Single-slot self-lubricating oscillating bearing with outer ring provided with composite lining plates and manufacturing method thereof

A composite lining plate, joint bearing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as falling off, and achieve the effects of low manufacturing cost, firm and reliable bonding, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the present invention is manufactured according to the following method:

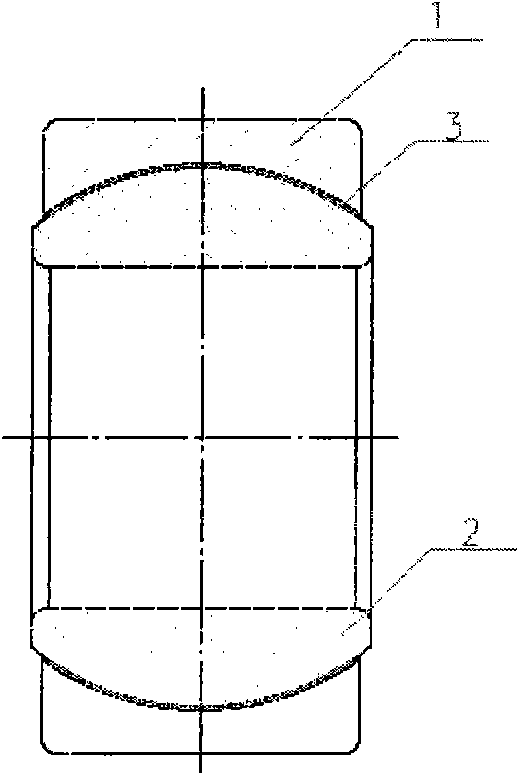

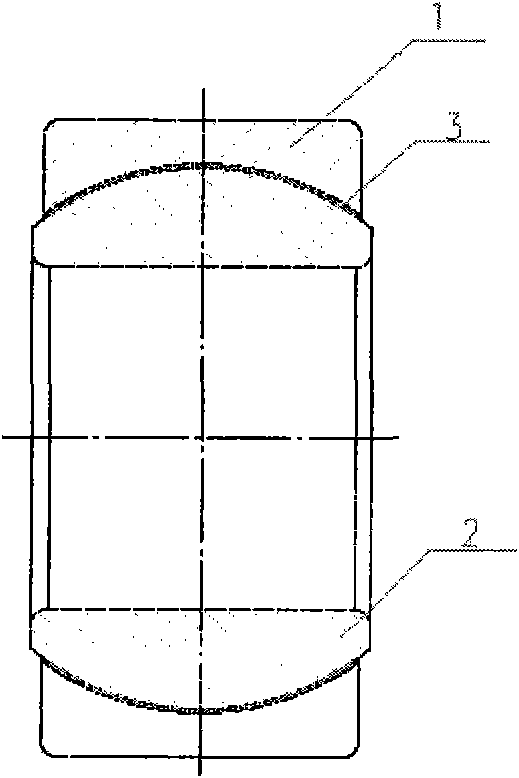

[0020] a. According to the method of the prior art, the outer ring 1 and the inner ring 2 are processed with bearing steel, wherein there is an axial seam on the outer ring;

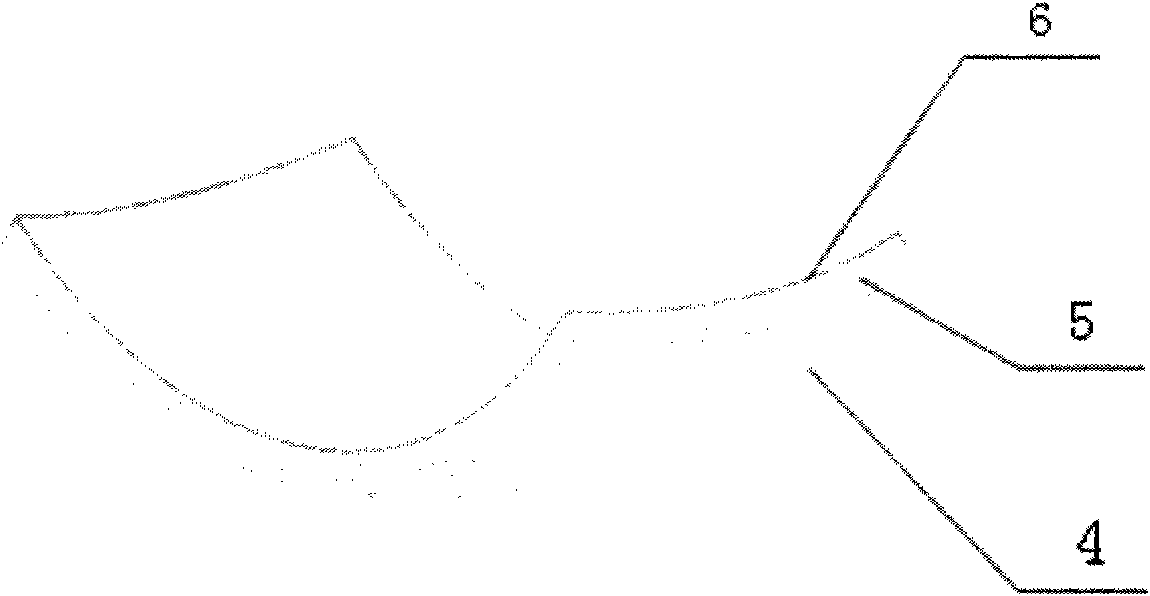

[0021] b. make steel-backed composite plane liner boards according to the method of the prior art, and then press them into at least four pieces such as figure 2 The steel-backed composite material liner 3 shown is composed of a steel base layer 4, a copper powder layer 5 and a polytetrafluoroethylene plastic layer 6, and multiple steel-backed composite material liners 3 are radially spliced to the inner surface of the outer ring. match in shape

[0022] c. Roughen the steel back surface of each steel back composite liner and process grooves on the steel back surface. At the same time, it needs to be equipped with a radial splicing surface to increase surface roughness, increase friction resistance, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com