Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Simplify the bonding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

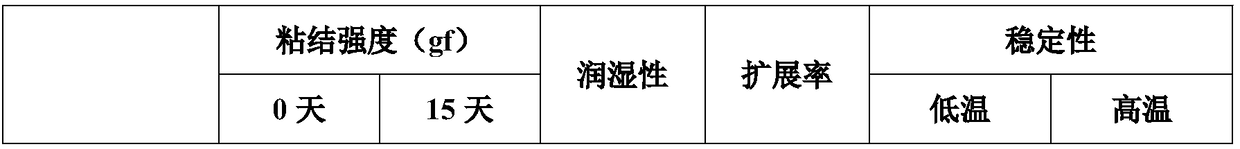

Hot melt adhesive membrane for bonding bi-metallic composite plate and preparing method thereof

InactiveCN102559078AUniform thicknessSimple bonding processFilm/foil adhesivesPolyureas/polyurethane adhesivesWeather resistanceChemistry

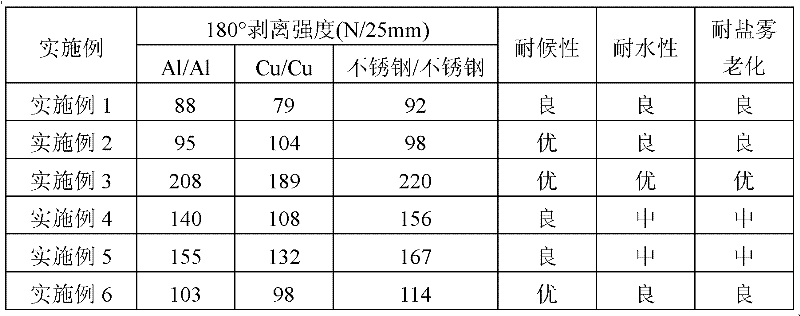

The invention provides a hot melt adhesive membrane for bonding a bi-metallic composite plate and a preparation method of the hot melt adhesive membrane. The adhesive membrane is prepared by the following steps: adopting one or several from polyacrylate rubber, polyethylene-acrylic acid (ester) copolymer or polyvinyl chloride-vinyl acetate esters copolymer as adhesive-based resin; adopting one or several blends from polyethylene, chloridize polyethylene, polyethylene-octene copolymer, ethylene propylene rubber, polyethylene-vinyl acetate, polymethyl methacrylate, polymethyl methacrylate-butadiene-styrene copolymer, polystyrene, thermoplastic polyurethane and polyvinyl chloride as a second matrix; adding a certain amount of thickening agents, fillers and functional additives after pre-mixing; and then casting to form the membrane. The hot melt adhesive membrane has high bonding strength and lasting stability, excellent weather resistance, aging resistance of salt mist, and water resistance, and is suitable for compounding and bonding of metal materials such as stainless steel, galvanized steel, iron, aluminum, copper, titanium alloys and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

High-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and preparation method thereof

ActiveCN103205210AHigh bonding strengthImprove heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesElastomerPolyester

The invention discloses a high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and a preparation method thereof. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards is made from, by weight percent, 30-50% of polyester elastomer with above 180 DEG C of melting point, 10-40% of polyolefin copolymer modified by maleic anhydride, 0-40% of polyolefin copolymer, 10-30% of tackifying resin, 0-15% of filler, and 1-3% of functional aid. The components add up to 100%. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards has the advantages of high adhesion strength, instantaneous resistance to the temperature up to 170-190 DEG C, and long-term resistance to the temperature up to 130 DEG C.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

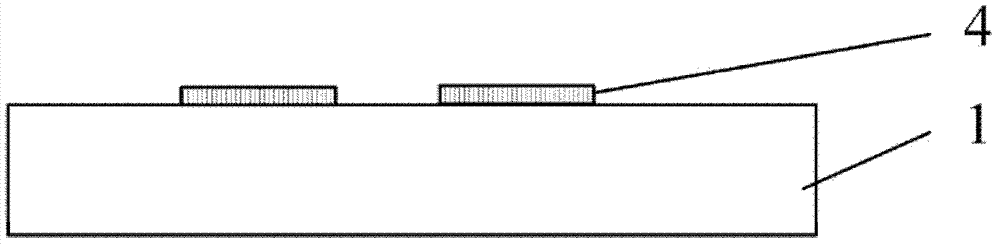

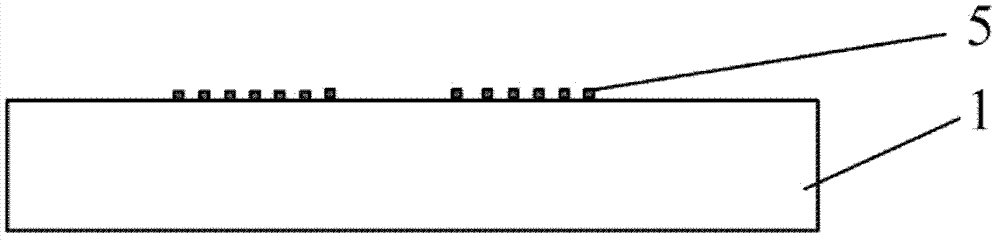

Flexible display panel, display device and making method of flexible display panel

ActiveCN107564415AExtend your lifeImprove bending resistanceIdentification meansDisplay deviceEngineering

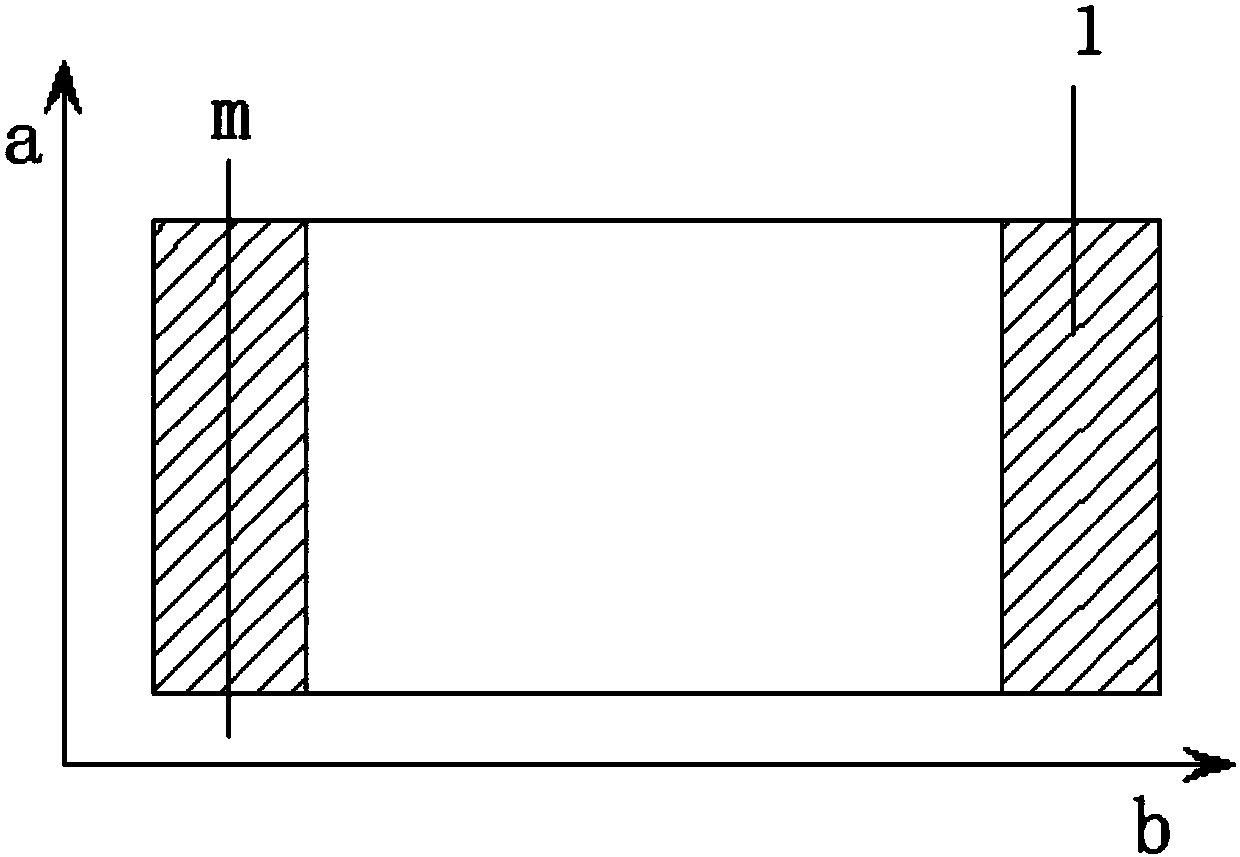

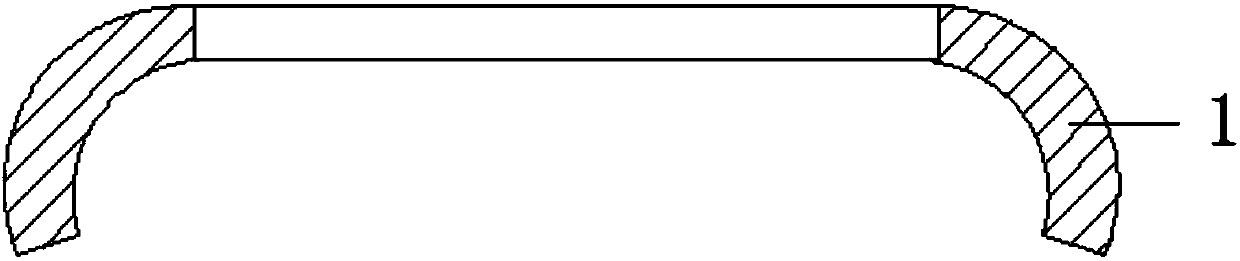

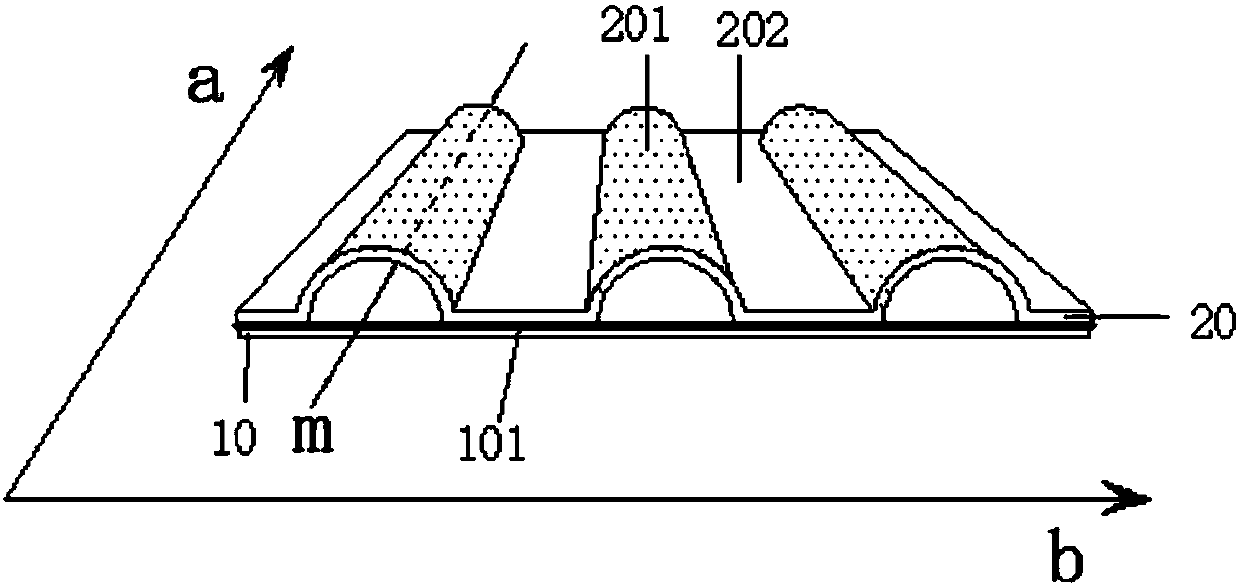

The invention discloses a flexible display panel, a display device and a making method of the flexible display panel. A bending shaft in a bendable area of the flexible display panel extends in the first direction, and the flexible display panel comprises a support membrane and a flexible display module which is arranged on the first surface of the support membrane, wherein in the bendable area, the flexible display module comprises a plurality of crinkled parts and fixed parts, the crinkled parts and the fixed parts are sequentially arranged in the second direction in an alternated mode, thecrinkled parts extend in the first direction, the fixed parts are fixed to the first surface, and the first direction is perpendicular to the second direction. When the bendable area is in a flattenedstate, the crinkled parts are in a crinkled state, and when the bendable area is in a bending state, the crinkled parts can be flattened. According to the flexible display panel, when the flexible display module of the bendable area is divided into the crinkled parts and the fixed parts, the fixed parts are fixed to the first surface of the support membrane, and the states of the crinkled parts are changed along with the state of the bendable area, the bending stress is absorbed, the bending resistance and the tension resistance of the flexible display module are enhanced, and the service life of the flexible display panel is prolonged.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

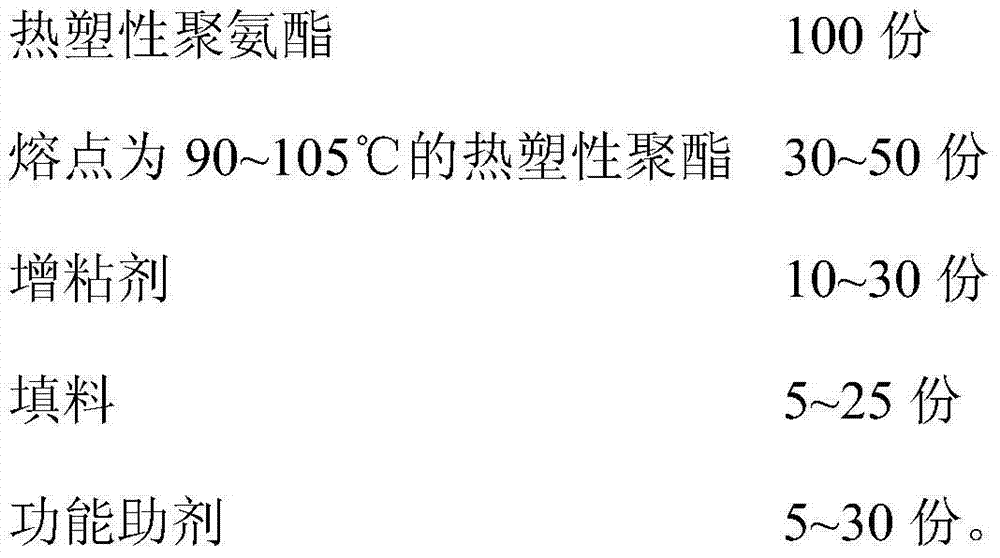

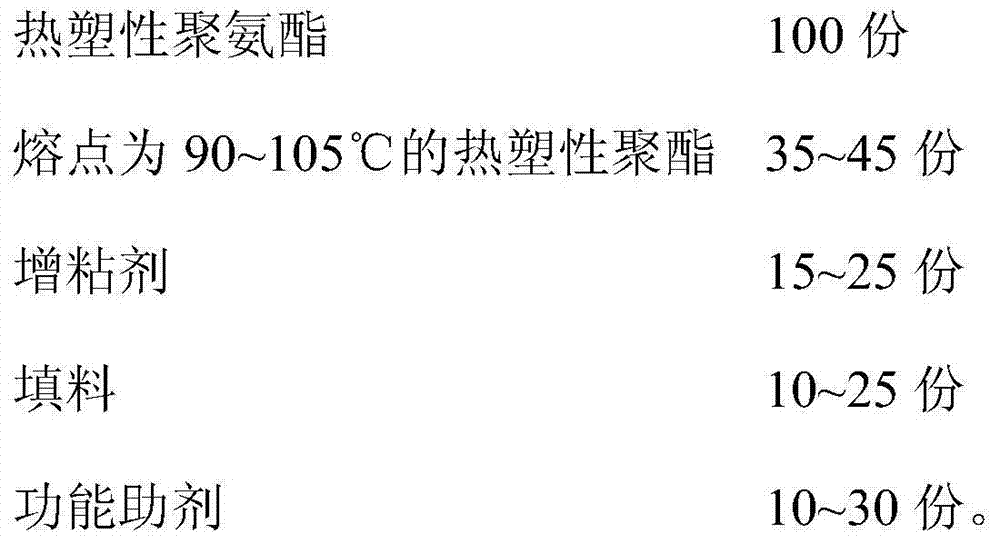

Low-melting-point and high-bonding-strength TPU (thermoplastic polyurethane) hot melt adhesive membrane and preparation method thereof

ActiveCN104263259AUniform thicknessSimple bonding processNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyester

The invention provides a TPU (thermoplastic polyurethane) hot melt adhesive membrane. The TPU hot melt adhesive membrane is mainly prepared from the following raw materials in parts by weight: 100 parts of TPU, 30-50 parts of thermoplastic polyester of which the melting point is 90-105 DEG C, 10-30 parts of a tackifier, 5-25 parts of a filling material and 5-30 parts of a functional auxiliary agent. The hot melt adhesive membrane prepared by using the method provided by the invention is of a thermoplastic adhesive, is uniform in thickness and simple in bonding process, is suitable for bonding by adopting an automatic production line, is high in production efficiency and large in peeling strength after bonding, can resist water, heat and salt fog aging in an outdoor harsh environment, is durable in bonding, and can be used for significantly improving the bonding strength of the hot melt adhesive membrane adhered to fabrics.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Polyester hot-melt adhesive and coating method thereof

ActiveCN102703013AReduce melt viscosityExcellent film appearanceFilm/foil adhesivesLaminationEpoxyPolyester

The invention relates to the technical field of adhesives, and in particular relates to a polyester hot-melt adhesive. The polyester hot-melt adhesive comprises polyester hot-melt adhesive resin, epoxy resin and curing agents, wherein the mass ratio of the polyester hot-melt adhesive resin to the epoxy resin and to the total amount of the curing agents is 70:(30-99):1. The polyester hot-melt adhesive is low in adhesive strength attenuation, so that the adhesive strength of the polyester hot-melt adhesive on metal can be obviously improved, the melting viscosity of the polyester hot-melt adhesive is reduced, and the film-forming appearance of the polyester hot-melt adhesive is improved; and moreover, the polyester hot-melt adhesive can be prevented from being hydrolyzed, high adhesion of the polyester hot-melt adhesive at low temperature, normal temperature even high temperature is kept, and the mass production property is high.

Owner:东莞市安派电子有限公司

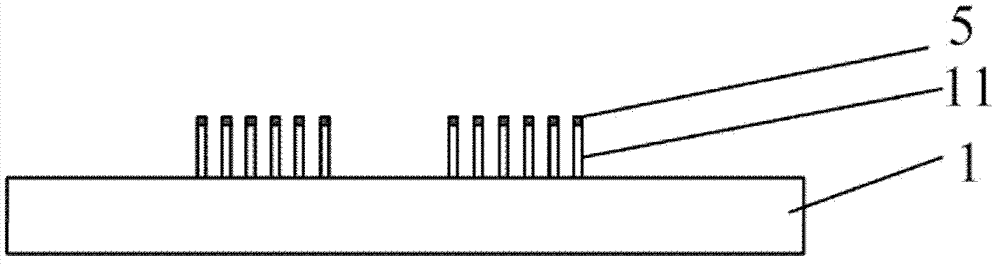

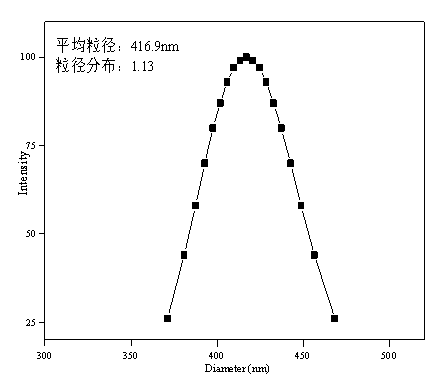

Microfluidic surface-enhanced Raman scattering detector and its preparation method and use

The invention discloses a microfluidic surface-enhanced Raman scattering detector and its preparation method and use. The microfluidic surface-enhanced Raman scattering detector comprises an active base and a microfluidic channel-containing structure layer. A microfluidic channel chamber is formed between the active base and the microfluidic channel-containing structure layer. The active base corresponding to the microfluidic channel chamber is provided with multiple nanoscale concave structures. The microfluidic channel-containing structure layer corresponding to the microfluidic channel chamber is provided with at least one pair of a liquid inlet and a liquid outlet communicated with the microfluidic channel chamber. A metal layer is coated on nanoscale concave structure surfaces and an active base surface located in the microfluidic channel chamber. The microfluidic surface-enhanced Raman scattering detector having a double-layer polydimethylsiloxane structure has a high yield, a low cost, good detection consistency and no noise interference and can realize real-time monitoring. The microfluidic surface-enhanced Raman scattering detector can be used for detection of an analyte in gas, colloid and liquid environments.

Owner:PEKING UNIV

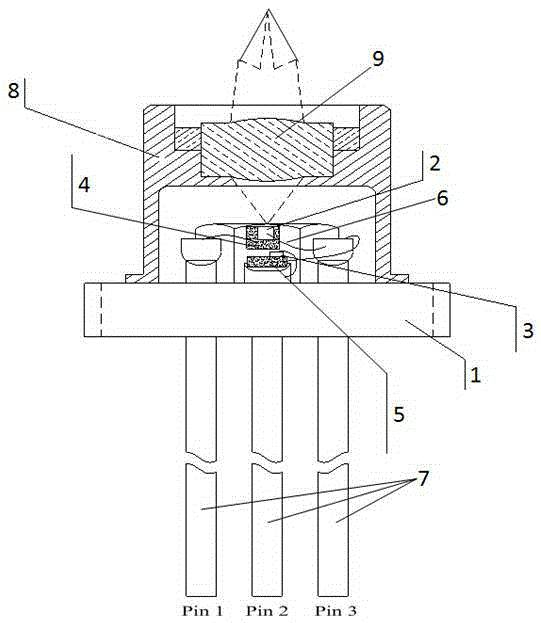

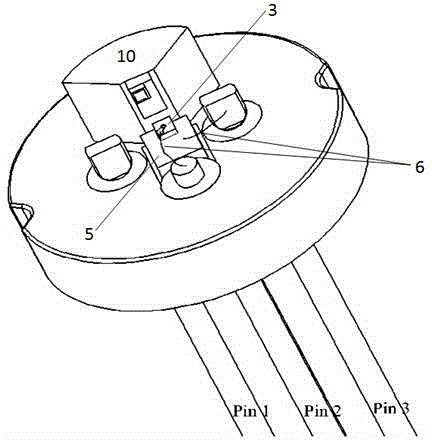

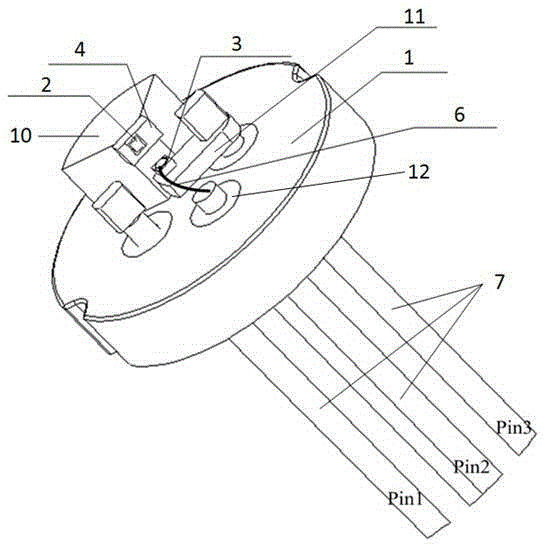

Transistor outline (TO)-CAN packaged semiconductor laser and fabrication method thereof

InactiveCN105261929ALow costAvoid the risk of easy sheddingLaser detailsSemiconductor lasersSemiconductor packageSemiconductor chip

The invention proposes a transistor outline (TO)-CAN packaged semiconductor laser and a fabrication method thereof. The TO-CAN packaged semiconductor laser comprises a TO tube base, a semiconductor laser chip, a backlight detector chip, a gold bonding wire, pins and a heat sink block, wherein the heat sink block is arranged on the upper surface of the TO tube base, the pins are fixed on the TO tube base in an insulation way, the upper end of at least one pin protrudes out of the upper surface of the TO tube base, the semiconductor laser chip is fixed on the surface of the heat sink block, the upper part of the pin protruding out of the upper surface of the TO tube base is connected with a support table, and the backlight detector chip is arranged on the support table and below the semiconductor laser chip. In the TO-CAN packaged semiconductor laser, the backlight detector chip is arranged on the support table integrated and connected with the pins, thus, an independent cushion block is omitted, and the material cost of the cushion block is saved; and moreover, the gold wire bonding process between the backlight detector chip and the cushion block in one time is omitted, the gold wire bonding process is simplified, the gold wire bonding cost is saved, and the stability of a laser product is improved.

Owner:武汉海赛姆光电技术有限公司

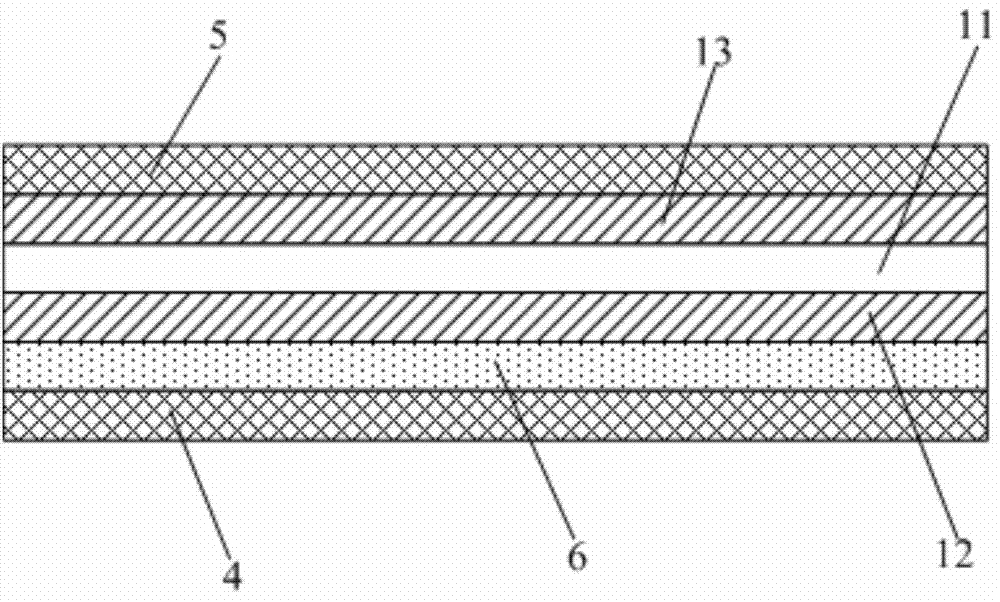

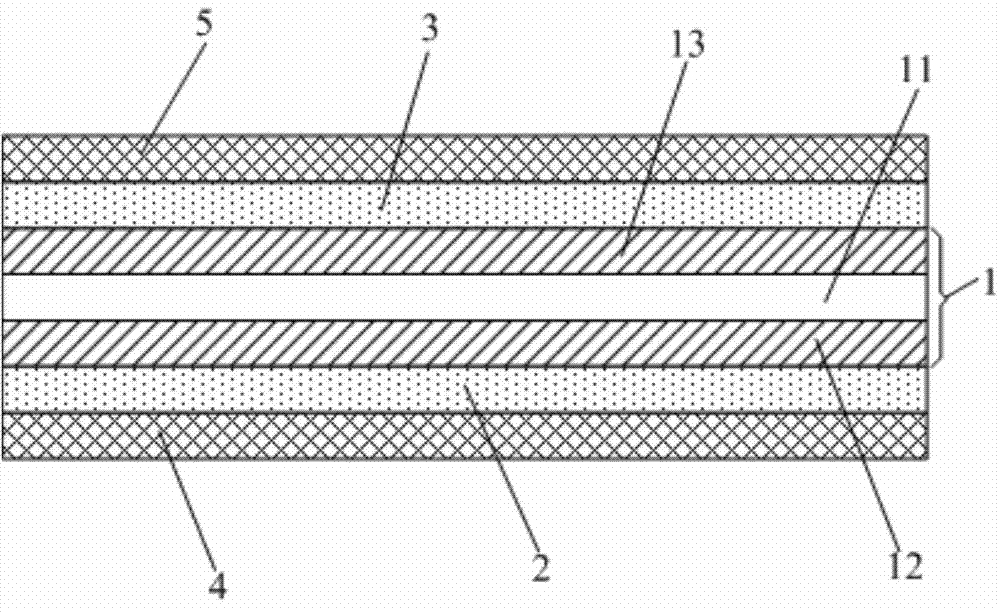

Polarizer, display panel, display panel forming method and display device

InactiveCN104267456ASimplify the bonding processImprove fitPolarising elementsNon-linear opticsDisplay devicePolarizer

The invention provides a polarizer, a display panel, a display panel forming method and a display device. The polarizer comprises a polarizing film layer and a first bonding layer arranged on the lower surface of the polarizing film layer. The first bonding layer is used for being bonded with a display substrate. The polarizer further comprises a second bonding layer arranged on the upper surface of the polarizing film layer. The second bonding layer is used for being bonded with a first film layer. The polarizer is formed by adding the second bonding layer to an existing polarizer, the two faces of the polarizer can be easily and conveniently attached to the display substrate and the first film layer, and therefore the attaching technology of the polarizer in the two-face attaching process is greatly simplified.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Styrene modified polyvinyl acetate emulsion and preparation method

InactiveCN103131354AWith boiling water resistanceSystem stabilityMonocarboxylic acid ester polymer adhesivesAdhesiveCarvacryl acetate

The invention relates to a styrene modified polyvinyl acetate emulsion and a preparation method, and relates to the modified polyvinyl acetate emulsion and the preparation method. The styrene modified polyvinyl acetate emulsion comprises the following raw materials by weight: 58-62% of deionized water, 2-10% of polyving akohol, 20-35% of mixed monomer 1, 4-20% of mixed monomer 2, 0.6-2% of compound emulsifier, 0.1-0.5% of pH buffering agent and 0.1-1% of initiator. The preparation method employs a staging polymerization mode, in a first stage, vinyl acetate monomer is polymerized to form a polymer seed; in a second stage, a styrene monomer is polymerized in the polymer seed to form emulsion particles with a two-phase separation structure. According to the invention, the process is simple, the cost is low, the boiling water resistance performance of the polyvinyl acetate emulsion is increased, no environmental pollution is generated, and cold pressure curing at normal temperature, and the styrene modified polyvinyl acetate emulsion can be directly used as aqueous adhesives.

Owner:NORTHEAST FORESTRY UNIVERSITY

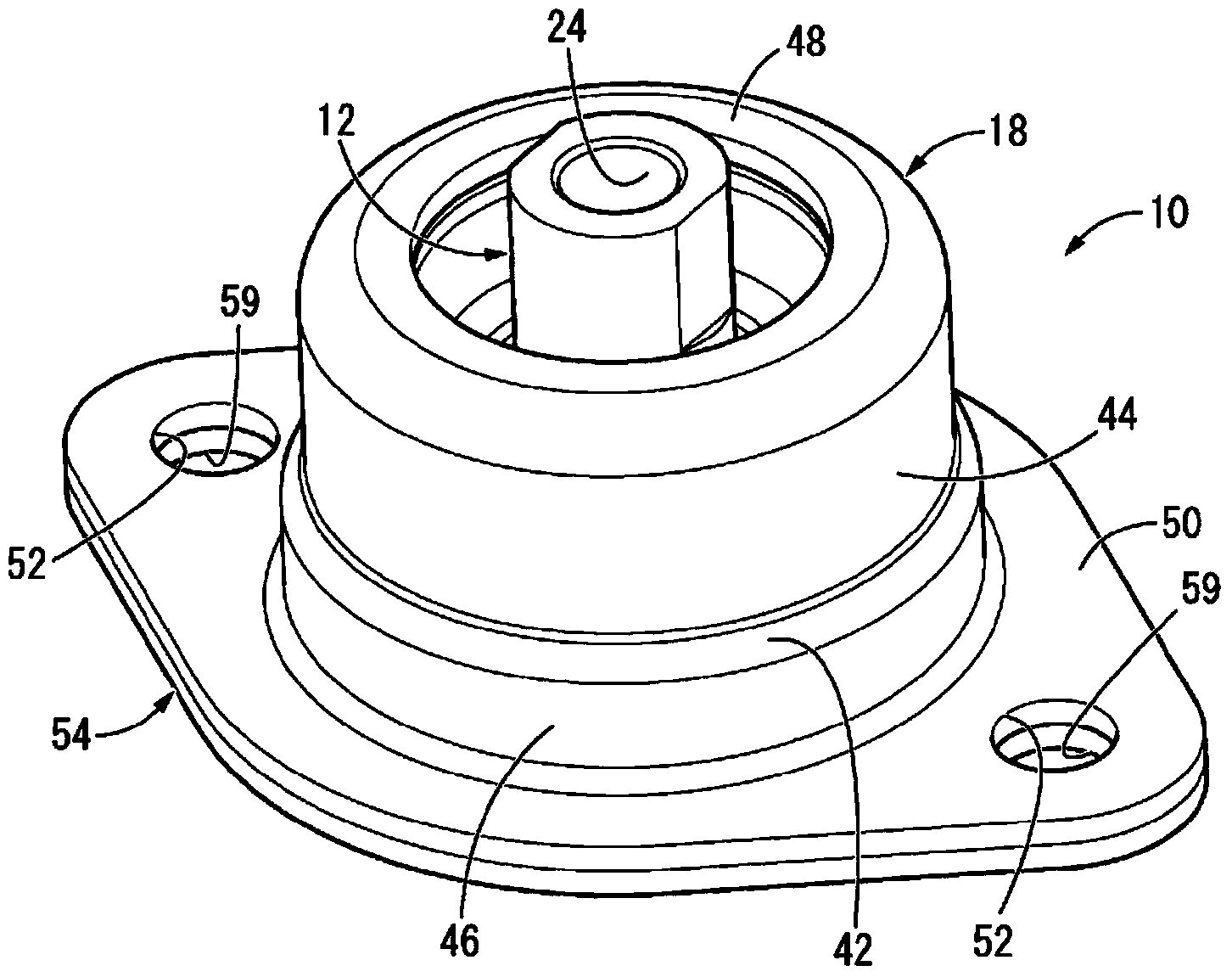

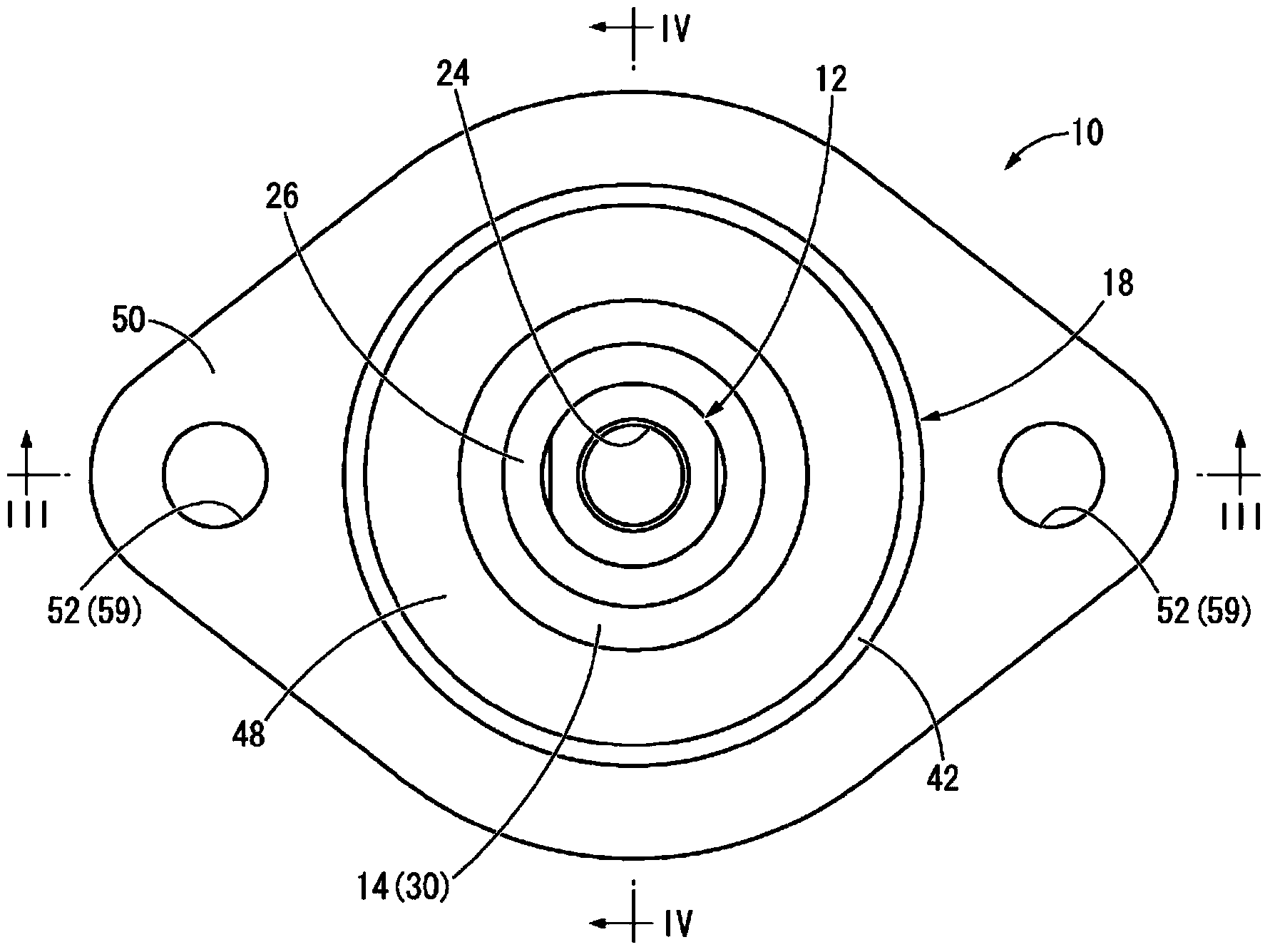

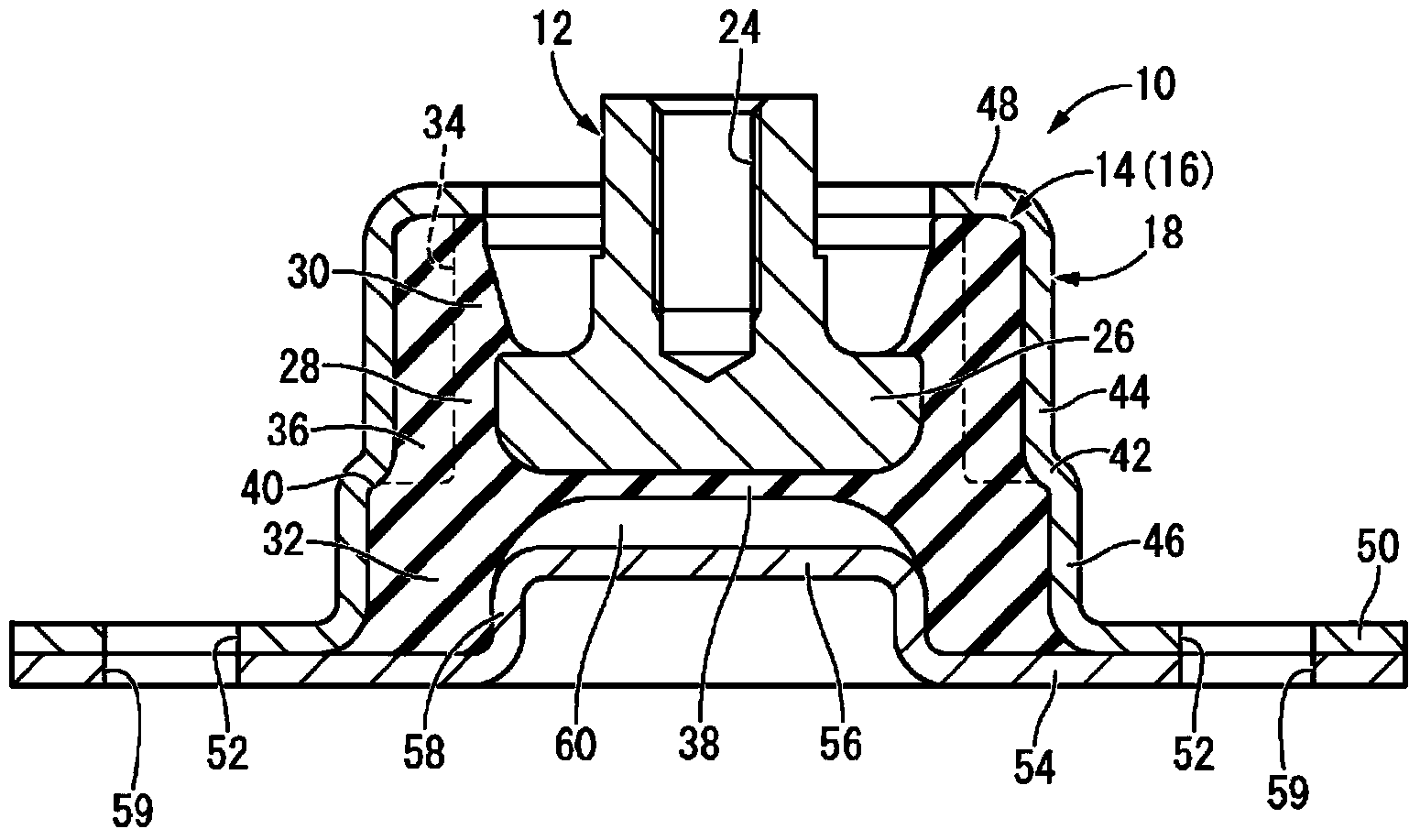

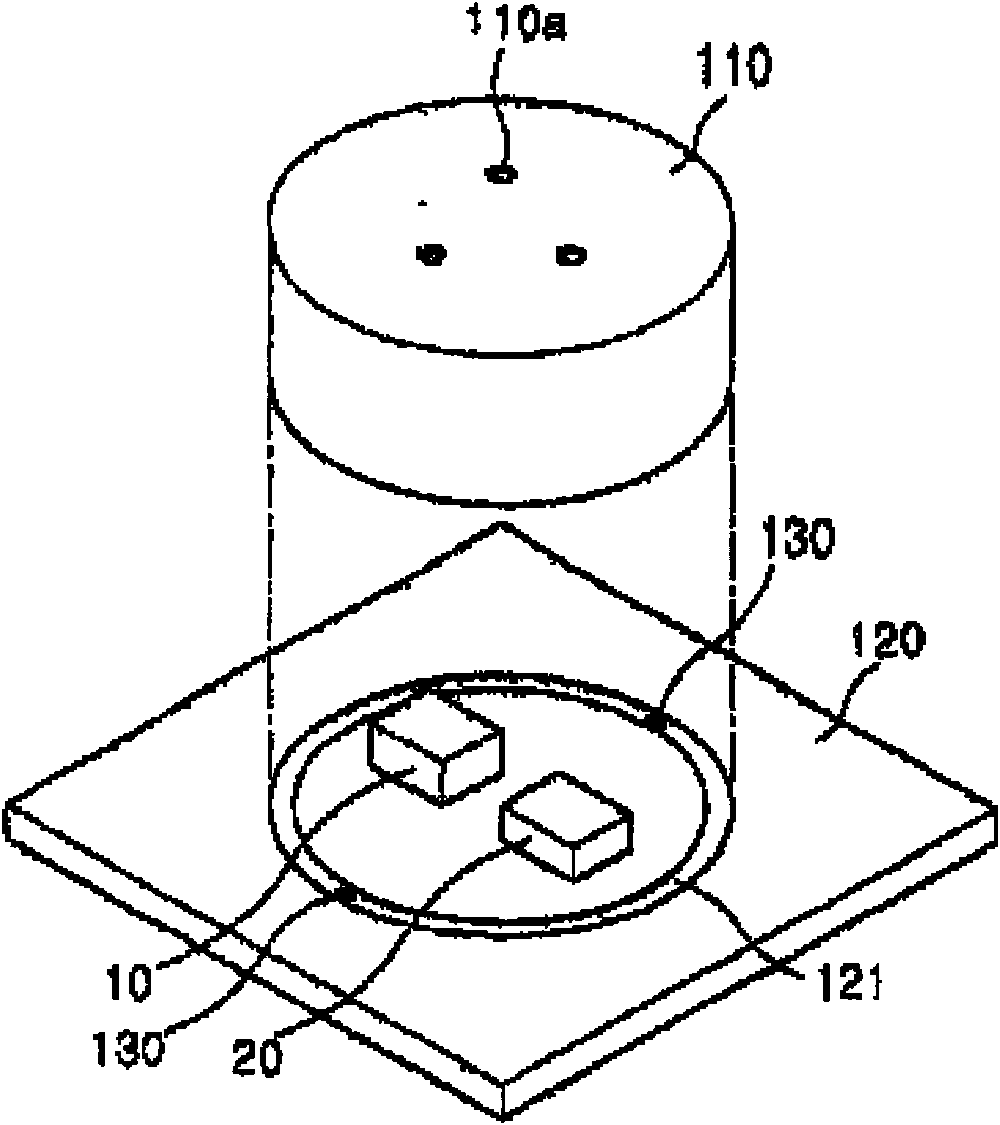

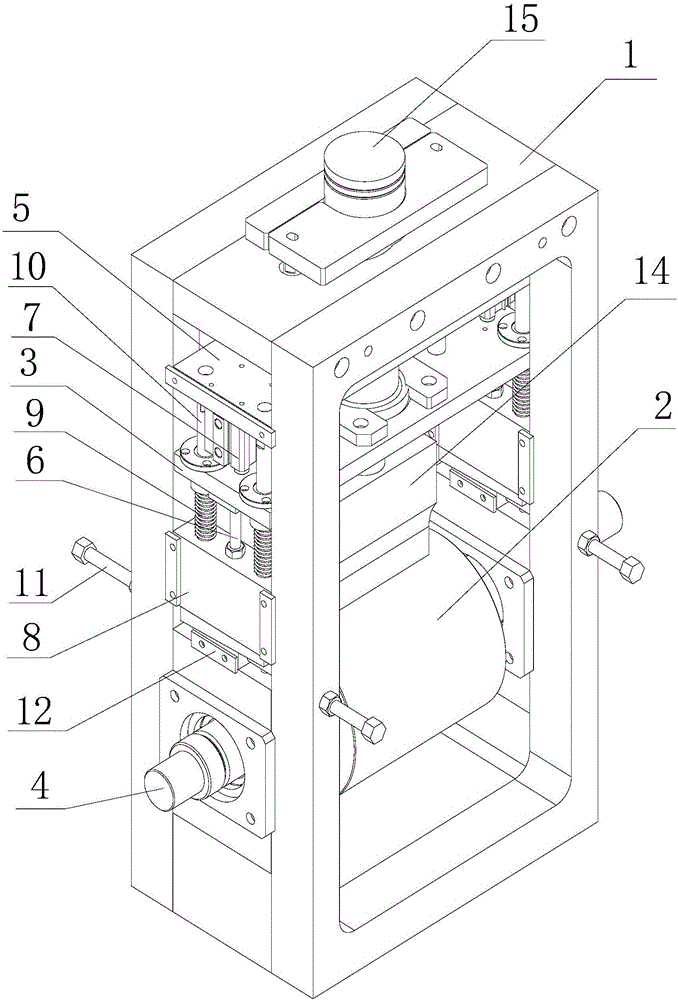

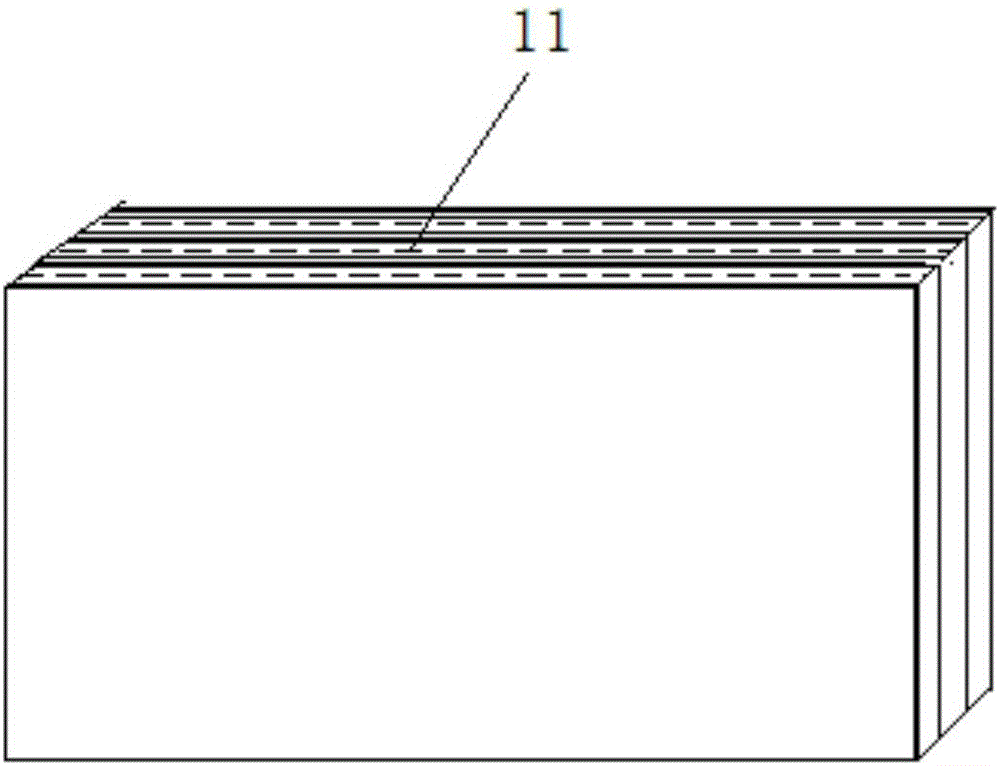

Antivibration apparatus

InactiveCN103459884ASimplify the bonding processIncreased durabilityNon-rotating vibration suppressionRubber-like material springsEngineeringMechanical engineering

Provided is an antivibration apparatus having a novel structure allowing separate adjustment of each spring on a main rubber elastic body according to the required spring characteristics. An outer circumferential linking rubber (28) and a first and second axial-direction projecting rubber (30, 32) are formed on the main rubber elastic body (14). An outer attachment member (18) is provided on both sides of a stepped part (42) with a small-diameter cylinder (44) and a large-diameter cylinder (46), an inward-projecting part (48) being formed in the opening of the small-diameter cylinder (44) and an inner circumferential cylinder wall (58) being formed on a restraining member (54) affixed to the opening of the large-diameter cylinder (46). The outer circumferential linking rubber (28) is disposed in the space facing the direction perpendicular to the axis of an inner attachment member (12) and the inward-projecting part (48). The first axial-direction projecting rubber (30) is held by compression in the axial direction between the inner attachment member (12) and the inward-projecting part (48). The second axial-direction projecting rubber (32) is held by compression in the axial direction between the restraining member (54) and the inner attachment member (12) and stepped part (42), and is also held by compression in the direction perpendicular to the axis between the inner circumferential cylinder wall (58) and the large-diameter cylinder (46).

Owner:SUMITOMO RIKO CO LTD

Soldering assisting glue and preparing method and application thereof

ActiveCN108747090AEasy to understandSimplify the bonding processWelding/cutting media/materialsSoldering mediaActive agentDiluent

The invention relates to the technical field of welding, in particular to soldering assisting glue and a preparing method and application thereof. The soldering assisting glue at least comprises the following components including, by weight, 20-60 parts of rosin, 2-15 parts of an active agent, 5-30 parts of a tackifier, 0-20 parts of a thixotropic agent and 5-60 parts of a diluent.

Owner:上海华庆焊材技术股份有限公司

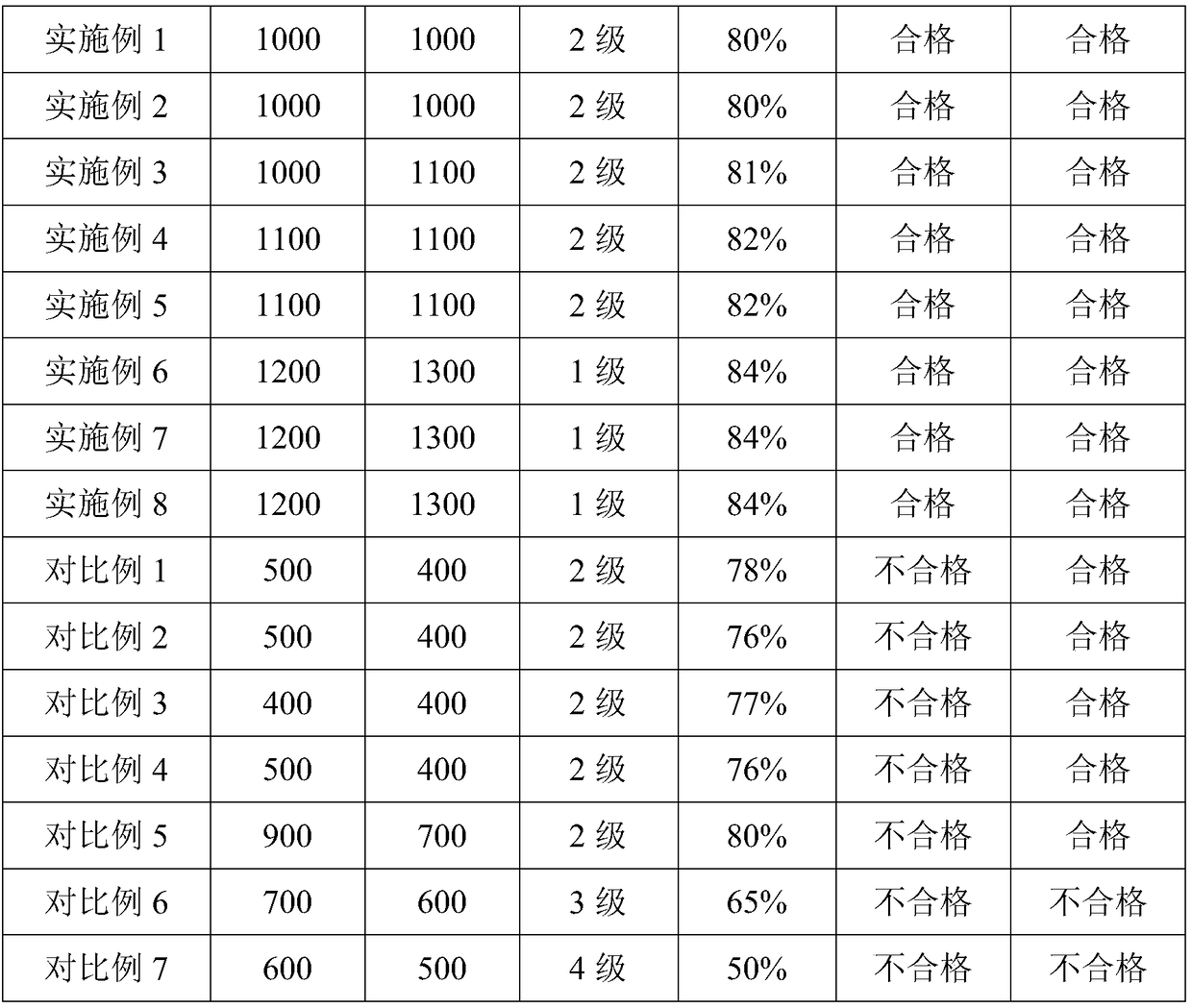

Vulcanization bonding process by template method for conveying belt

The invention relates to a vulcanization bonding process by a template method for conveying belts, which comprises: cutting a cloth layer and a glue layer of a belt joint part into symmetric gradient according to a certain form and angle, smearing rubber cement for bonding, then heating for a certain time to perform a vulcanization reaction at a certain pressure and temperature so as to allow rawrubber to become vulcanized rubber and provide the joint with optimal bonding strength. The invention introduces a bold innovation based on the original thermal bonding process, establishes a new process of lineation cutting and peeling for vulcanization bonding template; the process greatly shortens the bonding time; the new cutting and bonding process for the vulcanization bonding template method is safe, simple and rapid, saves human and material resources, improves working efficiency, increases the quality by 15-20%, and fills a gap in belt vulcanization bonding technology.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

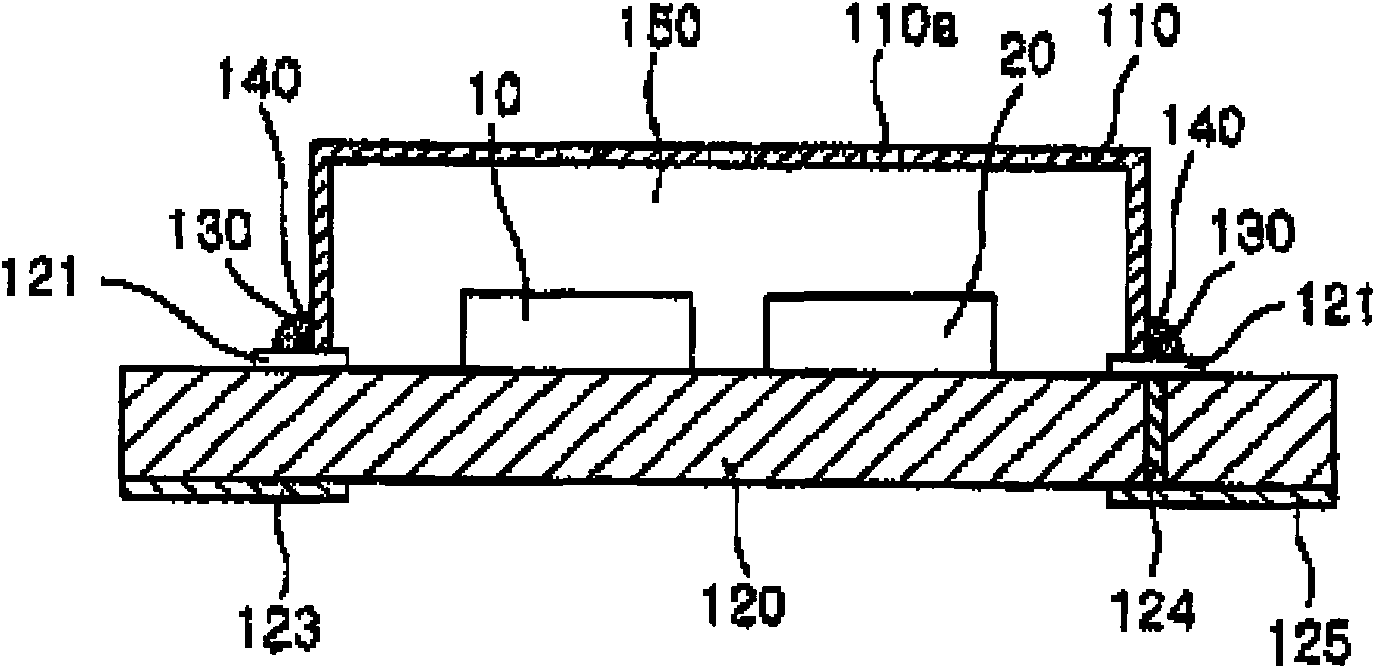

MEMS microphone and encapsulation method thereof

ActiveCN102118674ASimple bonding processReduce manufacturing costElectrostatic transducer microphonesAdhesiveEngineering

The invention provides a micro electro mechanical system (MEMS) microphone and an encapsulation method thereof. The MEMS microphone comprises a circuit board and a shell fixedly connected with the circuit board; the circuit board is combined with the opening end of the shell to form an encapsulation structure of the MEMS microphone; moreover, an annular insulation adhesive layer is arranged between the circuit board and the opening end of the shell; and the three parts, namely the surface of the opening end of the shell, the annular insulation adhesive layer, and the position, combined with the opening end of the shell, of the circuit board form a capacitor. In the MEMS microphone, the insulation adhesive layer instead of a conductive adhesive which has high boundedness, high cost and poor adhering effect is adopted between the shell and the circuit board; and by the technical scheme, the adhering process is simple, the production cost is reduced, and the large-scale popularization of the MEMS microphone is facilitated.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

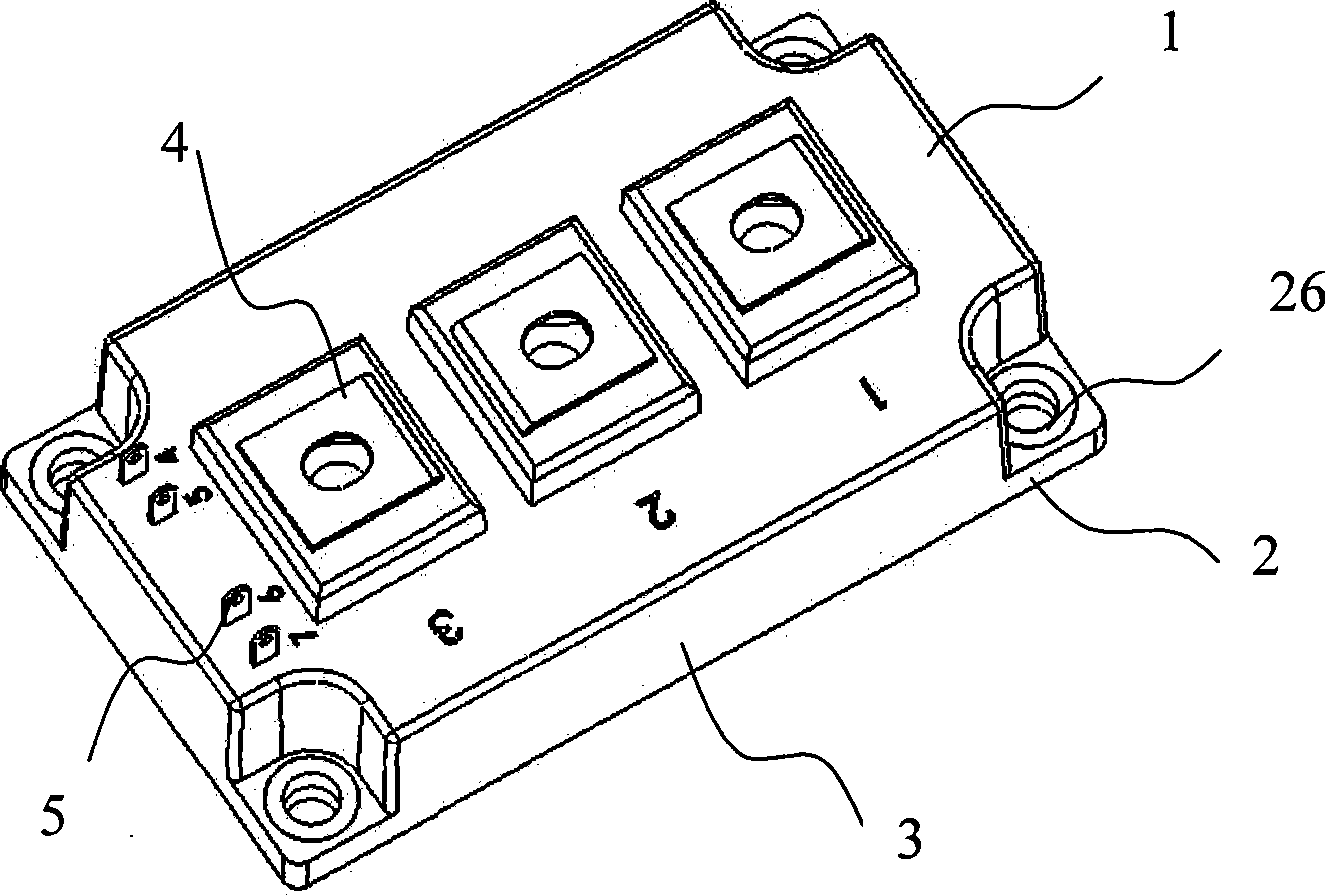

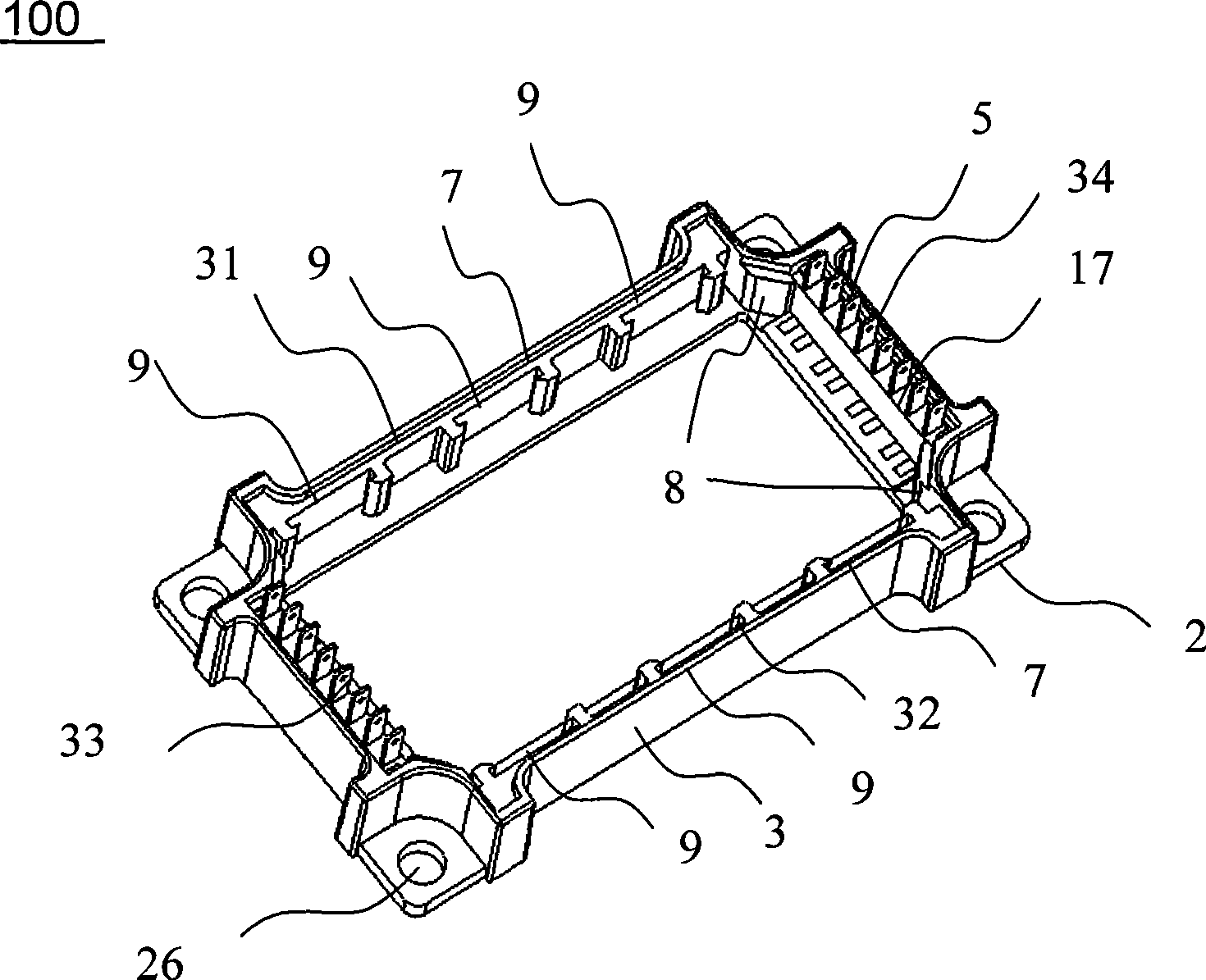

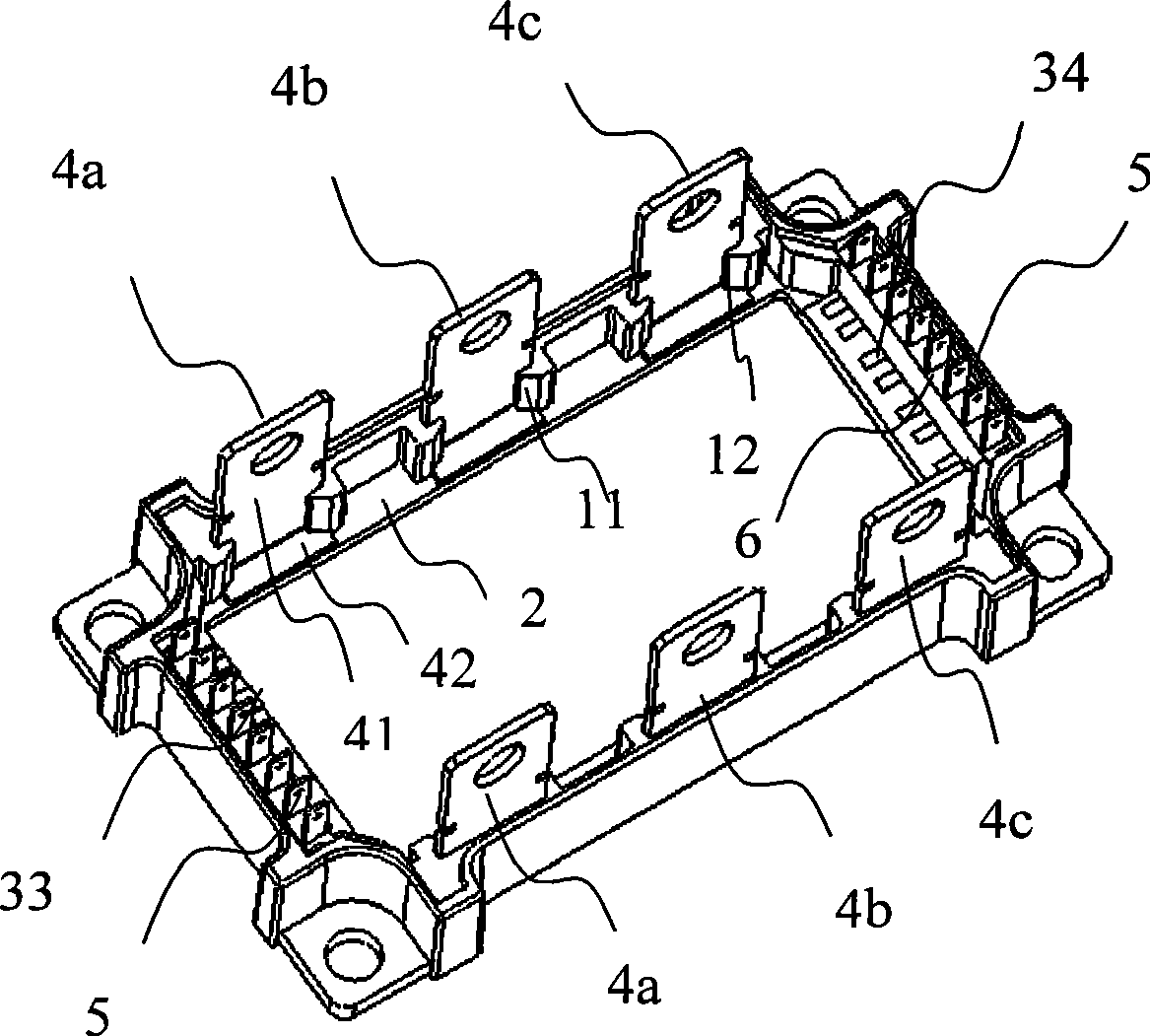

Power terminal having built-in power terminal

ActiveCN101453159AMaximum output current rangeSimplify the bonding processSemiconductor/solid-state device detailsSolid-state devicesCurrent rangeEngineering

The invention relates to a power module with an embedded power terminal. The module can accommodate a plurality of circuit structures, can make the output current range of the module with the same dimension maximized through the combination of lead wire terminals, has a simple structure and is convenient to replace. The power module comprises the following technical proposal to realize the aim: the power module with the embedded power terminal comprises a top cover, a base plate, a side frame, a power terminal and a signal terminal; the side frame extends upwards along the periphery of the base plate; the inner wall of the side frame is provided with the power terminal and the signal terminal; the base plate is provided with a circuit substrate and a chip; the inner side of at least one side of the side frame is provided with a slot; a power terminal main body is arranged in the slot; and the bottom of the power terminal is bonded with the base plate.

Owner:南京银茂微电子制造有限公司

Capacitive acceleration transducer for bending elastic beam and manufacturing method

ActiveCN102879608ASmall structure sizeStrong process compatibilityDecorative surface effectsAcceleration measurementClassical mechanicsTransducer

The invention provides a capacitive acceleration transducer for a bending elastic beam and a manufacturing method. The transducer at least comprises a first electrode structure layer, a middle structure layer and a second electrode structure layer, wherein the first electrode structure layer and the second electrode structure layer are respectively provided with electrode lead-out through holes; the middle structure layer comprises a frame formed by an oxygen-containing silicon chip comprising a dual-device layer, mass blocks of which two sides are symmetrical, and a bending elastic beam of which one side is connected with the frame and the other side is connected with the mass blocks; anti-overload convex points and damping adjusting grooves are symmetrically formed on the two sides of the two mass blocks; and the bending elastic beams positioned in different planes are distributed in a staggered mode and are not overlapped in space. Because the bending times, the total beam length and the total beam width of the bending elastic beams can be determined based on the needs, the capacitive acceleration transducer with different sensitivities can be prepared, and the flexibility is high.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

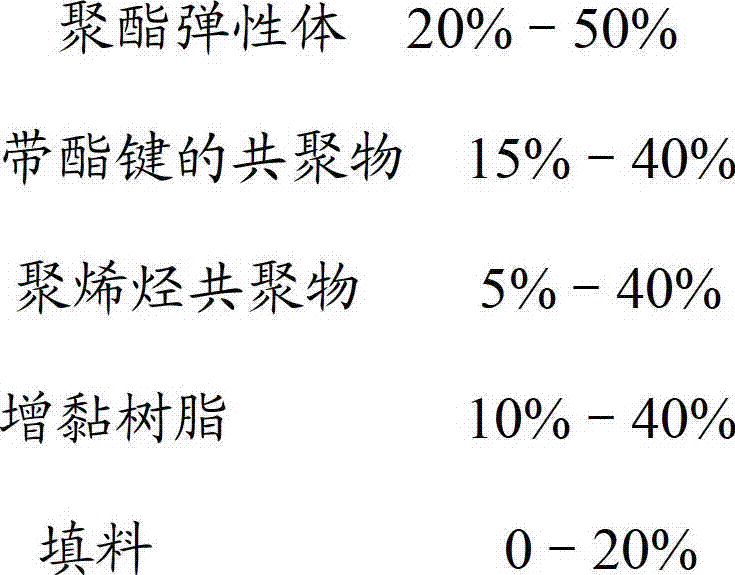

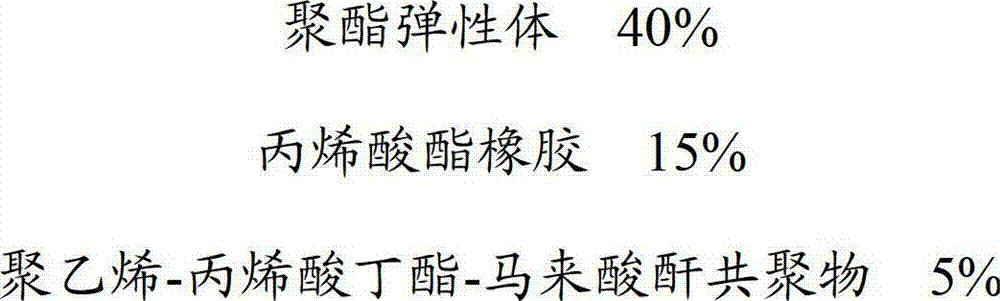

Polyester elastomer hot melt adhesives and preparation method thereof for bonding polar polymers and metallic materials

InactiveCN103059792BModerate polarityGood compatibilityFilm/foil adhesivesEster polymer adhesivesElastomerPolyester

The invention discloses polyester elastomer hot melt adhesives for bonding a polar polymer and metallic materials. The polyester elastomer hot melt adhesives for bonding the polar polymer and the metallic materials comprise, by weight, polyester elastomer 20%-50%, copolymers with ester bond 15%-40%, polyolefin copolymers 5%-40%, tackifying resin 10%-40%, filler 0%-20%, and functional additives 0%-3%. Due to the fact that the polyester elastomer hot melt adhesives are thermoplastic adhesives, bonding process is simple, bonding speed is fast, the thermotolerance of the polyester elastomer hot melt adhesives can be adjusted by selecting polyester elastomer of different melting points, and bonding strength is strong. In addition, the polyester elastomer hot melt adhesive for bonding the polar polymer and the metallic materials has the advantages of being strong in bonding strength, waterproof, moist-heat resistant, high and low temperature resistant, ageing resistant and durable and stable in bonding.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +2

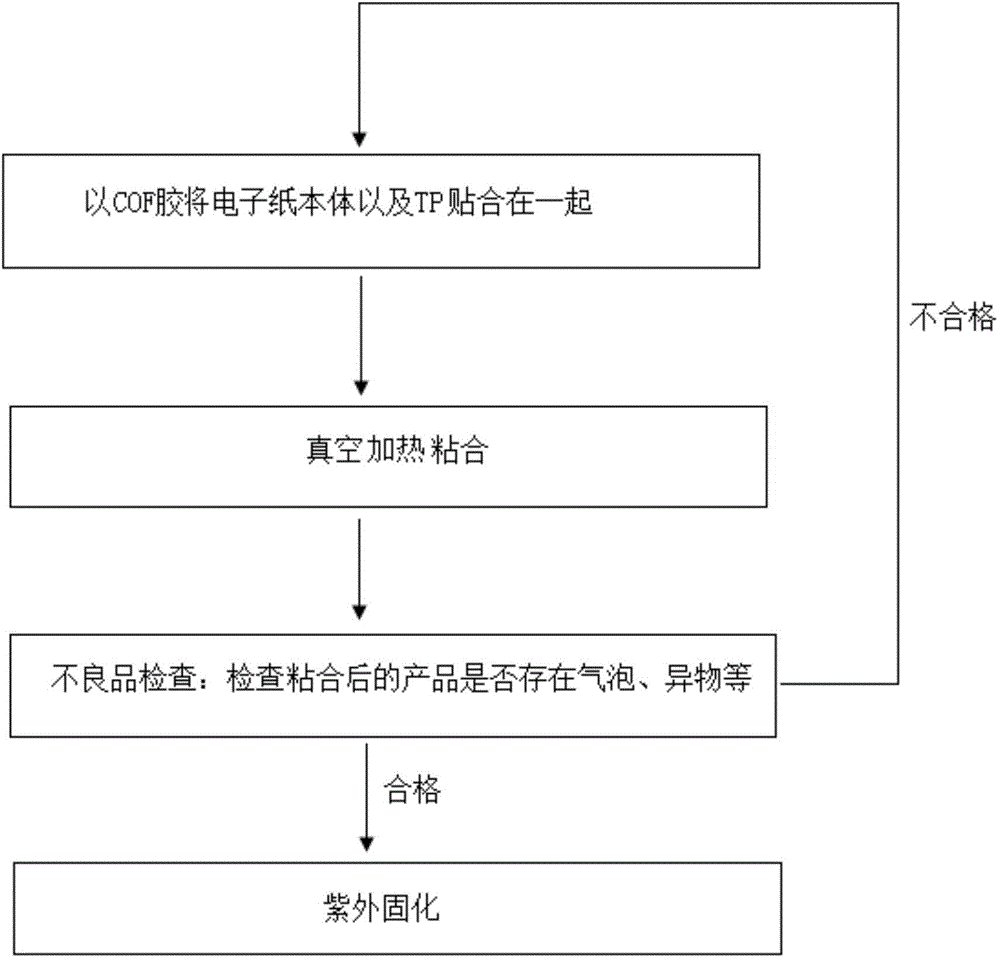

Process and structure for adhering electronic paper and touch screen

InactiveCN104388000AHigh clarityHigh light transmittanceAdhesive processes with adhesive heatingInput/output processes for data processingWeather resistanceAdhesive

The invention discloses a process for adhering electronic paper and a touch screen. The process comprises the steps of (1) adhering: adhering and fixing an electronic paper body and the touch screen by using a COF adhesive; (2) vacuum heating and adhering: heating and adhering the adhered product in step (1) under the vacuum environment; (3) ultraviolent curing: performing ultraviolent curing on the vacuum heated product. According to the process for adhering the electronic paper and the touch screen, the COF adhesive is taken as the adhesive, so that the clarity and the highlight degree are high, the adhesive power is high, and the water resistance and high-temperature resistance are excellent; the weather resistance is excellent, and the adhered product is not yellowed after being used for a long term; the electronic products are adhered by the COF adhesive, so that the problems that the water resistance of an adhered product is not up to standard after glue is squeezed out, and the electronic paper adhered by an OCA adhesive generates white points can be completely solved; furthermore, the adhesive membrane can be removed any time; the yield is high, and the adhering process is simple; the process is not only suitable for adhering the electronic paper and the touch screen, but also suitable for adhering the electronic paper and other electronic elements.

Owner:SHENZHEN JINGHUA DISPLAY

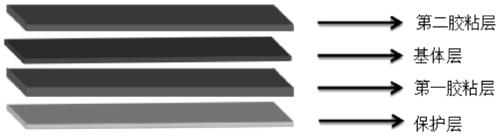

TPU adhesive, hot melt adhesive film and application

ActiveCN111040711AHigh strengthReduce deformation rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention relates to the field of polymer adhesives, in particular to a TPU adhesive, a hot melt adhesive film and an application. The TPU adhesive is prepared from the following components in parts by weight: 75 to 97 parts of TPU particles, 0 to 15 parts of modified polyester, 2 to 10 parts of an anti-hydrolysis agent and 0.1 to 1 part of an auxiliary agent. The hot melt adhesive film sequentially comprises a first adhesive layer, a matrix layer and a second adhesive layer, the first adhesive layer is made of the TPU adhesive, and the second adhesive layer is made of the TPU adhesive. The base layer is a screen cloth or a thin film. The hot melt adhesive film with the three-layer composite structure is soft in hand feeling, high in tensile strength, excellent in tensile resilience, good in adhesion and washing resistance and capable of being widely applied to seamless adhesion of elastic clothes such as underwear, underpants, bras, mold cups, shoulder straps, shapewear and sportswear.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

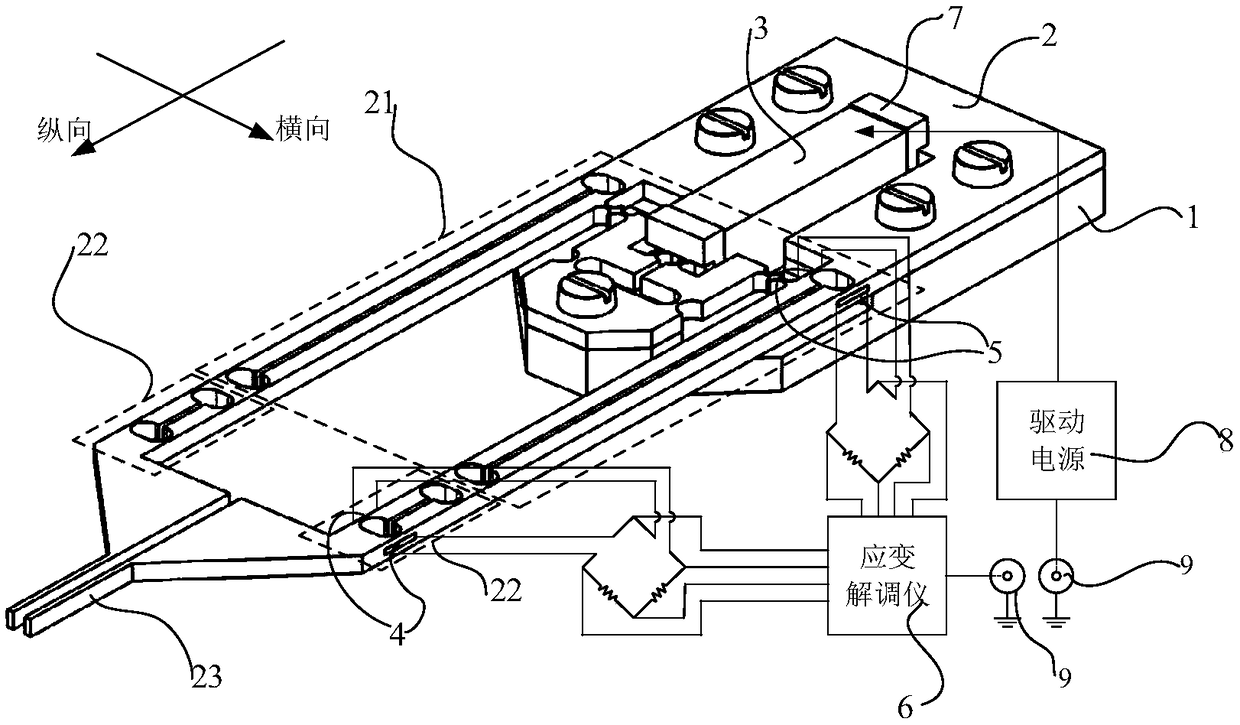

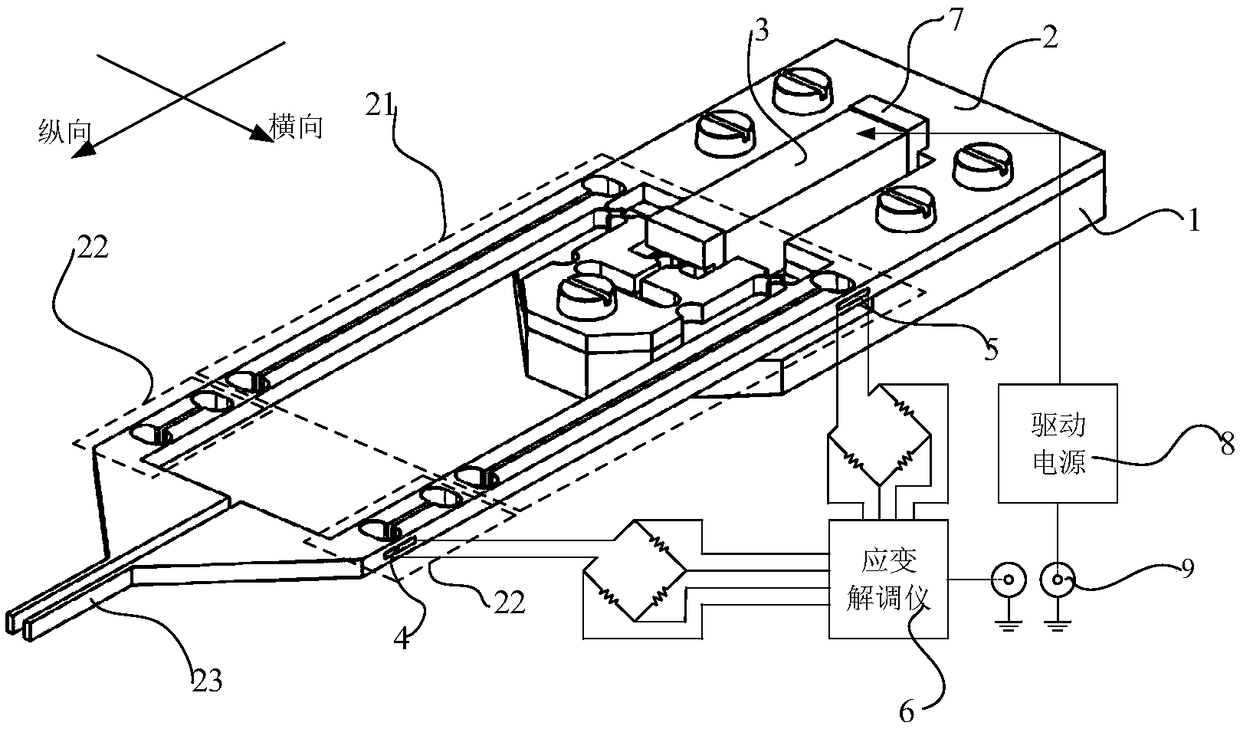

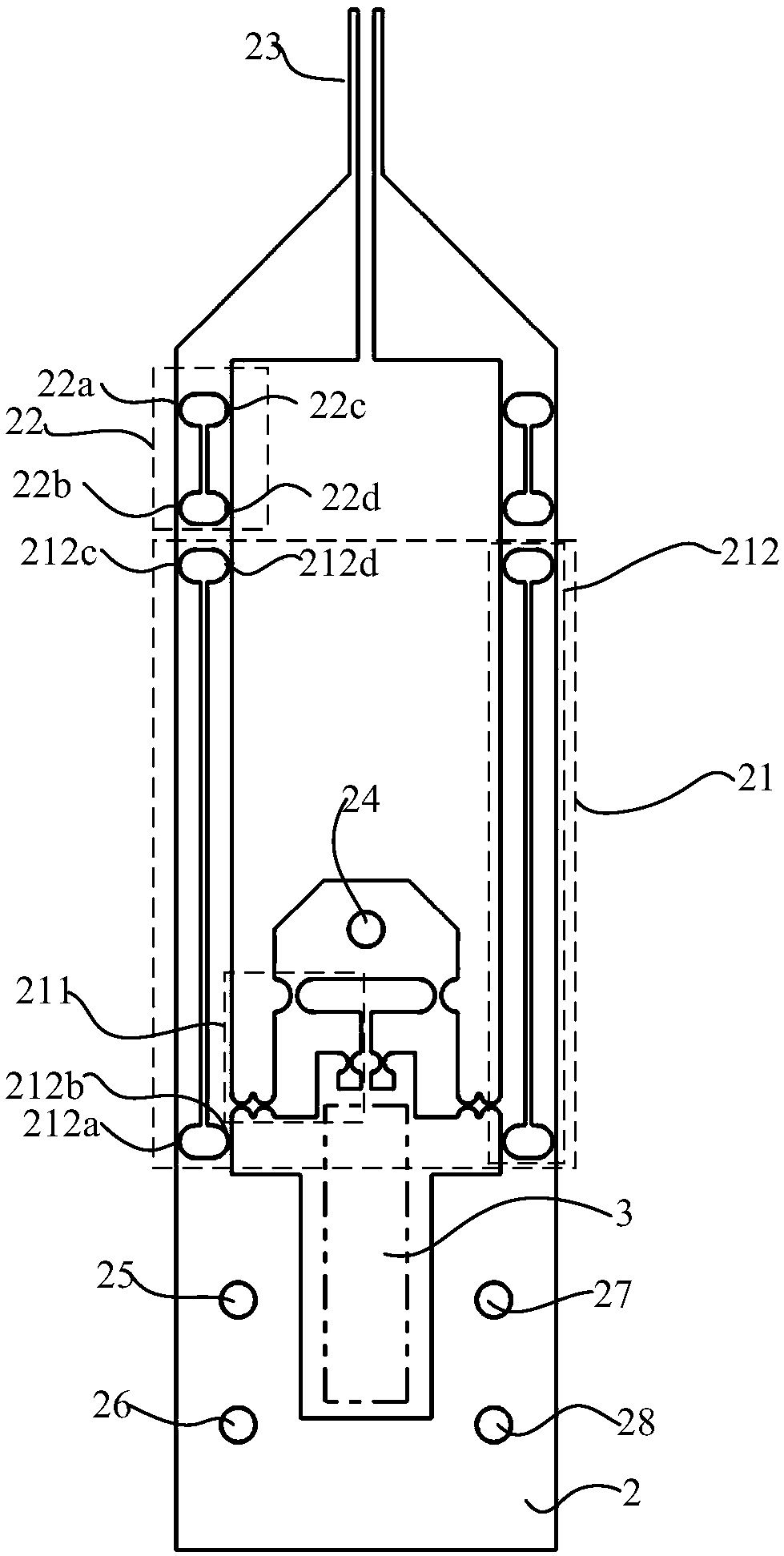

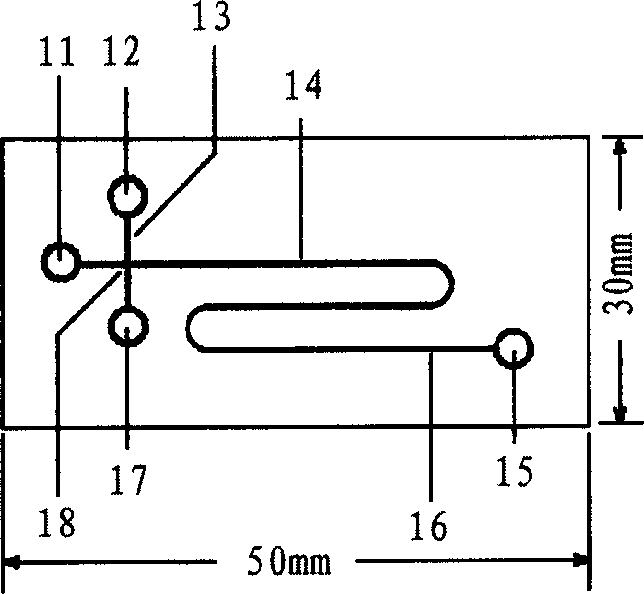

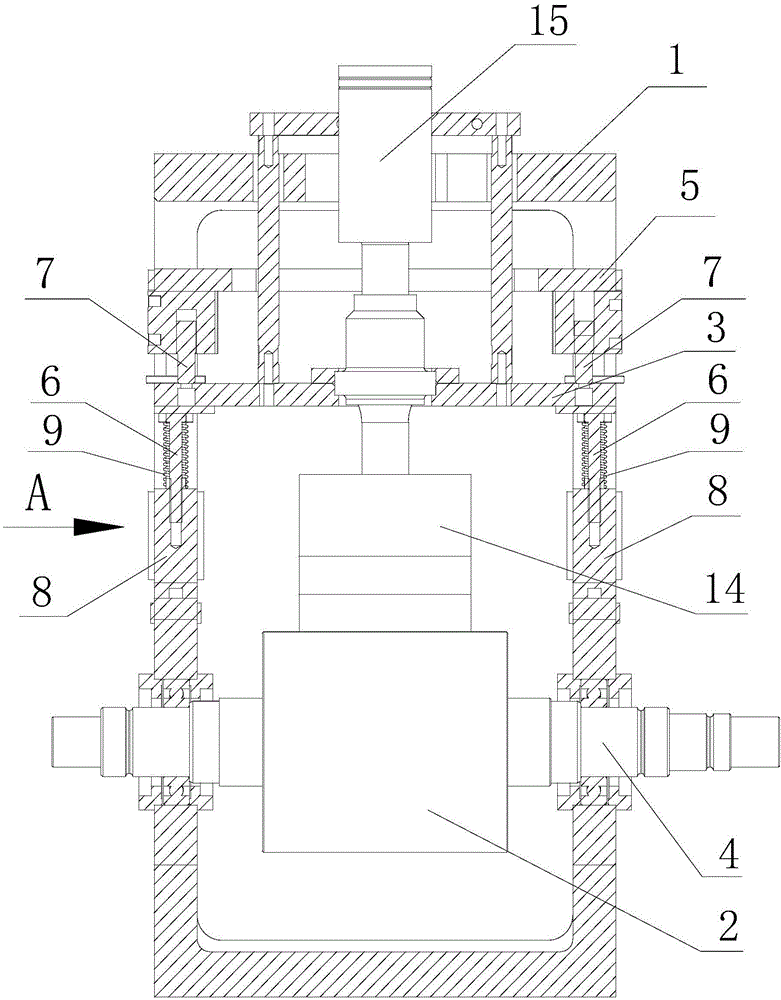

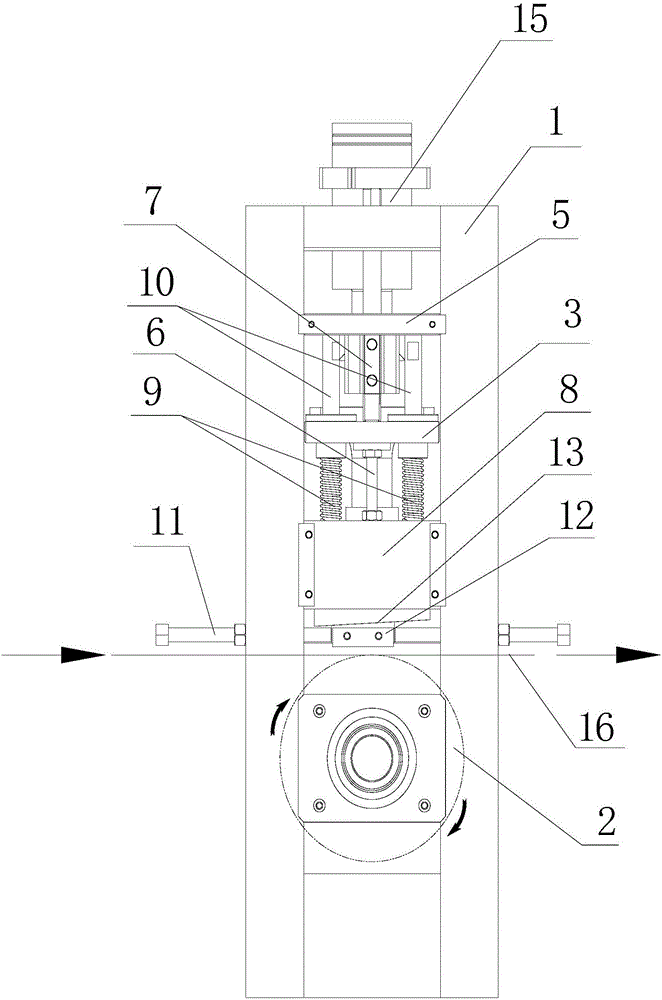

Tiny clamp capable of integrating clamping force sensor and clamping jaw displacement sensor

The invention relates to a tiny clamp capable of integrating a clamping force sensor and a clamping jaw displacement sensor and aims to solve the problems in the prior art that the tiny clamp cannot simultaneously measure the clamping force and the displacement of a clamping jaw and cannot ensure that the clamping jaw moves in parallel. According to the technical scheme, the tiny clamp comprises abase, a single-piece flexible mechanism fixed on the base, an actuator mounted in a cavity formed in the single-piece flexible mechanism, a controller, a strain demodulator connected with the controller, and the clamping force sensor and the clamping jaw displacement sensor connected with the strain demodulator, wherein the single-piece flexible mechanism comprises a displacement amplifying mechanism, two symmetrical clamping force sensing mechanisms and two symmetrical clamping jaws; the input stage of the displacement amplifying mechanism is connected with the actuator in a propped manner;the two output stages of the displacement amplifying mechanism, the two clamping force sensing mechanisms and the two clamping jaws are in one-to-one correspondence; and the output stages of the displacement amplifying mechanism, the clamping force sensing mechanisms and the clamping jaws are sequentially connected.

Owner:CHONGQING UNIV

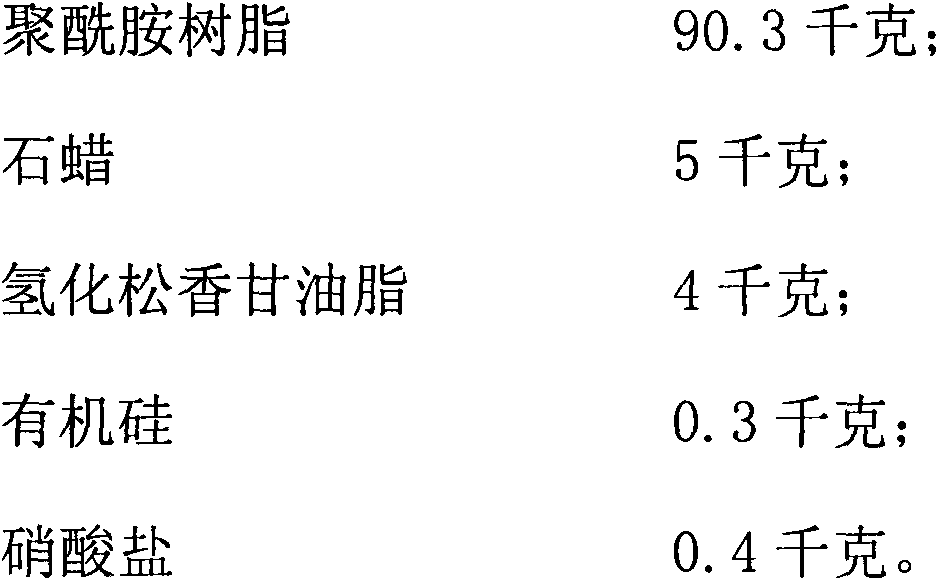

Hot melt adhesive

ActiveCN103396755AFast curingHigh bonding strengthNon-macromolecular adhesive additivesRosin adhesivesSolventMorning

The invention discloses a hot melt adhesive. The hot melt adhesive consists of the following materials in parts by weight: 89-92 parts of polyamide resin, 3-7 parts of paraffin, 3-7 parts of rosin ester-rosin glycerol resin, less than 0.5 part of organic silicon and less than 0.5 part of nitrate. The hot melt adhesive has the following advantages that firstly, the curing speed is quick, and the bonding strength and the flexibility are better; the hot melt adhesive can be used for curing and bonding within a fraction of second to a few seconds, and has the characteristics of being molten while being heated up and being bonded while being cooled, so that a packer using the hot melt adhesive can adopt a production line with higher speed, the yield can be increased while the defective goods are reduced, the continuous and automatic high-speed operation is convenient, and the cost is lower; secondly, the bonding power of the hot melt adhesive is very stable and not affected by morning-evening temperature and humidity changes in a working environment, so that the bonding firmness is ensured, and a bonding exposure problem of a packing machine is eliminated; and thirdly, the hot melt adhesive does not contain water and any other solvent. Besides, the hot melt adhesive is easy to transport and store, long in service life, capable of eliminating damages and waste, and convenient to use.

Owner:东莞市三创智能卡技术有限公司

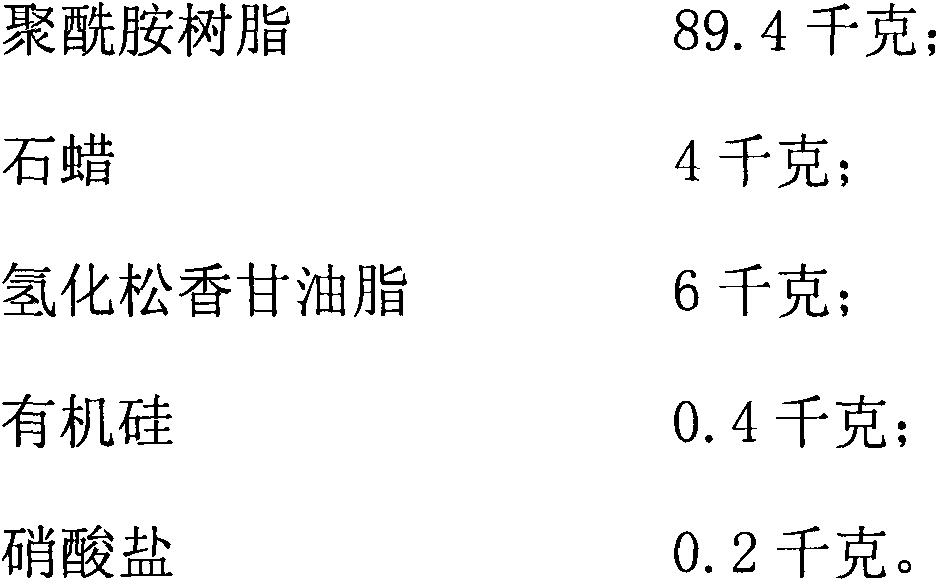

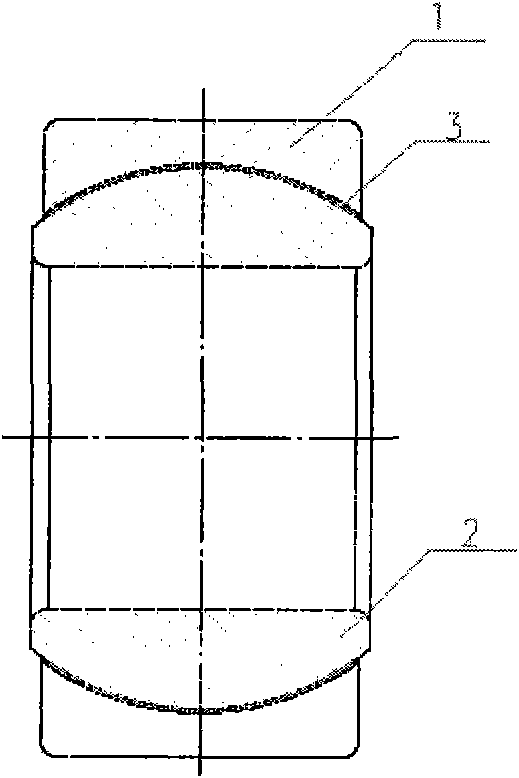

Single-slot self-lubricating oscillating bearing with outer ring provided with composite lining plates and manufacturing method thereof

InactiveCN101915272AReduce manufacturing costReduce coefficient of frictionBearing componentsEngineeringMechanical engineering

The invention discloses a single-slot self-lubricating oscillating bearing with an outer ring provided with composite lining plates and a manufacturing method thereof. The single-slot self-lubricating oscillating bearing has the advantages of simple structure, low cost, good self-lubricating effect and strong bearing capacity and adopts the structure that at least four steel backing composite lining plates distributed radially along the circumference are adhered on the inner surface of the outer ring. The manufacture method comprises the steps of: processing the outer ring and an inner ring by using bearing steel, wherein the outer ring is provided with an axial seam; manufacturing the at least four steel backing composite lining plates coincident with the inner surface of the outer ring in shape after being spliced radially; hacking the surface of the steel backing of each steel backing composite lining plate, grooving the surface of the steel backing and carrying out running-in on a radial splicing surface; sequentially and radially splicing the steel backing composite lining plates tightly along the circumference direction by taking the axial seam of the outer ring as an initial point and adhering on the inner surface of the outer ring, heating and solidifying an adhering agent under the condition of applying external force on an adhering surface; and directly loading the inner ring into the outer ring.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

Nickel-imitative metallic powder coating and preparation method thereof

InactiveCN107057535AStrong metal feelingRealistic decorative metal nickel plate effectPowdery paintsEpoxy resin coatingsEpoxyTitanium

The invention discloses a nickel-imitative metallic powder coating, which is prepared from the following raw-material components in parts by weight: 90 to 110 parts of polyester resin, 65 to 72 parts of epoxy resin, 0.5 to 1.8 parts of antifoaming agent, 2.5 to 4 parts of luster enhancing agent, 3.5 to 4.3 parts of flatting agent, 1.5 to 2.5 parts of scratch resisting agent, 90 to 120 parts of filling, 8 to 15 parts of titanium pigment, 0.3 to 0.5 part of carbon black, 6 to 7 parts of iron oxide yellow, 0.6 to 0.7 part of iron oxide red, 0.62 to 0.72 part of HR yellow, 0.3 to 1.1 parts of flow anti-caking agent, 0.6 to 1.4 parts of silver powder and 0.025 to 0.075 part of aluminum powder diffusion and arrangement auxiliary. The invention also discloses a preparation method of the powder coating.

Owner:江西杰克西新材料有限公司

High-strength vertical-fiber waterproof rock wool plate and production method thereof

InactiveCN105239680AImprove insulation effectImprove fire and water resistanceHeat proofingBuilding insulationsFiberHigh intensity

The invention discloses a high-strength vertical-fiber waterproof rock wool plate and a production method thereof. The high-strength vertical-fiber waterproof rock wool plate has both sides to which inorganic fireproof waterproof films are combined. The inorganic fireproof waterproof films are combined to the vertical-fiber rock wool plate through quick instant glue. The inorganic fireproof films are fiberglass mats the surface of each of which is infiltrated with an inorganic silicon nano-material waterproof layer. By using the automatic line production manner, overcome are the defects that at present, existing various combined rock wool plates are generally high in production cost, a binding process is complex, steam-curing maintenance is required, thermal solidifying is required, a processing cycle is long and large-scale continuous production is unable to be achieved.

Owner:JINCHANG WANLONG IND

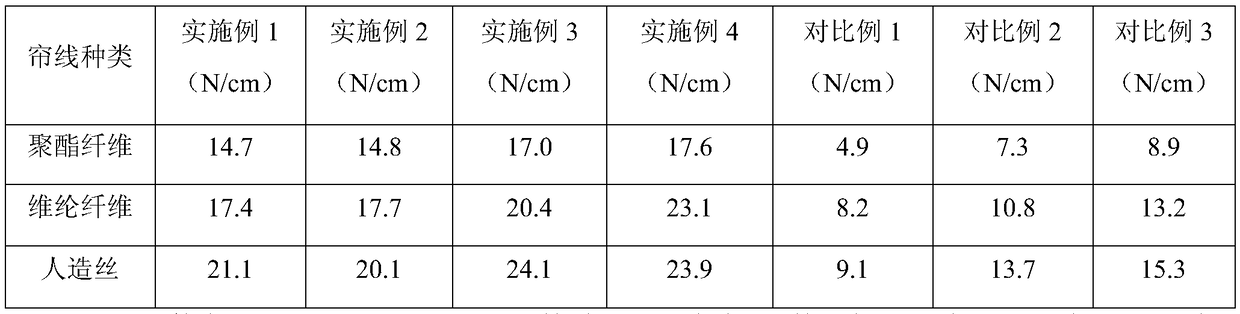

Environment-friendly type EPDM (ethylene propylene diene monomer) adhesive for increasing adhesion force between EPDM rubber and curtain lines

ActiveCN108659744AHigh bonding strengthWide range of materialsNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberPolyester

The invention discloses an environment-friendly type EPDM (ethylene propylene diene monomer) adhesive for increasing adhesion force between EPDM rubber and curtain lines. The environment-friendly typeEPDM adhesive is mainly prepared from an EPDM mixing glue and a hydrocarbon solvent oil according to a weight ratio of 1 to (2 to 8), wherein the EPDM mixing glue is mixed by the EPDM rubber, a vulcanizer, a crosslinking additive, an adhesive, zinc oxide, stearic acid, carbon black, white carbon black and maleic anhydride-grafted polymer. The environment-friendly type EPDM adhesive has the advantages that the adhesion force between the EPDM rubber and the polyester fiber, vinylon curtain lines as well as manmade yarns is effectively increased; the environment-friendly effect is realized, theproduction of toxic or harmful matters is avoided in the preparation and use process, and the injury to human bodies and environments is extremely low.

Owner:NANJING ORIENTLEADER TECH CO LTD

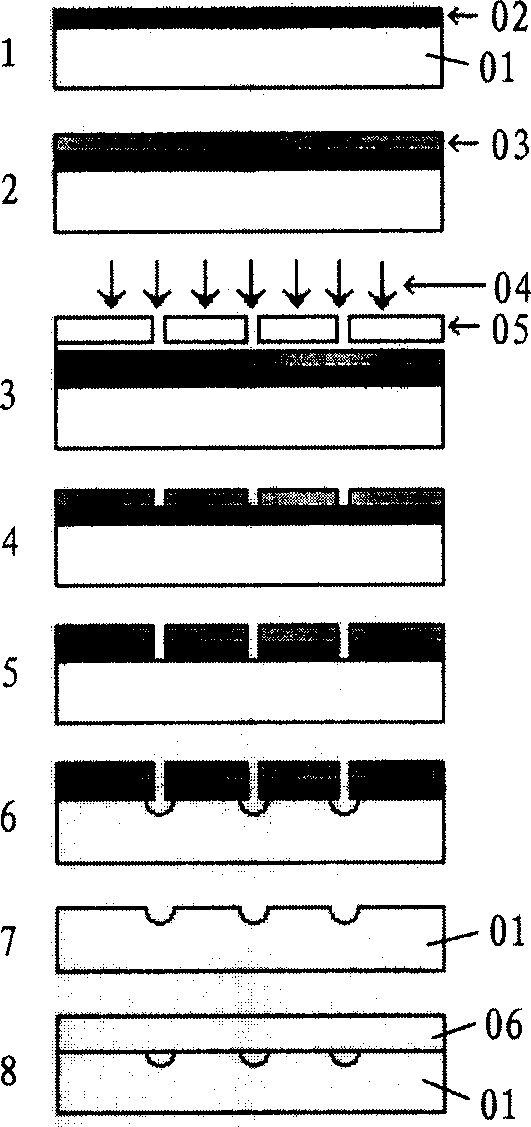

Method for producing electrophoretic microchip

InactiveCN1365003AImprove protectionProcess conditions are easy to meetMaterial analysis by electric/magnetic meansEtchingElectrophoresis

The production process of electrophoretic microchip incldues the steps of: designing electrophoretic microchip based on functional requirement and corresponding technological conditions while considering the parameters of sample inlet electrophoretic channel and separating electrophoretic channel width and length, pipe shape and interval, and making mask based on the designed microchip figure; and the making electrophoretic microchip through selecting high quality quartz as substrate, wet photoetching to form notches and other patterns in the substrate and linkage to form microtube network to constituted electrophoretic microchip. The present invention has the advantages of reliable protection in wet etching process, simple linkage process combining pre-linkage and sintering, etc.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Adhesive for bonding EVA (ethylene vinyl acetate) foam material with PU (polyurethane) film, as well as preparation method and application thereof

ActiveCN103305176AImprove adhesionHigh peel strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolyol

The invention relates to an adhesive for bonding an EVA (ethylene vinyl acetate) foam material with a PU (polyurethane) film, as well as a preparation method and an application thereof. The adhesive is a polyurethane adhesive, and the polyurethane adhesive is prepared from the following raw materials in content by weight: 20-30% of polyester polyol, 10-15% of polyether polyol, 5-10% of diisocyanate, 1-3% of chain extender, and 50-60% of solvent. The adhesive provided by the invention is good in bonding property with the weakly-polar EVA foam material and the polar PU film, thus effectively bonding the weakly-polar EVA foam material with the polar PU film together; the adhesive is high in peel strength, simple in bonding process, and capable of being used by replacing a hot-melt adhesive and reducing the production cost in case of being applied to bonding the EVA foam material with the polar PU film.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

Ultrasonic welding device for hygienic product compositing

InactiveCN106273411ASimplify the bonding processReduce manufacturing costDomestic articlesUltrasonic weldingEngineering

The invention discloses an ultrasonic welding device for hygienic product compositing. The device comprises a supporting frame, an ultrasonic assembly, an anvil roller and a distance adjusting mechanism. A movable plate is arranged in the middle of the supporting frame. The ultrasonic assembly is arranged on the movable plate. The two sides of the movable plate are connected with the supporting frame through the distance adjusting mechanism. The distance adjusting mechanism drives the movable plate and the ultrasonic assembly to move up and down along the supporting frame. The anvil roller is arranged below the ultrasonic assembly and connected with the supporting frame through a rotating shaft. According to the ultrasonic welding device, by means of the welding function of an ultrasonic device, two layers of materials are welded and bonded, a traditional hot melting adhesive bonding technology is replaced, consumption of hot melting adhesive raw materials is replaced, the production cost is lowered, meanwhile, the bonding technology is simplified, and the production efficiency is improved. The distance between the ultrasonic assembly and the anvil roller is adjusted through the distance adjusting mechanism, the parallelism between the ultrasonic assembly and the anvil roller is adjusted through a precision adjusting mechanism, and composite material bonding accuracy can be effectively ensured.

Owner:GUANGZHOU XINGSHI EQUIPS

Outer wall insulating board and mounting method thereof

InactiveCN106836535ASuperior insulationImprove tensile and compressive strengthLaminationLamination apparatusEngineeringFiber

The invention discloses a thermal insulation board for an outer wall, which comprises a thermal insulation layer and an interface layer, and the thermal insulation layer adopts inorganic fiber cotton. The important feature of the present invention is that the fiber orientation of the inorganic fiber cotton is perpendicular to the interface layer and the wall surface. This makes the drawing direction of the inorganic fiber cotton parallel to the direction of the wind and the direction of the force after installation, which improves the tensile and compressive strength and resists the damage to the wall caused by the wind pressure.

Owner:赵泊然

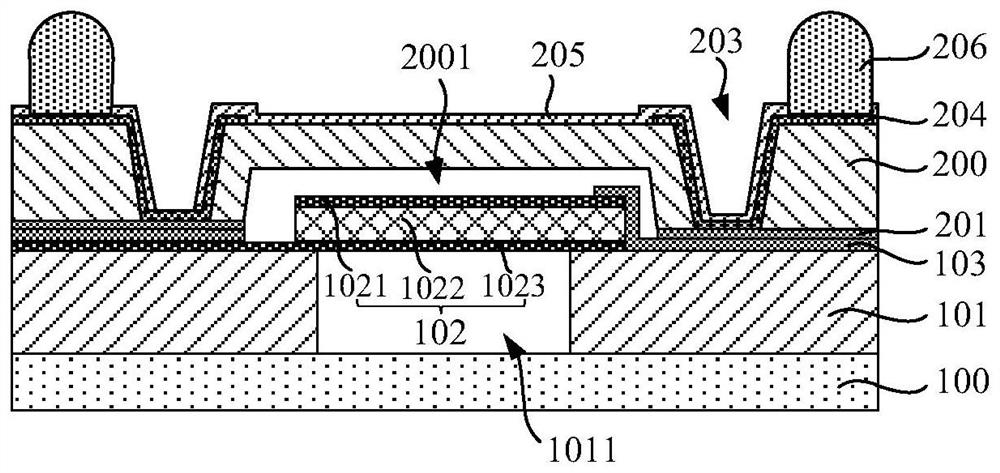

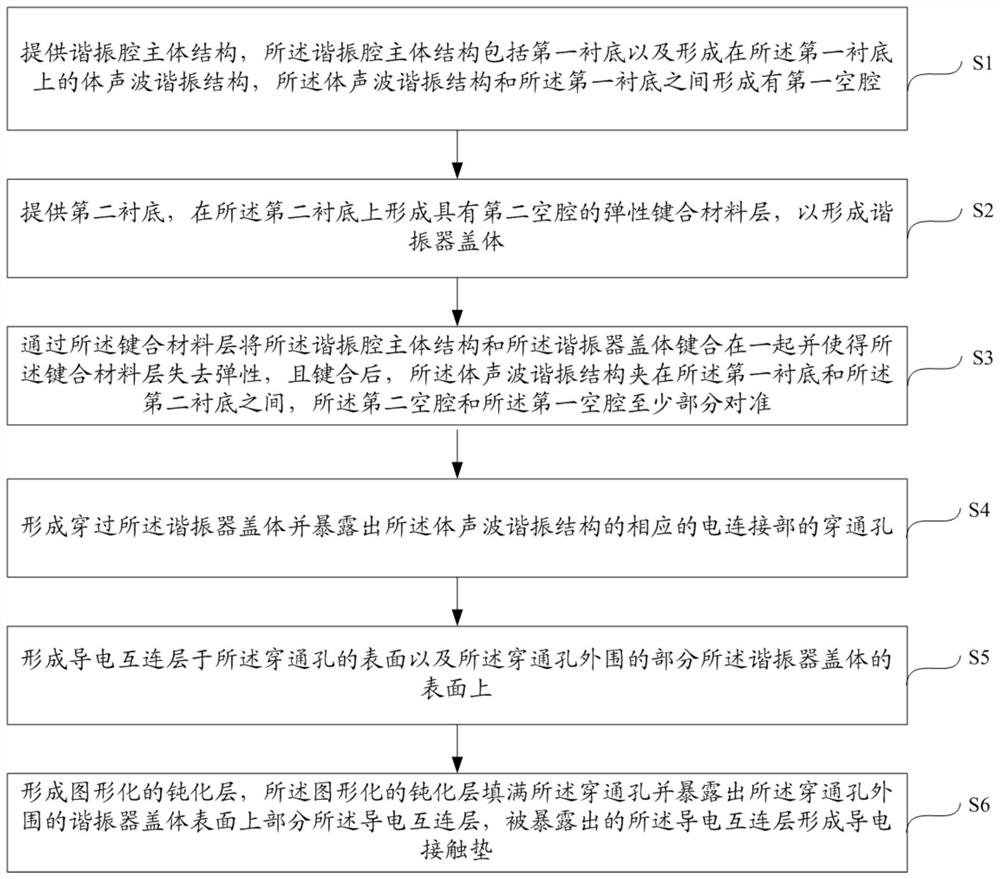

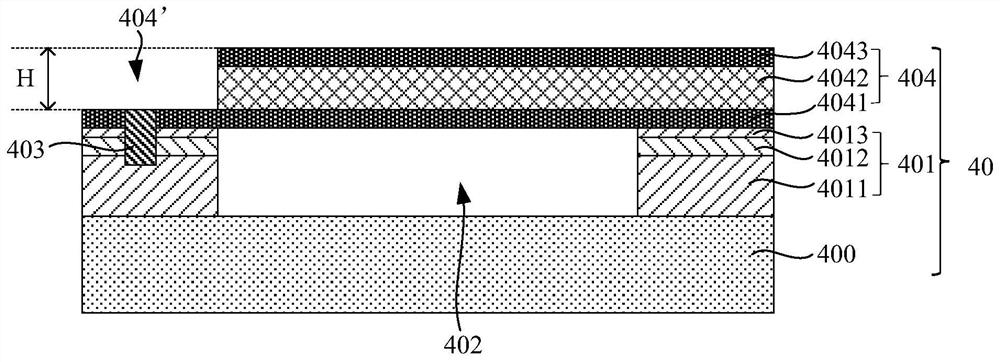

Packaging method and packaging structure of bulk acoustic wave resonator

According to a packaging method and a packaging structure of a bulk acoustic wave resonator provided by the invention, a resonator cover body is manufactured by forming an elastic bonding material layer with a second cavity on a second substrate, then the resonator cover body can be directly bonded with a resonant cavity main body structure through the elastic bonding material layer on the resonator cover body, the elastic bonding material layer loses elasticity, after that, a through hole and a conductive interconnection layer covering the inner surface of the through hole can be formed on the resonator cover body. The process has the characteristics of low cost, simple process and high compatibility with a resonant cavity main body structure process, does not cause the pollution problemof a gold-gold bonding process, and can reduce the influence on a first cavity to the maximum extent; and the elasticity of the elastic bonding material layer can be utilized to tolerate a certain step height difference of the bulk acoustic wave resonance structure in the peripheral area of the first cavity in the bonding process, so that the bonding reliability and stability can be ensured.

Owner:NINGBO SEMICON INT CORP

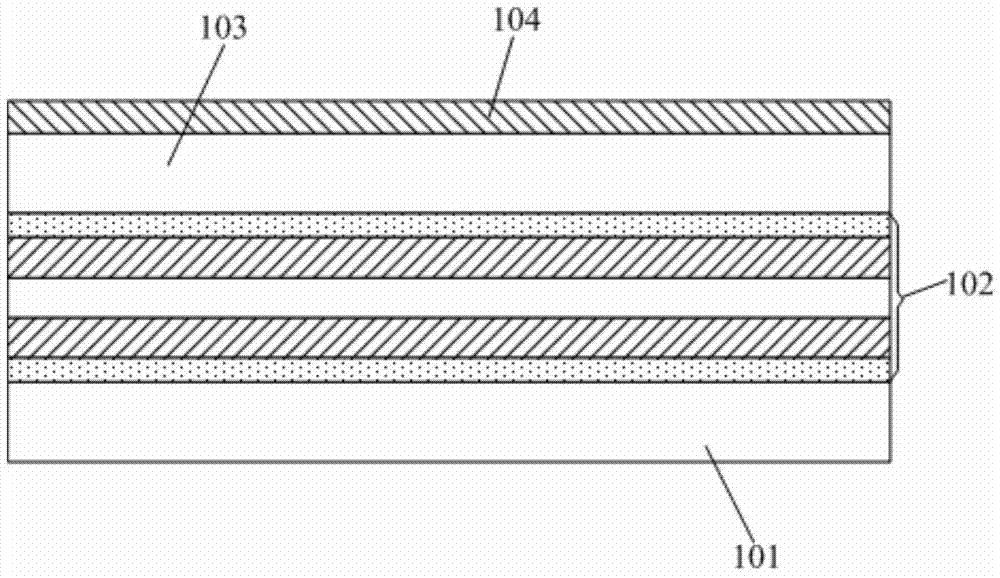

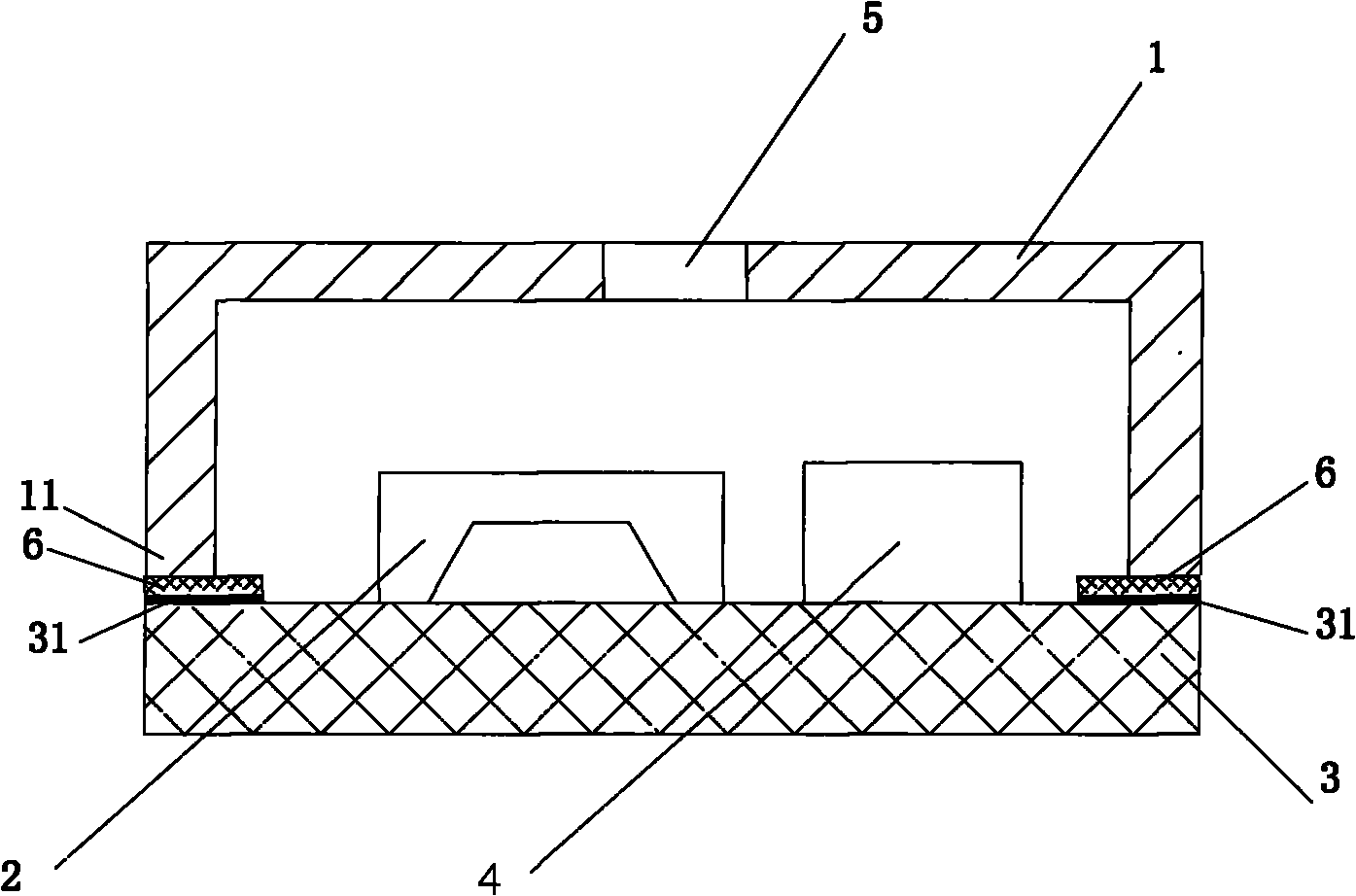

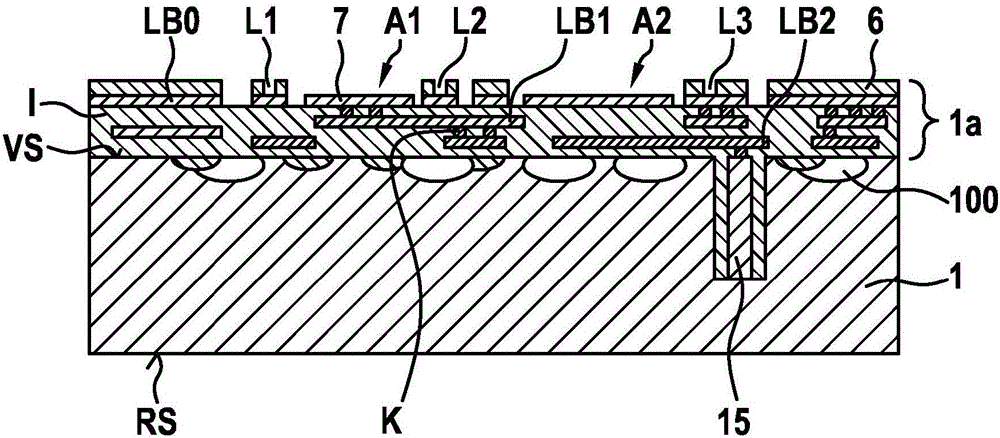

Micromechanical pressure sensor and corresponding production method

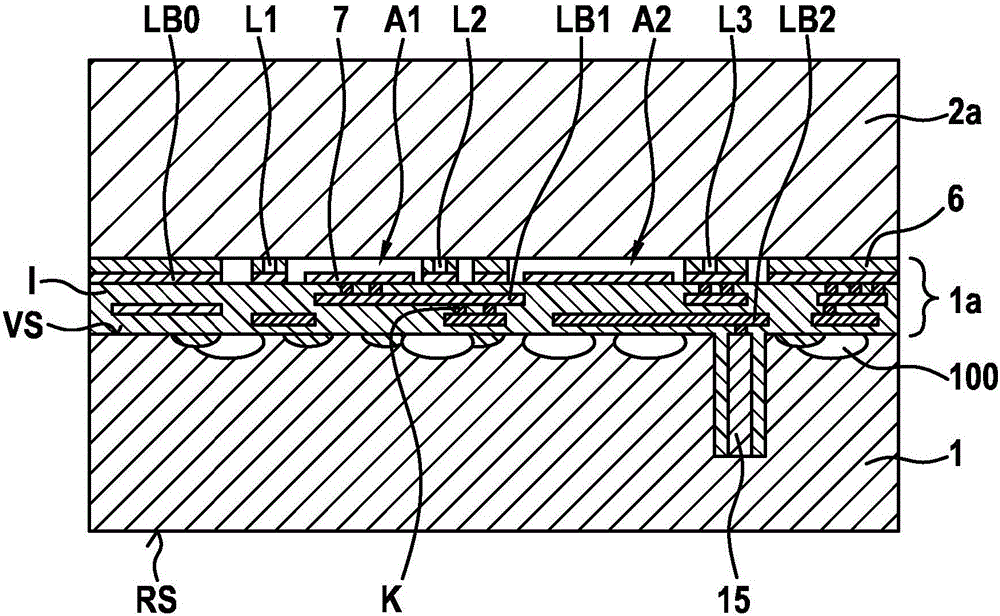

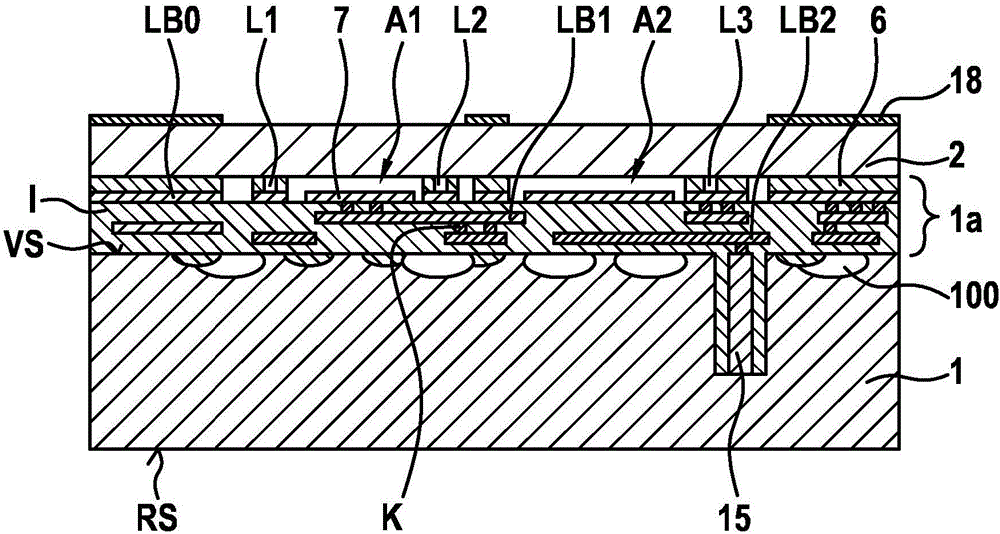

InactiveCN106170682AImprove air tightnessAchieve protectionDecorative surface effectsFluid pressure measurement by electric/magnetic elementsElectricityInsulation layer

The invention relates to a micromechanical pressure sensor and to a corresponding production method. The micromechanical pressure sensor comprises: an ASIC wafer (1) with a front face (VS) and a rear face (RS); a wiring system (1a) formed on the front face (VS), said system having a plurality of conductor path planes (LB0, LB1, LB2) and insulation layers (I) lying therebetween; a patterned insulation layer (6) formed above an uppermost conductor path plane (LB0) of the plurality of conductor path planes (LB0, LB1, LB2); a micromechanical functional layer (2; 2") on the insulation layer (6), said functional layer having a membrane region (M; M'; M"), which can be supplied with pressure and acts as a first pressure detection electrode, above a cavity (A1; A1 ") in the insulation layer (6); and a second pressure detection electrode (7; 7") on the uppermost conductor path plane (LB0), said second electrode being formed in the cavity (A1; A1"), being spaced from the membrane region (M; M'; M") and being electrically insulated from said membrane region (M; M'; M"). The membrane region (M; M'; M") is electrically connected to the uppermost conductor path plane (LB0) by one or more first contact plugs (P1, P2; P1", P2") running through the membrane region (M; M'; M") and through the insulation layer (6).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com