Environment-friendly type EPDM (ethylene propylene diene monomer) adhesive for increasing adhesion force between EPDM rubber and curtain lines

A technology of EPDM rubber and adhesive, which is applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., to achieve the effect of simple bonding process, wide range of materials and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

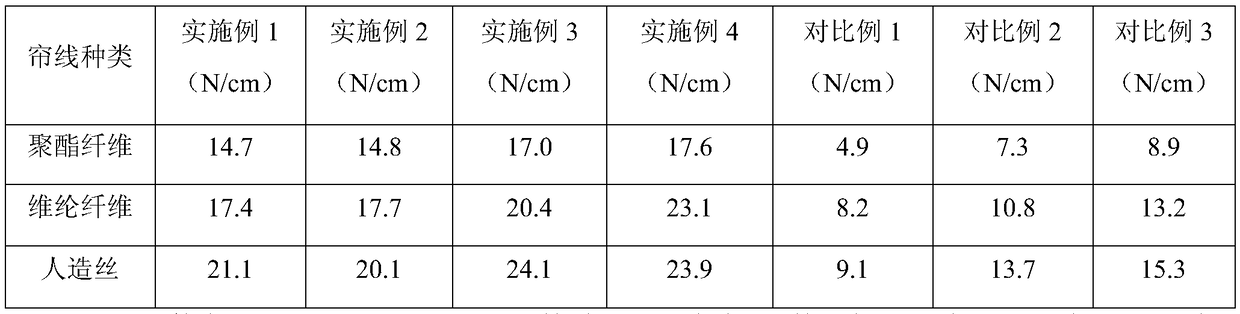

Examples

Embodiment 1

[0042] Weigh the following parts by weight raw materials: 100 parts of EPDM rubber 4010M; additives: 5 parts of zinc oxide, 1 part of stearic acid StA, 5 parts of N330 carbon black, 20 parts of N550 carbon black, 10 parts of white carbon black; Mixture: 15 parts of binder RS, 10 parts of binder A; vulcanizing agent: 0.5 parts of sulfur; 10 parts of maleic anhydride-grafted EPDM rubber, wherein the maleic anhydride-grafted EPDM rubber has a grafted amount of maleic anhydride (MA) = 1.0 wt%.

[0043] The internal mixer is cooled with water, and the temperature of the working room of the internal mixer is controlled not to exceed 50°C. Mix EPDM rubber and maleic anhydride grafted EPDM rubber in the internal mixer for 1 minute, and then add zinc oxide in turn. , stearic acid StA, binder RS and A to the internal mixer and knead for 3min, then add N330 carbon black, N550 carbon black, white carbon black and knead for 4min; finally, add sulfur and crosslinking additives and knead f...

Embodiment 2

[0046] Weigh the following parts by weight raw materials: 100 parts of EPDM rubber 4010M; additives: 5 parts of zinc oxide, 1 part of stearic acid StA, 5 parts of N330 carbon black, 20 parts of N550 carbon black, 10 parts of white carbon black, viscose Mixture: 15 parts of binder RS, 10 parts of binder A; vulcanizing agent: 0.5 parts of sulfur, 2 parts of cross-linking aid TBzTD, 1.5 parts of cross-linking aid DTDC, 1.0 parts of cross-linking aid ZBEC; 10 parts of acid anhydride grafted polybutadiene (MA=7.5wt%).

[0047] The internal mixer is cooled by water, and the temperature of the working room of the internal mixer is controlled not to exceed 50°C. Mix EPDM rubber and maleic anhydride grafted polybutadiene in the internal mixer for 0.5min, and then add zinc oxide in sequence , stearic acid StA, binder RS and A to the internal mixer and knead for 3min, then add N330 carbon black, N550 carbon black, white carbon black and knead for 4min; finally, add sulfur and crosslink...

Embodiment 3

[0050] Weigh the following parts by weight raw materials: 100 parts of EPDM 4010M; additives: 5 parts of zinc oxide, 1 part of stearic acid StA, 25 parts of N550 carbon black, 10 parts of white carbon black; adhesive: adhesive 15 parts of RS, 10 parts of binder A; vulcanizing agent: 0.5 parts of sulfur, 2.0 parts of cross-linking auxiliary agent CBBS, 1.0 parts of cross-linking auxiliary agent DTDC, 2.0 parts of cross-linking auxiliary agent TBzTD; maleic anhydride grafted terpolymer 10 parts of propylene rubber (MA=1.0 wt%).

[0051] The internal mixer is cooled with water, and the temperature of the working room of the internal mixer is controlled not to exceed 50°C. Mix EPDM rubber and maleic anhydride grafted EPDM rubber in the internal mixer for 1 minute, and then add zinc oxide in turn. , stearic acid StA, binder RS and A to the internal mixer and knead for 3 minutes, then add N550 carbon black and white carbon black and knead for 5 min; finally, add sulfur and cross-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com