Water quenching and air cooling modified treatment technology of 42CrMo material

A process method, a quenching and tempering treatment technology, applied in the field of quenching and tempering treatment of 42CrMo materials, can solve problems such as unqualified tissue, large pollution, and prone to cold cracking, and achieve the goal of improving comprehensive performance, improving comprehensive performance, and preventing cold cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The 42CrMo product used in this embodiment is: product size: Φ930mm×17285mm, a long-axis forging with a weight of about 92 tons, and the material is 42CrMo.

[0013] Product ingredients, %

[0014] C mn Si S P Cr Mo Ni Cu 0.39 0.53 0.22 0.001 0.005 0.93 0.17 0.13 0.07

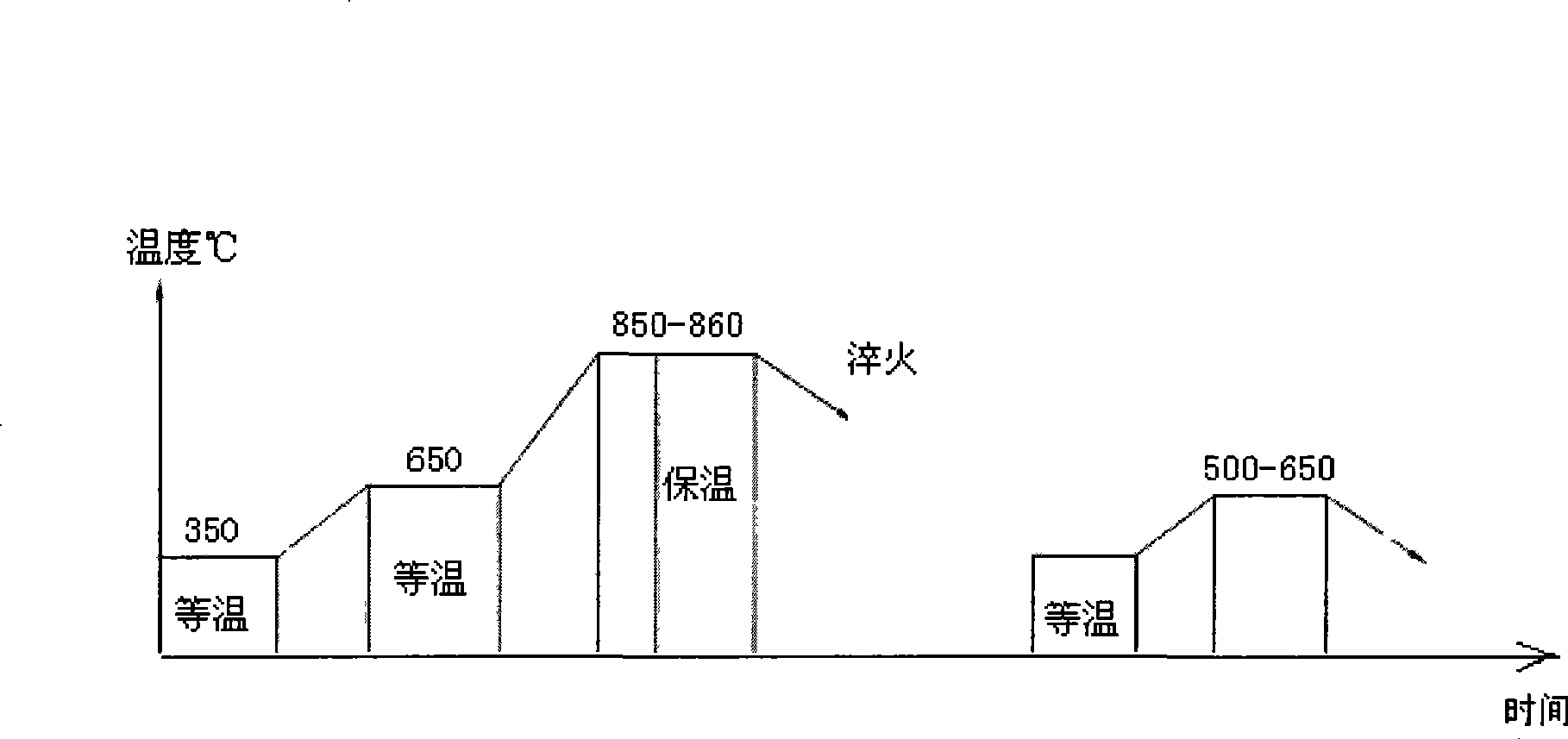

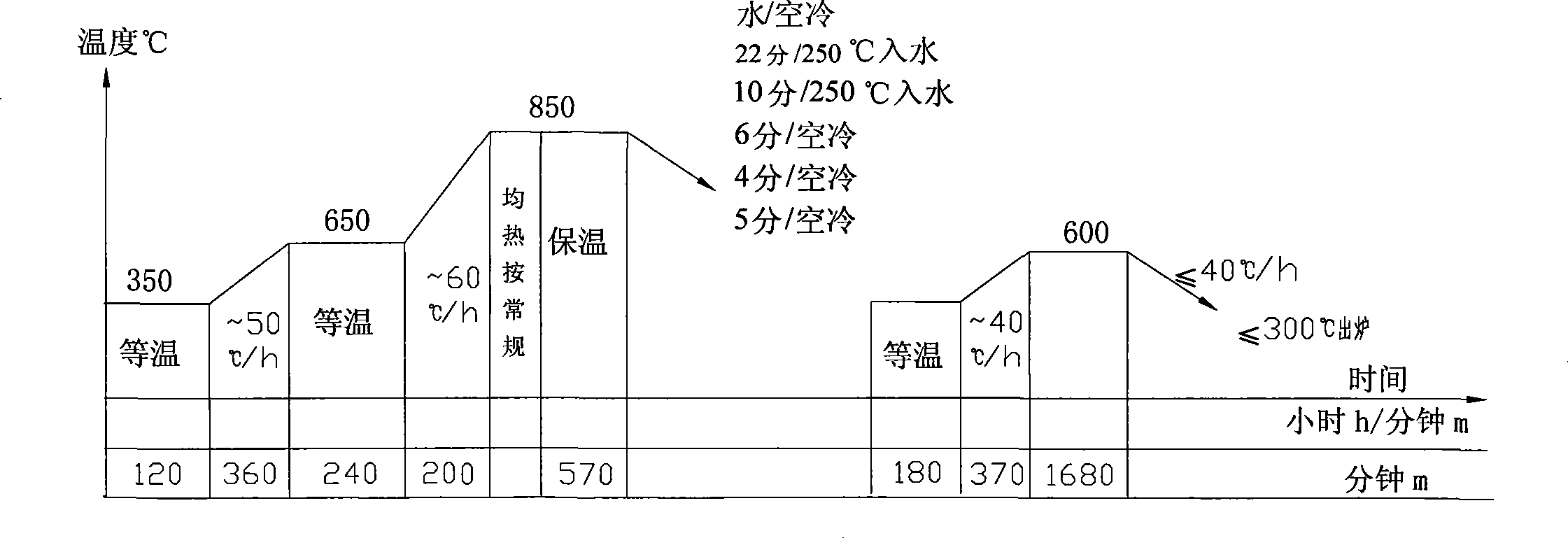

[0015] After rough machining, the product is arranged to be hoisted in the heat treatment workshop, and then quenched and tempered. Such as figure 2 Shown, the water-quenching air-cooling quenching and tempering treatment process of 42CrMo material of the present invention comprises the steps:

[0016] (1) Heating: 350°C isothermal for 120 minutes, after 360 minutes from 350°C to 650°C, at 650°C for 240 minutes, after 200 minutes from 650°C to 850°C;

[0017] (2) Heat preservation: 850°C isothermal for 570 minutes;

[0018] (3) Quenching: Use 5 cycles of water cooling and air cooling: after 22 minutes of water cooling, lift out the air-cooled buffer, wait for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com