Ultrasonic welding device for hygienic product compositing

A technology of ultrasonic welding and sanitary products, applied in applications, household components, household appliances, etc., can solve the problems of complex production process, high market price, low production efficiency, etc., to simplify the bonding process, reduce production cost, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

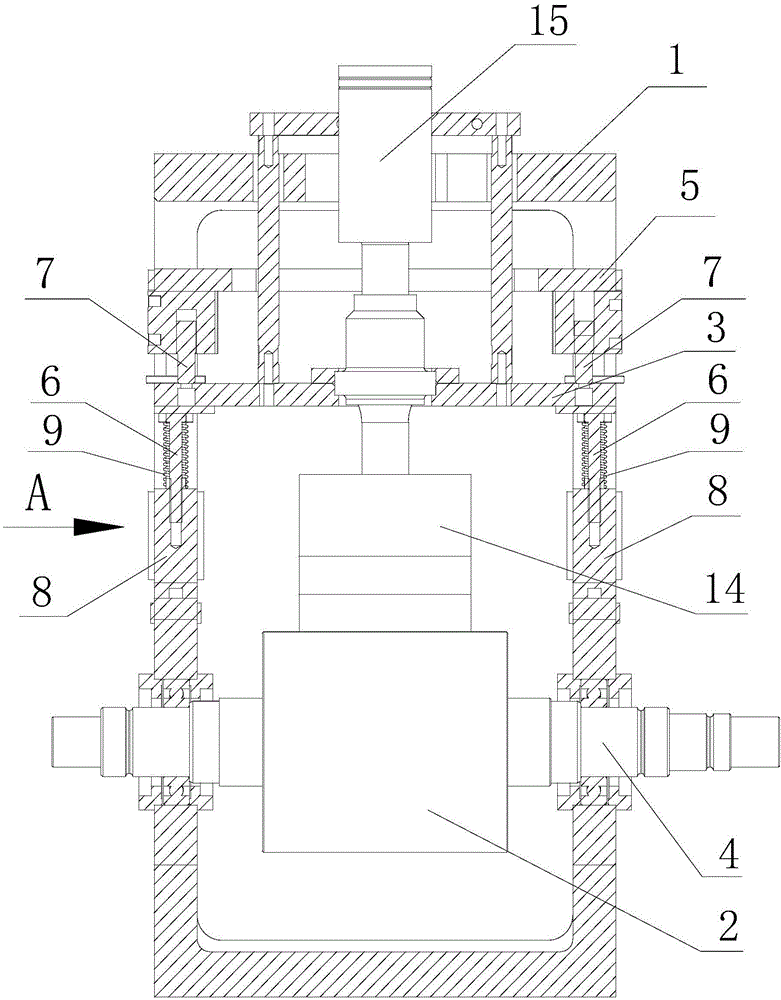

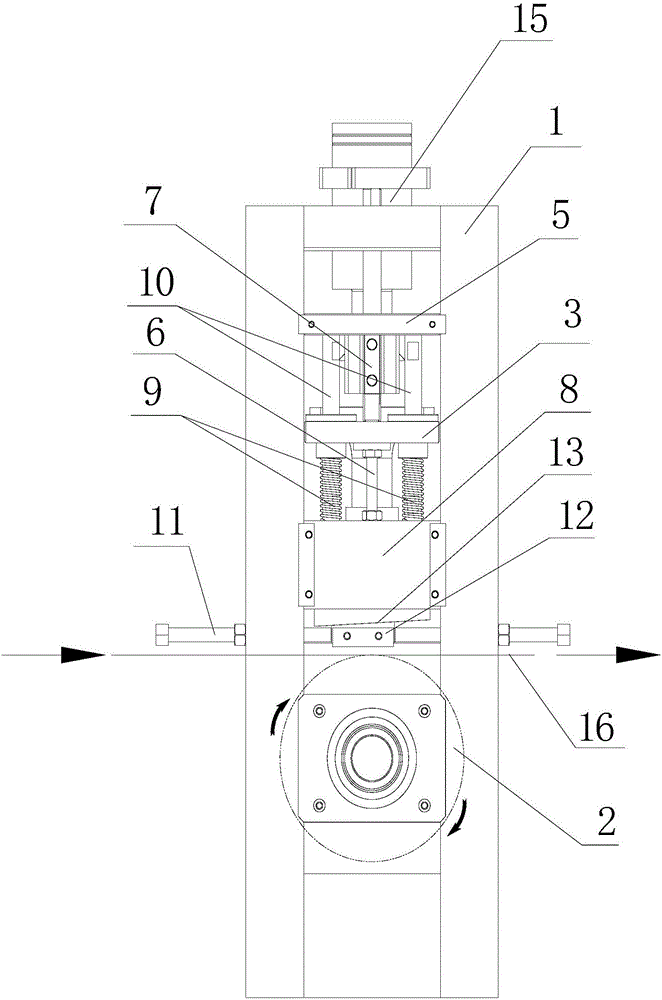

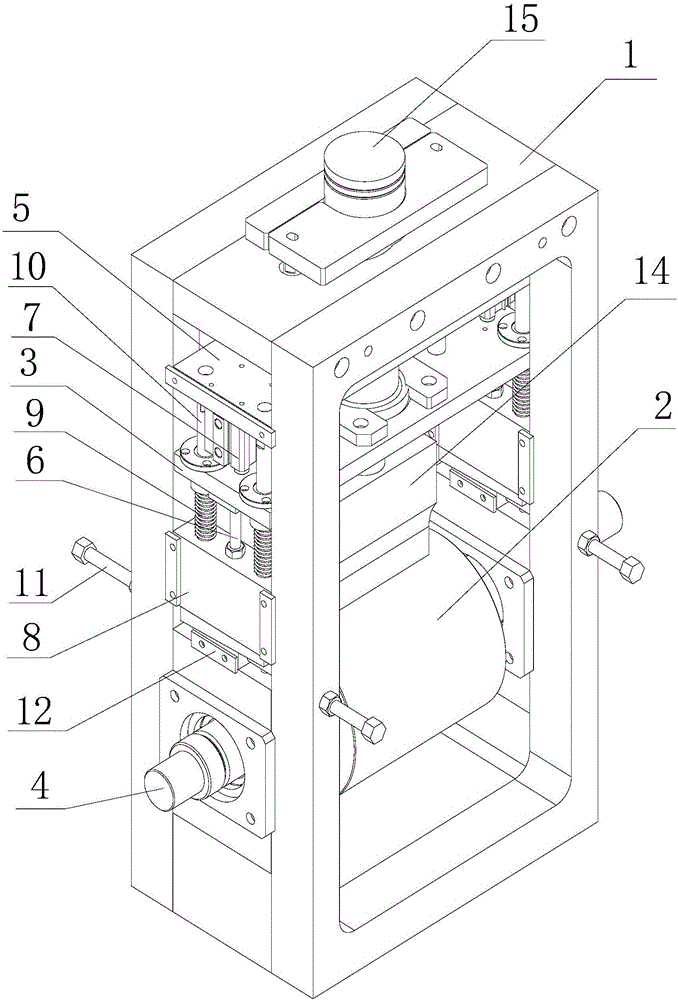

[0026] The present embodiment is an ultrasonic welding device for composite sanitary products, such as Figure 1 ~ Figure 3 As shown, it includes a support frame 1, an ultrasonic assembly, an anvil roller 2 and a spacing adjustment mechanism. The middle of the support frame is provided with a movable plate 3, the ultrasonic assembly is arranged on the movable plate, and both sides of the movable plate are connected with the support frame through the spacing adjustment mechanism. The adjusting mechanism drives the movable plate and the ultrasonic component to move up and down along the support frame, the anvil roller is arranged below the ultrasonic component, and the anvil roller is connected with the support frame through the rotating shaft 4 . Among them, the main function of the distance adjustment mechanism is to adjust the distance between the ultrasonic component and the anvil roller to make it fit the thickness of the composite material; the main function of the movable ...

Embodiment 2

[0038] The ultrasonic welding device of a kind of hygienic product composite of present embodiment, compares with embodiment 1, and its difference is:

[0039] The surface of the anvil roller is also distributed with concave-convex sealing embossing. When the ultrasonic indenter seals and composes the material passing through the surface of the anvil roller, it can also use the concave-convex sealing embossing to form the product required on the surface of the composite material. pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com