Transistor outline (TO)-CAN packaged semiconductor laser and fabrication method thereof

A TO-CAN and semiconductor technology, applied in the laser field, can solve the problems affecting the quality stability of laser products, increase the application of high-cost gold wire, and the complicated bonding operation process, so as to simplify the gold wire bonding operation process and save The cost of bonding gold wire and the effect of improving the quality of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can clearly understand the present invention, but the protection scope of the present invention is not limited thereby.

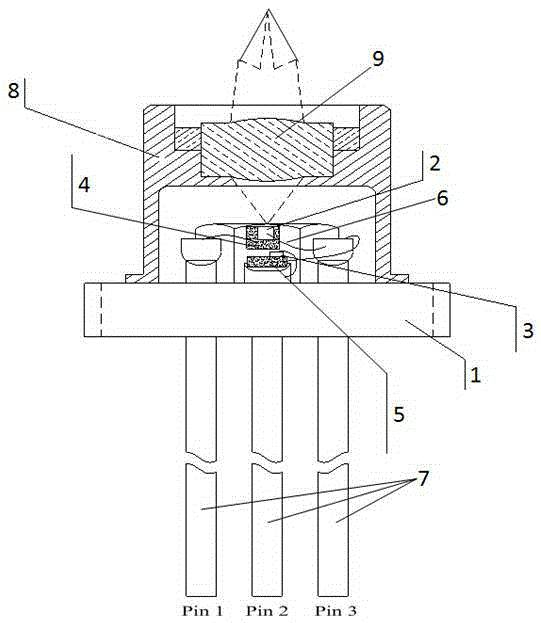

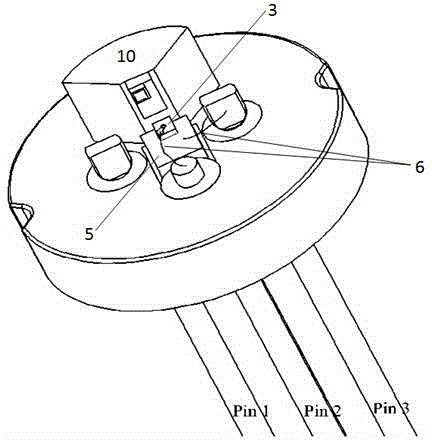

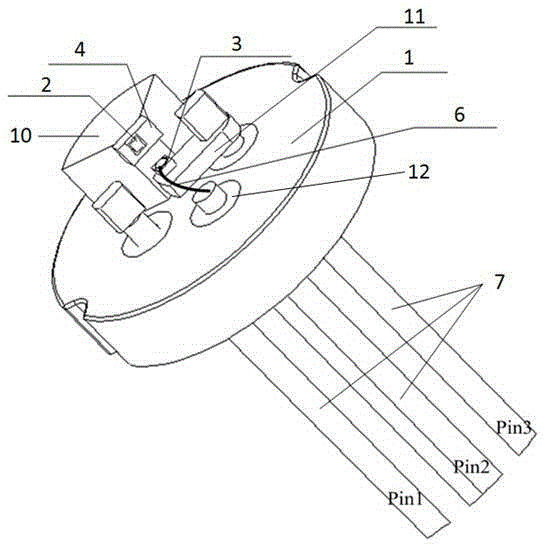

[0039] TO-CAN packaged semiconductor laser is currently widely used as a communication light source device, and its structure is constantly being optimized and developed. This invention is based on long-term innovative experimental research, and proposes a TO-CAN packaged semiconductor laser with a new structure, which greatly improves The comprehensive performance of TO-CAN packaged semiconductor laser is shown, as attached image 3 As shown, the TO-CAN packaged semiconductor laser of the present invention includes a TO socket 1, a semiconductor laser chip 2, a backlight detector chip 3, a laser chip spacer 4, a bonding gold wire 6, a pin 7, a heat sink block 10, Support table 11, TO tube c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com