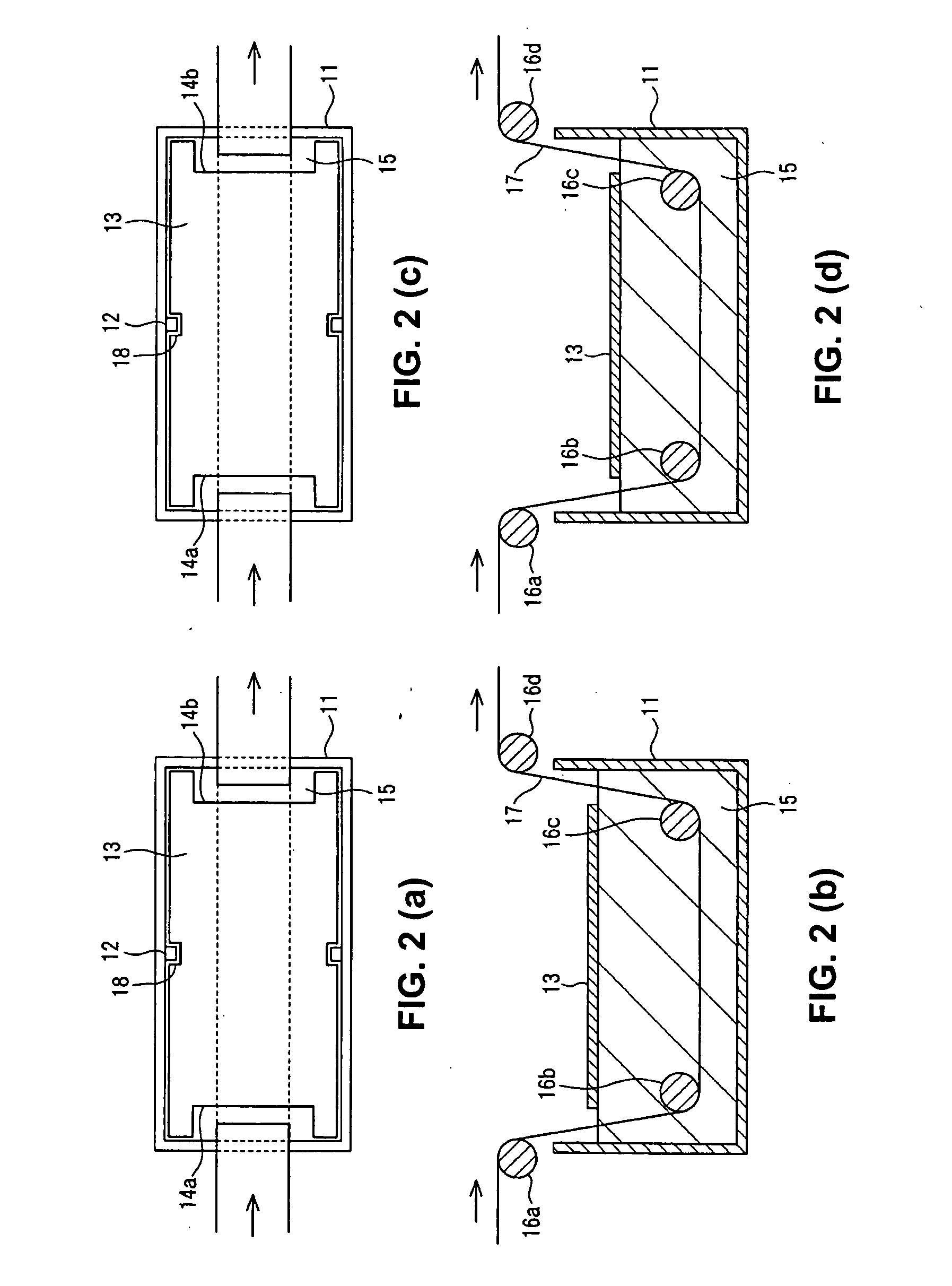

Substrate processing device, substrate processing method, and developing device

InactiveUS20050223980A1Development defect can be reducedShort timeReversal processingDiffusion developmentEngineering

Rinsing nozzles 310a to 310e are moved on a wafer W while they are discharging rinsing solution 326. At that point, discharging openings 317a to 317e are contacted to developing solution 350 coated on the wafer W or rinsing solution 326 on the wafer W. Thus, the impact against the wafer W can be suppressed. As a result, pattern collapse can be prevented. In addition, a front portion of the developing solution 350 can push away the developing solution 350.

Owner:TOKYO ELECTRON LTD

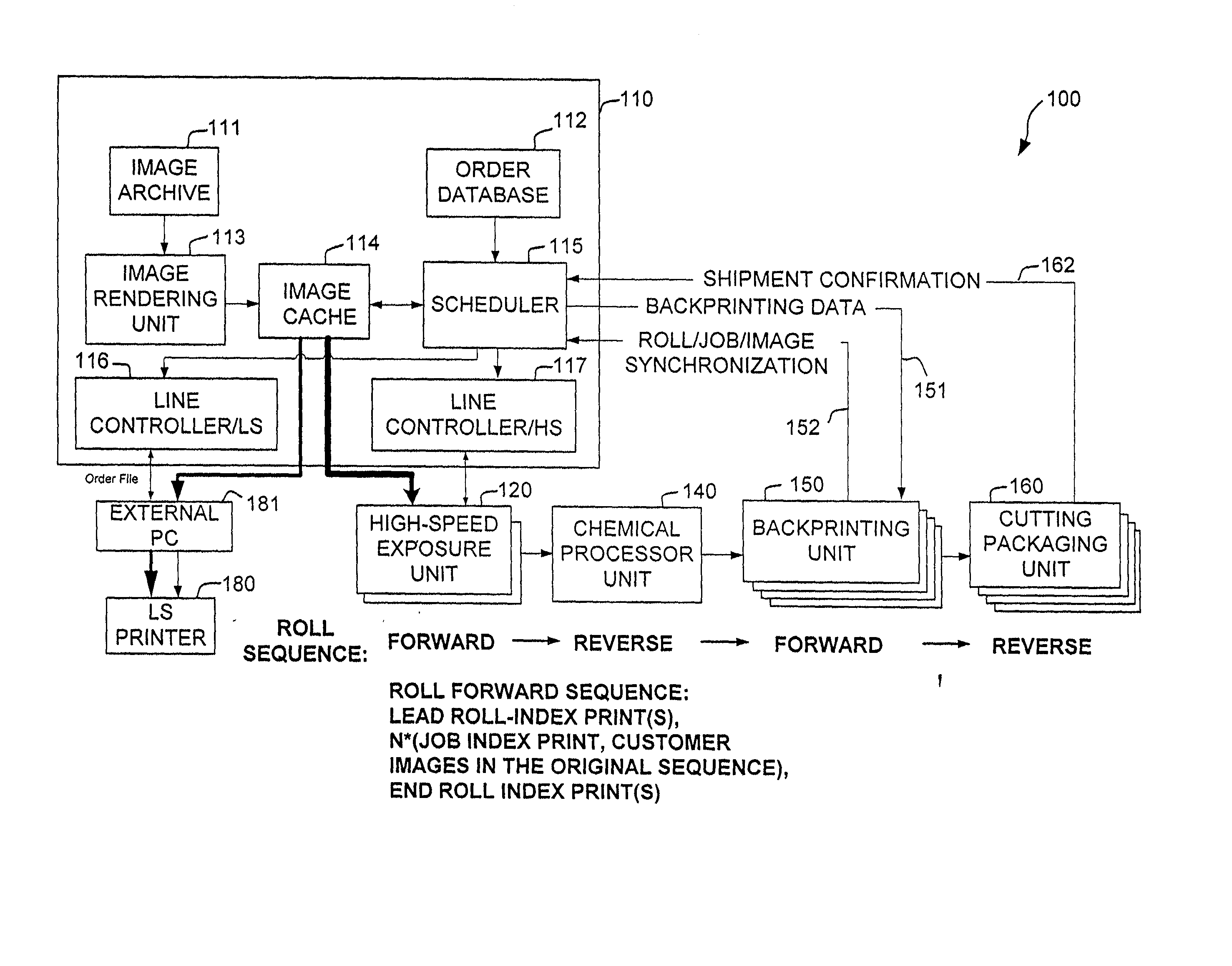

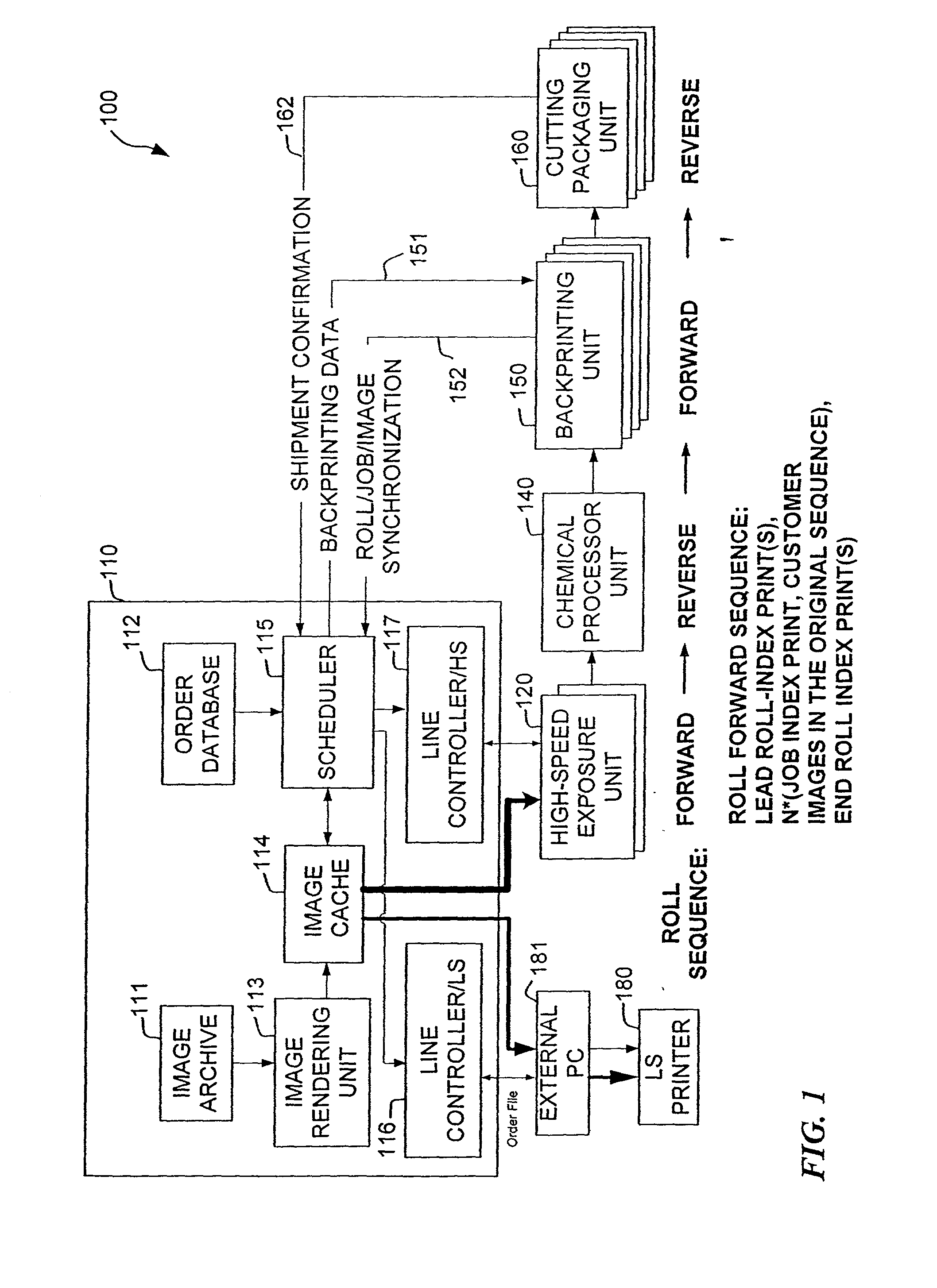

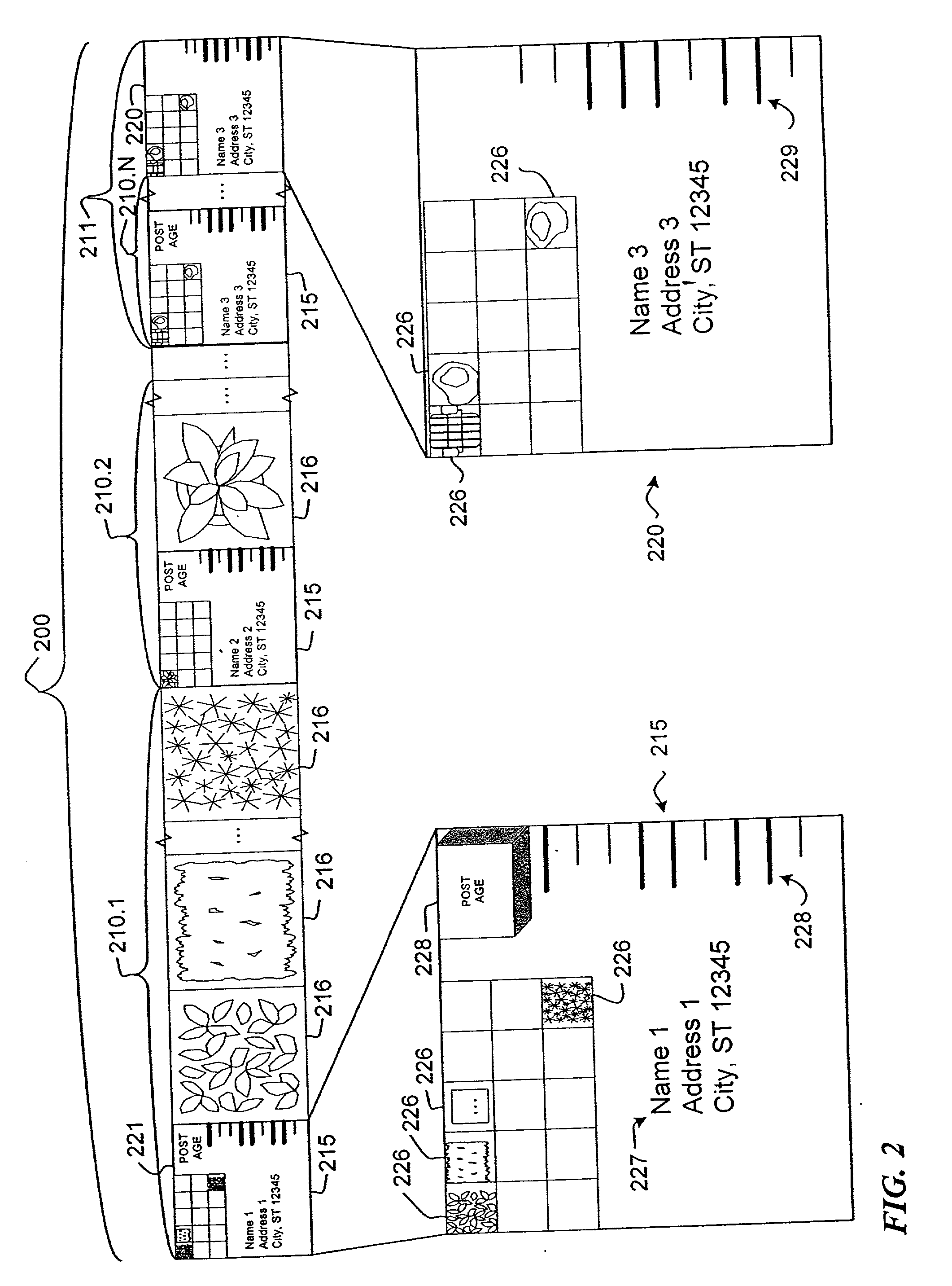

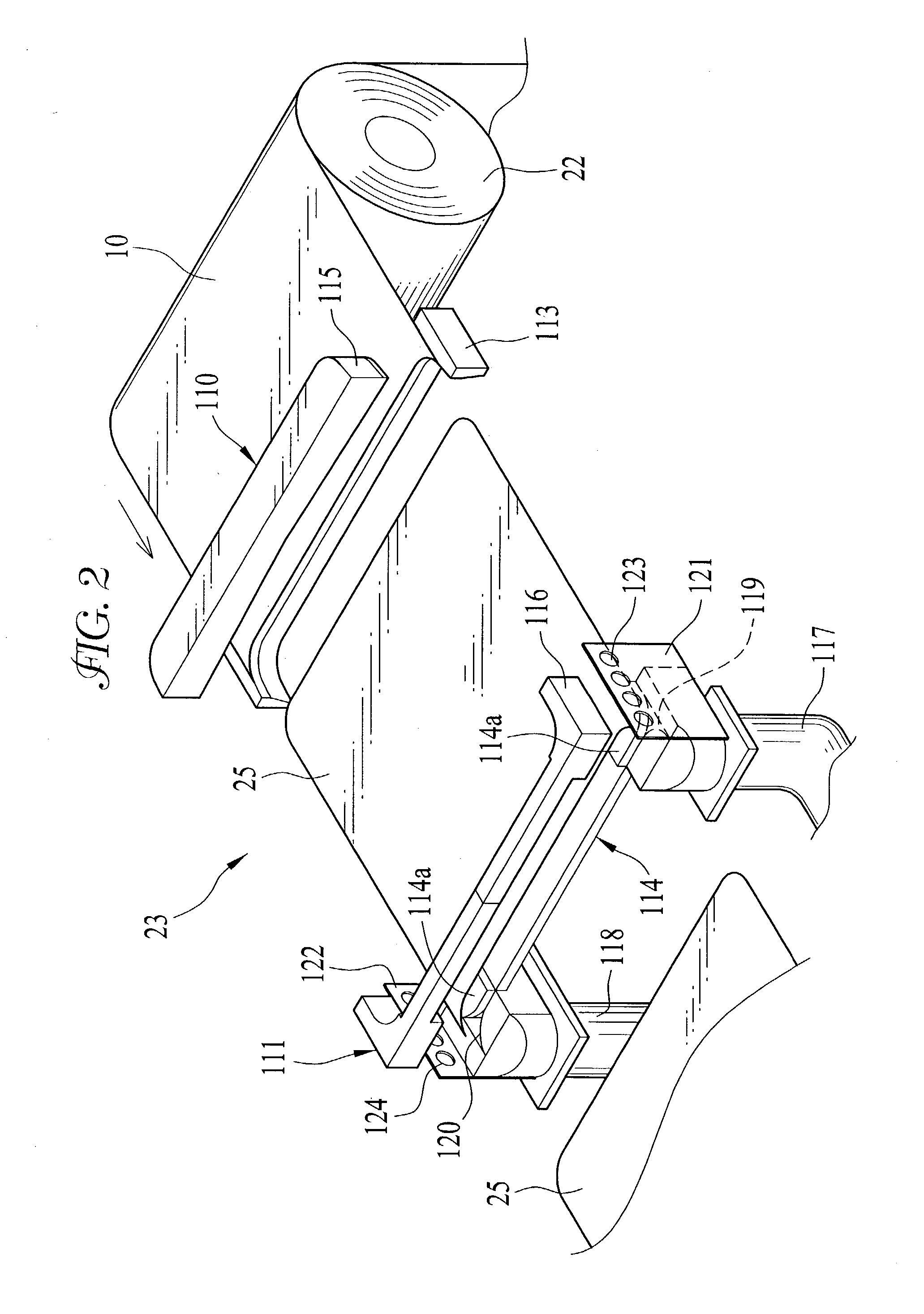

Apparatus, architecture and method for high-speed printing

A high-speed digital photographic printing system and method includes image-specific backprinting and automatic tracking and sorting of printed jobs. The system includes one or more photographic printers, where each printer can have a different printing rate. A scheduler schedules printing orders to the different printers. The printer-independent image rendering is conducted asynchronous to the printing to maximize the printing throughput. In some embodiments, the rendering image processor does the vast majority of the image processing and outputs a printer-independent data file (generally much larger than the source image data file) that requires little if any further data manipulations or processing in the exposure unit. A photographic printing method and system for producing prints in response to input digital images includes a high-speed exposure unit that exposes a photosensitive material coated on a substrate in response to the input digital image, a chemical processor unit that receives and processes the exposed photosensitive material to form visible dye images on the substrate, a backprinting unit that receives the substrate having the visible dye images and prints information on the opposite surface of the substrate to the dye image, and a cutting unit that produces separate sheets of printed images after the backprinting unit prints information.

Owner:SHUTTERFLY LLC

Coating and developing apparatus and coating and developing method

ActiveUS7322756B2Reduce yieldQuality improvementLiquid processingReversal processingEngineeringTransfer mechanism

A coating and developing apparatus comprises a process block which forms a resist film on a wafer, then transfers the wafer to an exposure apparatus, and performs a developing process on the wafer after exposure, and an interface transfer mechanism provided between the process block and the exposure apparatus. The process block includes unit blocks for coating-film formation and unit blocks for development laid out in a stacked manner. When an abnormality occurs in the interface transfer mechanism, an ordinary process in the unit block for coating-film formation is performed on those substrates which are present in that unit block for coating-film formation, after which processed wafers are retreated to a retaining unit and transfer of any wafer into the unit block for coating-film formation is inhibited.

Owner:TOKYO ELECTRON LTD

Method and apparatus for removing organic films

InactiveUS6851873B2Efficient removalRapid stripping rateDetergent mixture composition preparationChemical paints/ink removersOrganic filmResist

A method and an apparatus for removing an organic film, such as a resist film, from a substrate surface are provided wherein a treatment liquid containing dissolved ozone, and preferably formed from liquid ethylene or propylene carbonate, or both, is contacted with the substrate having the organic film, and the organic film removed, wherein the apparatus contains (A) a treatment liquid delivery device, (B) a film contact device, (C) a liquid circulation device and (D) an ozone dissolution device.

Owner:NOMURA MICRO SCI CO LTD +1

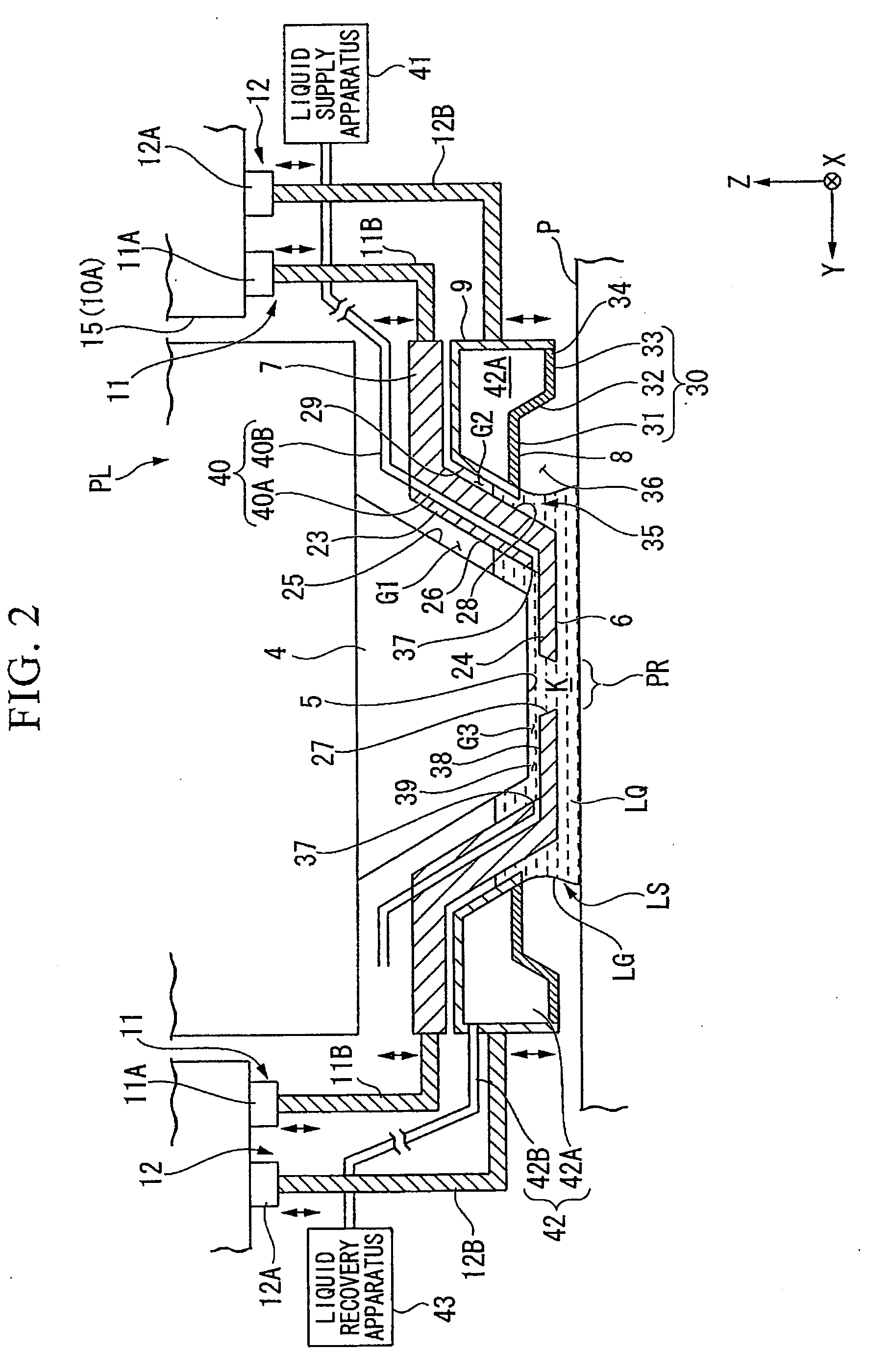

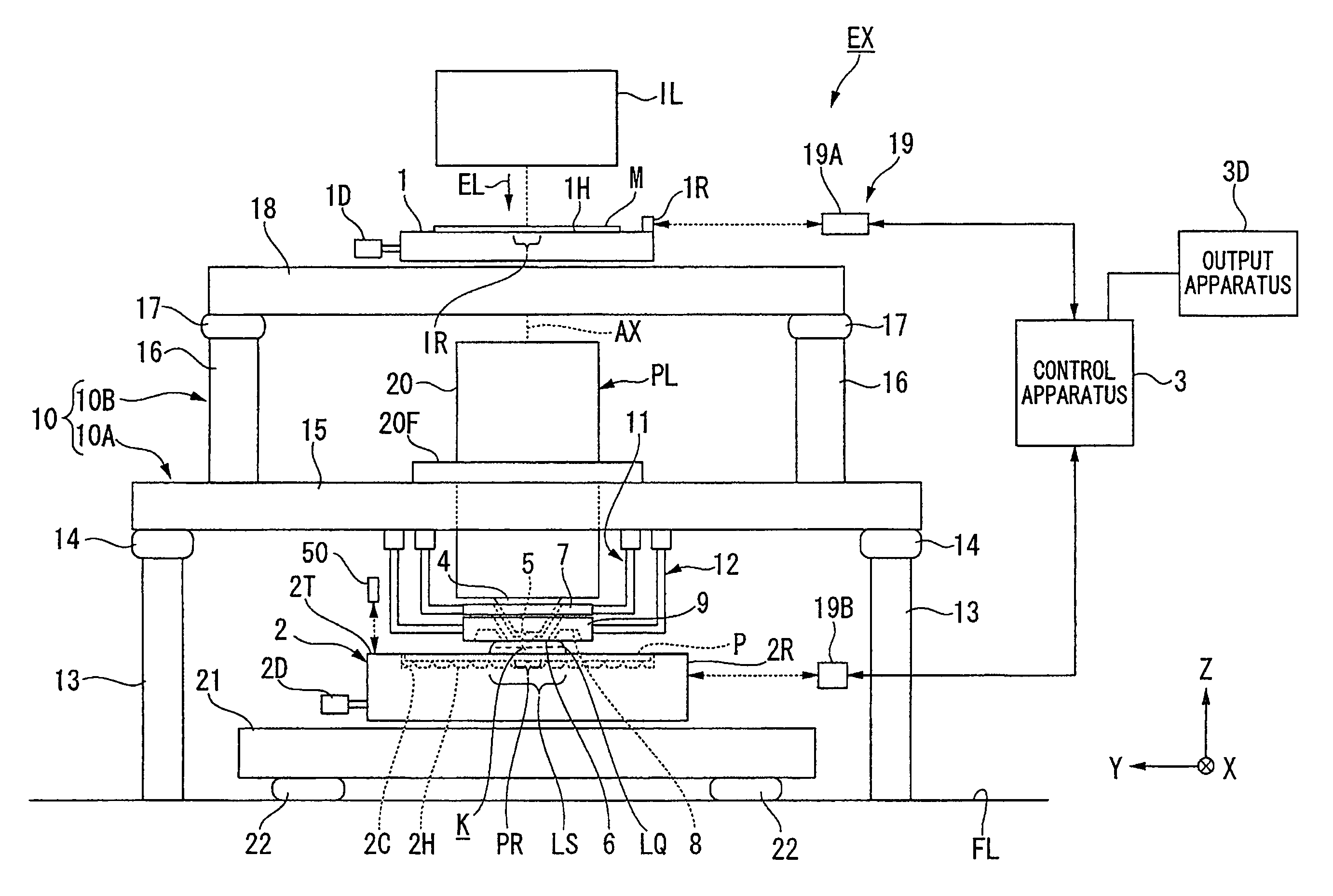

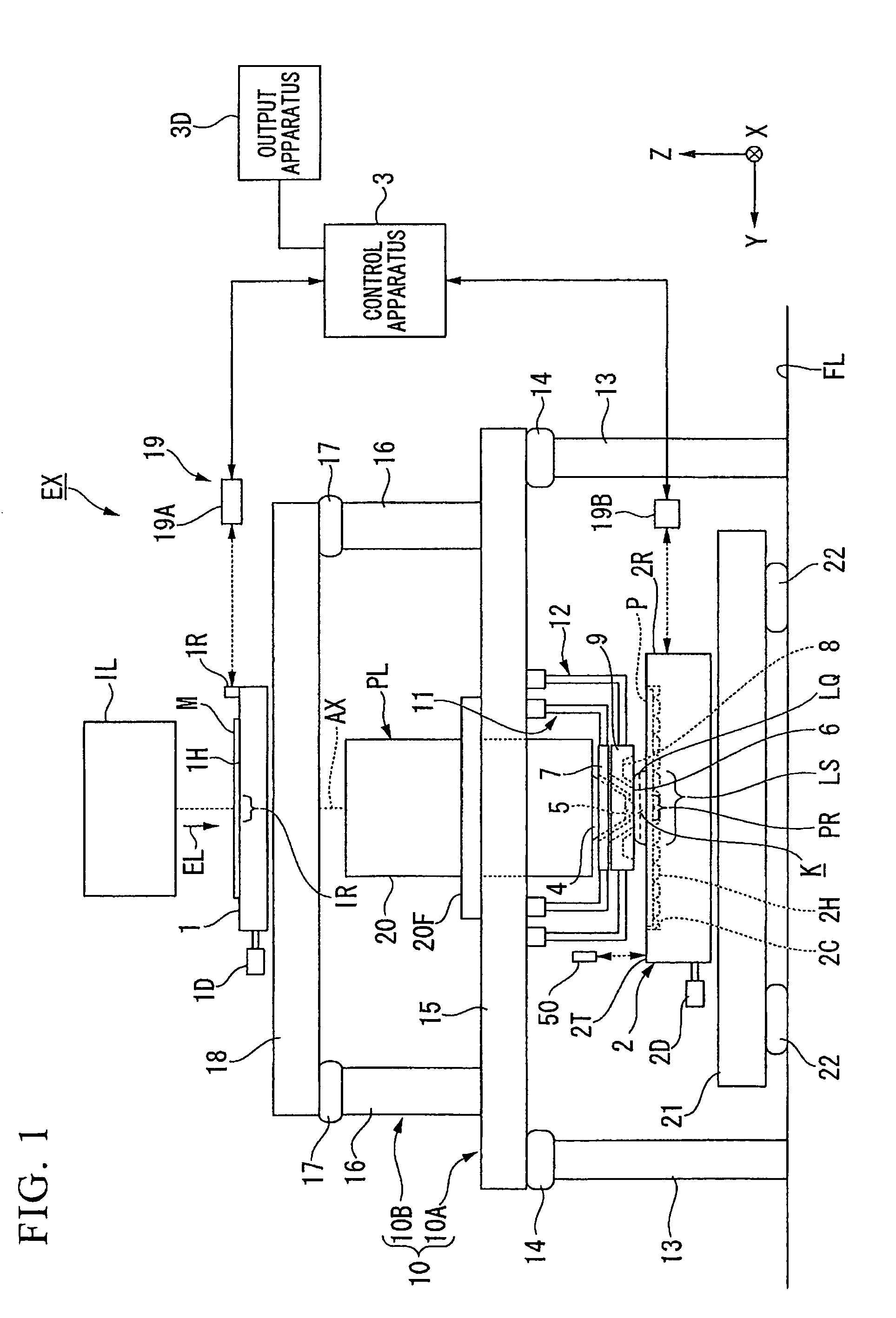

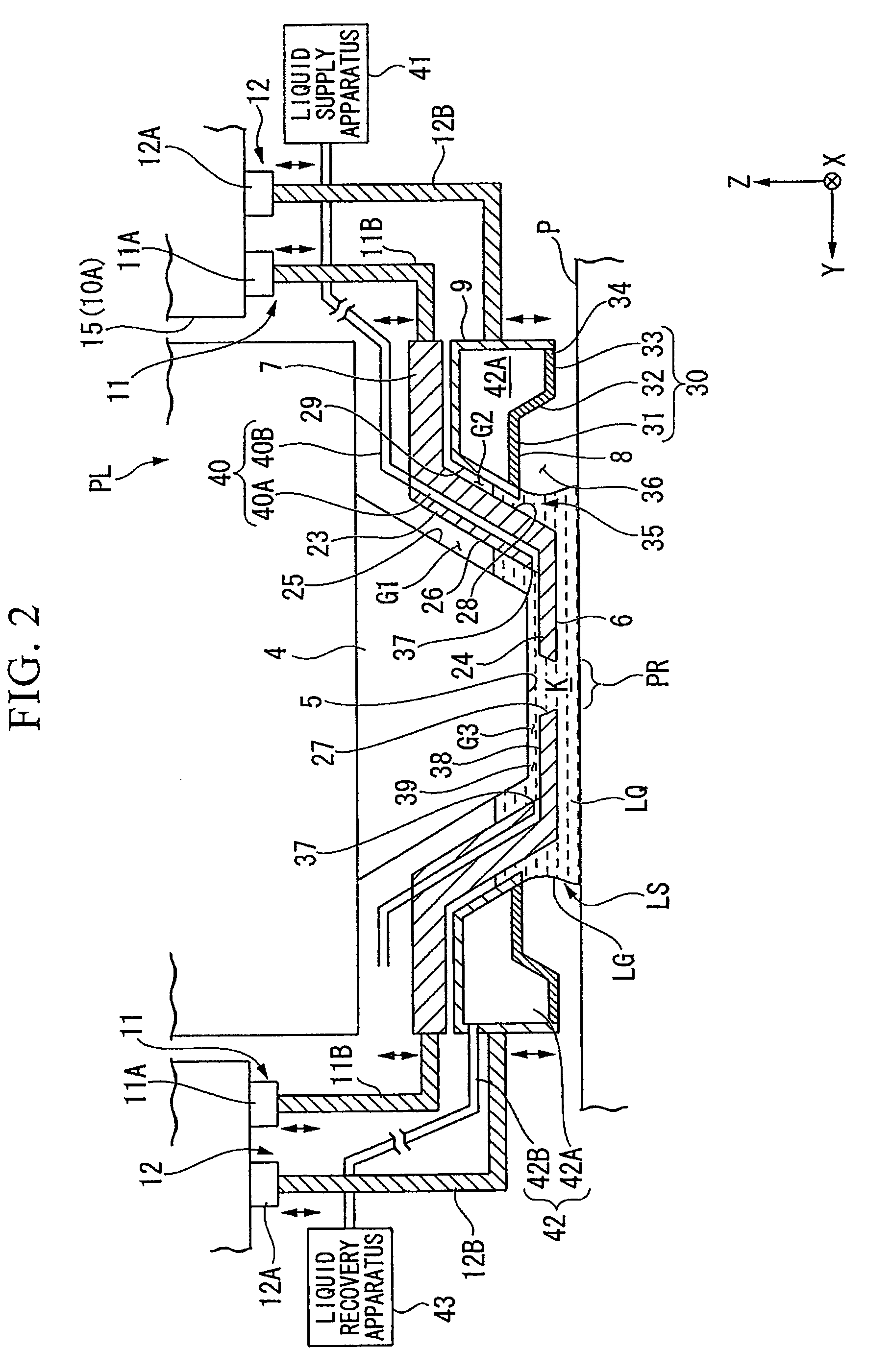

Immersion system, exposure apparatus, exposing method, and device fabricating method

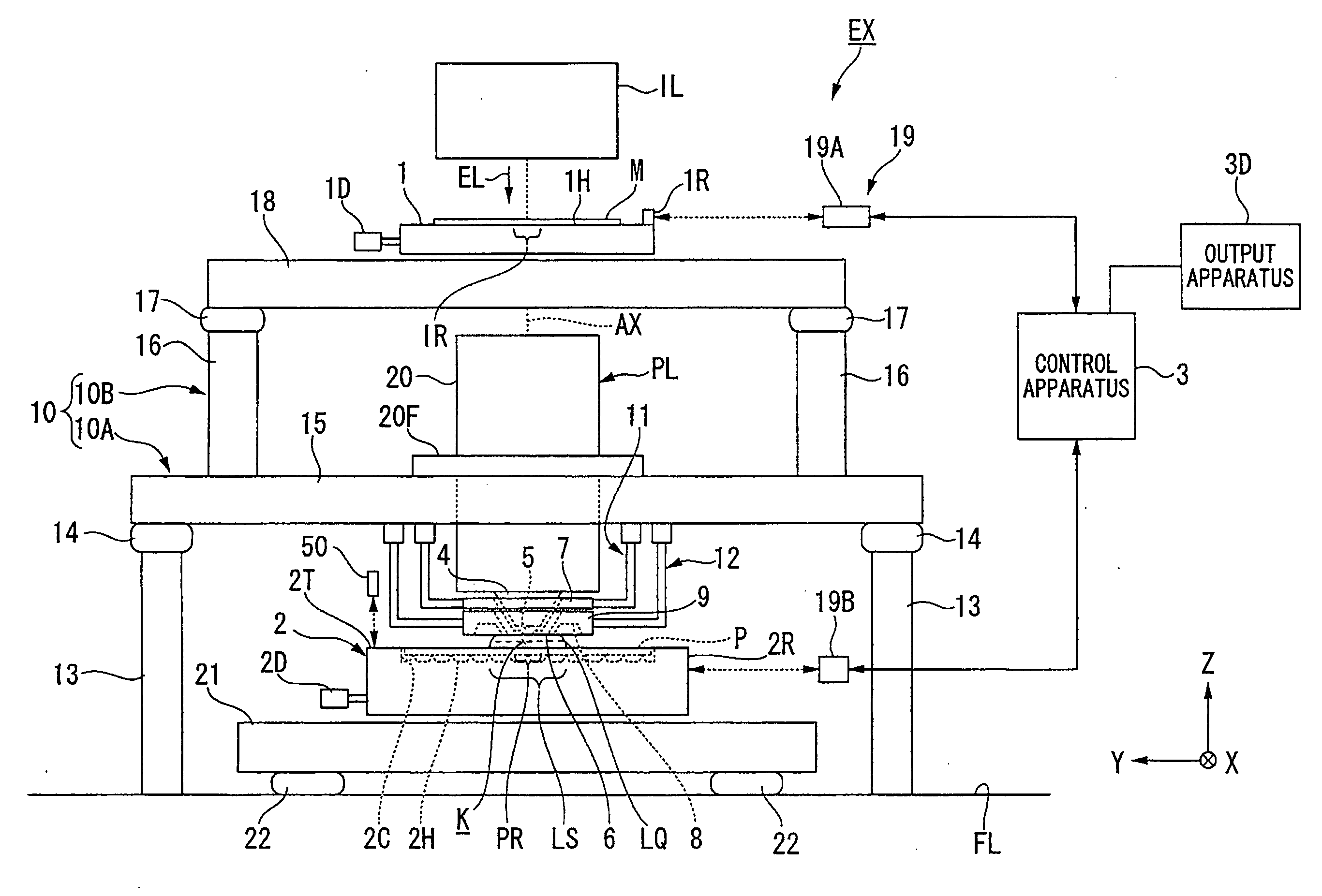

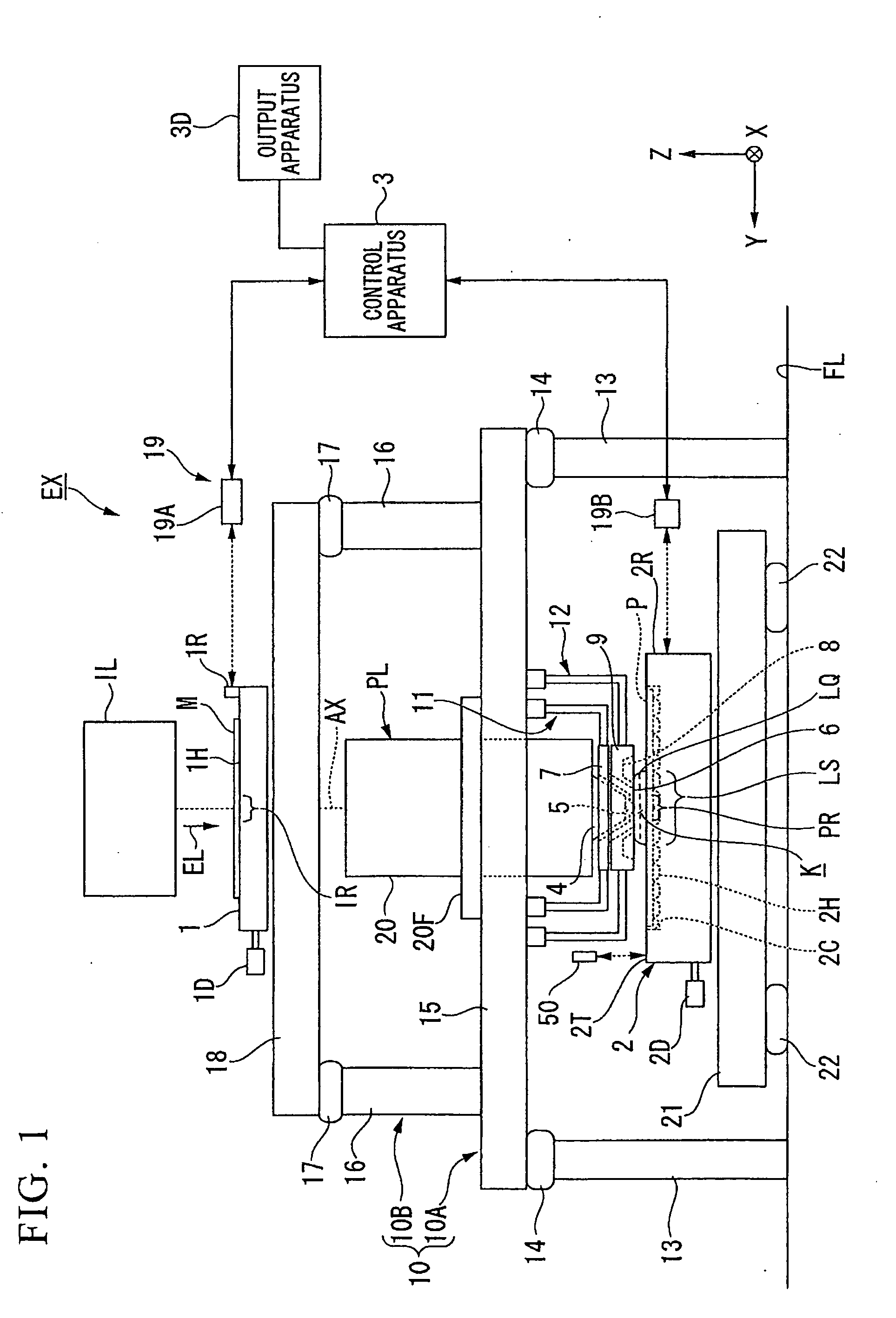

ActiveUS20090280436A1Prevent exposure failureAvoid contactLiquid processingReversal processingOptical path

An immersion system is used in an immersion exposure, wherein a substrate is exposed with an exposure light through an optical member and a liquid, and that fills an optical path of the exposure light between the optical member and the substrate with the liquid. The immersion system comprises: a first member, which is disposed around the optical path of the exposure light and has a first surface that faces in a first direction; a second member that has a liquid recovery port, which is disposed on the outer side of the first surface with respect to the optical path of the exposure light; a first drive apparatus that is capable of moving the first member parallel to the first direction; and a second drive apparatus that is capable of moving the second member parallel to the first direction independently of the first member; wherein, a space between the first surface and a front surface of an object can hold the liquid; and a liquid between the liquid recovery port and the front surface of the object is recovered via the liquid recovery port.

Owner:NIKON CORP

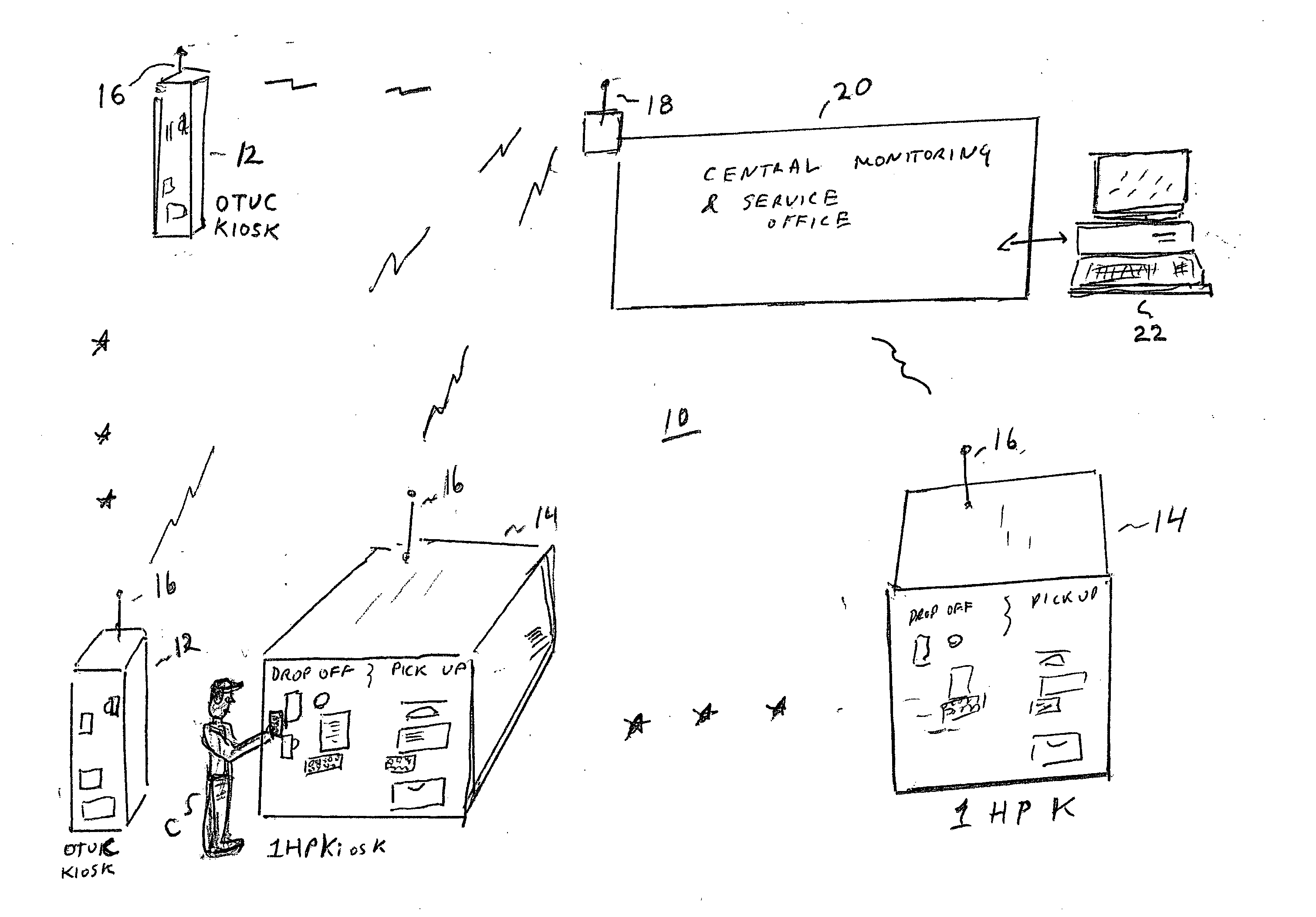

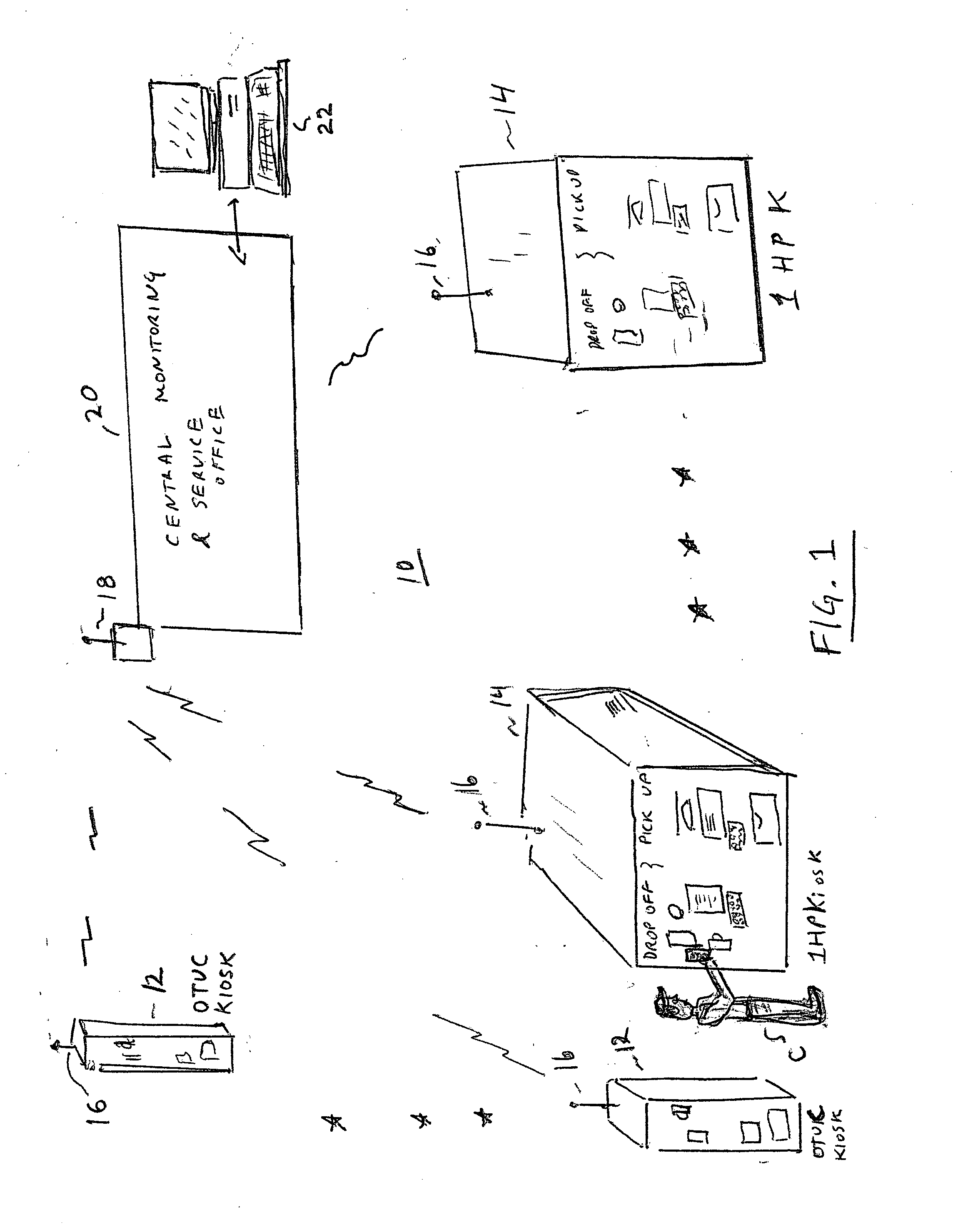

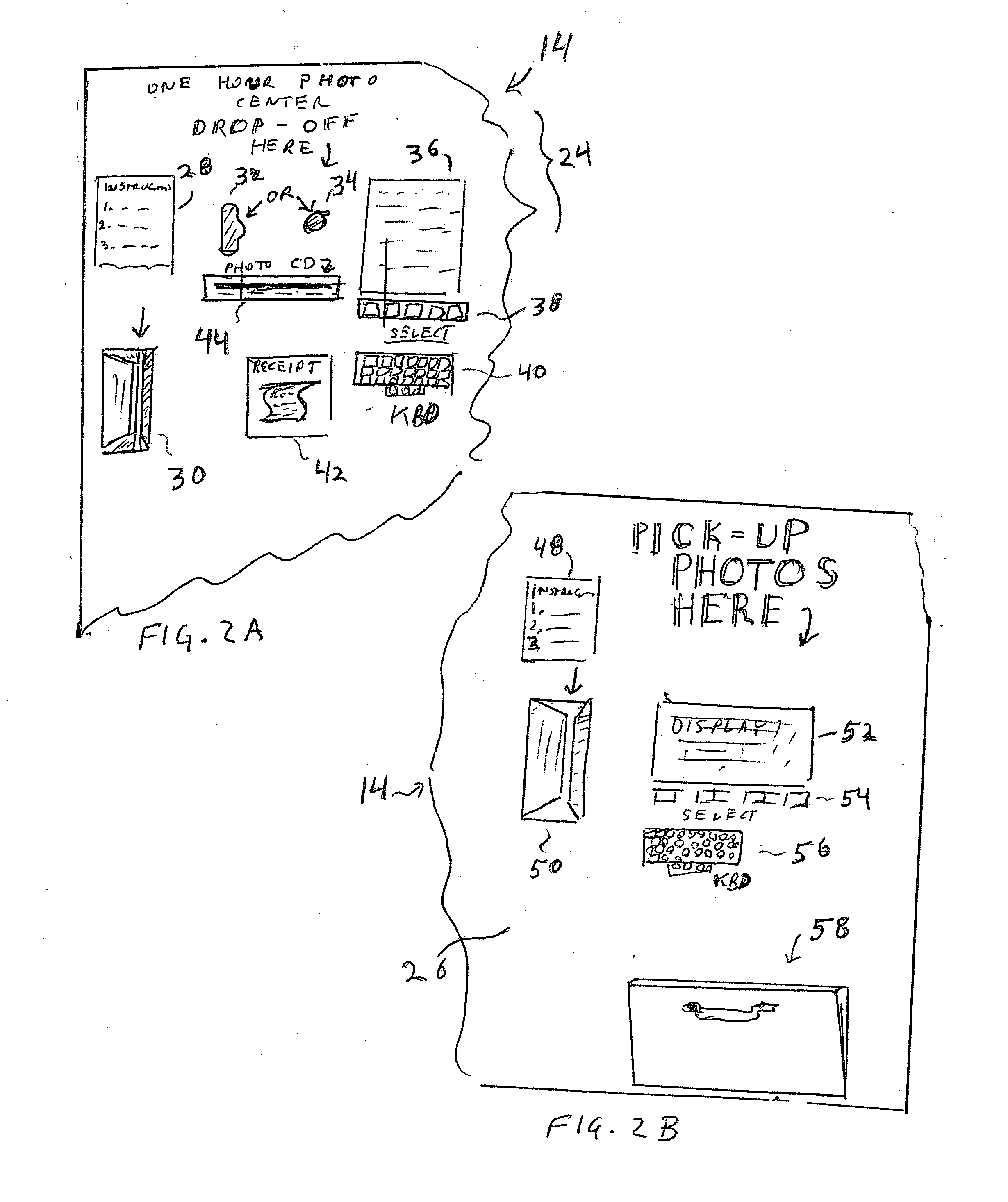

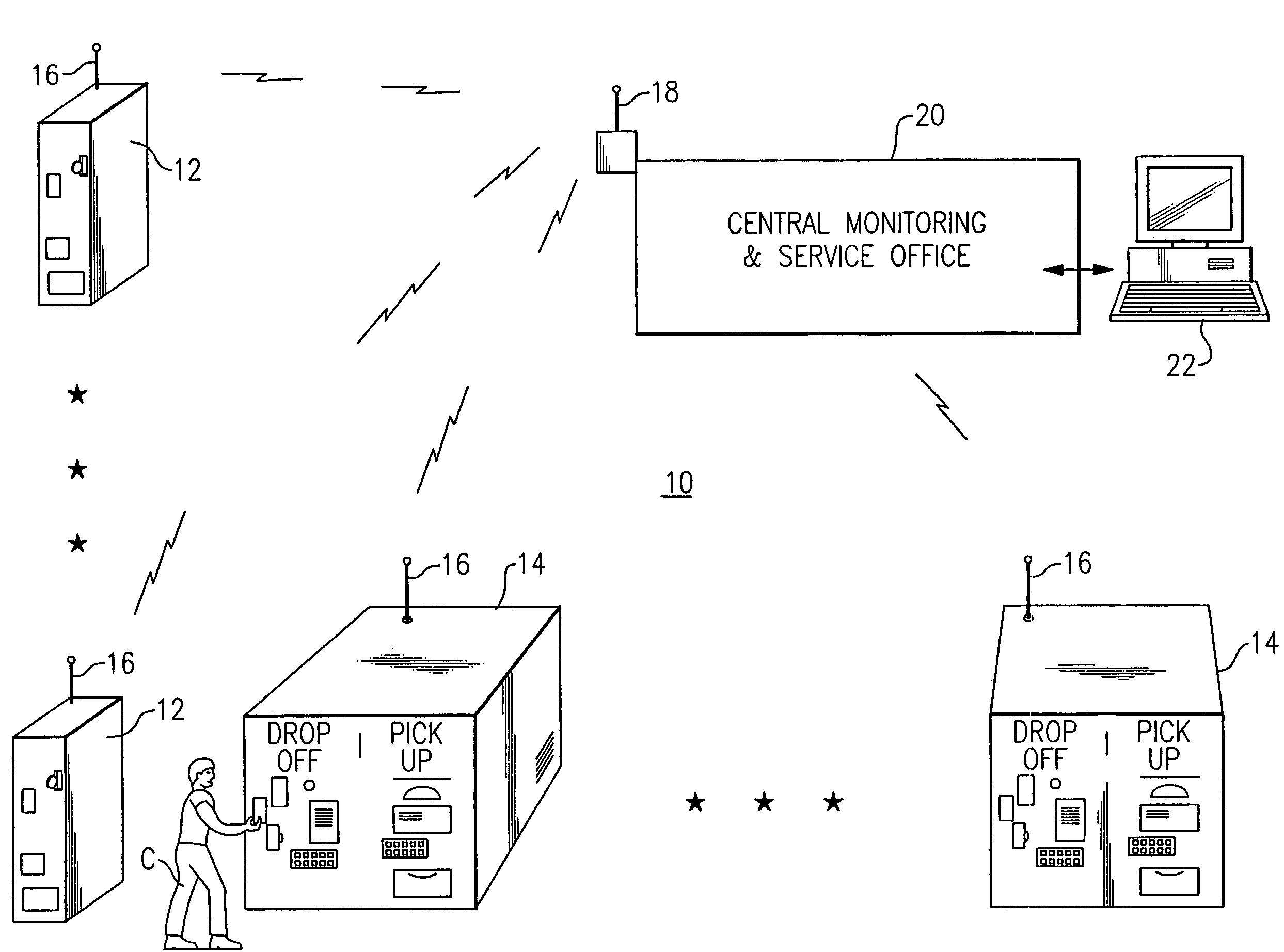

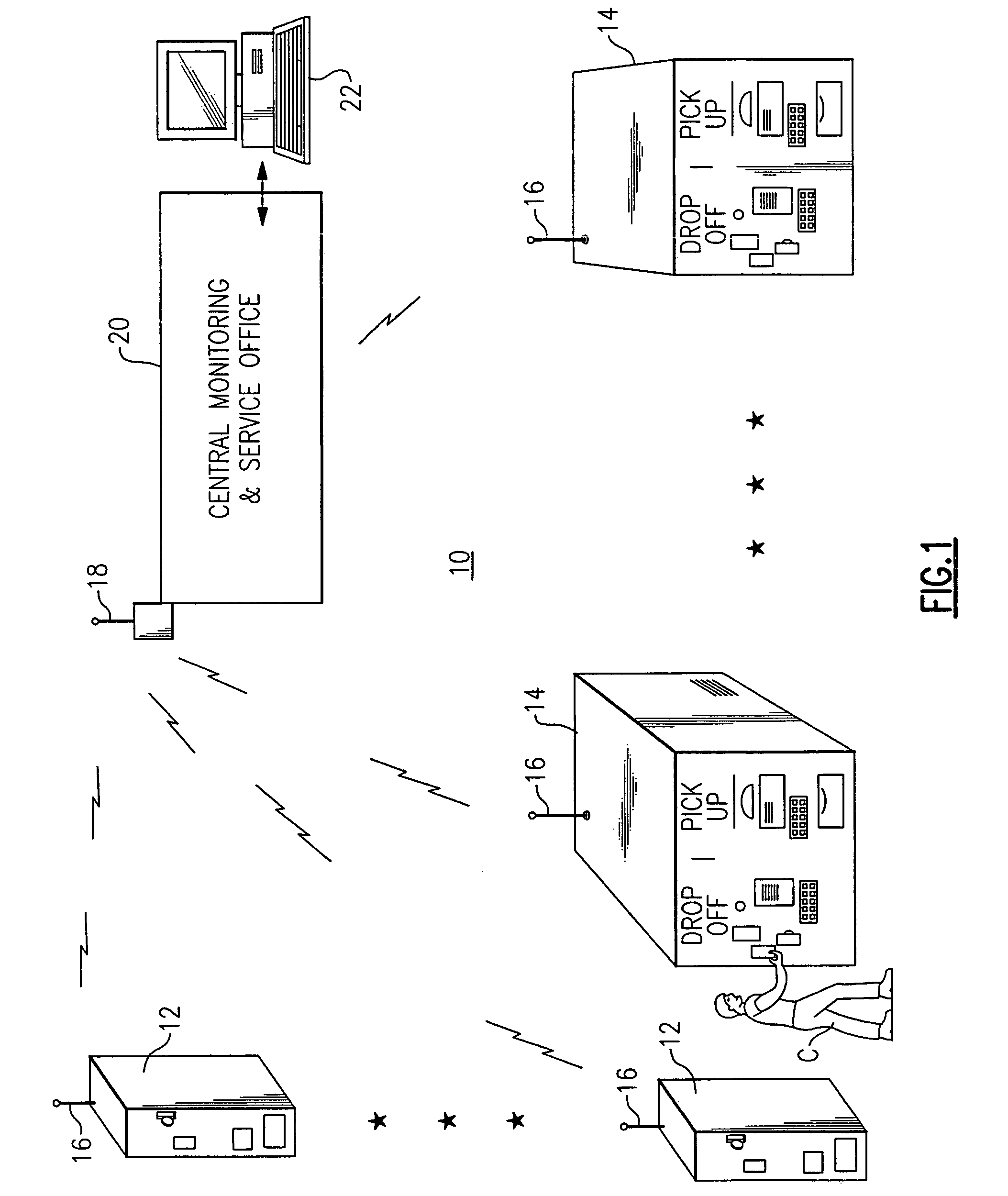

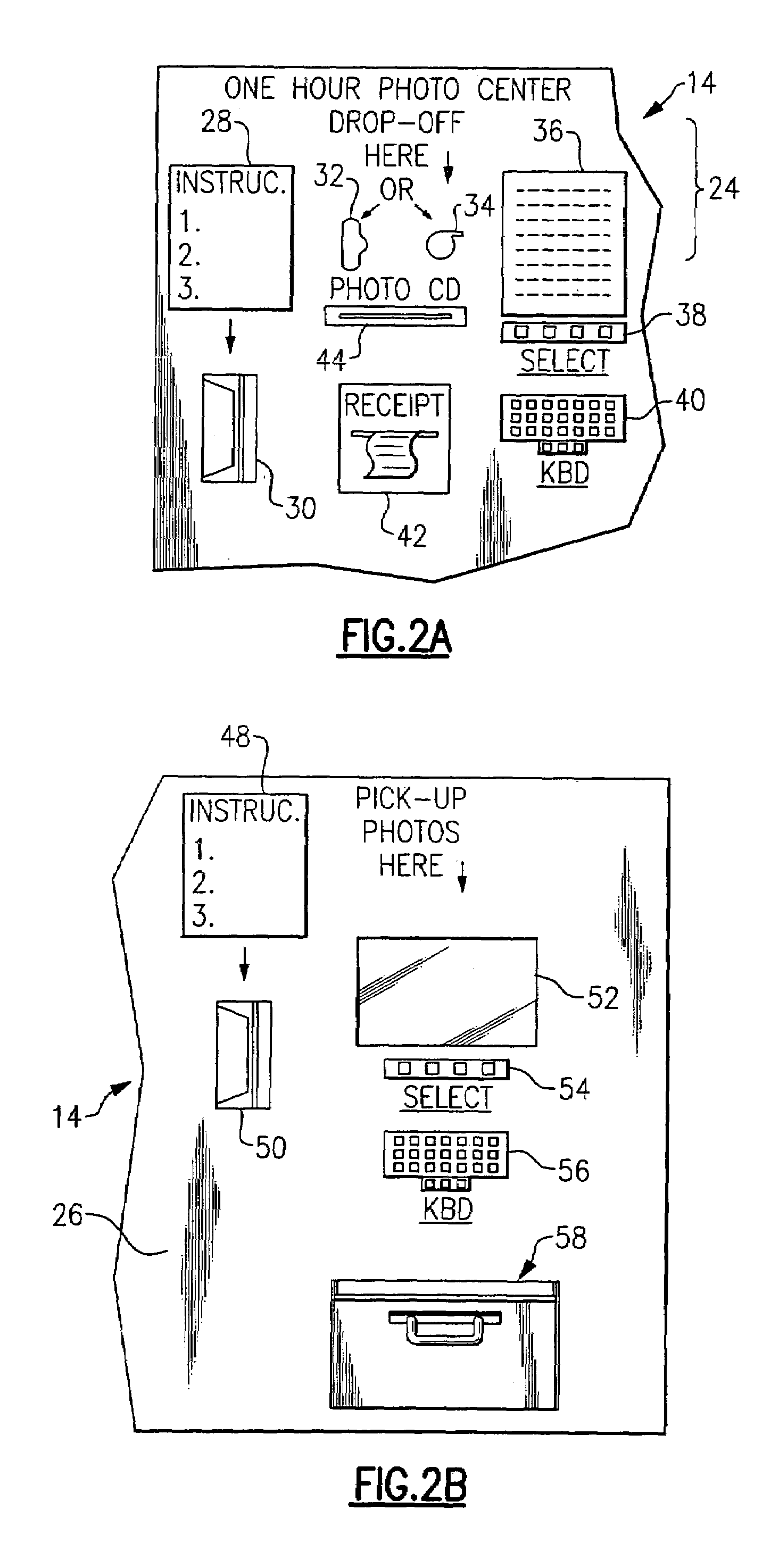

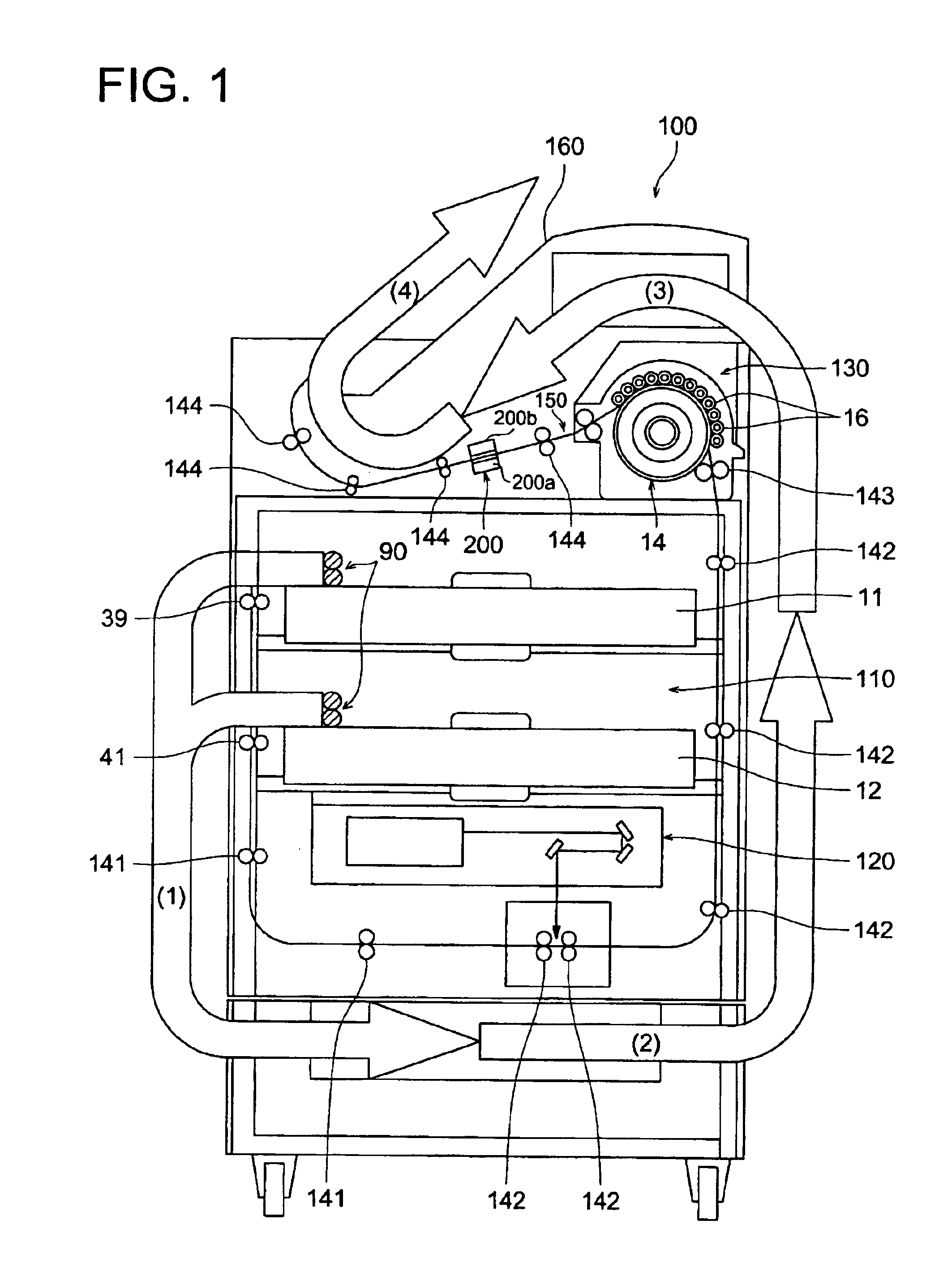

Automated film processing kiosk system

InactiveUS20050047777A1High-speed broadbandQuality of filmLiquid processingReversal processingFilm (photographic)Engineering

Automated film processing kiosk automatically receives and processes a customer film unit, e.g., a film cartridge or OTUC, and the finished prints can be picked up when processing is completed. The interior is climate controlled. The customer swipes a credit or debit card through a card reader, and inserts the exposed film unit into the kiosk. Inside the enclosure a mini-lab processor automatically processes the film, using either a wet or dry process, and extracts images from the film, either negatives, or else as digital images. A digital printer (i.e., color ink-jet printer) produces photographic prints of the customer's images and a print packaging unit packages and labels the photographic prints for each customer film unit, and an optional optical disk with digital images. A storage carousel within enclosure has chambers for storing the packaged prints for the customers. At pick-up, the customer swipes a card through for identification. A carousel unload mechanism transfers the customer's finished prints from the carousel to a delivery bin. A communications module communicates order status, inventory, and equipment status to a central monitoring station. Print correction for color, density, and contrast can be carried out remotely.

Owner:MOLLDREM JR BERNHARD P

Automated film processing kiosk system

InactiveUS6985673B2Quality of filmEnsure film qualityLiquid processingReversal processingCard readerDigital image

Automated unattended film processing kiosk permits a customer to drop off a film unit, e.g., OTUC, and come back later to pick up the finished prints. The customer swipes a credit or debit card through a card reader, and inserts the exposed film unit. Inside the enclosure a mini-lab processor automatically processes the film and extracts images from the film, as negatives or as digital images. A digital printer makes prints of the customer's images. The photographic prints are packaged and labeled, and provided with an optional optical disk. A carousel stores the packaged prints for the customers. At pick-up, the customer swipes a card through for identification. An unload mechanism transfers the customer's finished prints from the carousel to a delivery bin. Print correction for color, density, and contrast can be carried out remotely.

Owner:MOLLDREM JR BERNHARD P

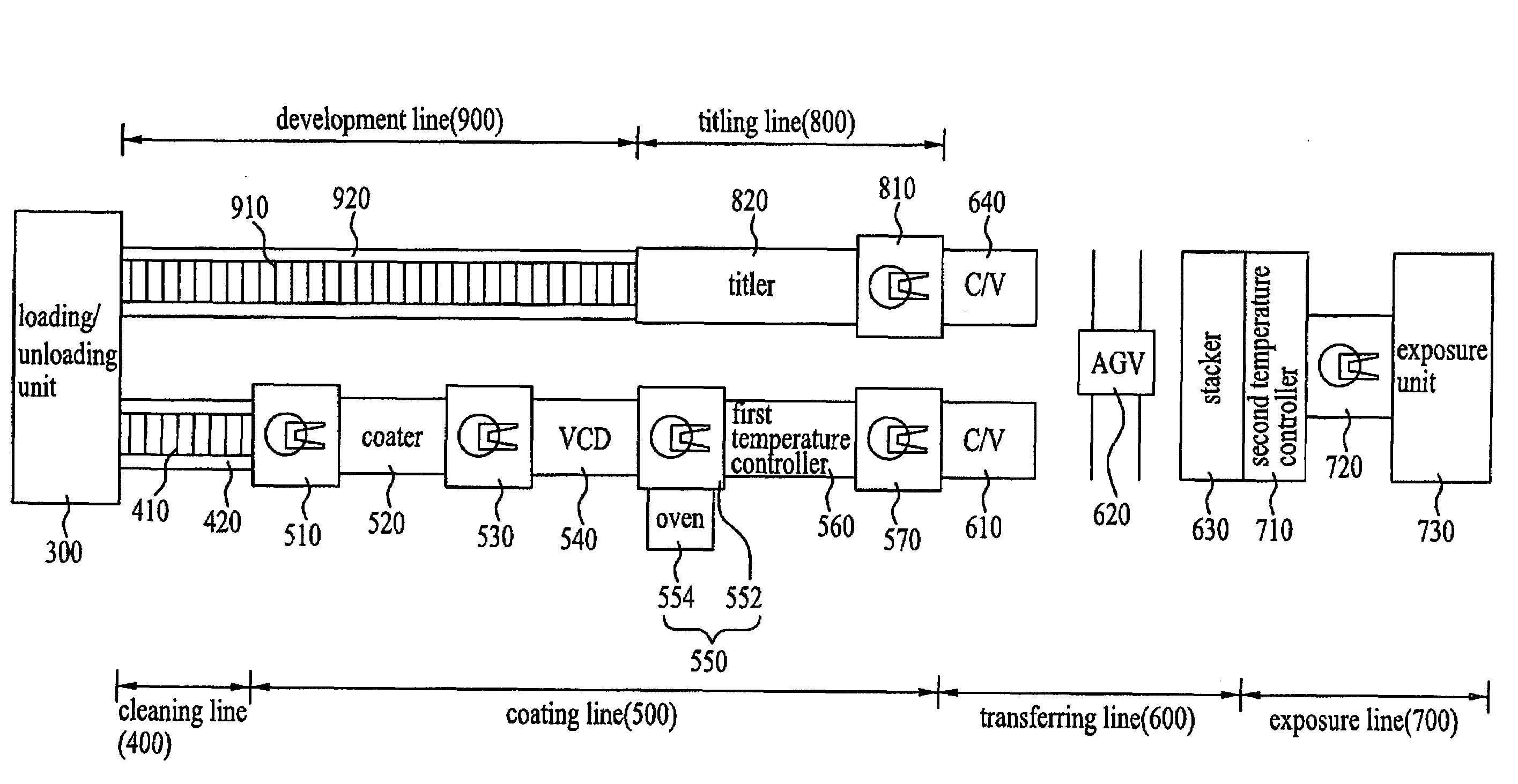

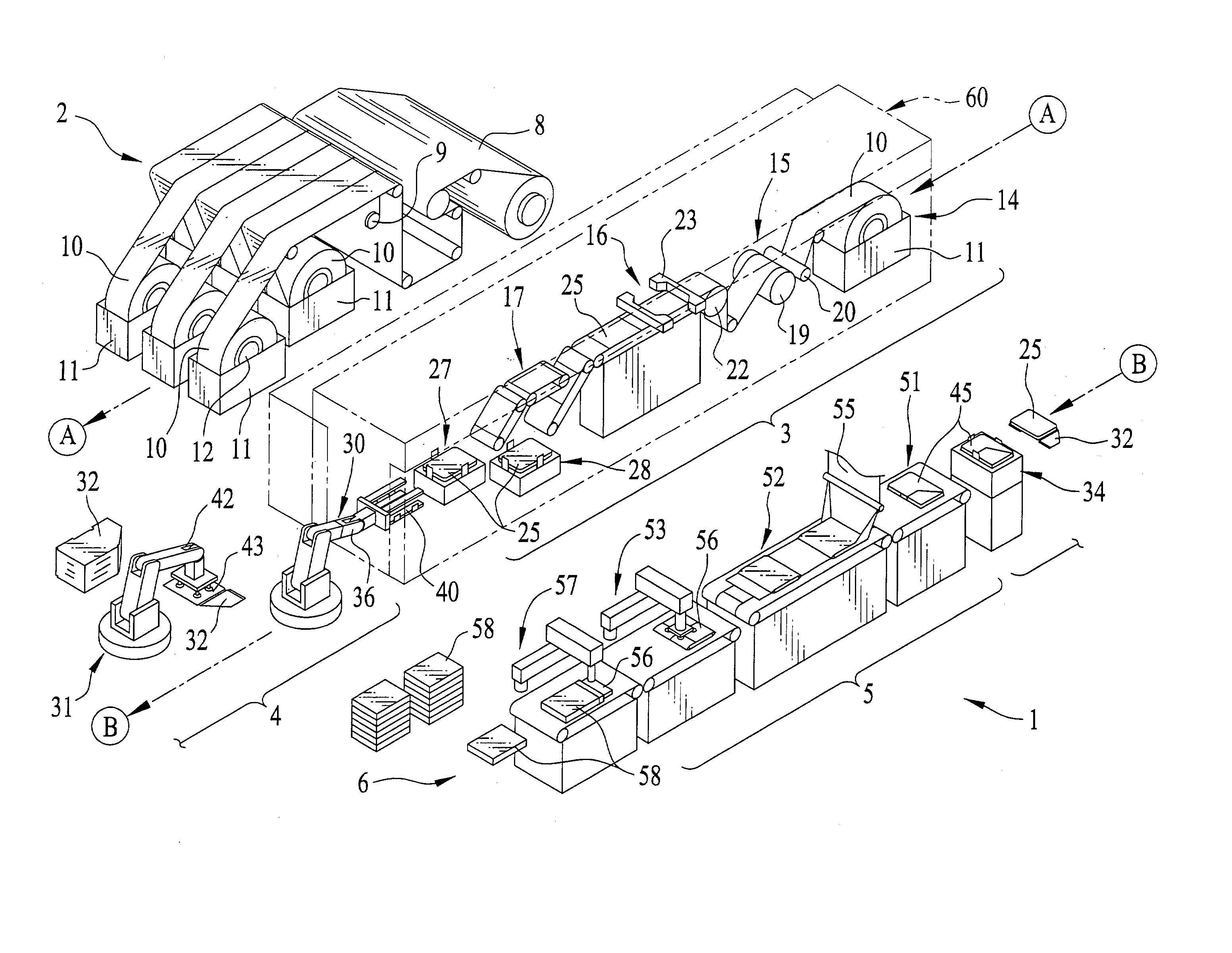

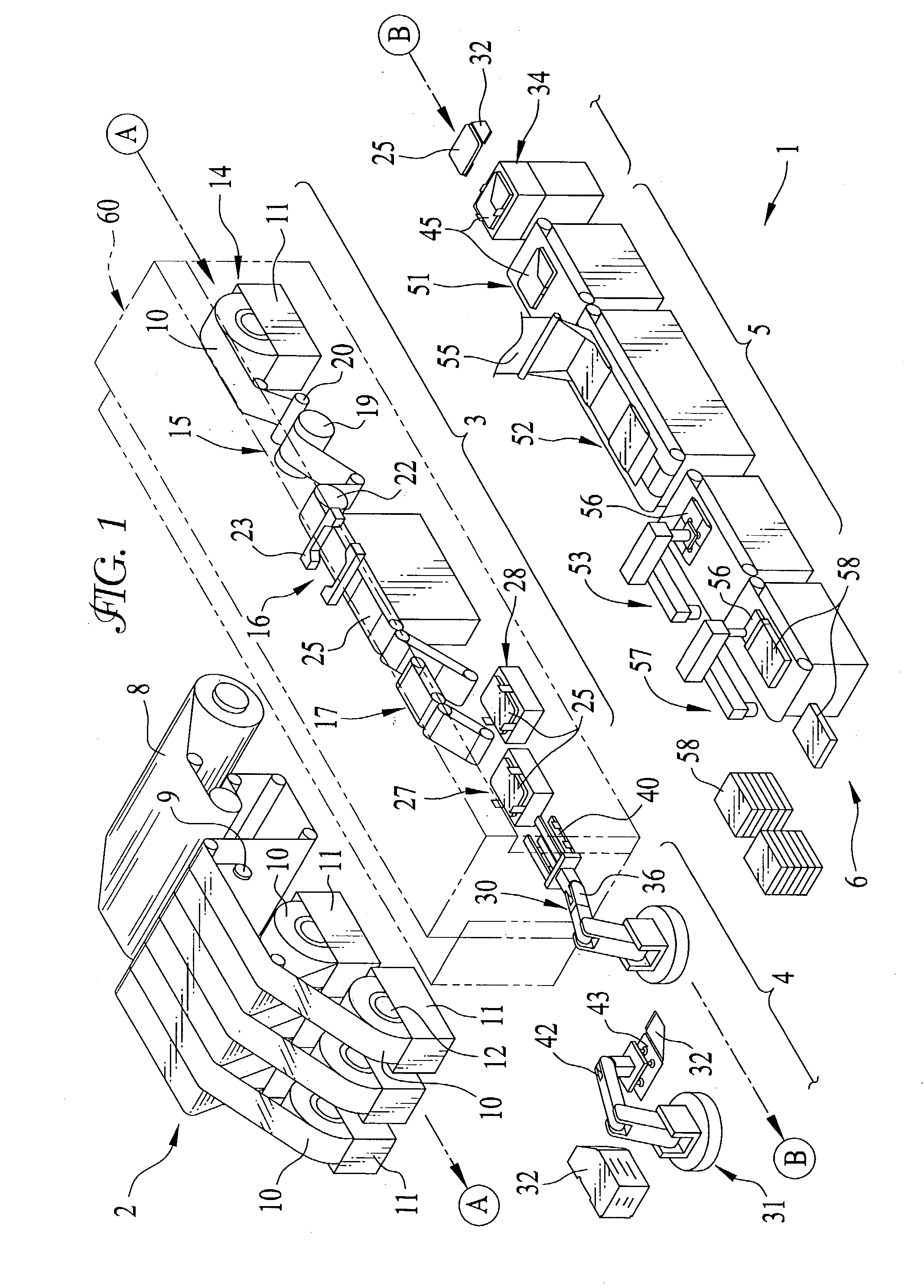

Photo apparatus and method

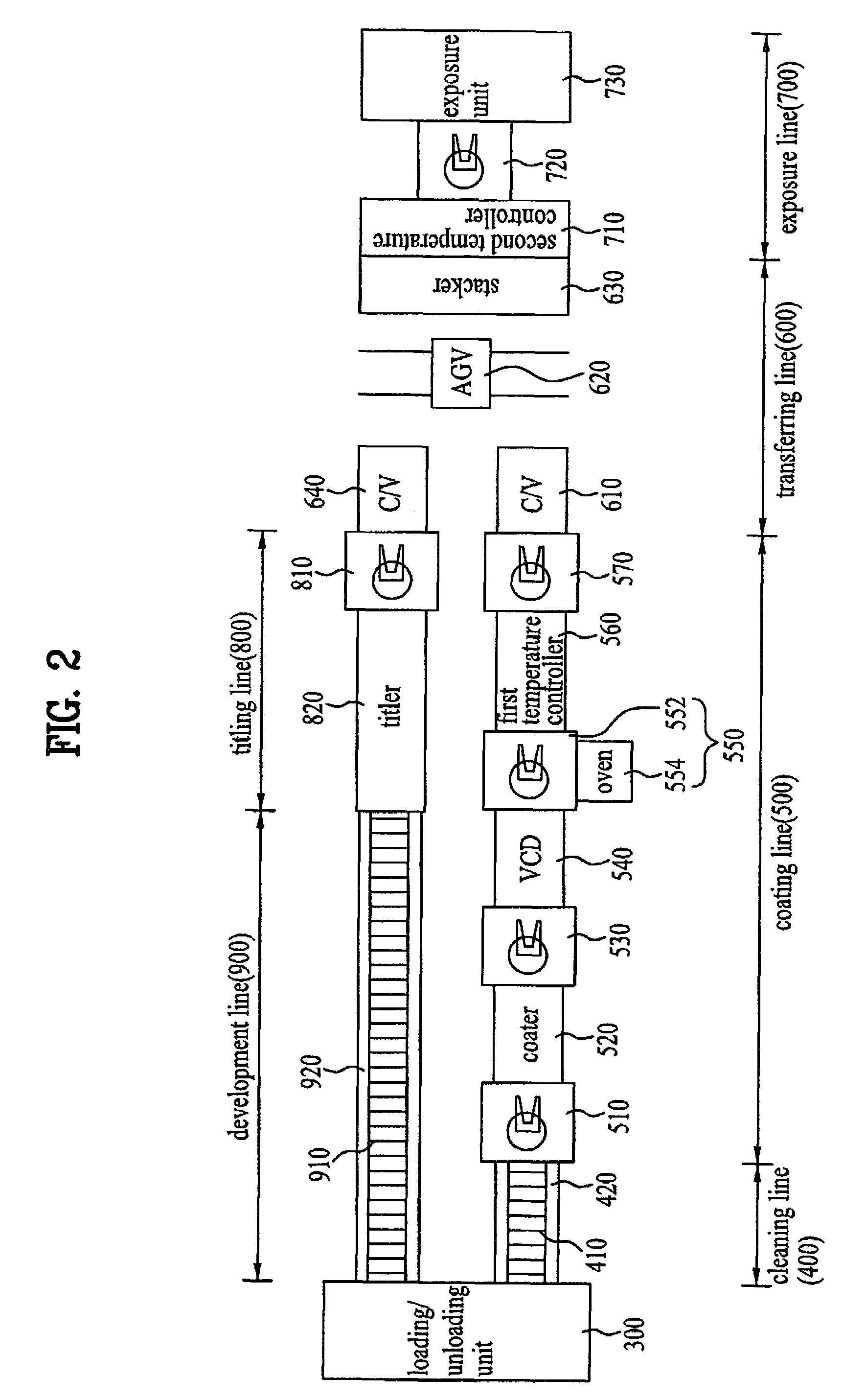

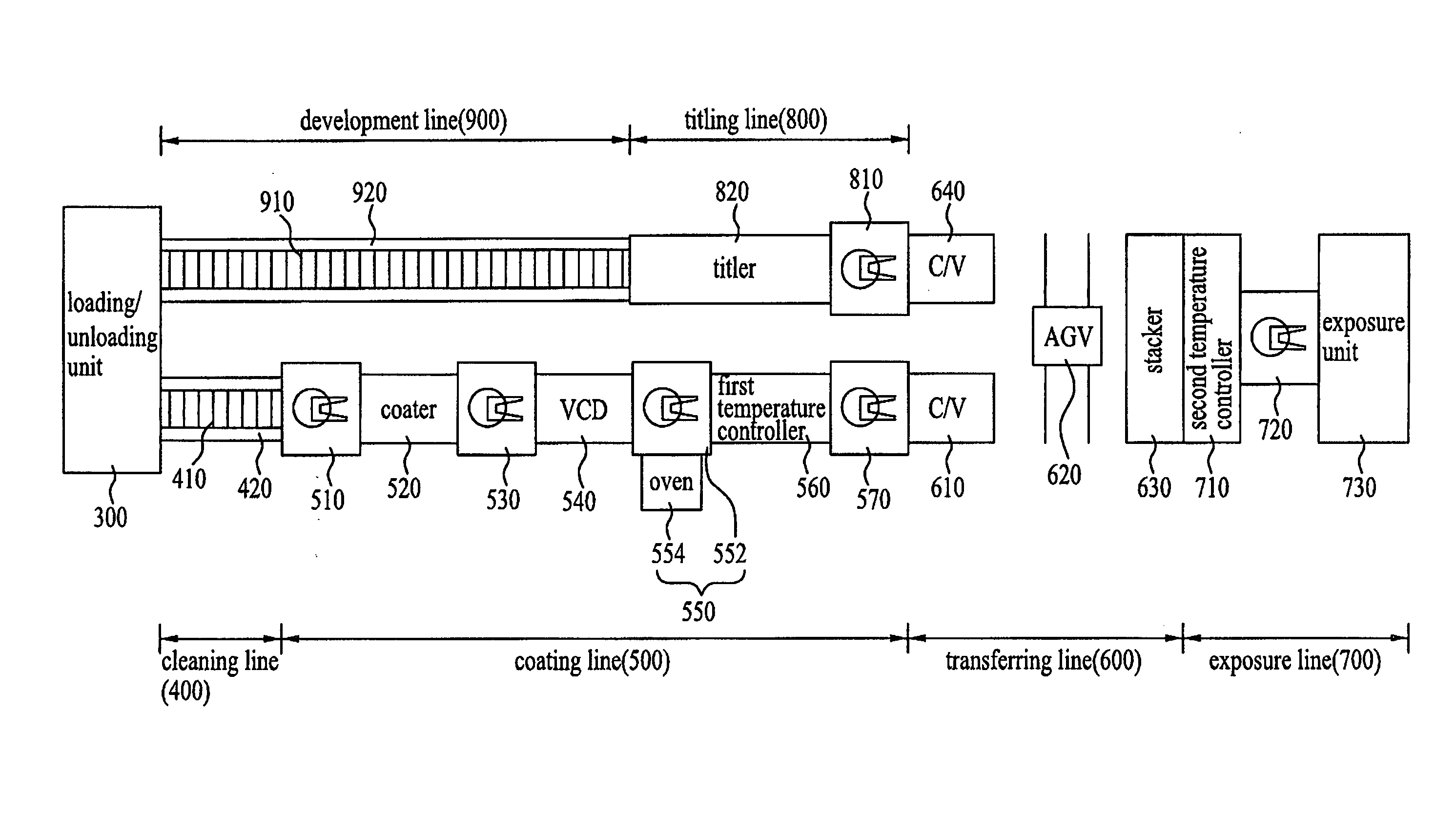

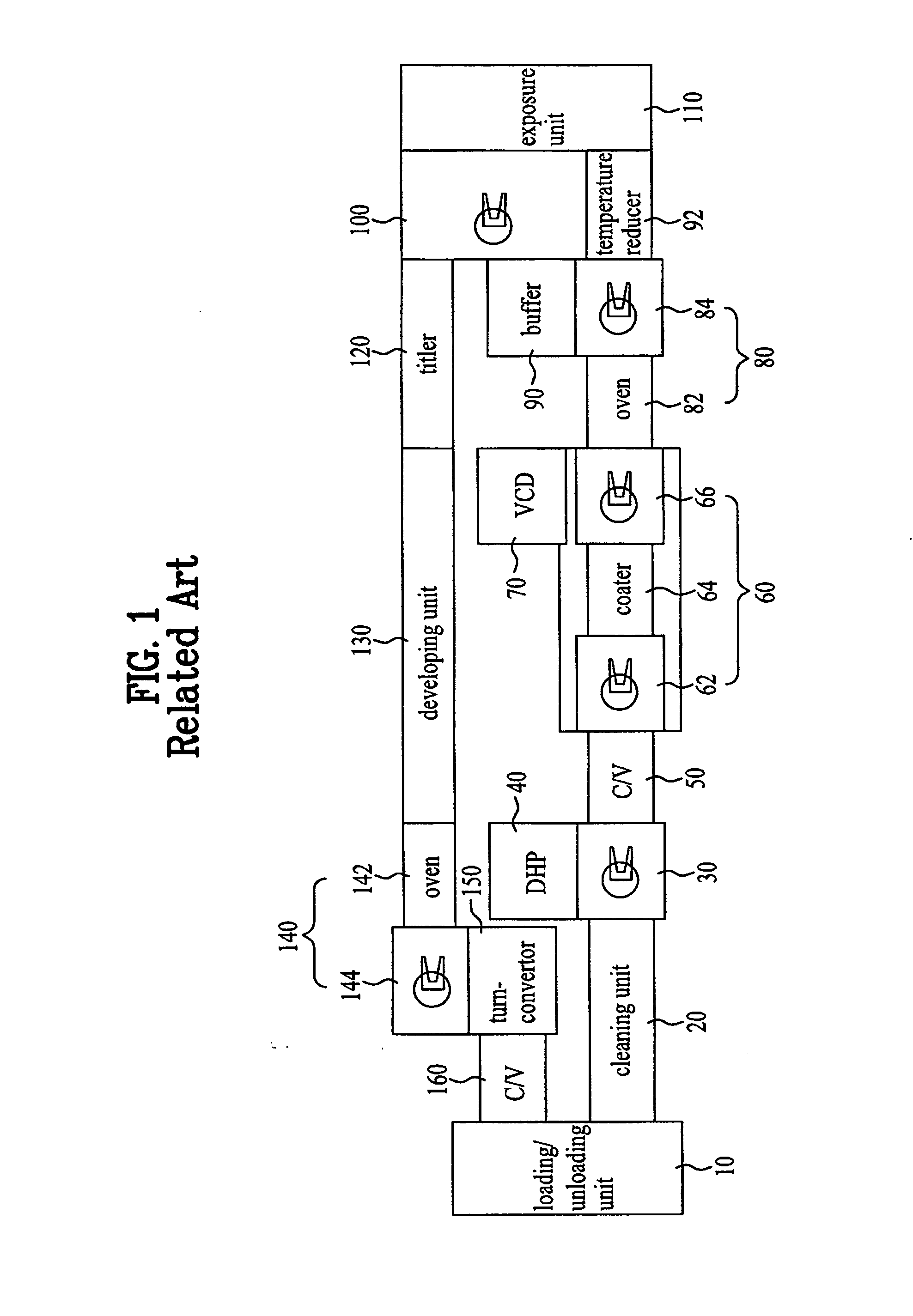

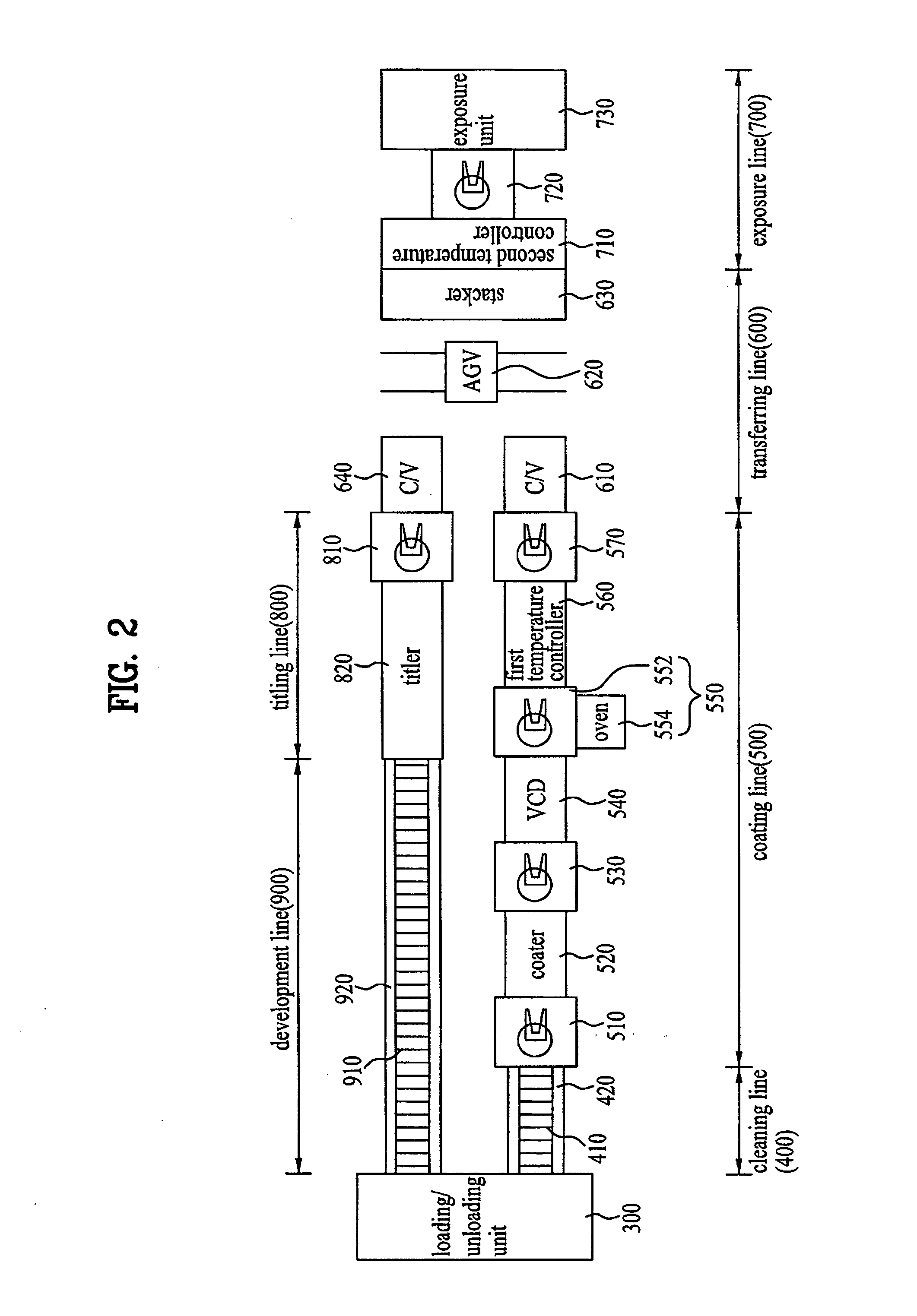

ActiveUS7537401B2Increase productionLiquid surface applicatorsLiquid processingEngineeringPhotoresist

A photo process apparatus including: a loading / unloading unit that loads and unloads a substrate; a coating line that coats photoresist on the substrate; an exposure line that exposes the photoresist coated on the substrate; a development line that develops the exposed substrate; and a transferring line that temporarily stores the substrate coated with the photoresist and loads the substrate coated with the photoresist to the exposure line and temporarily stores the exposed substrate and loads the exposed substrate to the development line.

Owner:LG DISPLAY CO LTD

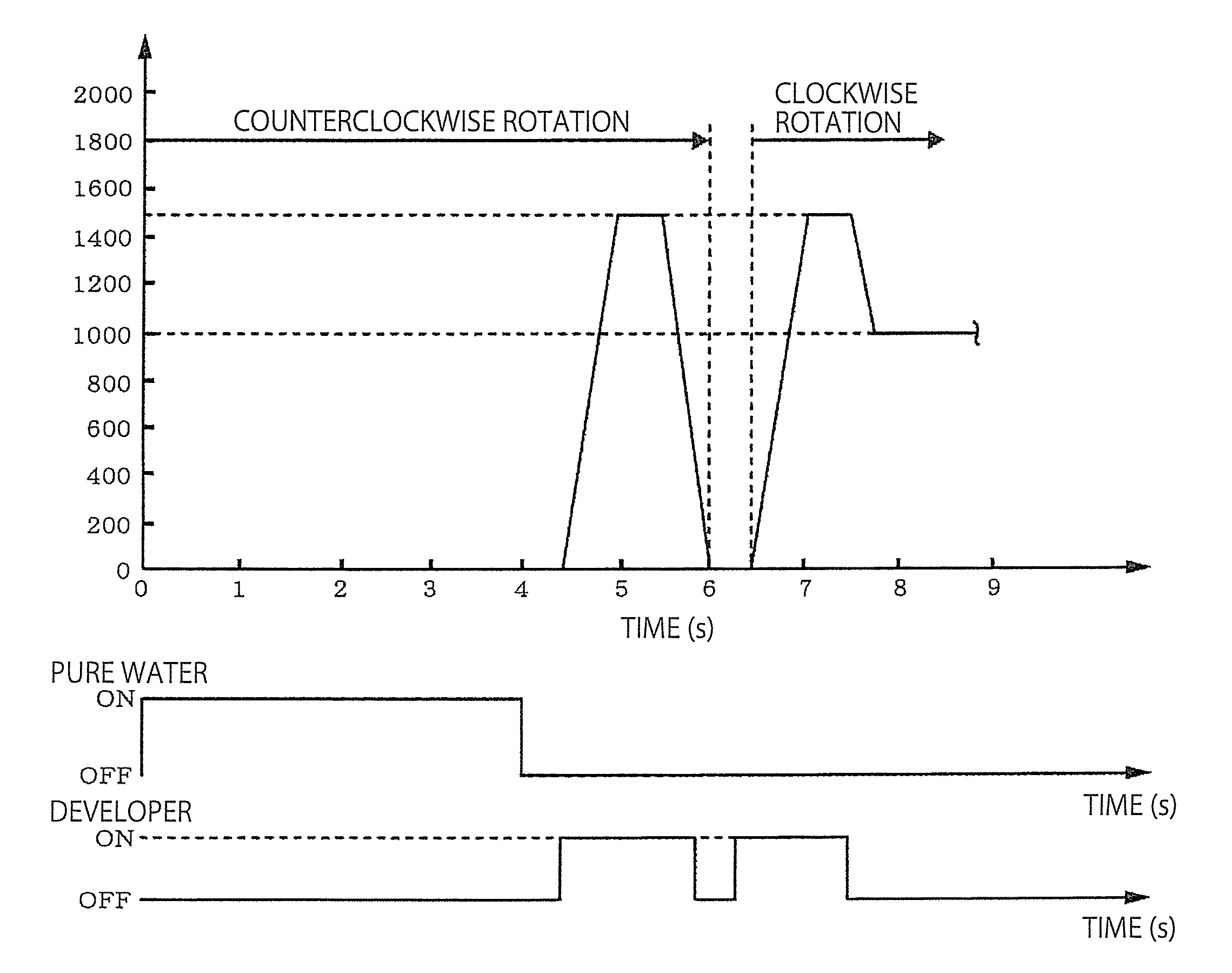

Developing apparatus, developing method and storage medium

ActiveUS20110096304A1Highly uniformly processing surfaceHigh water repellencyLiquid processingReversal processingResistWaste management

A pretreatment process, carried out prior to a developing process, spouts pure water, namely, a diffusion-assisting liquid for assisting the spread of a developer over the surface of a wafer, through a cleaning liquid spouting nozzle onto a central part of the wafer to form a puddle of pure water. The developer is spouted onto the central part of the wafer for prewetting while the wafer is rotated at a high rotating speed to spread the developer over the surface of the wafer. The developer dissolves the resist film partly and produces a solution. The rotation of the wafer is reversed, for example, within 7 s in which the solution is being produced to reduce the water-repellency of the wafer by spreading the solution over the entire surface of the wafer. Then, the developer is spouted onto the rotating wafer to spread the developer on the surface of the wafer.

Owner:TOKYO ELECTRON LTD

Photo apparatus and method

ActiveUS20070280680A1Increase productionLiquid surface applicatorsLiquid processingEngineeringPhotoresist

A photo process apparatus including: a loading / unloading unit that loads and unloads a substrate; a coating line that coats photoresist on the substrate; an exposure line that exposes the photoresist coated on the substrate; a development line that develops the exposed substrate; and a transferring line that temporarily stores the substrate coated with the photoresist and loads the substrate coated with the photoresist to the exposure line and temporarily stores the exposed substrate and loads the exposed substrate to the development line.

Owner:LG DISPLAY CO LTD

Development apparatus and development method

InactiveUS20070065145A1Suppressing of liquid flowImprove uniformityLiquid processingReversal processingResistSpray nozzle

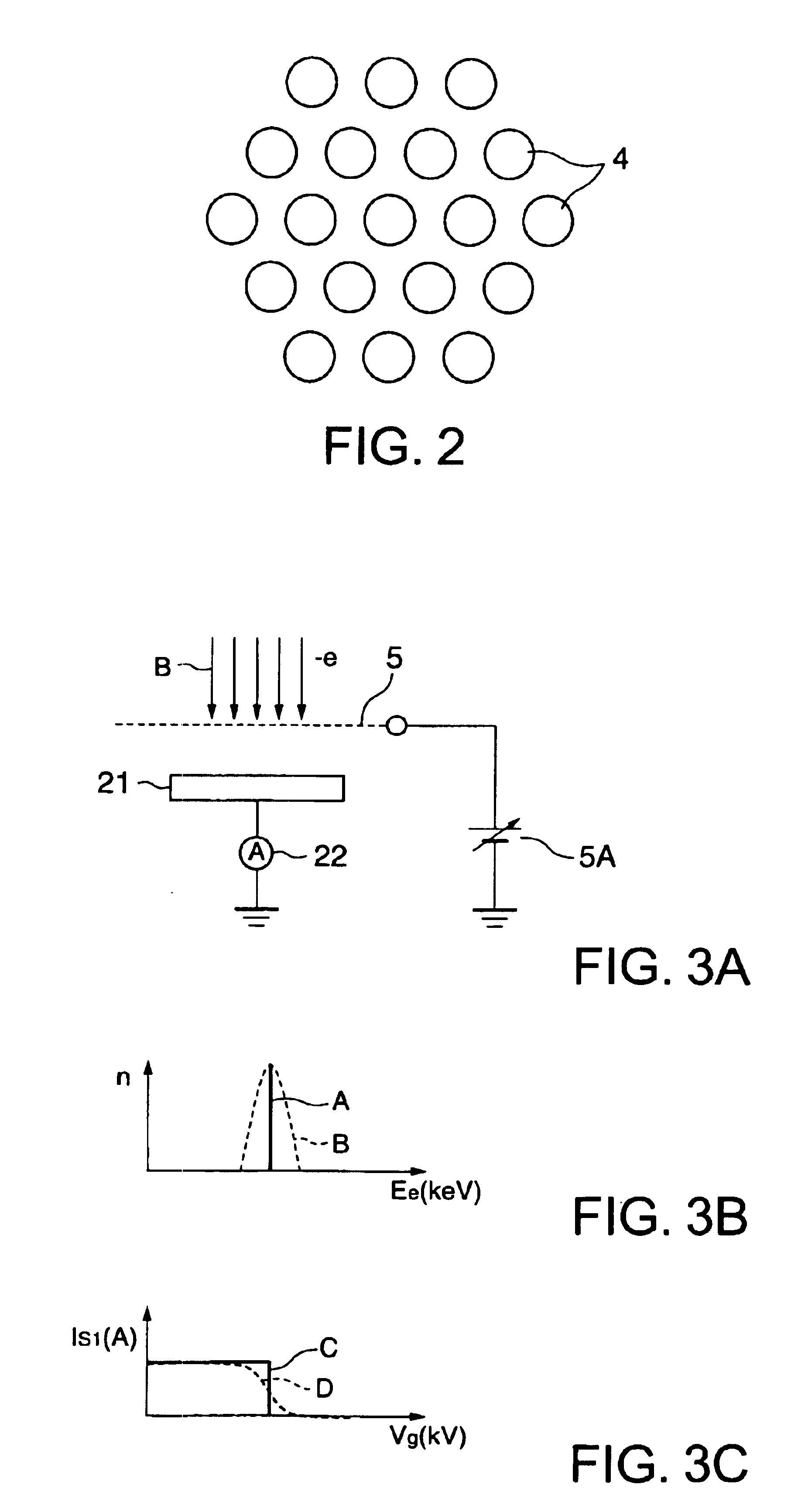

A development apparatus has a holder which horizontally holds a substrate, a nozzle which supplies a developer to a resist film on the substrate held by the holder, a liquid flow suppressing member whose size in a two-dimensional plane viewing field is equal to or larger than that of the substrate and which has a mesh having many openings and hydrophilic properties with respect to the developer and transmits the developer supplied from the nozzle through the openings of the mesh to form a liquid film of the developer between the mesh and the substrate, and a moving mechanism which movably supports this liquid flow suppressing member, sets the mesh to face the resist film on the substrate and brings the mesh into contact with a surface of the liquid film of the developer or immerges the mesh in the liquid film.

Owner:TOKYO ELECTRON LTD

Immersion system, exposure apparatus, exposing method, and device fabricating method

An immersion system is used in an immersion exposure, wherein a substrate is exposed with an exposure light through an optical member and a liquid, and that fills an optical path of the exposure light between the optical member and the substrate with the liquid. The immersion system comprises: a first member, which is disposed around the optical path of the exposure light and has a first surface that faces in a first direction; a second member that has a liquid recovery port, which is disposed on the outer side of the first surface with respect to the optical path of the exposure light; a first drive apparatus that is capable of moving the first member parallel to the first direction; and a second drive apparatus that is capable of moving the second member parallel to the first direction independently of the first member; wherein, a space between the first surface and a front surface of an object can hold the liquid; and a liquid between the liquid recovery port and the front surface of the object is recovered via the liquid recovery port.

Owner:NIKON CORP

Substrate processing device, substrate processing method, and developing device

Rinsing nozzles 310a to 310e are moved on a wafer W while they are discharging rinsing solution 326. At that point, discharging openings 317a to 317e are contacted to developing solution 350 coated on the wafer W or rinsing solution 326 on the wafer W. Thus, the impact against the wafer W can be suppressed. As a result, pattern collapse can be prevented. In addition, a front portion of the developing solution 350 can push away the developing solution 350.

Owner:TOKYO ELECTRON LTD

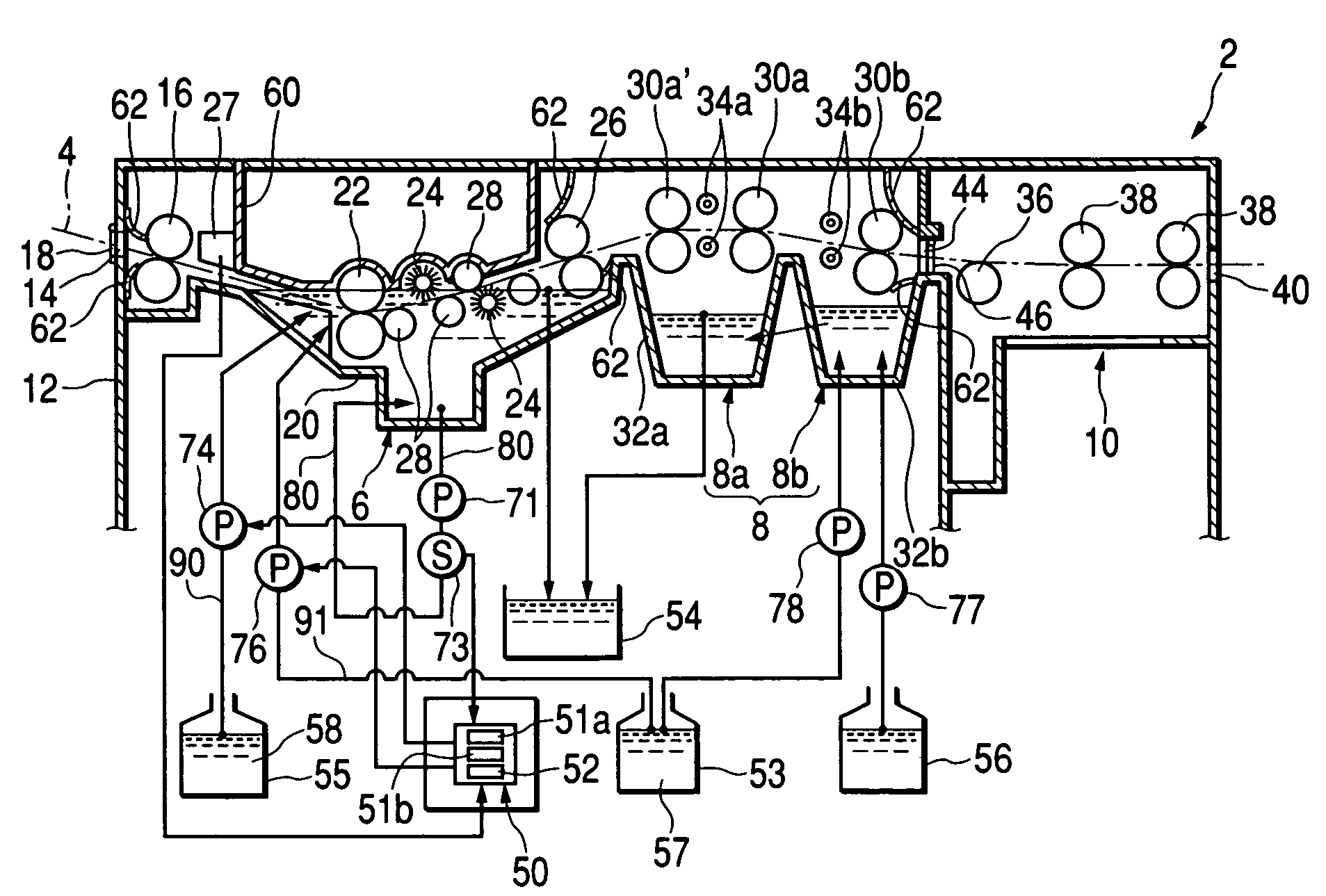

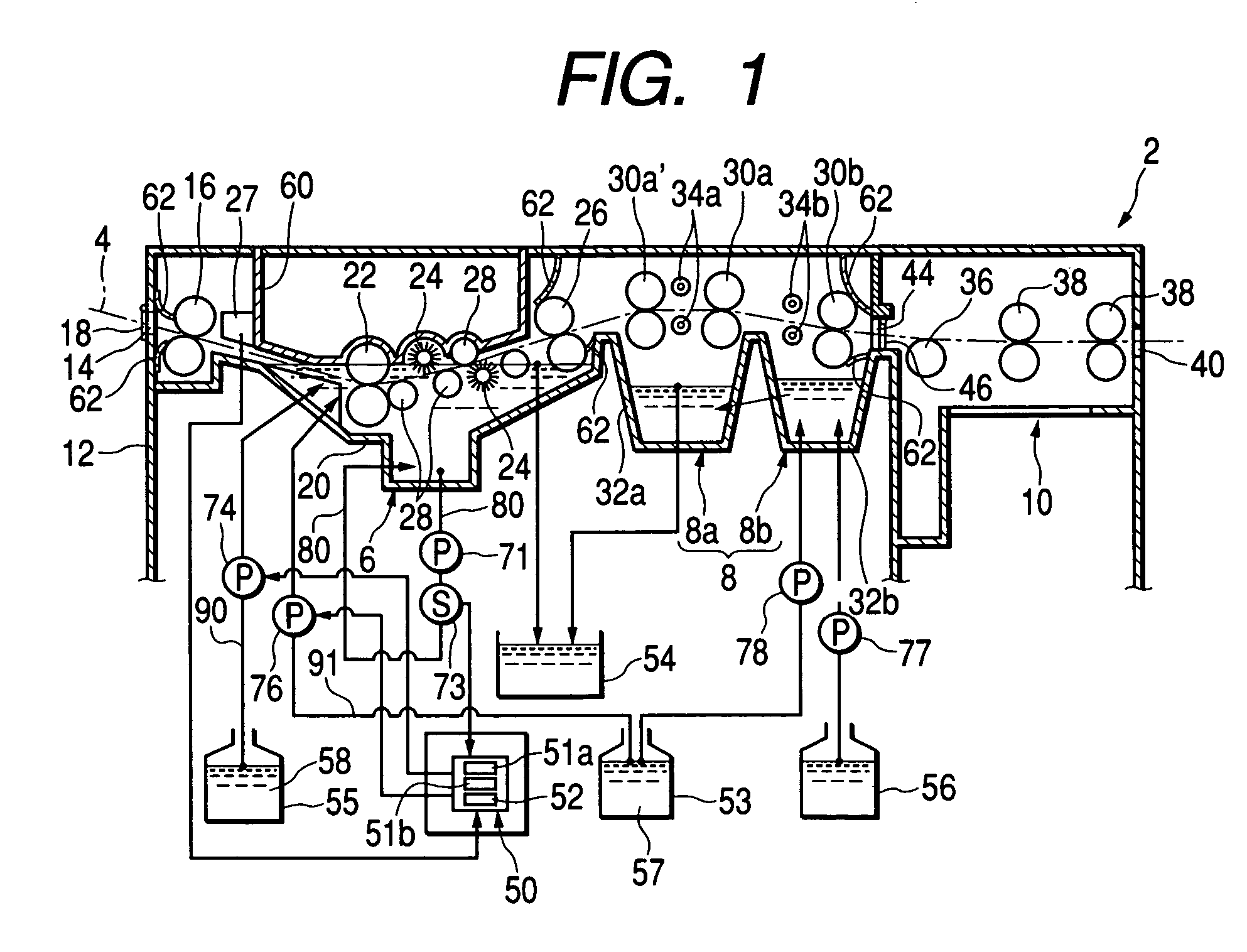

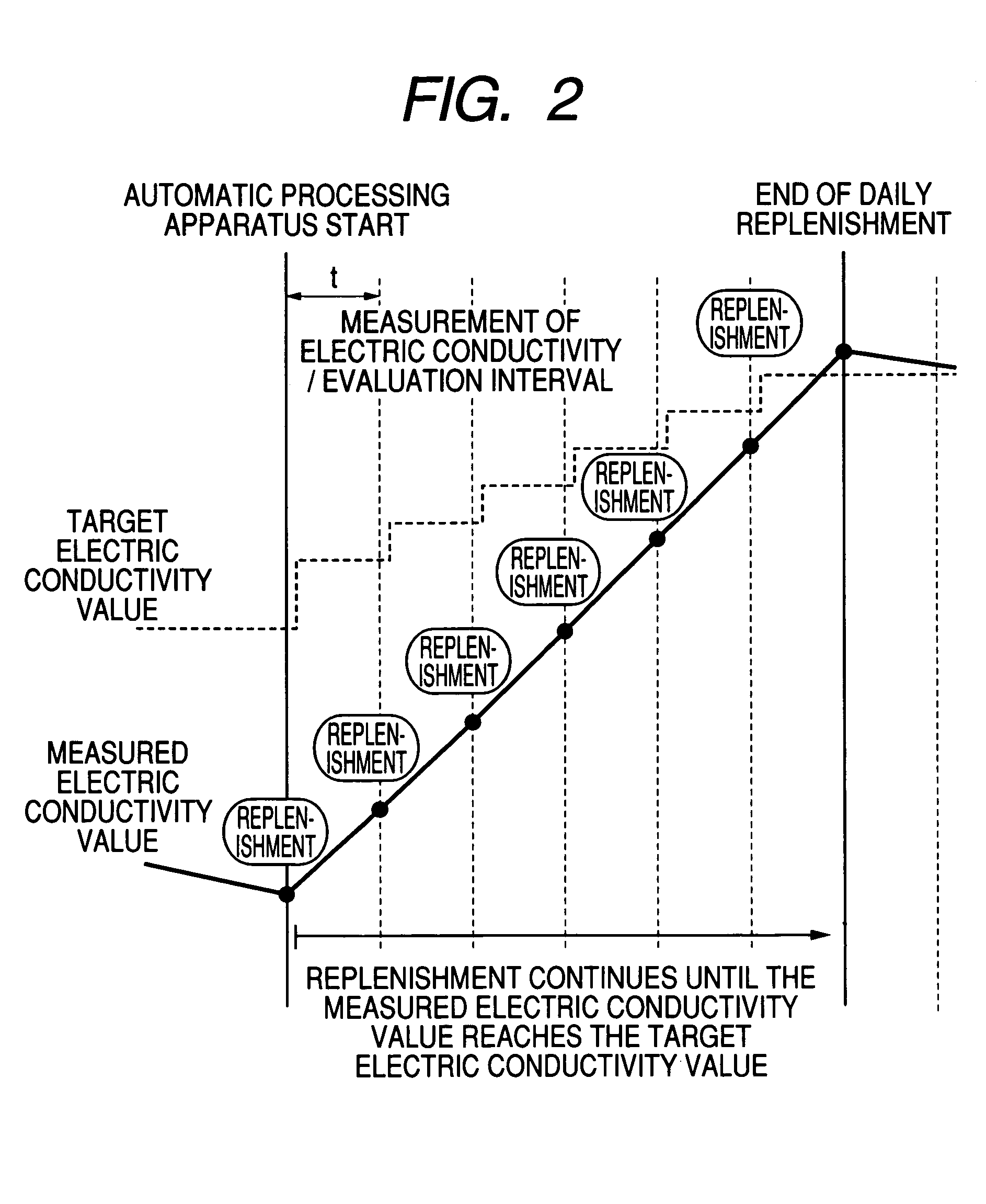

Automatic processing method of photosensitive lithographic printing plate and automatic processing apparatus thereof

ActiveUS7024996B2Simple and cheap configurationMinimizing sensitivityReversal processingDiffusion developmentEngineeringElectrical resistivity and conductivity

An automatic processing method by developing a plural number of exposed photosensitive lithographic printing plates with a developer, which comprises the previously calculating step, the measuring step and the replenishing step as defined herein, wherein during a period from immediately after start of operation of an automatic processing apparatus until the measured electric conductivity value of the developer exceeds the target electric conductivity value, the target electric conductivity value is corrected using a first operation expression as previously defined for every replenishment of the developer replenisher; and after the measured electric conductivity value of the developer first exceeds the target electric conductivity value after start of operation of the automatic processing apparatus, the target electric conductivity value is corrected using a second operation expression for every replenishment of the developer replenisher.

Owner:FUJIFILM CORP +1

Processing method and processing apparatus

InactiveUS6799910B2Avoid energy lossImprove throughputTableLiquid surface applicatorsProcess conditionsManufacturing engineering

After the first workpieces have been processed in the first process portion while the second workpieces are being processed in the second process portion, the first process portion in which the first process condition has been set for the third process condition. By repeating such processes, a plurality of workpieces can be successively processed in different types of process conditions.

Owner:TOKYO ELECTRON LTD

Method of developing a resist film and a resist development processor

InactiveUS20040096210A1Rule out the possibilitySuitable for developmentLiquid processingReversal processingResistSolvent

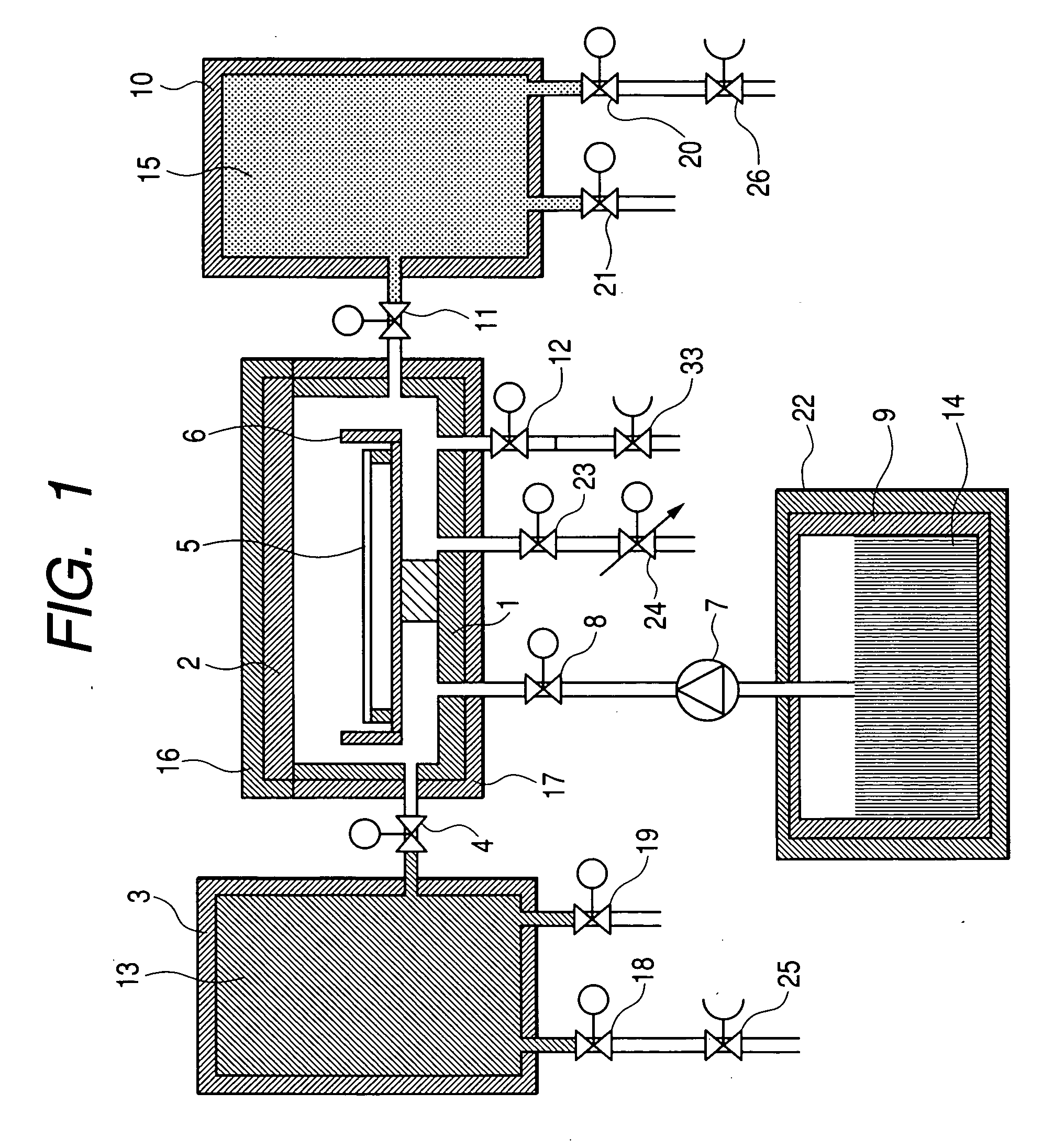

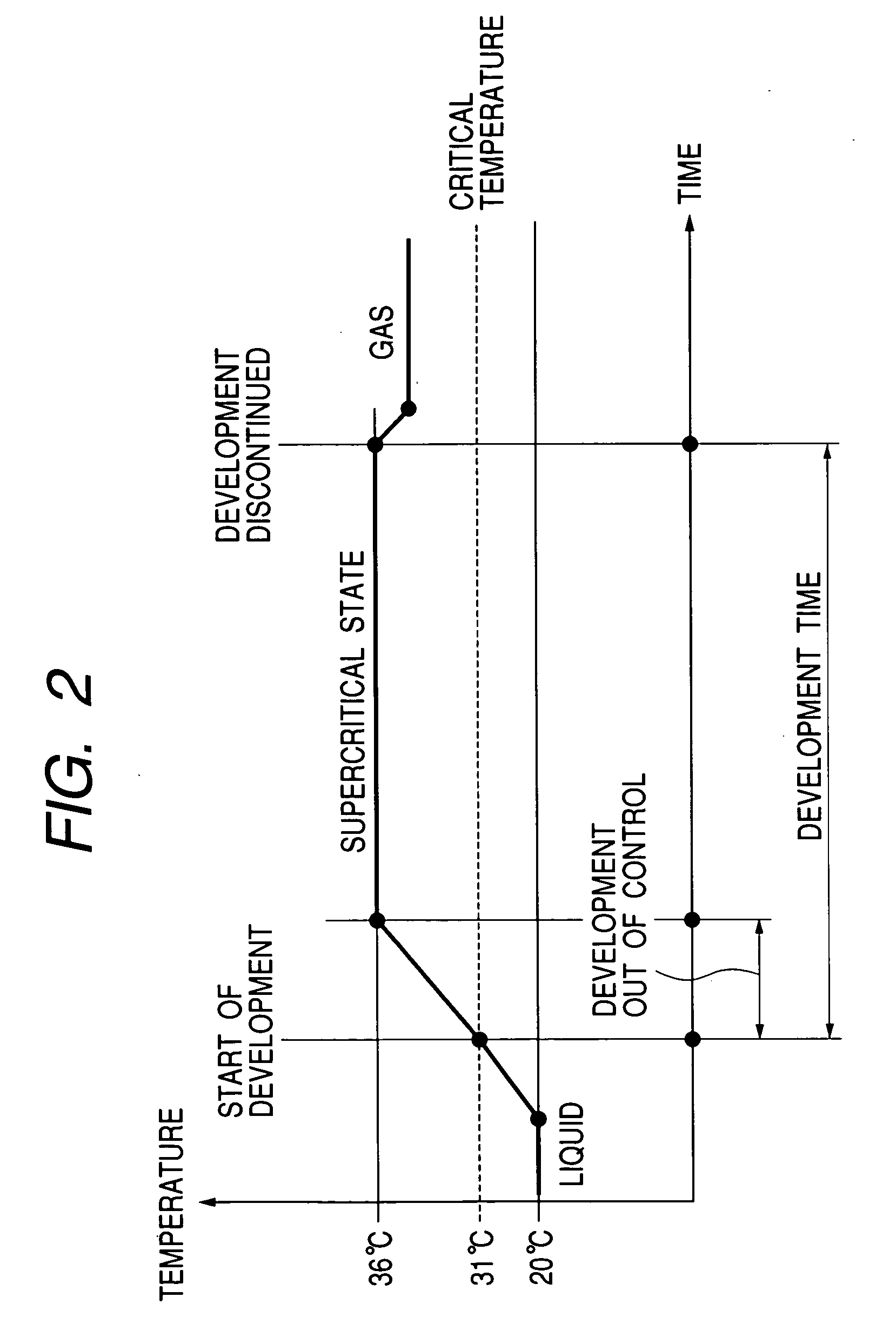

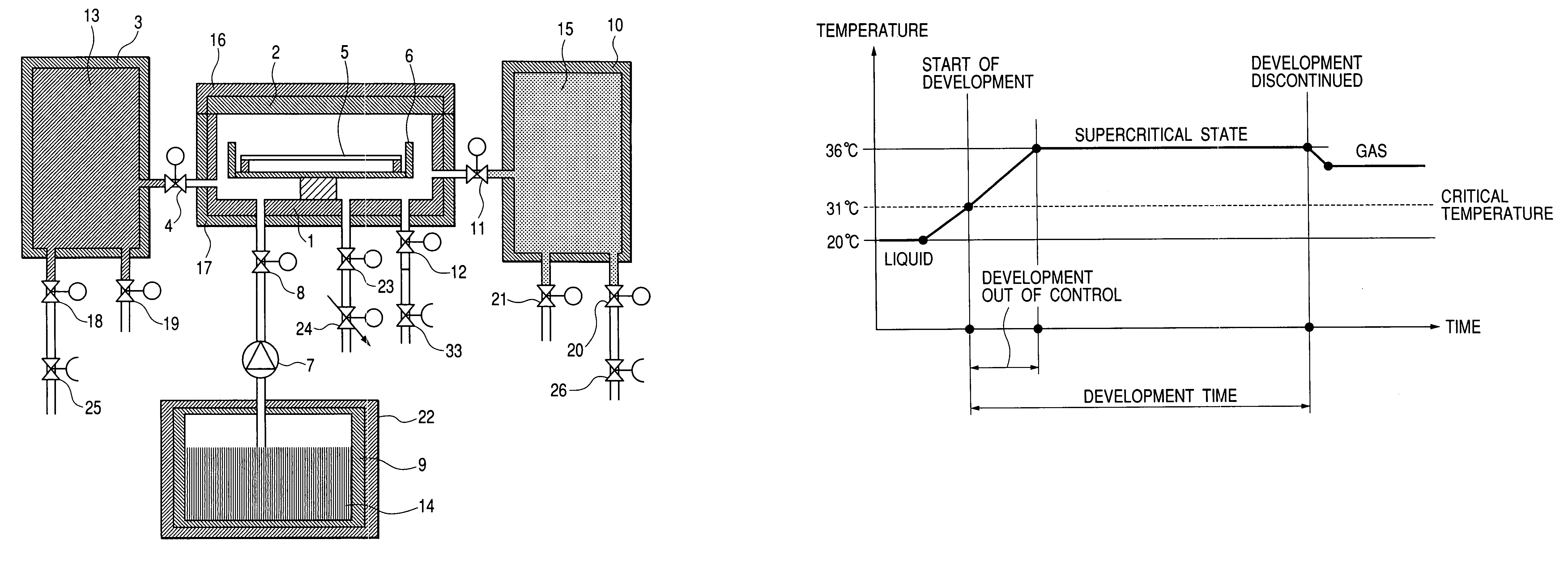

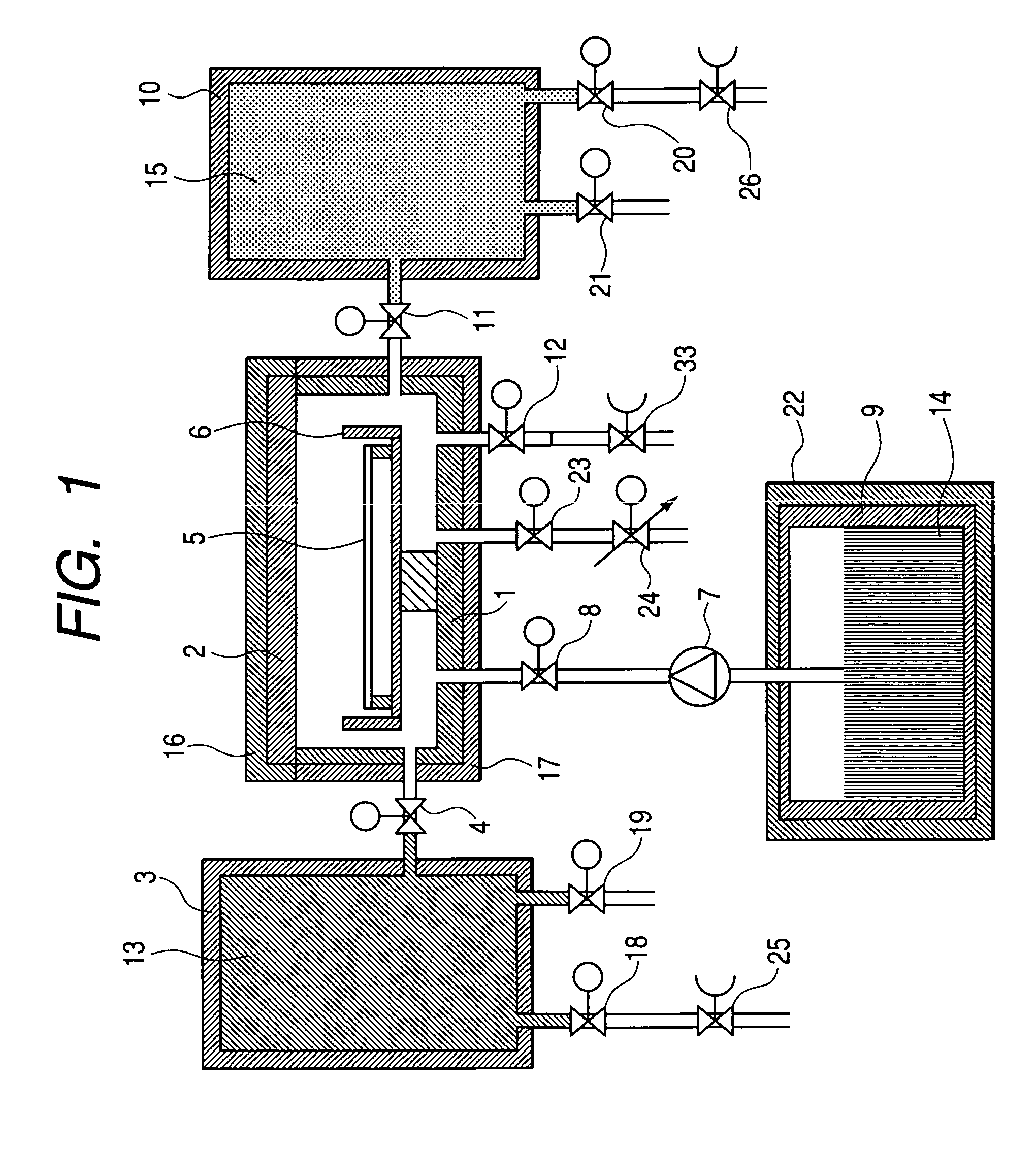

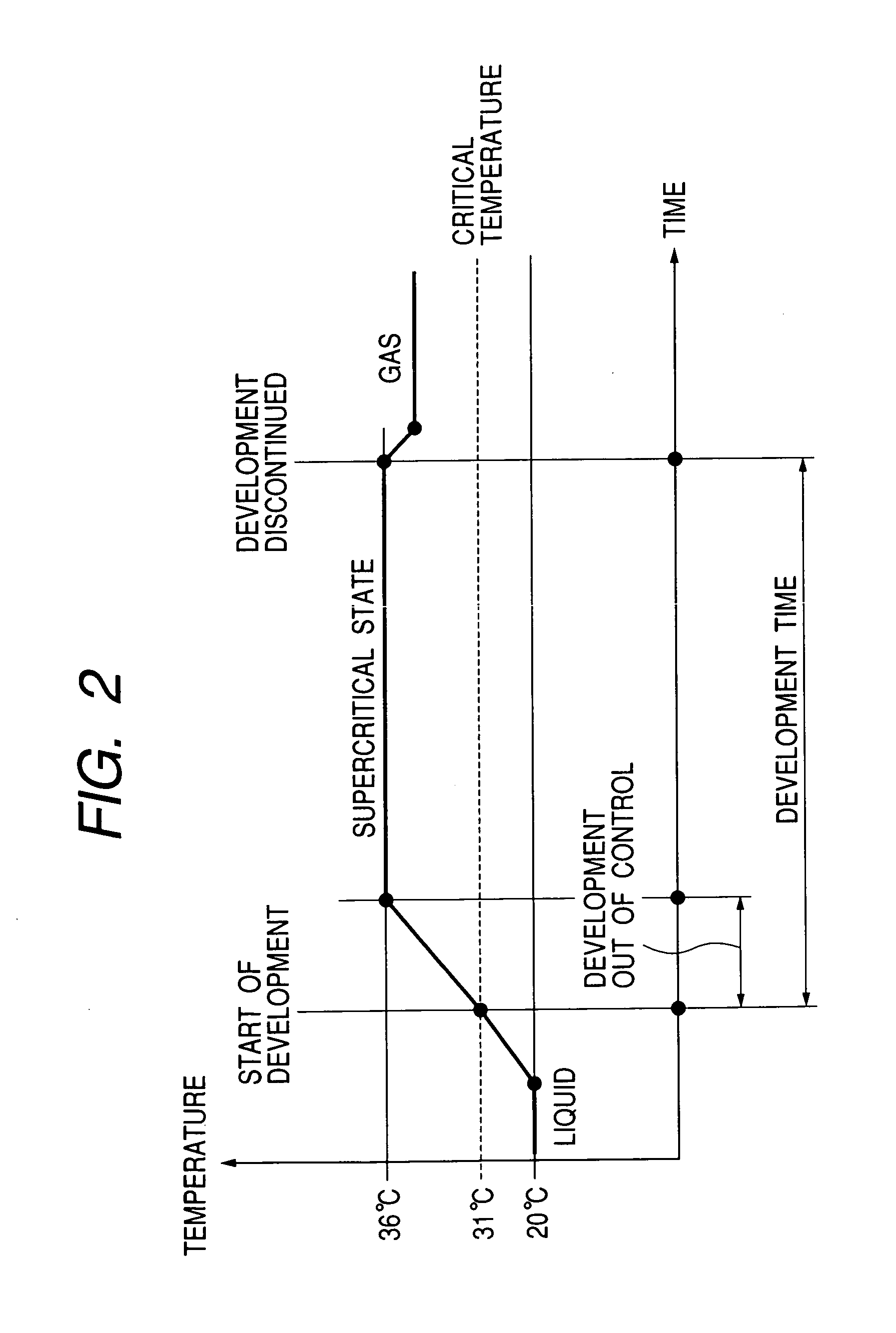

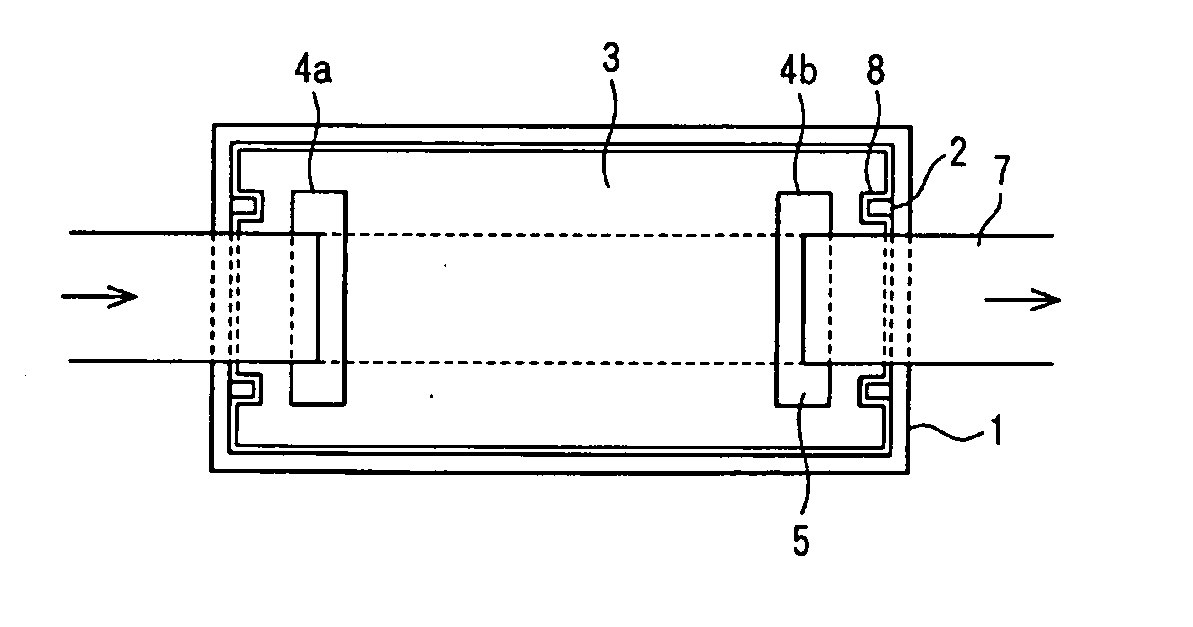

The present invention provides a resist development processor consisting of a development processing chamber for storing a resist substrate having an exposed resist on the substrate and for developing the exposed resist by means of a development solvent consisting of a supercritical fluid; and a supercritical fluid container for storing a supercritical fluid, where the supercritical fluid container is connected to the development processing chamber through a valve.

Owner:HITACHI SCI SYST LTD

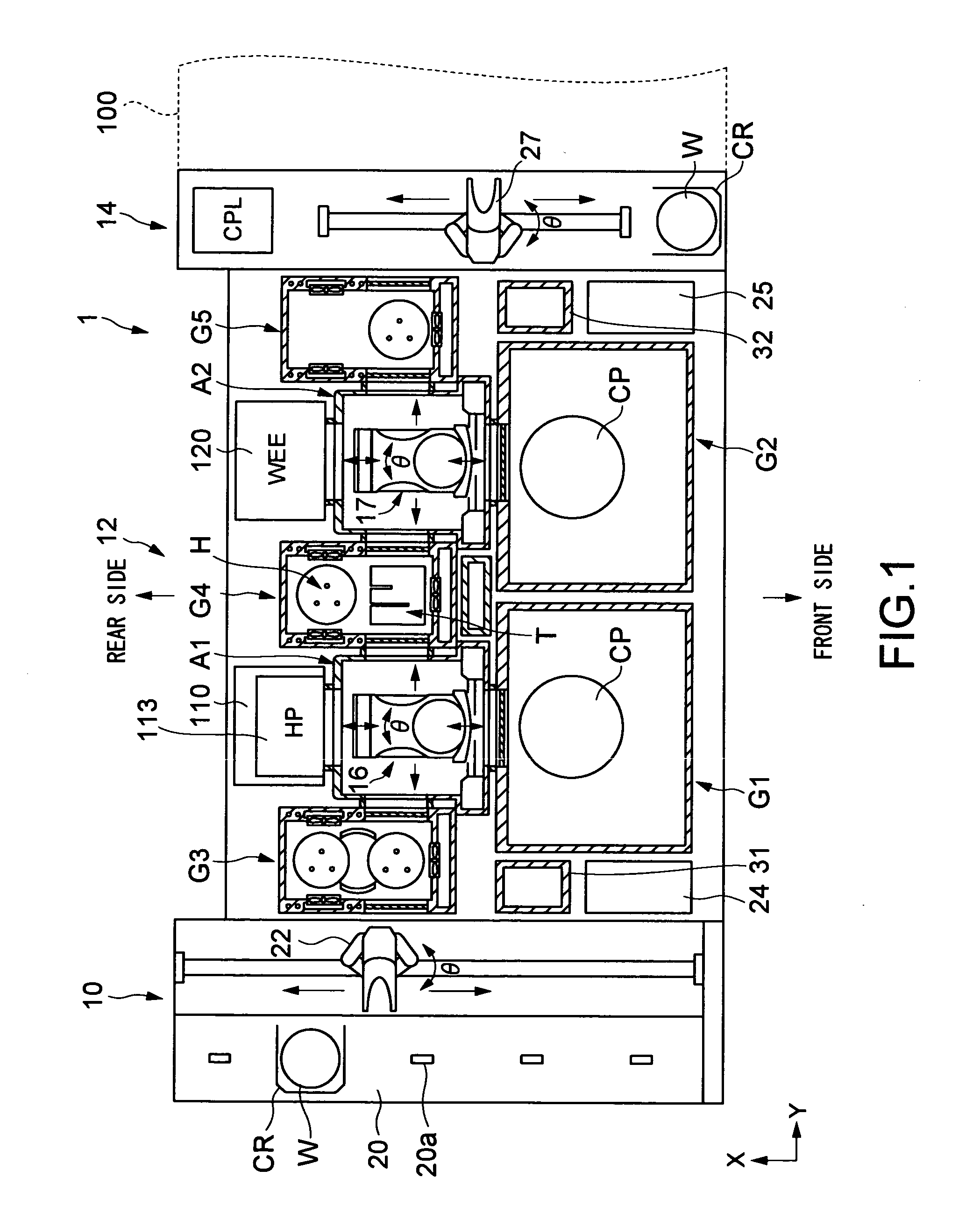

Substrate processing apparatus and substrate transferring method

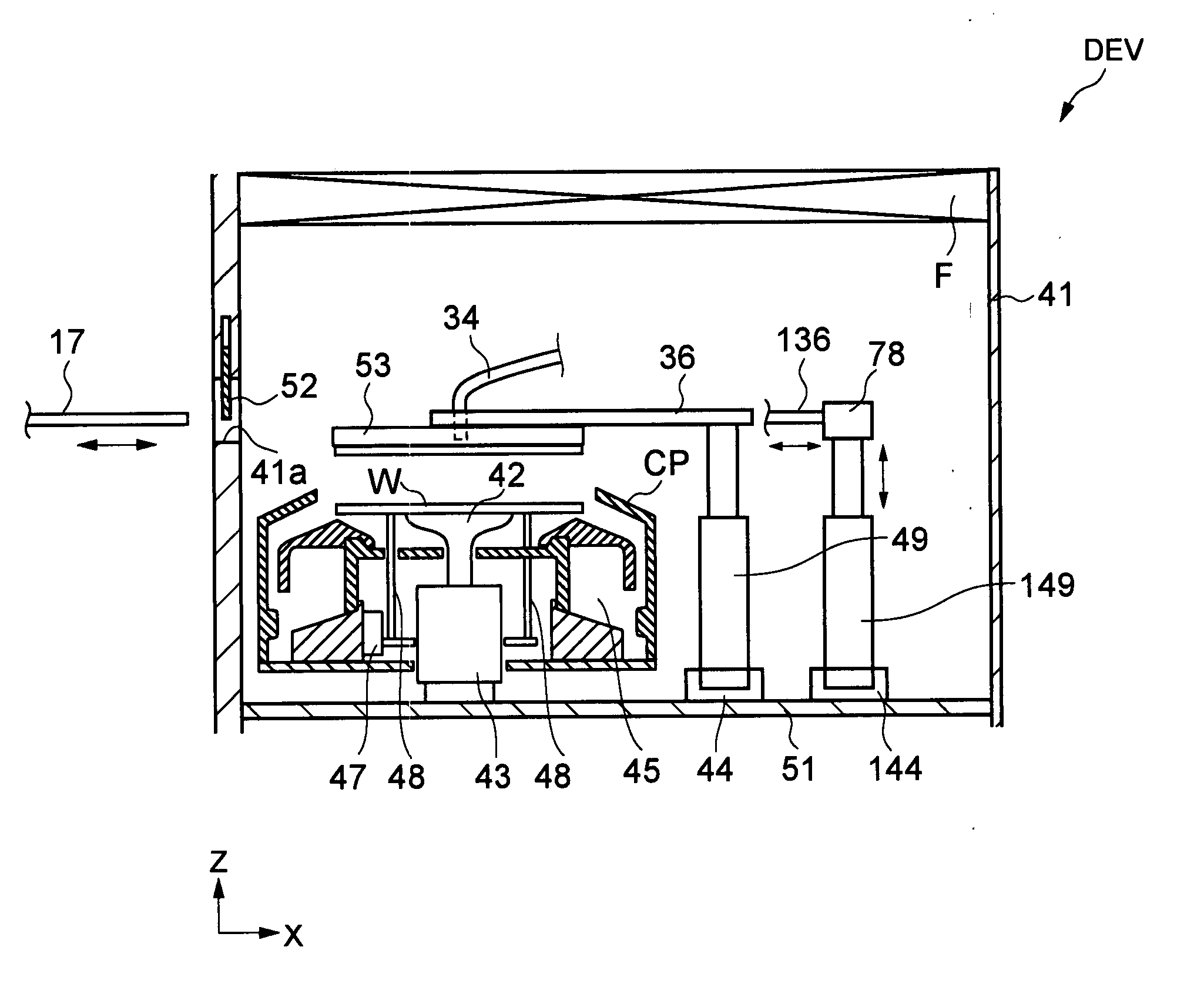

ActiveUS6981808B2Reduce stepsAvoid damageLiquid processingReversal processingTemperature controlWafer

A resist coating / developing system comprises a cassette station, a process station, and an interface station. A second wafer transfer member for transferring the wafer from a high precision temperature control unit mounted to the interface station to an in-stage of a light exposure device provisionally disposes the wafer held by the second wafer transfer member on a restoration unit in the case where the wafer was taken out from the high precision temperature control unit because it was possible to transfer the wafer onto the in-stage, but it was rendered impossible later to transfer the wafer W onto the in-stage.

Owner:TOKYO ELECTRON LTD

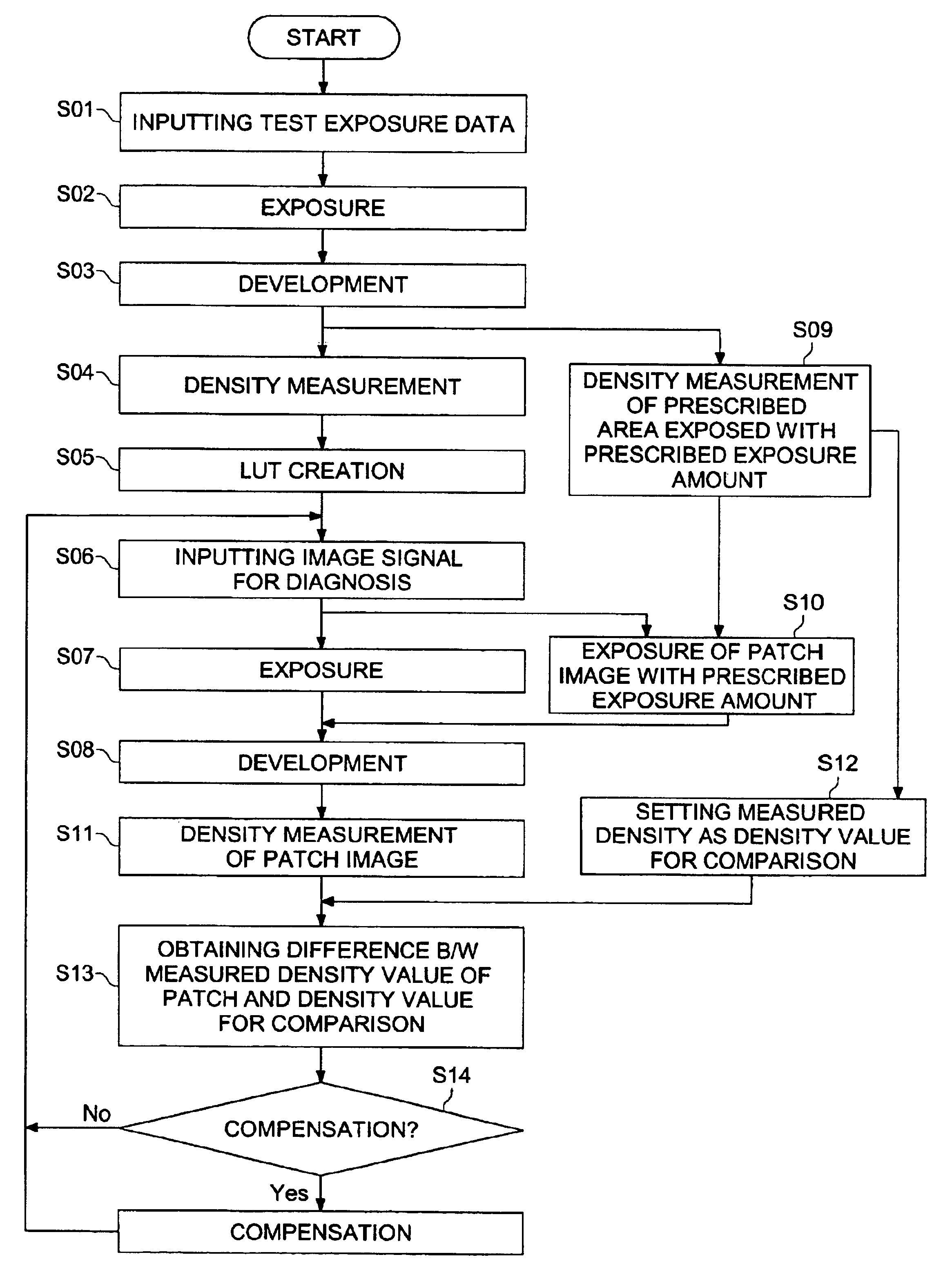

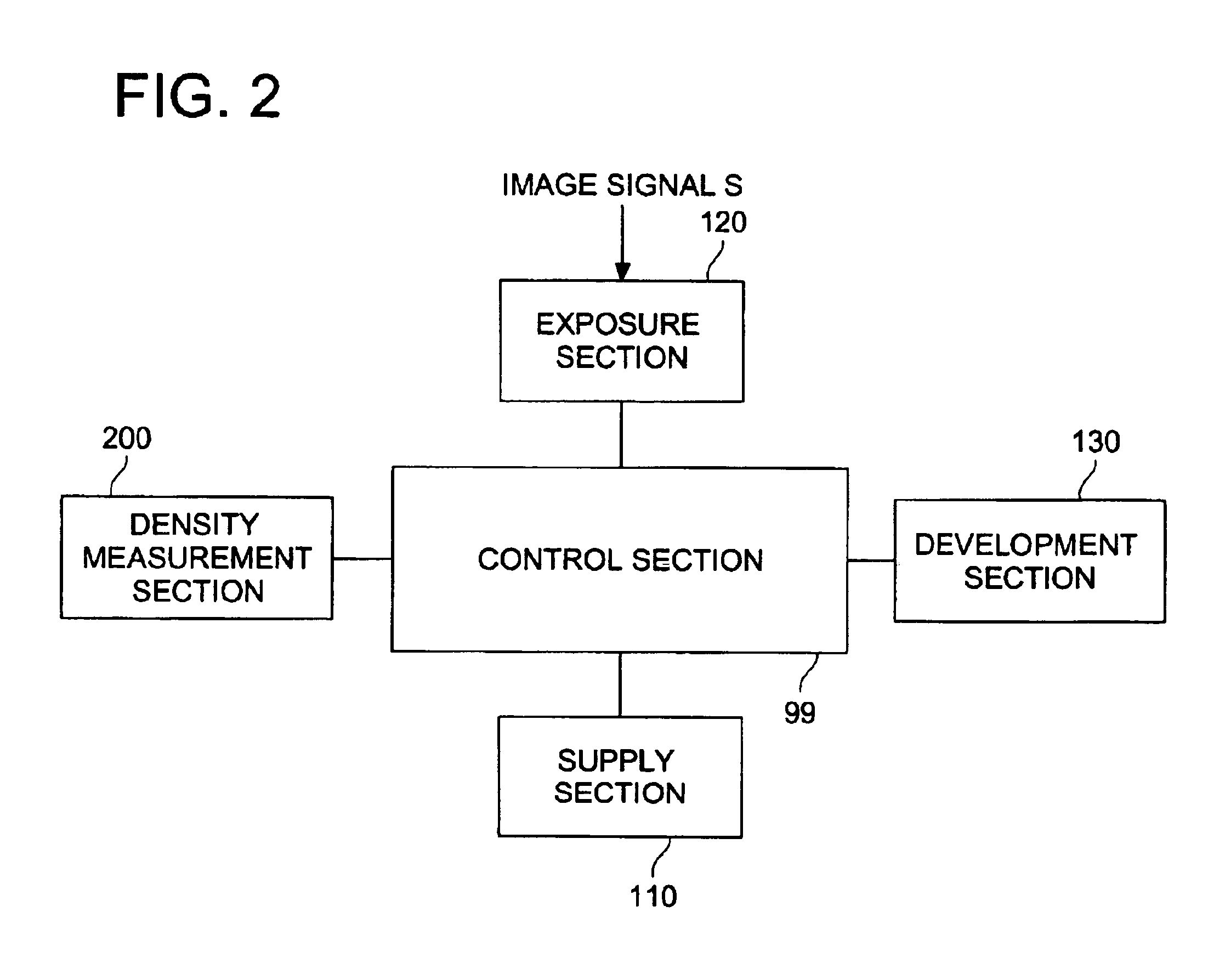

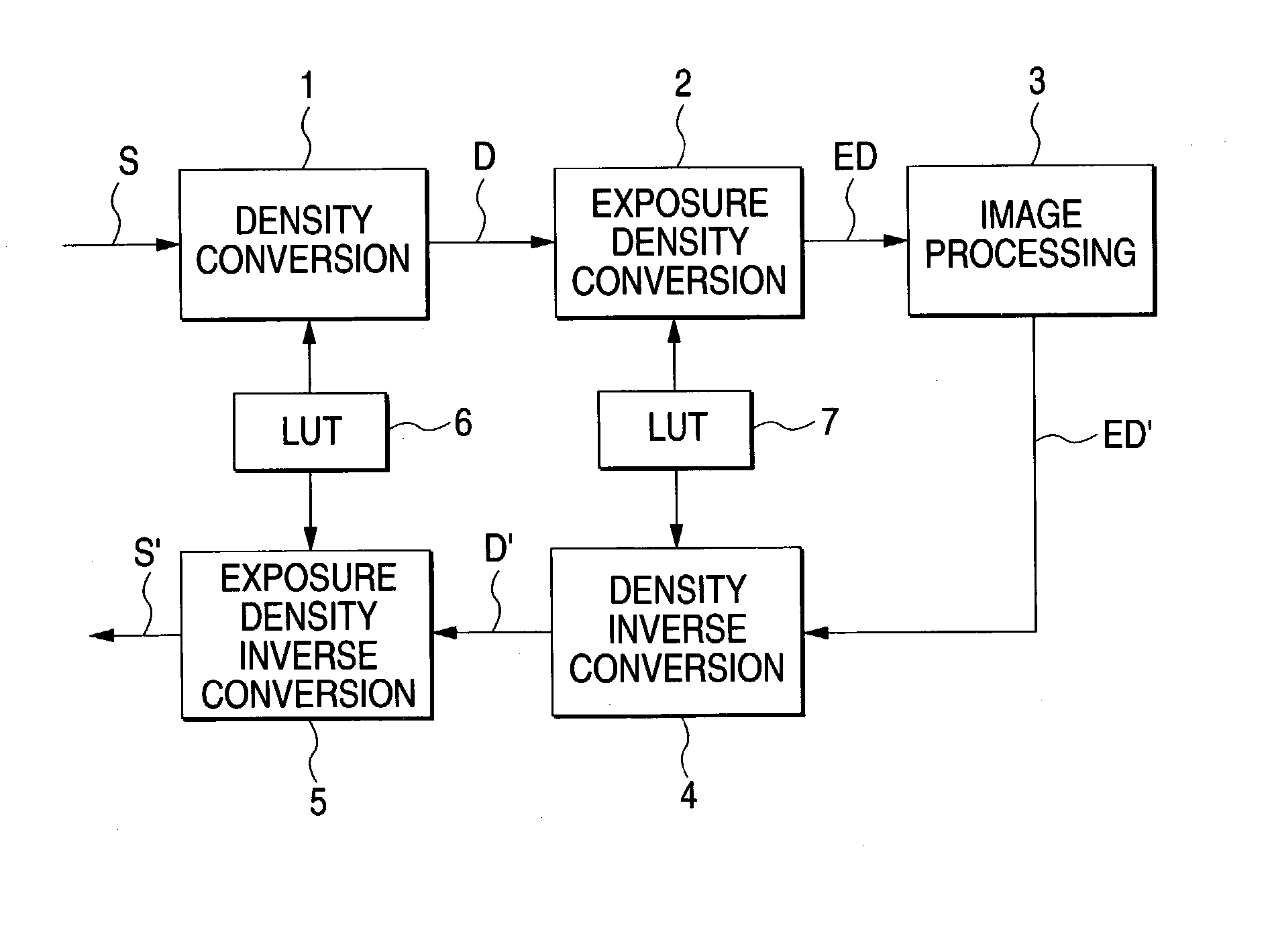

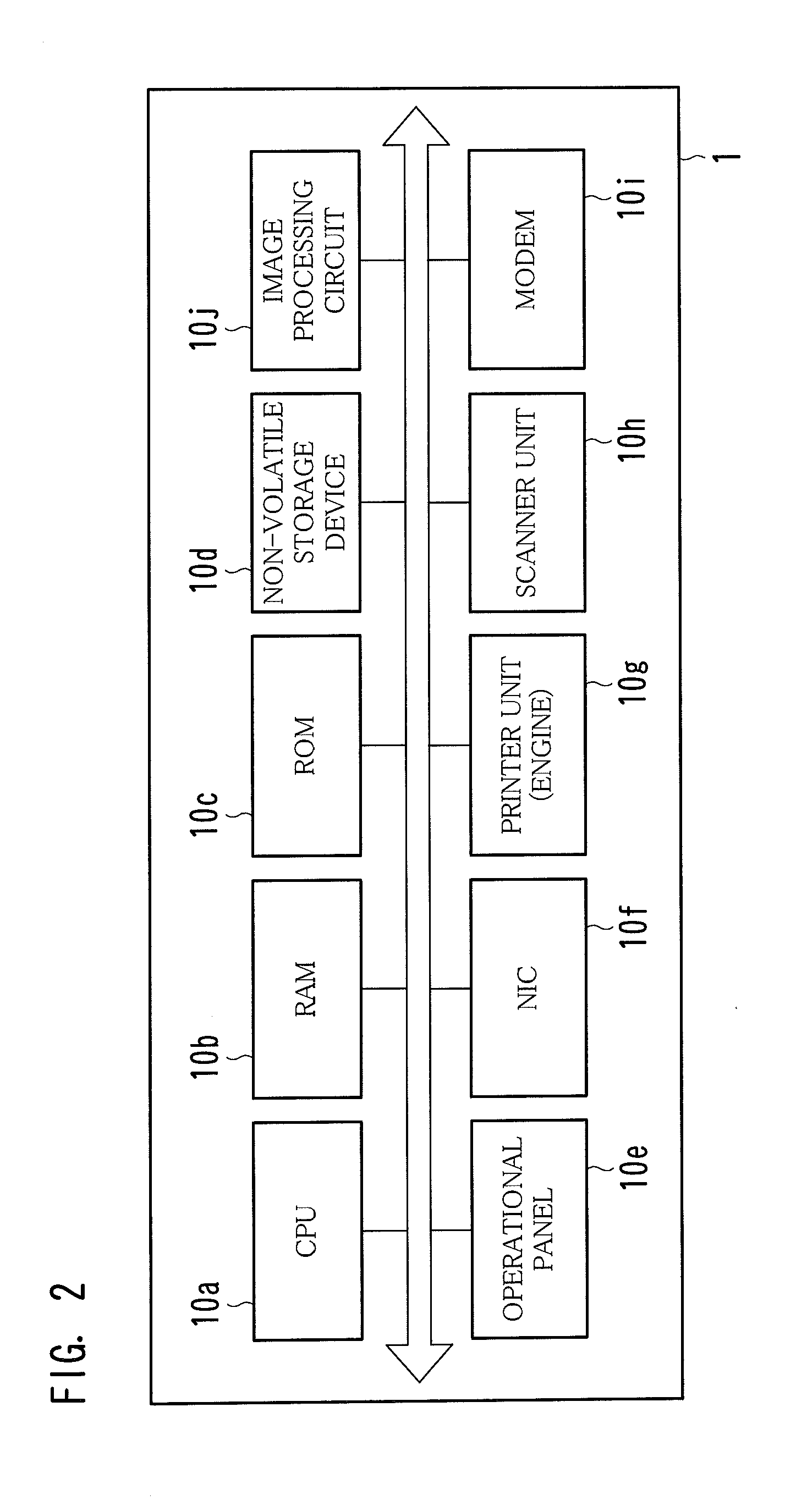

Image processing apparatus, image processing method and program

InactiveUS6812996B2Accurate compensationAccurate for image densityLiquid processingReversal processingImaging processingLatent image

A density adjustment method for adjusting a density of a diagnostic image, having the steps of; exposing an image; developing the latent image; measuring a density of the developed image; creating a lookup table for relating the diagnostic image data and amount of exposure so as to form a density specified by the diagnostic image data; and correcting at least one of an exposure condition and a development condition to ensure that the next film has the optimized density, based on the difference between the measured density of a partial area of the film, and a density for comparison; wherein, a density of a prescribed area in a test exposure image is used as the density for comparison; while the exposure amount is used for exposing the partial area of the film at the time of forming a diagnostic image.

Owner:KONICA MINOLTA INC

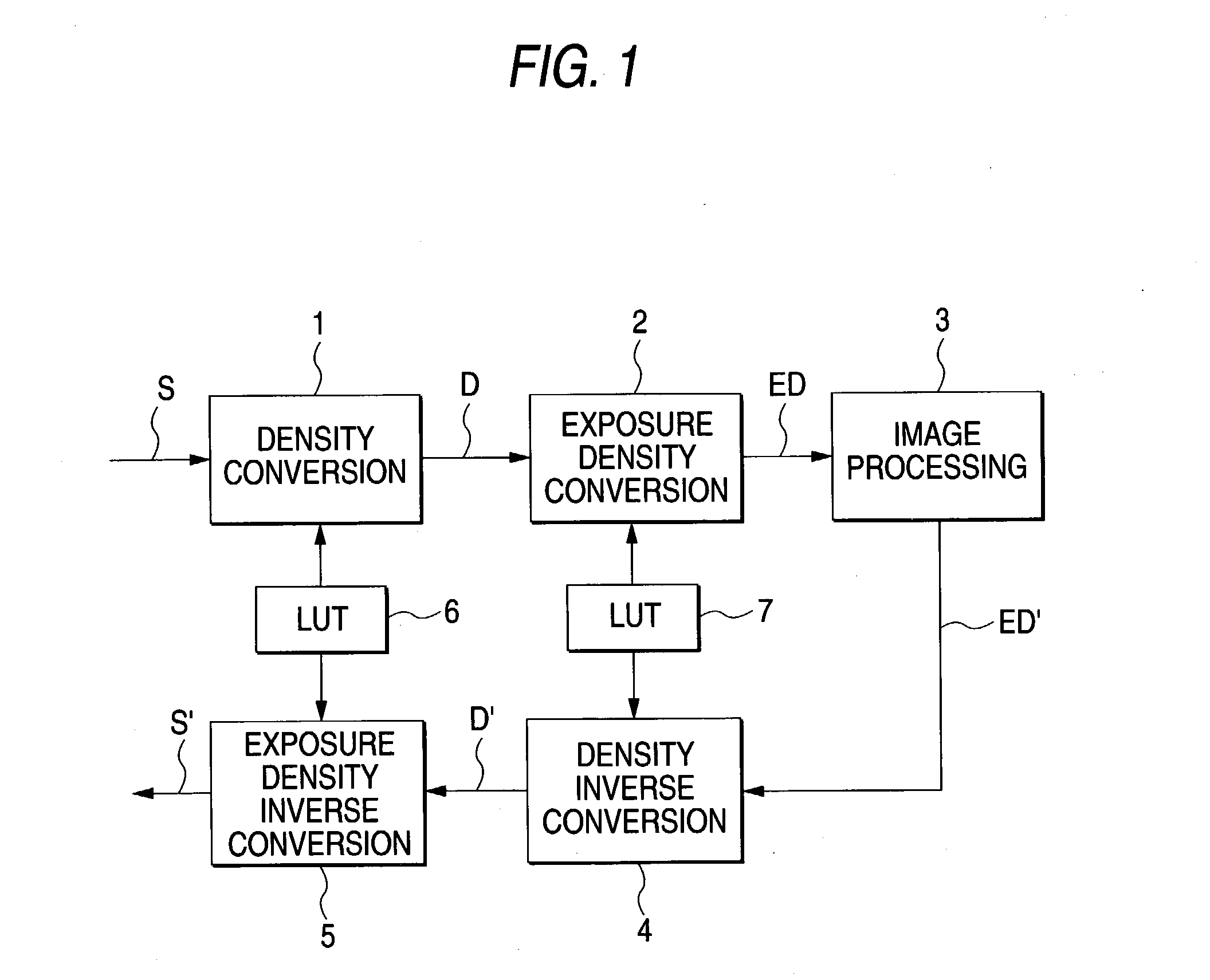

Image formation method

InactiveUS20030095802A1Not impair concisenessNot reduce chroma saturationLiquid processingReversal processingImage formationColor film

In the present invention, an image formation method of recording digital image information on a silver salt color film to obtain an image, comprises: applying chroma saturation changing processing to the digital image information; recording the image information to which the processing has been applied, on the silver salt color film by a scan exposure; and developing the exposed color film with a CD-3-containing developer to obtain the image.

Owner:FUJIFILM HLDG CORP +1

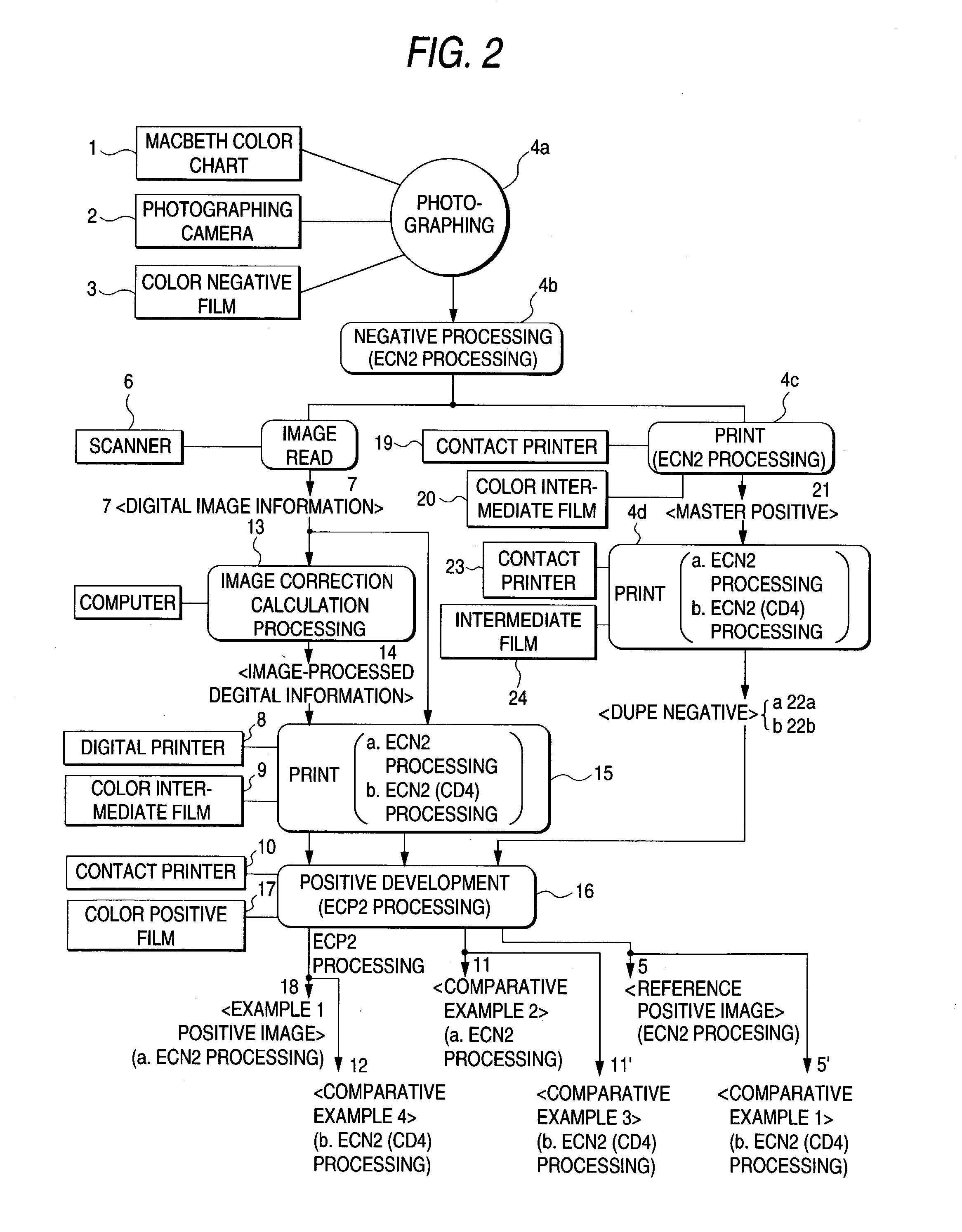

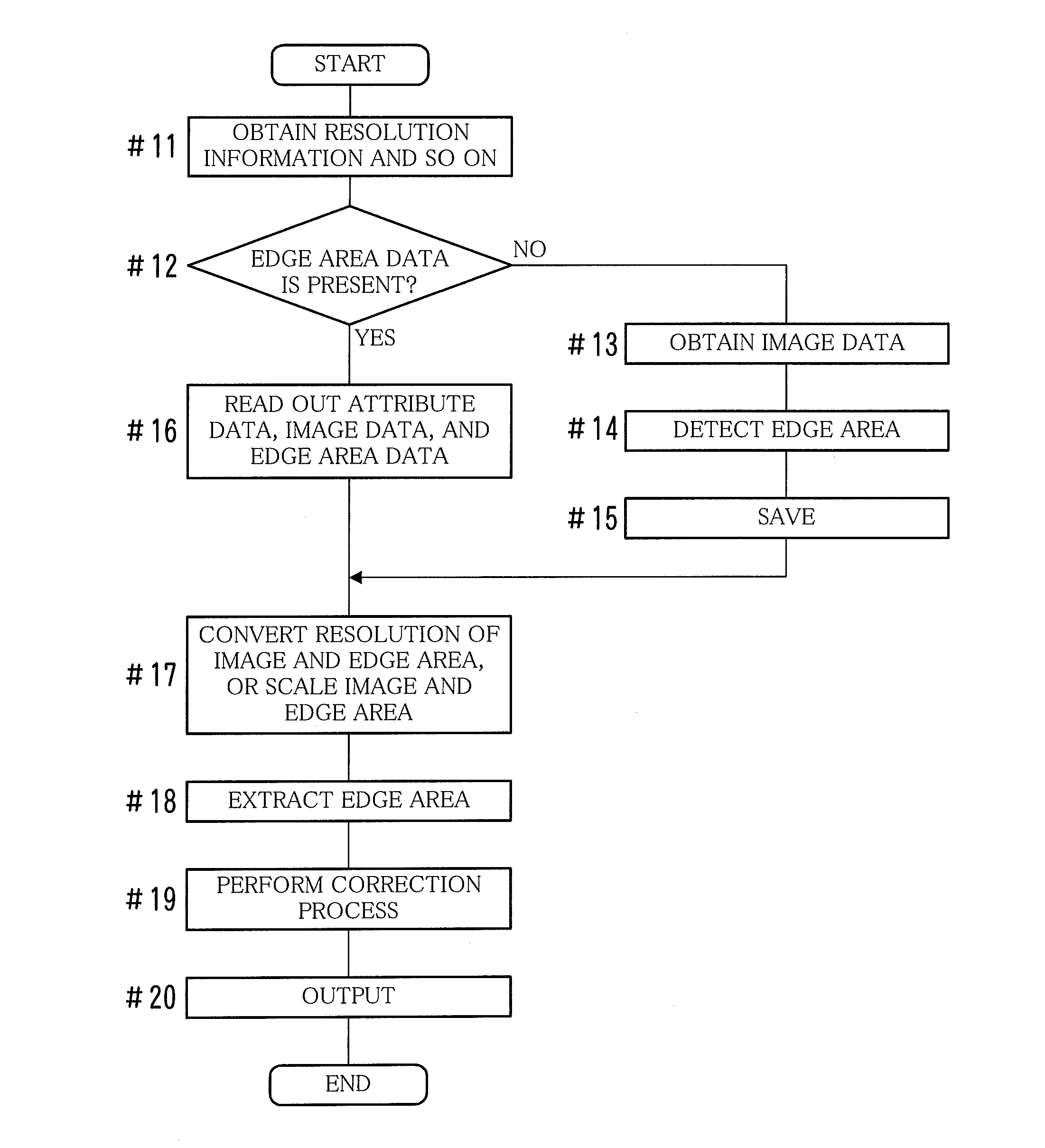

Image processing apparatus, image processing method, and computer-readable storage medium for computer program

ActiveUS20110235906A1Good lookingBrightness value increasedImage enhancementLiquid processingImaging processingImage resolution

An image processing apparatus includes a storage that stores, therein, edge position data indicating the position of a first edge image that represents a first edge of a first object image representing an object in a first image, a determination portion that detects a second edge image based on the edge position data and a specific scaling factor, the second edge image representing a second edge of a second object image that represents the object in a second image, the second image being obtained by modifying the size or the resolution of the first image by increasing the number of pixels by α times (α>1) corresponding to the scaling factor, the second edge having a width equal to that of the first edge, and a removal portion that performs a process for deleting an edge of an inner area surrounded by the second edge image.

Owner:KONICA MINOLTA BUSINESS TECH INC

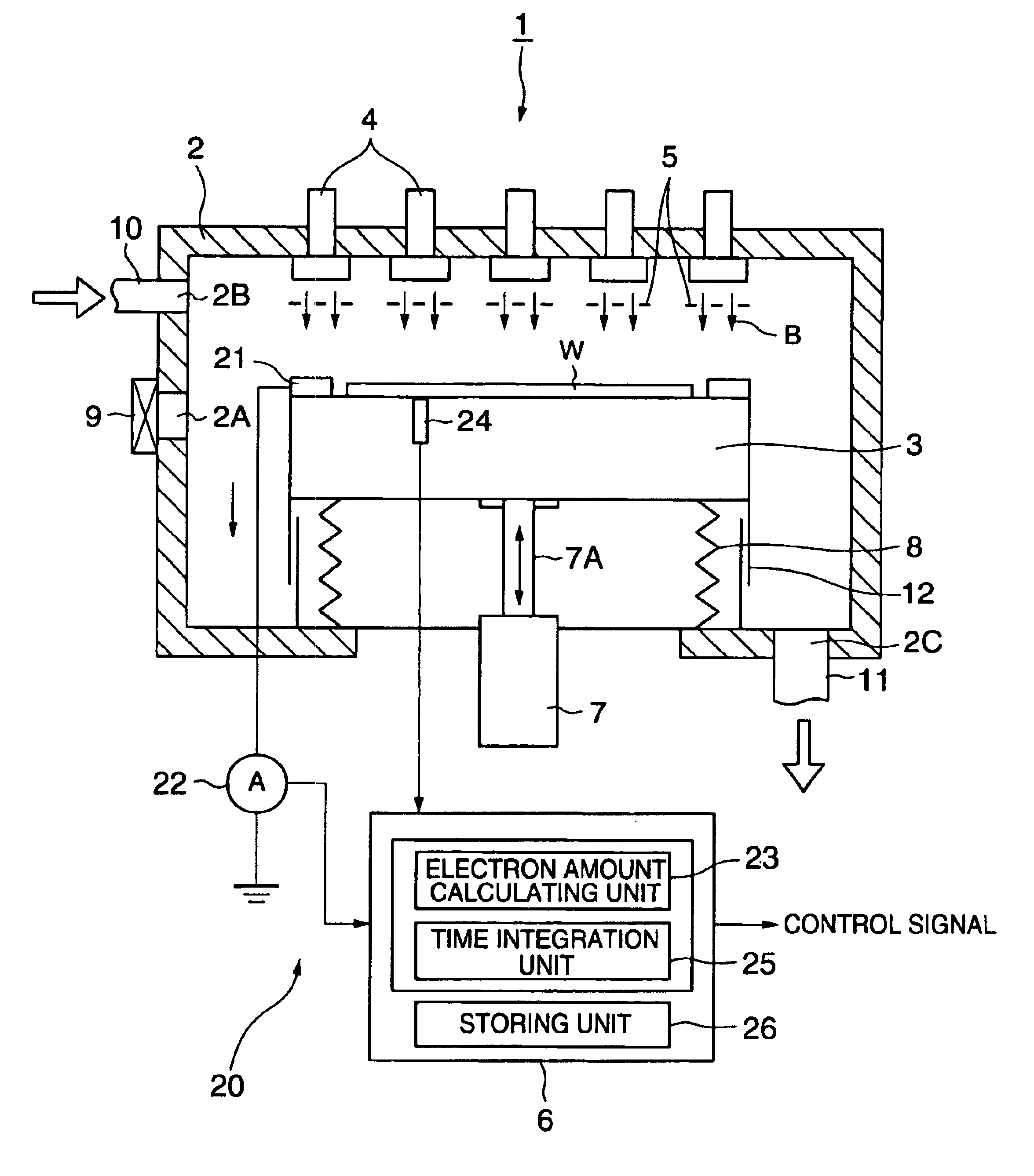

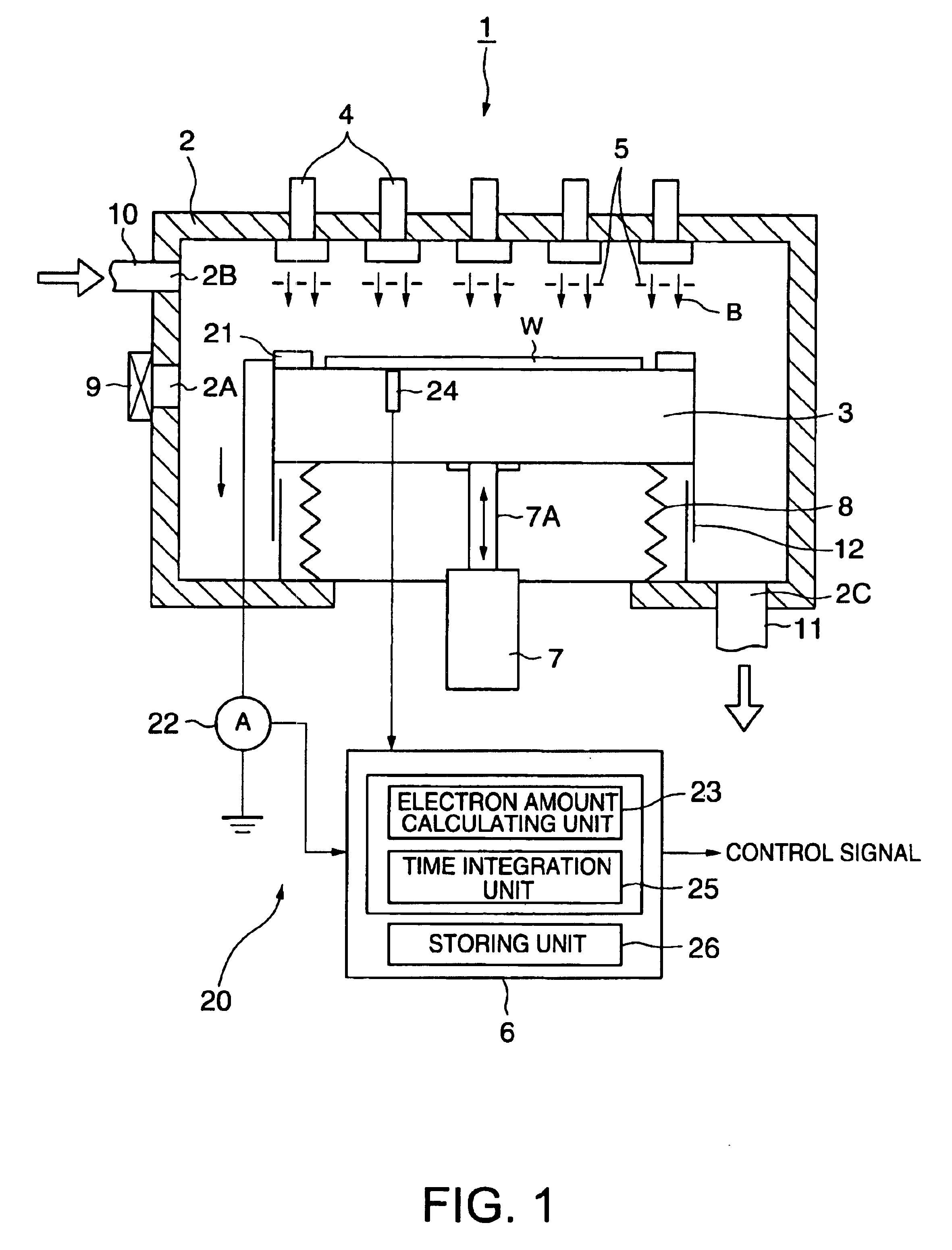

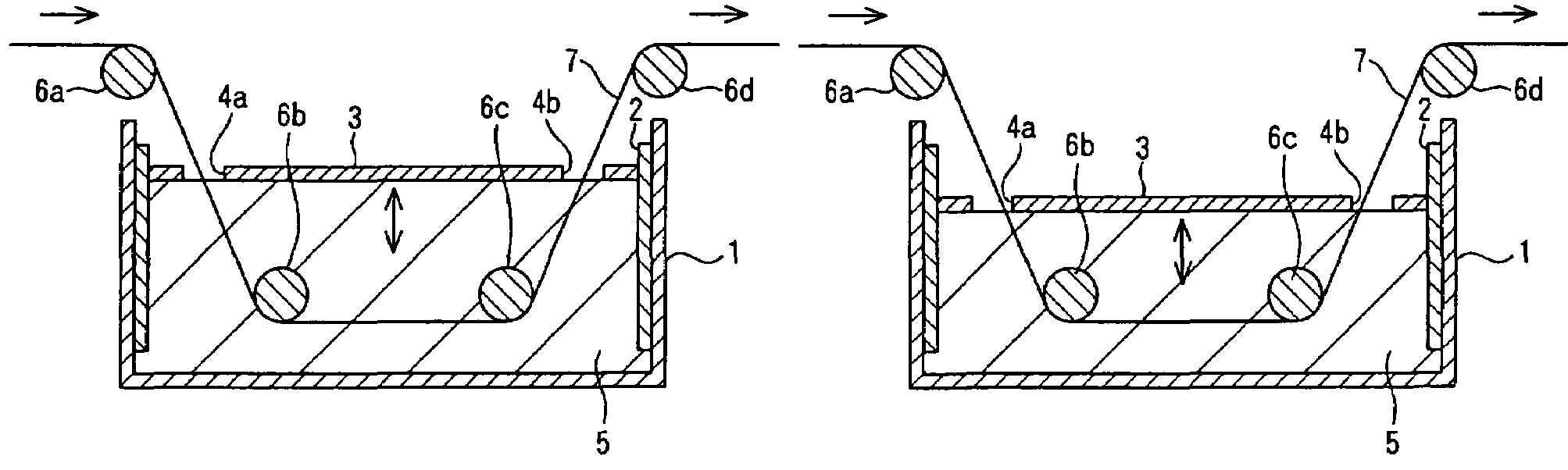

Film-processing method and film-processing apparatus

InactiveUS6903800B2Suitable film qualityLiquid processingSemiconductor/solid-state device testing/measurementSheet filmIrradiation

A film-processing method according to the present invention includes: a processing step of irradiating electron beams onto a film on a surface of an object to be processed to conduct a process to the film; an electric-current measuring step of capturing the electron beams in a vicinity of the object to be processed to measure an electric-current value during the processing step; and a detecting step of detecting an end point of the process to the film, based on an amount of electron obtained by means of a time integration of the electric-current value. According to the present invention, a suitable irradiation of the electron beams onto the film on a surface of the object to be processed can be realized. Thus, a suitable film quality can be obtained.

Owner:TOKYO ELECTRON LTD

Chemical processing apparatus for manufacturing circuit substrates

InactiveUS7553457B2Extended service lifeMaintain qualityLiquid processingPrinted circuit liquid treatmentChemical treatmentCompound (substance)

A chemical processing apparatus includes a chemical tank that stores a chemical, means for transferring an object to be processed into the chemical and a lid disposed to cover a liquid surface of the chemical and to float on the chemical.

Owner:SEIKO EPSON CORP

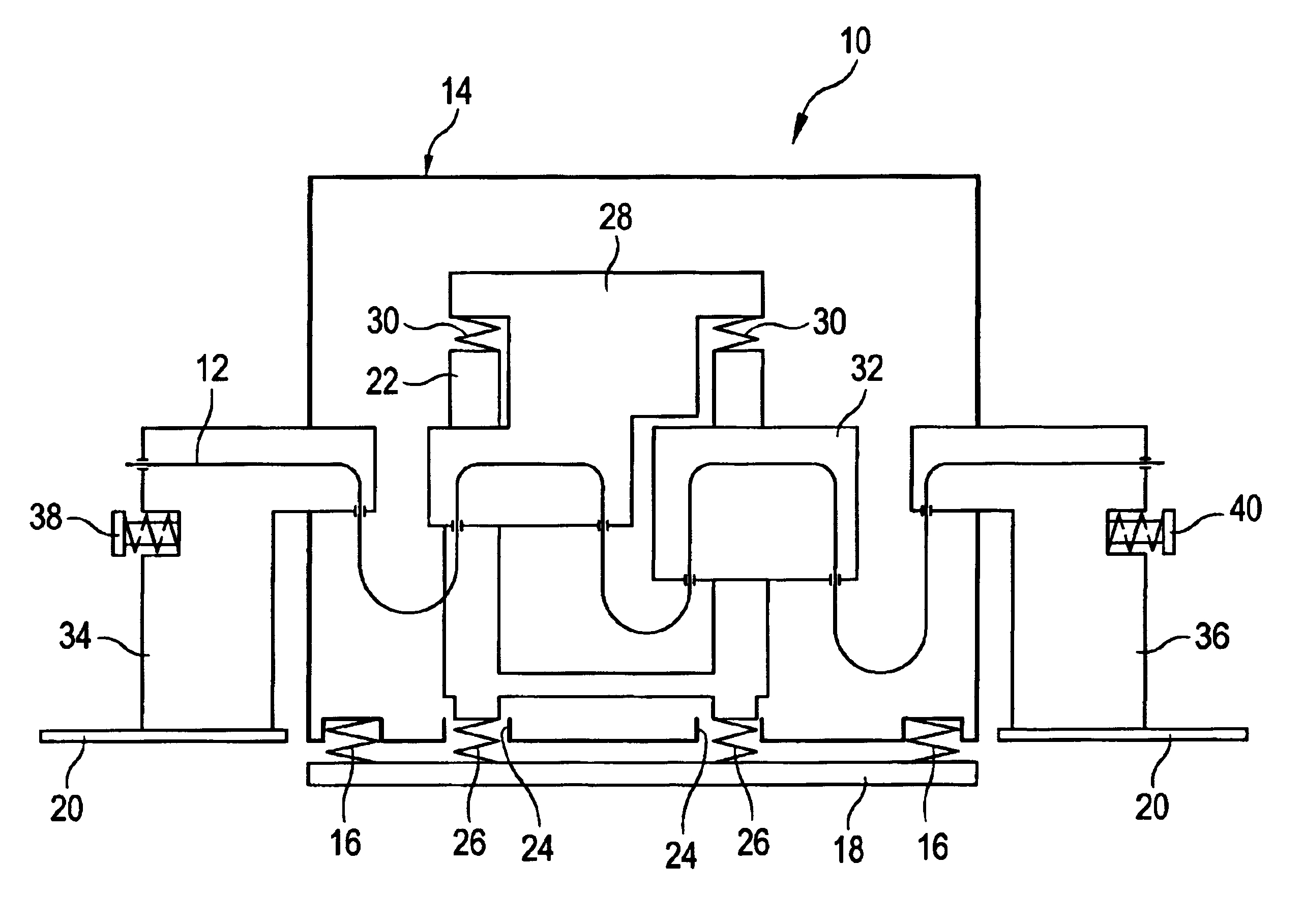

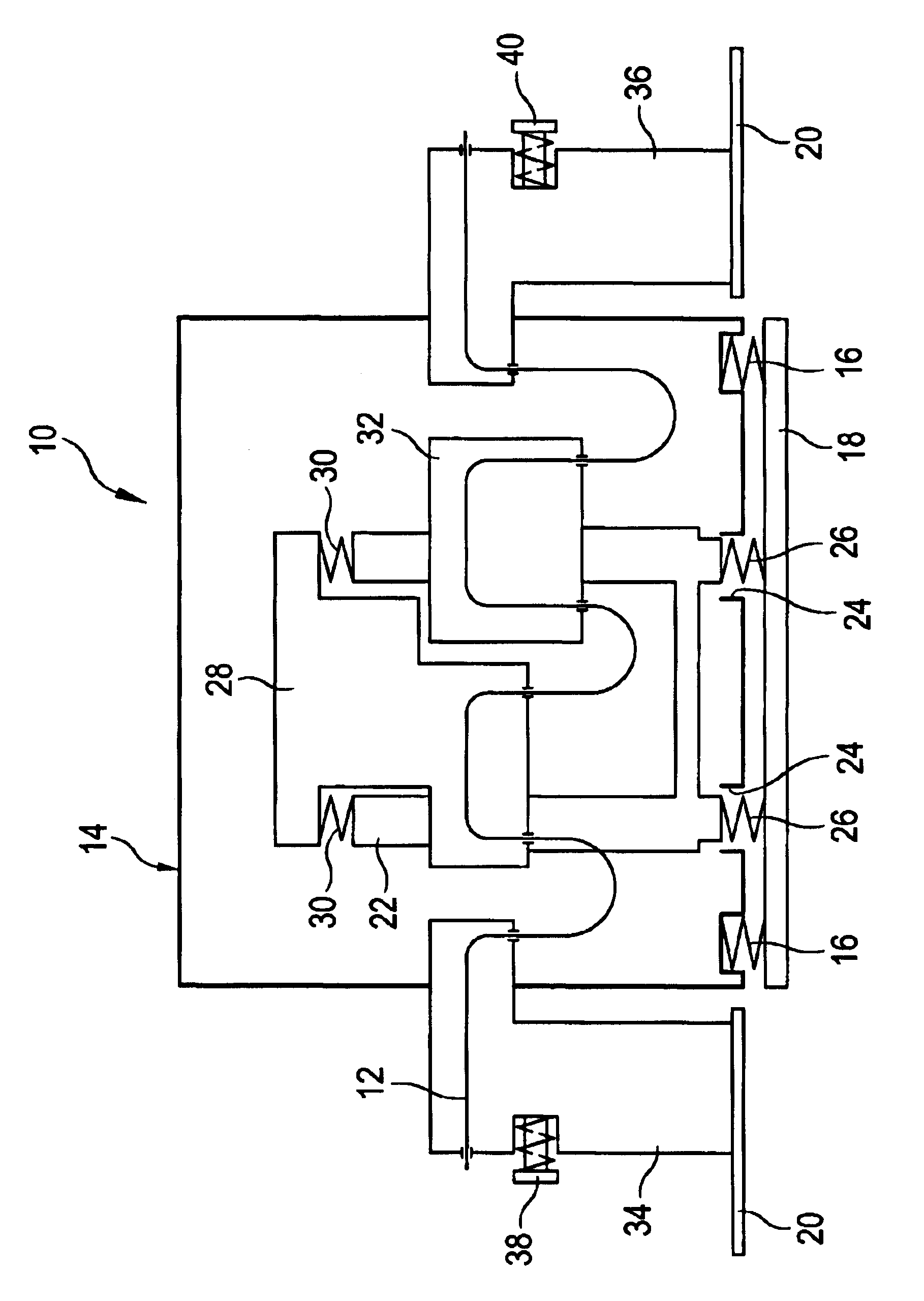

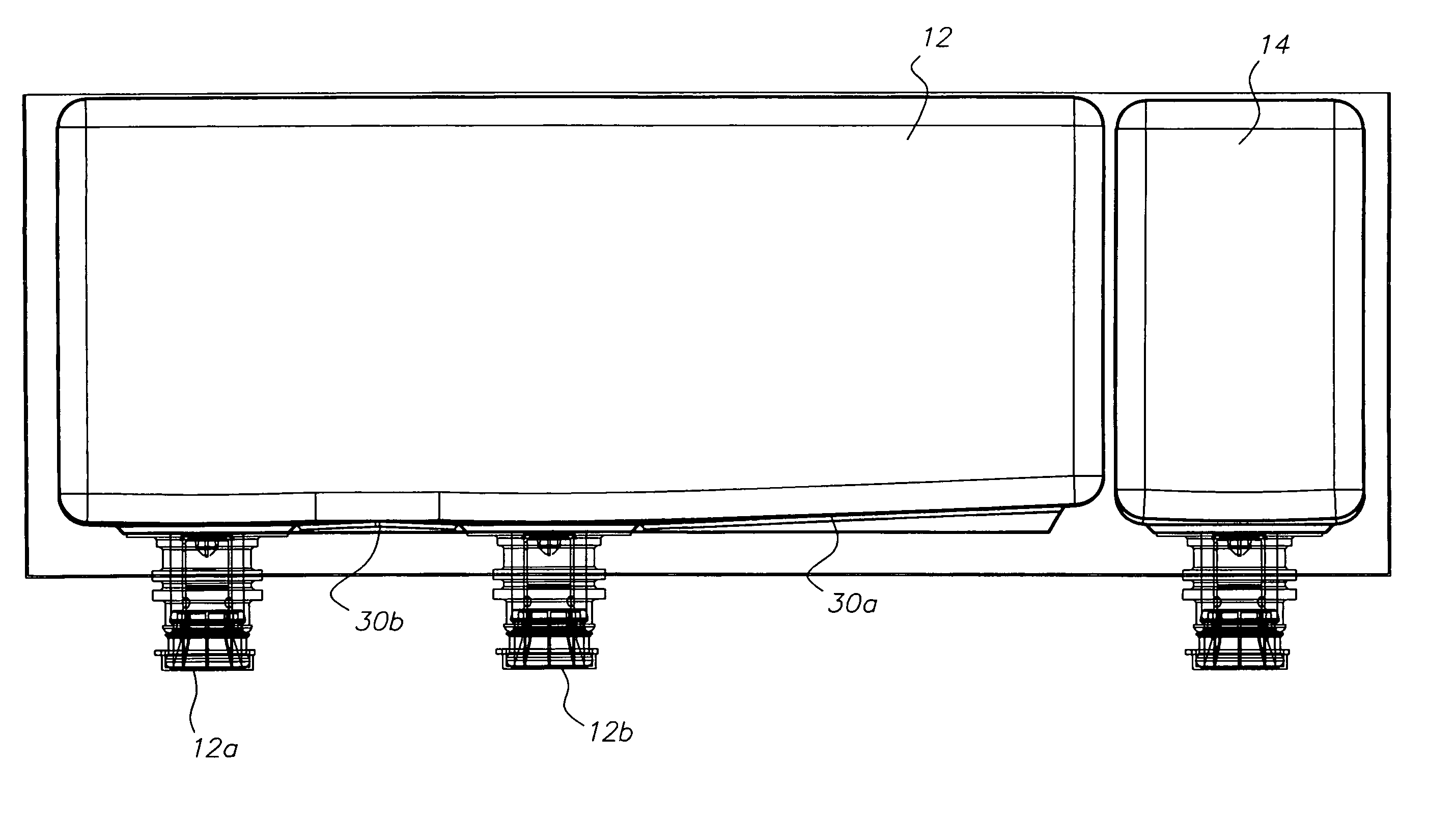

Apparatus for processing photographic materials

InactiveUS6739768B2Effective dampeningLiquid processingReversal processingPhotographic processorEngineering

An apparatus for processing photographic materials has at least one photographic processing station enclosed in a housing. The housing and the processing station are each independently mounted through their own oscillation-damping connections to a common support base, so that any connections between the housing and the processing station run exclusively through the common support base.

Owner:AGFAPHOTO

Developing apparatus, developing method and storage medium

ActiveUS8956694B2Highly uniformly processing surfaceHigh water repellencyLiquid processingSpraying apparatusResistSpray nozzle

A pretreatment process, carried out prior to a developing process, spouts pure water, namely, a diffusion-assisting liquid for assisting the spread of a developer over the surface of a wafer, through a cleaning liquid spouting nozzle onto a central part of the wafer to form a puddle of pure water. The developer is spouted onto the central part of the wafer for prewetting while the wafer is rotated at a high rotating speed to spread the developer over the surface of the wafer. The developer dissolves the resist film partly and produces a solution. The rotation of the wafer is reversed, for example, within 7 s in which the solution is being produced to reduce the water-repellency of the wafer by spreading the solution over the entire surface of the wafer. Then, the developer is spouted onto the rotating wafer to spread the developer on the surface of the wafer.

Owner:TOKYO ELECTRON LTD

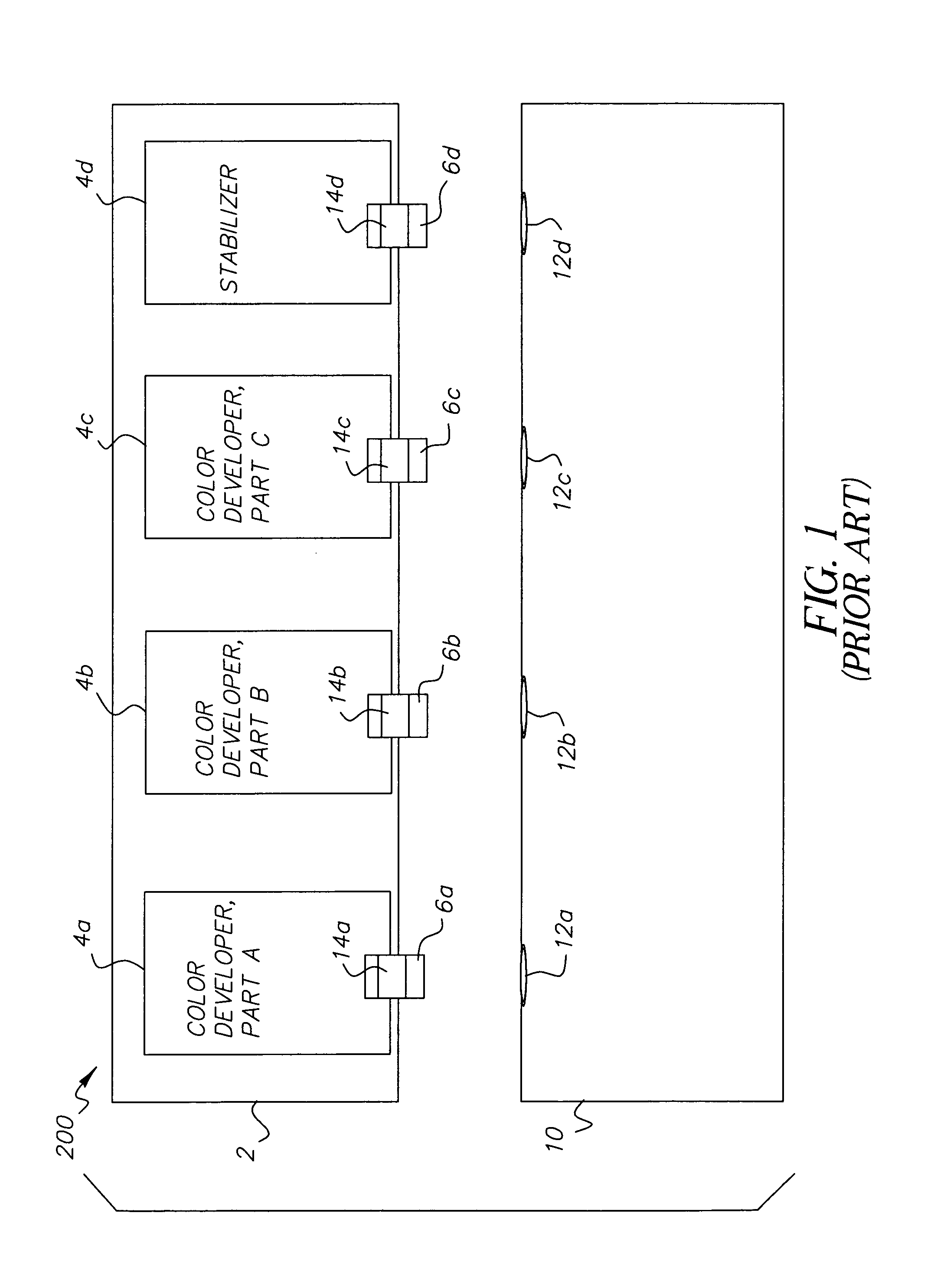

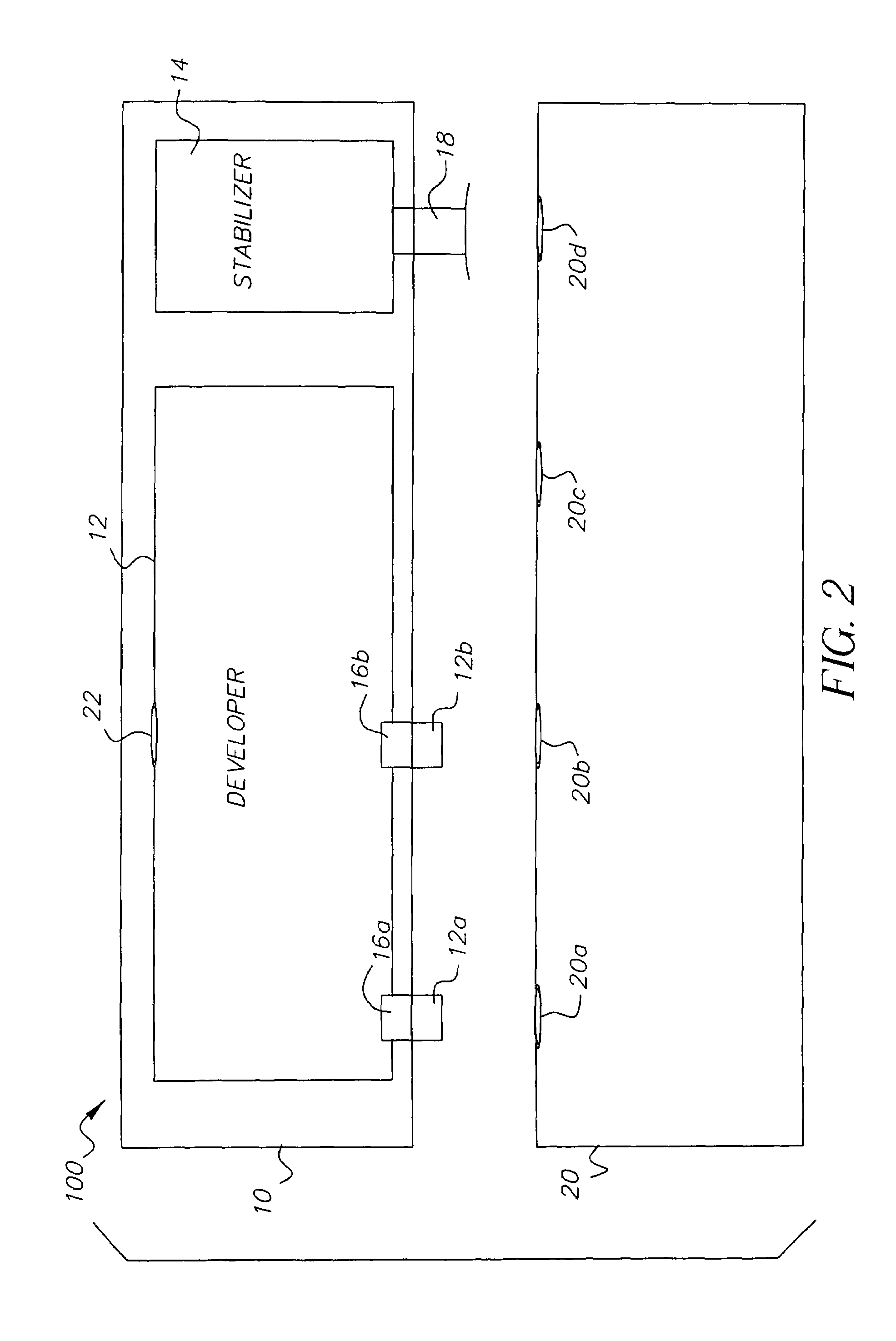

Photographic processing arrangement and a processing solution supply cartridge for the processing arrangement

InactiveUS7014373B2Easy to controlMaterial minimizationReversal processingDiffusion developmentPhotographic processingEngineering

The present invention relates to a processing solution supply cartridge which utilizes a single container for a single-part developer concentrate. The single container has at least two valves or necks and is adapted to be utilized on a existing processor or processing machine. The single developer container design of the present invention assures a complete emptying of the container by permitting the simultaneous replenishment of single-part developer through each of the valves into the processing machine. With the combination of the single developer container and the single-part developer the process of metering distinct developers through distinct containers is not required. By facilitating the complete emptying of the developer container, the likelihood of developer solution remaining in the container is minimized.

Owner:EASTMAN KODAK CO

Method of developing a resist film and a resist development processor

InactiveUS7033089B2Minimal fluctuationMaximum accuracyLiquid processingReversal processingResistSolvent

The present invention provides a resist development processor consisting of a development processing chamber for storing a resist substrate having an exposed resist on the substrate and for developing the exposed resist by means of a development solvent consisting of a supercritical fluid; and a supercritical fluid container for storing a supercritical fluid, where the supercritical fluid container is connected to the development processing chamber through a valve.

Owner:HITACHI SCI SYST LTD

Chemical processing apparatus, chemical processing method, and method for manufacturing circuit substrate

InactiveUS20050008360A1Maintain qualityOxidative deteriorationPrinted circuit liquid treatmentLiquid processingChemical treatmentCompound (substance)

A chemical processing apparatus includes a chemical tank that stores a chemical, means for transferring an object to be processed into the chemical and a lid disposed to cover a liquid surface of the chemical and to float on the chemical.

Owner:SEIKO EPSON CORP

Clean booth and sheet conveyor device

A clean booth has a conveyor area for carrying recording sheets, and a motor drive area for containing motor and mechanical parts that emit much dust. The conveyor area and the motor drive area are covered respectively, and separated by a frame plate. Moreover, fan filter units blow pressurized clean air into the conveyor area to discharge dust while a ventilation system exhausts air in the motor drive area. There is no airflow from motor drive area to the conveyor area because of the difference in air pressure. The recording sheets in the conveyor area are carried by belt conveyors with artificial suede belts. The artificial suede belt is suitable to be used as a conveyer belt because of low dust emission and sufficient flexibility to prevent flaw or pressure marks on the recording sheets.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com