Antivibration apparatus

A technology for vibration isolation and mounting components, applied in the direction of non-rotational vibration suppression, springs made of plastic materials, springs, etc., to achieve the effects of improving durability, simplifying the bonding process, and reducing tensile input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

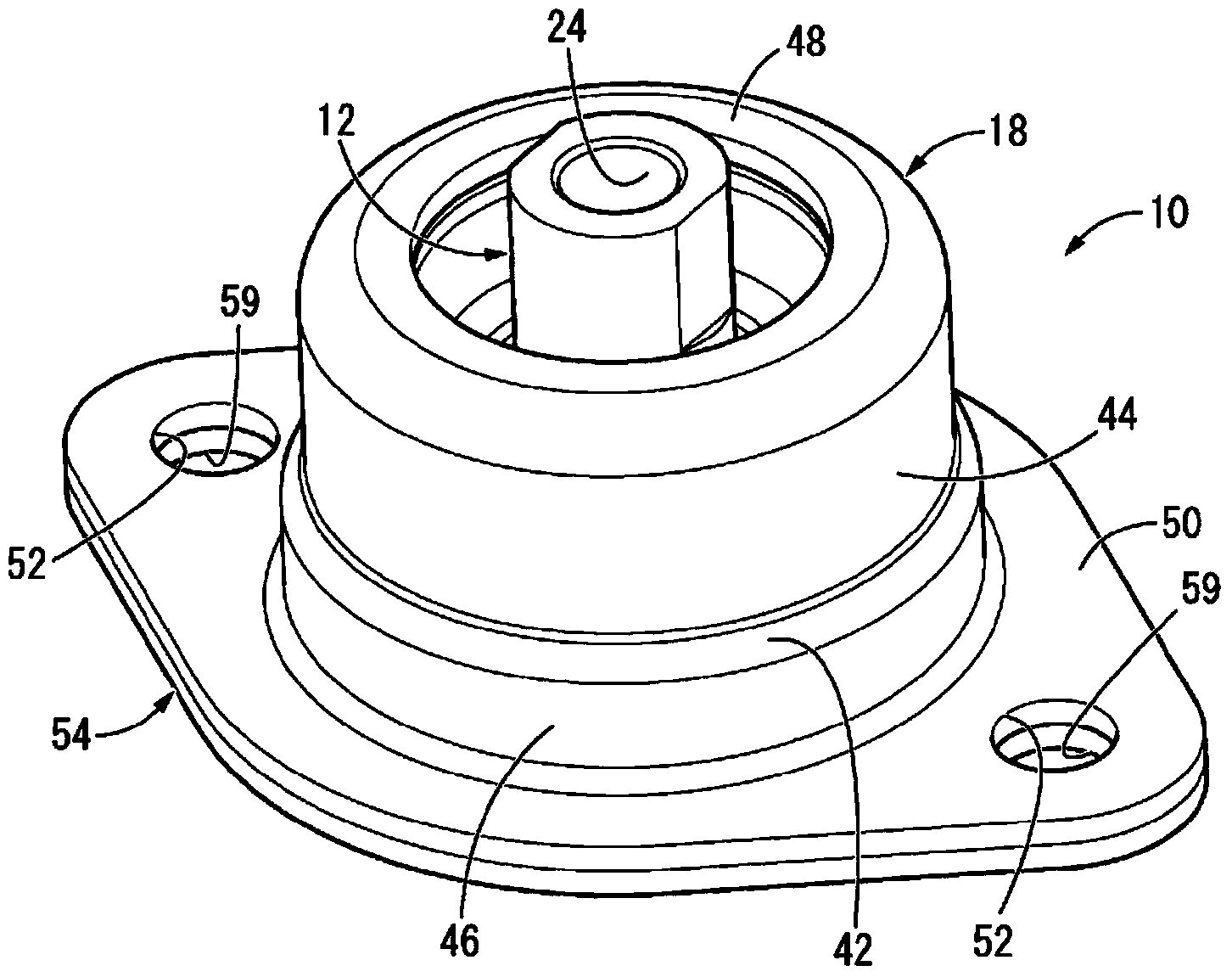

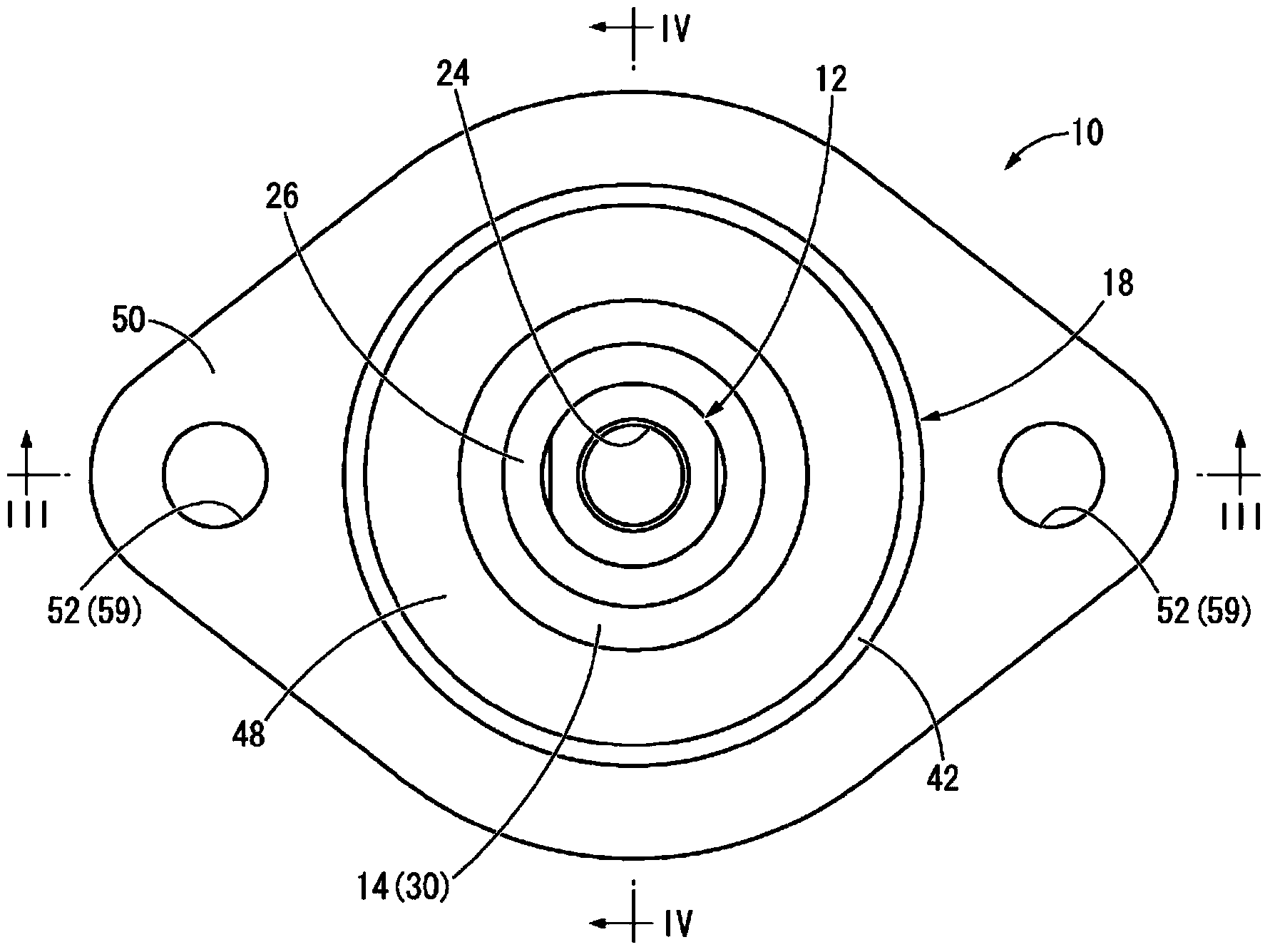

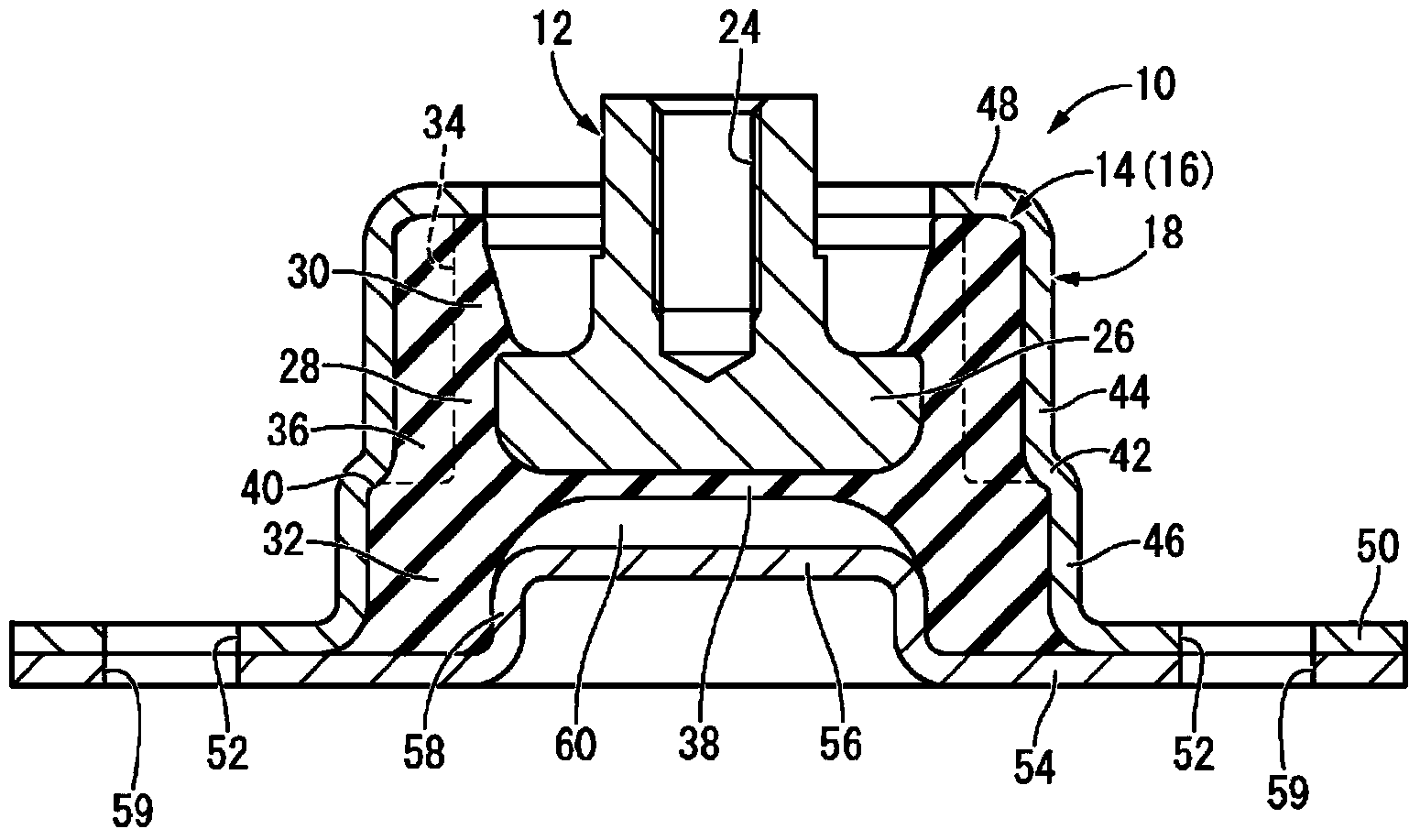

[0036] Figure 1 ~ Figure 4An engine mount 10 is shown as an embodiment of a vibration damping device designed according to the invention. The engine mount 10 has a structure in which the inner mounting member 12 and the outer mounting member are elastically connected by the main body rubber elastic body 14 by attaching the outer mounting member 18 to the integrally vulcanized molded product 16 having the main body rubber elastic body 14 of the inner mounting member 12 . 18. And, by installing the internal mounting member 12 on the power unit 20 (refer to Figure 9 ), and install the external mounting member 18 on the vehicle body 22 (see Figure 9 ), and the power unit 20 is vibration-isolated and supported on the vehicle body 22 . In addition, in the following description, unless otherwise specified, the vertical direction refers to the axial direction, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com