A kind of preparation method of amorphous soft magnetic composite material

A technology of soft magnetic composite materials and soft magnetic alloys, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of high toughness of amorphous strips, complex process and high cost of amorphous soft magnetic composite materials, and achieve improvement Amorphous formation ability, excellent DC bias characteristics, and effect of improving resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the amorphous soft magnetic composite material comprises the following steps:

[0021] 1) Preparation of amorphous thin strip: the soft magnetic alloy is smelted in a vacuum melting furnace, and the amorphous thin strip is obtained through a single-roller quenching and stripping process;

[0022] 2) Embrittlement annealing: Embrittlement annealing is carried out on the amorphous strip obtained by the rapid quenching method, the annealing temperature is 300~450°C, the annealing time is 0.5~2h, and the annealing atmosphere is vacuum or non-oxidizing atmosphere;

[0023] 3) Ball milling: Coarsely crush the brittle annealed amorphous strips, use a planetary ball mill to mill, and sieve to obtain amorphous soft magnetic powders less than 100 mesh;

[0024] 4) Particle size ratio: The obtained amorphous soft magnetic powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage content of the mixed powder is...

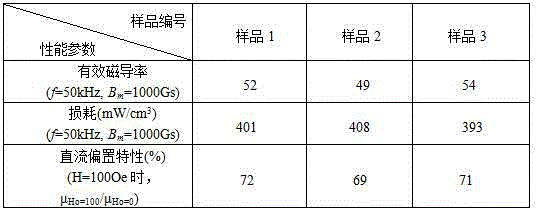

Embodiment 1

[0033] In this embodiment, the molecular formula of the alloy constituting the soft magnetic composite material is Fe 76 Si 9 B 12 Cr 2 Dy 1 , the following are the specific preparation steps:

[0034] (1) Preparation of Fe 76 Si 9 B 12 Cr 2 Dy 1 Amorphous thin strip: the alloy is smelted in a vacuum melting furnace, and the amorphous thin strip is obtained through a single-roller quenching and stripping process;

[0035] (2) Embrittlement annealing: 350°C / 1h embrittlement annealing is performed on the amorphous strip obtained by the rapid quenching method, and the annealing atmosphere is an argon atmosphere;

[0036] (3) Ball milling: Coarsely crush the brittle annealed amorphous strips, use a planetary ball mill to mill, and sieve to obtain a powder of less than 100 mesh;

[0037] (4) Particle size ratio: The obtained amorphous powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage of the mixed powder is: -100~+200 ...

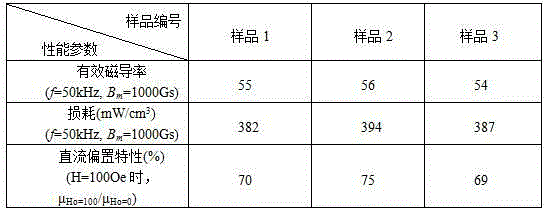

Embodiment 2

[0045] In this embodiment, the molecular formula of the alloy constituting the soft magnetic composite material is Fe 69.7 Si 18 B 12 Y 0.2 Dy 0.1 , the following are the specific preparation steps:

[0046] (1) Preparation of Fe 69.7 Si 18 B 12 Y 0.2 Dy 0.1 Amorphous thin strip: the alloy is smelted in a vacuum melting furnace, and the amorphous thin strip is obtained through a single-roller quenching and stripping process;

[0047] (2) Embrittlement annealing: 300°C / 2h embrittlement annealing is carried out on the amorphous strip obtained by the rapid quenching method, and the annealing atmosphere is an argon atmosphere;

[0048] (3) Ball milling: Coarsely crush the brittle annealed amorphous strips, use a planetary ball mill to mill, and sieve to obtain a powder of less than 100 mesh;

[0049] (4) Particle size ratio: The obtained amorphous powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage of the mixed powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com