Circuit breaker assembly quality problem tracing system and method based on large data analysis

A quality problem and traceability system technology, applied in data processing applications, instruments, character and pattern recognition, etc., can solve the problems of poor accuracy of traceability results, waste of analysis resources, low efficiency, etc., to avoid inefficiency and volatility, Ensuring data security and improving computing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]During the circuit breaker assembly and production process, it is necessary to carry out factory tests on the products in the mechanical characteristic test link, automatic running-in test link and power frequency withstand voltage test link, and trace the root cause of the assembly quality problem of unqualified products and adjust them until they are qualified. The traditional traceability method is that the inspectors compare the differences according to the test data and inspection standards, determine the category of quality problems, and make trial-and-error adjustments based on experience and knowledge. This method is one-sided, subjective, blind, and inefficient, and directly affects the product. quality and production progress.

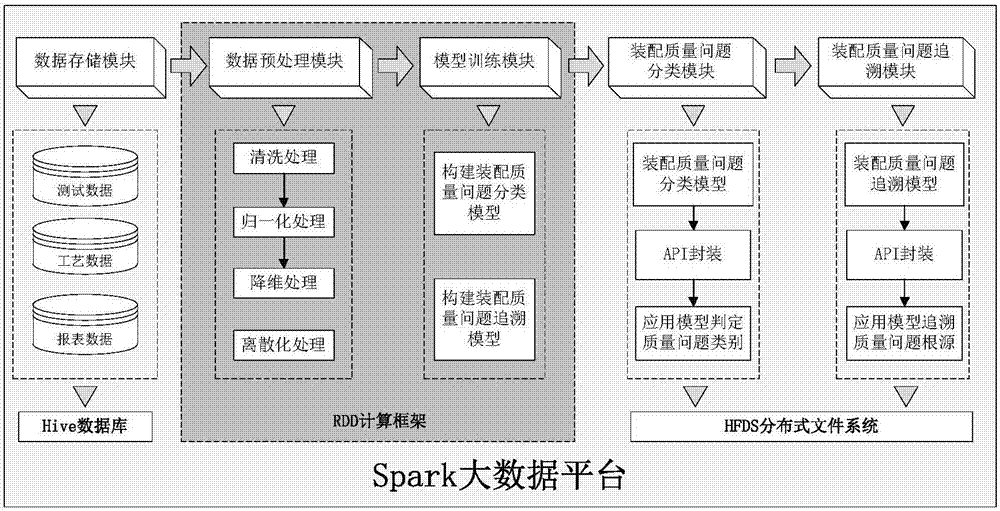

[0031] Aiming at this current situation and problem, the present invention has carried out research and proposed a circuit breaker assembly quality problem traceability system based on big data analysis. This system is based on the secon...

Embodiment 2

[0034] The overall composition of the circuit breaker assembly quality problem traceability system based on big data analysis is the same as that in Embodiment 1, see figure 1 , the data storage module in the present invention is to store the data required for training the classification model and the traceability model in the Hive database module of the Spark platform, and the data storage scope covers the necessary data in the whole life cycle process of the circuit breaker, from parts and components into From the field to the final assembly to complete the factory use, including test data, process data and report data.

Embodiment 3

[0036] The overall composition of the circuit breaker assembly quality problem traceability system based on big data analysis is the same as that in Embodiment 1-2, see figure 1 , the data preprocessing module of the present invention includes a cleaning processing submodule, a normalization processing submodule, a dimensionality reduction processing submodule and a discretization processing submodule. The cleaning processing sub-module is to detect and fill the null values in the original data, so as to avoid abnormalities caused by missing data when building the model. The normalization processing sub-module is to map the data processed by the cleaning processing sub-module to the [0,1] interval, to eliminate the dimensional influence caused by the inconsistency of data units between different features, so that all data are in the same reference system. The dimension reduction processing sub-module is to map the high-dimensional features processed by the cleaning processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com