A kind of thermoplastic polyolefin geotechnical composite material and preparation method thereof

A technology of thermoplastic polyolefin and geotechnical composite materials, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problem that anti-seepage materials cannot be used for long-term and direct exposure, and achieve UV aging resistance Excellent, high flexibility, elongation and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

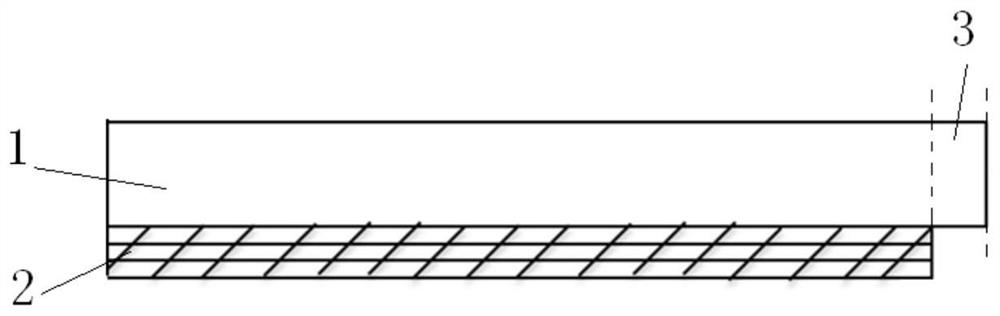

[0033] This embodiment provides a thermoplastic polyolefin geocomposite, such as figure 1 As shown, it consists of a composite thermoplastic polyolefin layer and a geotextile layer.

[0034] Among them, the thickness of the thermoplastic polyolefin layer is 2.5mm, the width is 1m, and the weight of the geotextile layer is 100g / m 2 Non-woven polypropylene geotextile, the edge of the geotextile layer is reserved 5cm from the edge of the thermoplastic polyolefin layer as a lap edge.

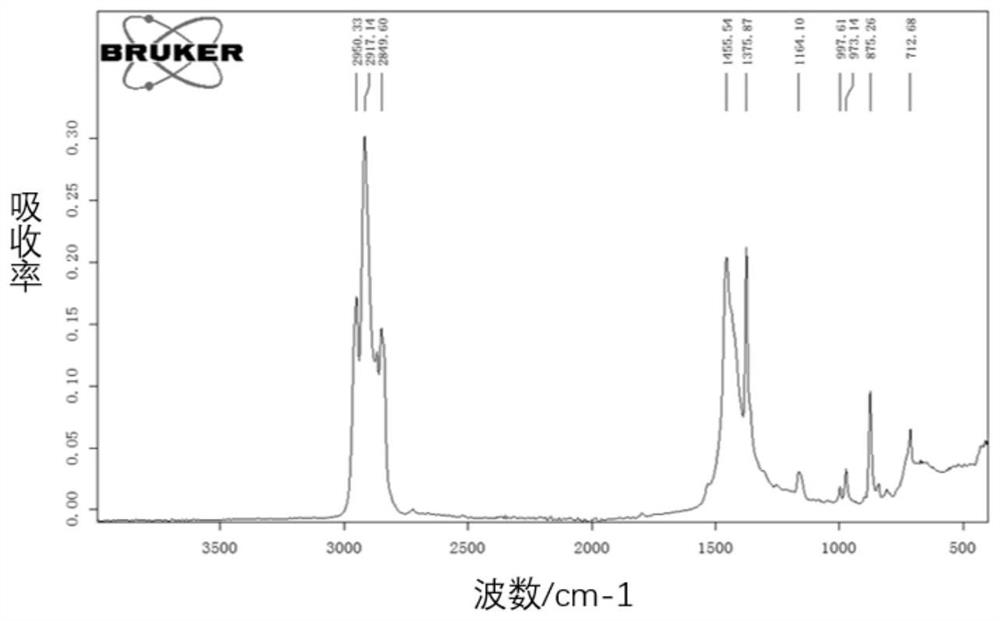

[0035] The infrared absorption spectrogram of the thermoplastic polyolefin geotechnical composite material of the present embodiment is shown in figure 2 , the preparation method of the composite material is as follows:

[0036] Transport the thermoplastic polyolefin resin, calcium carbonate filler, antioxidant and light stabilizer to the feeding device of the screw extruder, and carry out melt extrusion at the temperature of 200-240°C and the screw speed of 200 rpm to obtain the extruded The su...

Embodiment 2

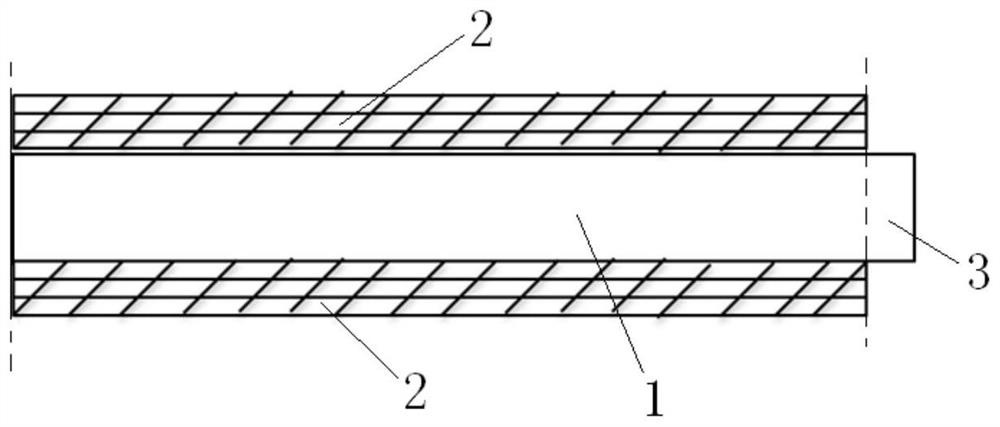

[0041] This embodiment provides a thermoplastic polyolefin geocomposite, such as image 3 As shown, it is a three-layer structure, from top to bottom: geotextile layer, thermoplastic polyolefin layer, geotextile layer.

[0042] Among them, the geotextile layer above the thermoplastic polyolefin layer is 500g / m 2 The non-woven needle-punched polyester geotextile, the geotextile layer below the thermoplastic polyolefin layer has a grammage of 800g / m 2 The woven polypropylene geotextile. The thickness of the thermoplastic polyolefin layer is 0.3mm, and the width is 2m; both ends of the geotextile layer are 10cm away from the edge of the thermoplastic polyolefin layer.

[0043] It should be noted that the material, structure, and weight of the two layers of geotextile above and below the thermoplastic polyolefin layer may be the same or different, and the specific conditions can be selected according to actual applications.

[0044] The preparation method of this composite materi...

Embodiment 3

[0050] This embodiment provides a thermoplastic polyolefin geotechnical composite material, which has a structure similar to that of the thermoplastic polyolefin geotechnical composite material in Example 1. The difference between it and Example 1 is that the thermoplastic polyolefin layer has a thickness of 3 mm and a width of 4 m. The weight of geotextile is 700g / m 2 A non-woven needle-punched polyester geotextile, and the edge of the geotextile layer is 10 cm away from the edge of the thermoplastic polyolefin layer as a lap edge.

[0051] The parts by weight of thermoplastic polyolefin resin, calcium carbonate filler, antioxidant and light stabilizer are: 80 parts, 15 parts, 3 parts, 3 parts, wherein the particle size of the filler is 2000 mesh. The weight of the non-woven needle-punched polyester geotextile is 800g / m 2 , screw speed 400 rev / min.

[0052] The infrared absorption spectrogram of the thermoplastic polyolefin geotechnical composite material of the present emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com