Preparation method of mu90 high-permeability Fe-based amorphous magnetic powder core

A high magnetic permeability and magnetic powder core technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems that it is difficult to further improve the magnetic permeability of amorphous magnetic powder cores, and achieve excellent DC bias characteristics, high magnetic The effects of conductivity, optimal loss characteristics and bias characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

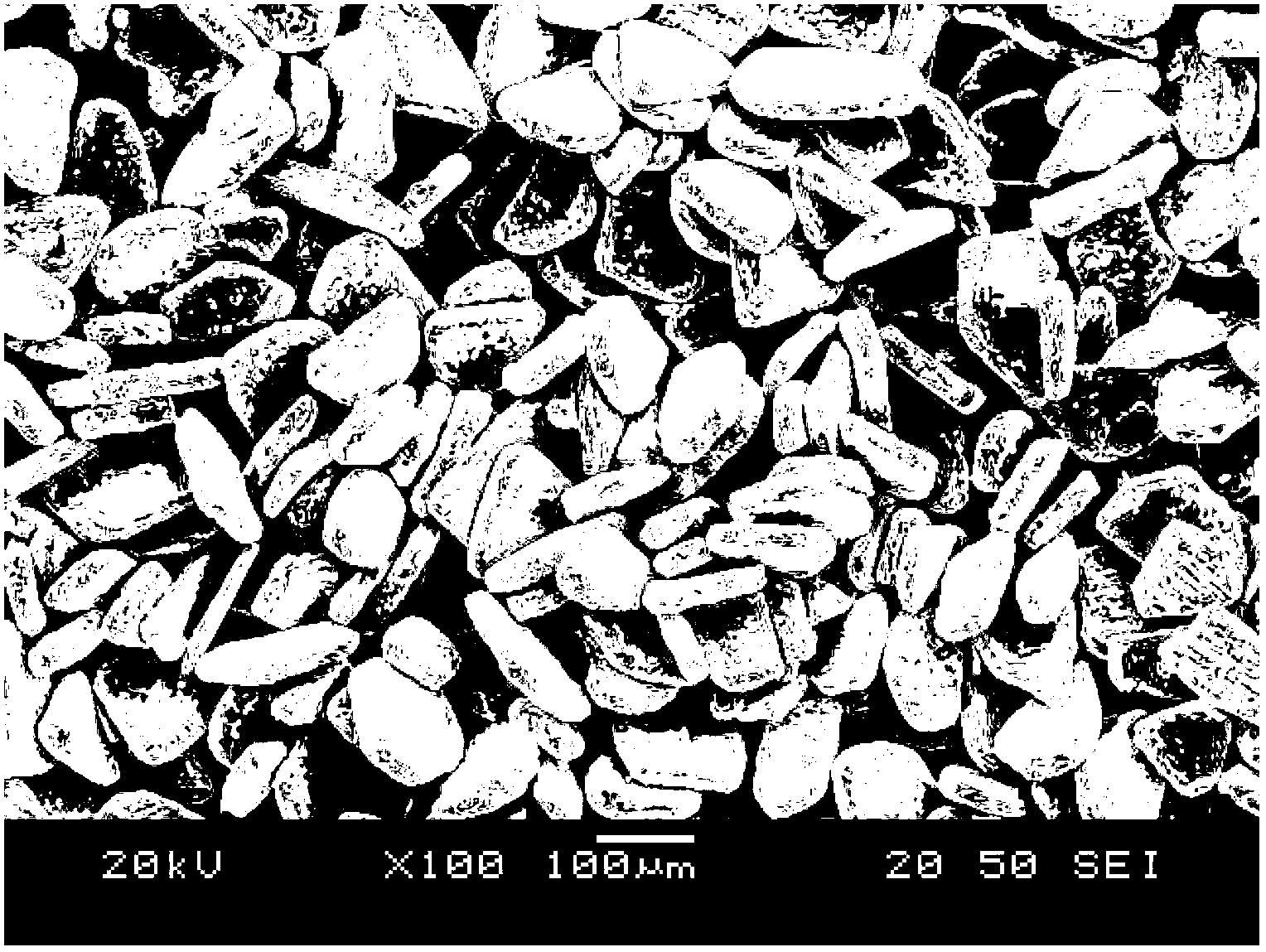

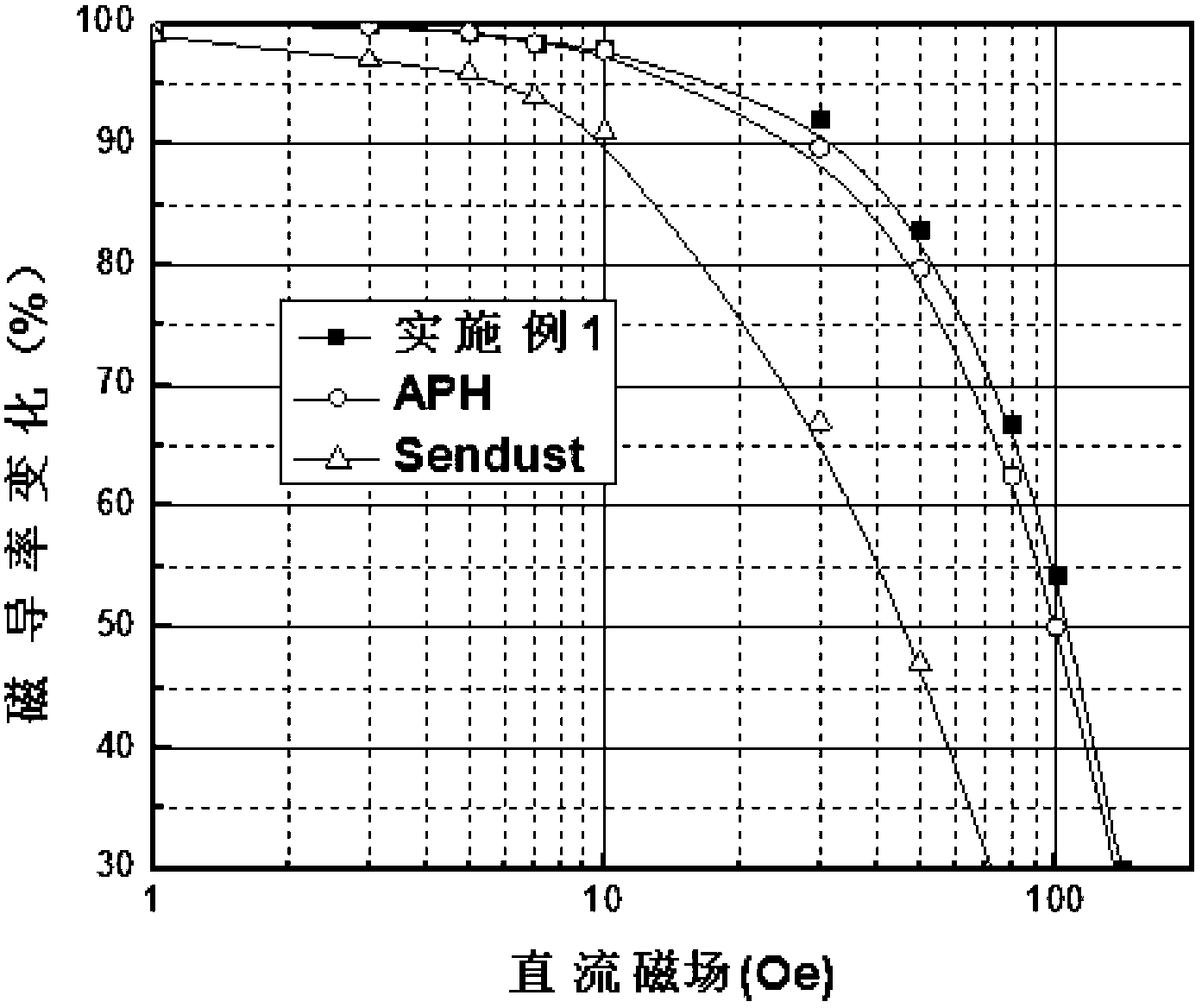

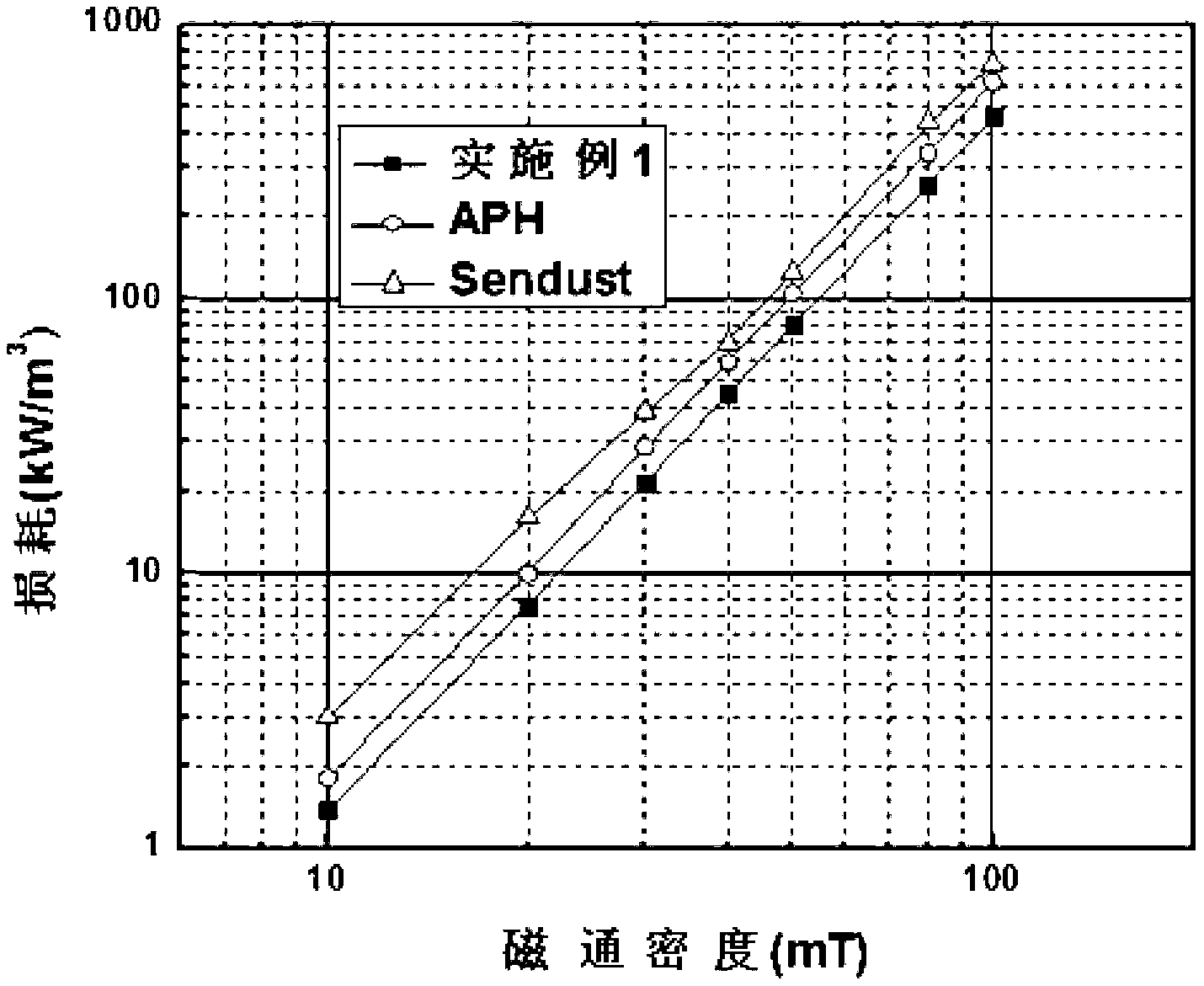

[0043] The composition is Fe prepared by single-roll rapid quenching method 82 Si 2 B 14 C 2 Fe-based amorphous alloy thin strips, the amorphous alloy thin strips were preheated at 300°C for 1 hour under a nitrogen atmosphere, then combined with mechanical milling and jet milling, and Fe-based amorphous alloys with a certain particle size range were screened. Powder, of which -100 mesh ~ +140 mesh powder accounts for 20%, -140 mesh ~ +200 mesh powder accounts for 80%. The powder is mixed with 10% phosphoric acid alcohol solution, dried at 100°C and mixed with 2% cyanate and 2% SiO 2 Mixing and coating granulation, stirring evenly, adding 0.8% zinc stearate, molding at room temperature, the pressing pressure is 2000MPa, and the holding time is 3s. The molded magnetic powder core was kept at 320°C for 1 hour in air for stress relief annealing, and the surface of the heat-treated magnetic powder core sample was coated with epoxy resin paint. The performance test results of th...

Embodiment 2

[0052] Prepare Fe-based amorphous powder in the same manner as in Example 1, change the particle size ratio to: -100 mesh to +140 mesh powder accounts for 30%, -140 mesh to +200 mesh powder accounts for 70%, and the phosphoric acid alcohol solution The amount of addition is changed to 5%, SiO 2 The addition amount of is changed to 1%, and all the other process conditions are unchanged, the performance of the prepared magnetic powder core is as follows:

[0053] (1) The magnetic permeability μ=97.8 under the condition of 100kHz and 1V;

[0054] (2) The frequency characteristics are shown in Table 3 below:

[0055] table 3

[0056]

[0057] (3) When the magnetic permeability drops to 50%, the DC bias magnetic field is H=102Oe;

[0058] (4) Under the condition of 100kHz and 0.1T, the loss of magnetic powder core P cv =627kW / m 3 ;

Embodiment 3

[0060] Prepare Fe-based amorphous powder in the same manner as in Example 1, change the particle size ratio to: -100 mesh to +140 mesh powder accounts for 10%, -140 mesh to +200 mesh powder accounts for 90%, and the cyanate ester The addition amount of is changed to 3%, and all the other process conditions are unchanged, the performance of the prepared magnetic powder core is as follows:

[0061] (1) The magnetic permeability μ=83.2 under the condition of 100kHz and 1V;

[0062] (2) The frequency characteristics are shown in Table 4 below:

[0063] Table 4

[0064]

[0065] (3) When the magnetic permeability drops to 50%, the DC bias magnetic field is H=110Oe;

[0066] (4) Under the condition of 100kHz and 0.1T, the loss of magnetic powder core P cv =470kW / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com