Iron-based amorphous/nanocrystalline thin band with low cost and excellent soft magnetic properties and preparation method thereof

An iron-based amorphous and low-cost technology, applied in the field of new FeCuSiBAl-based amorphous/nanocrystalline thin strips, can solve the problems of high price, increased cost and operability, and complex composition, and achieve low cost and excellent soft magnetic properties The effect of energy and production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

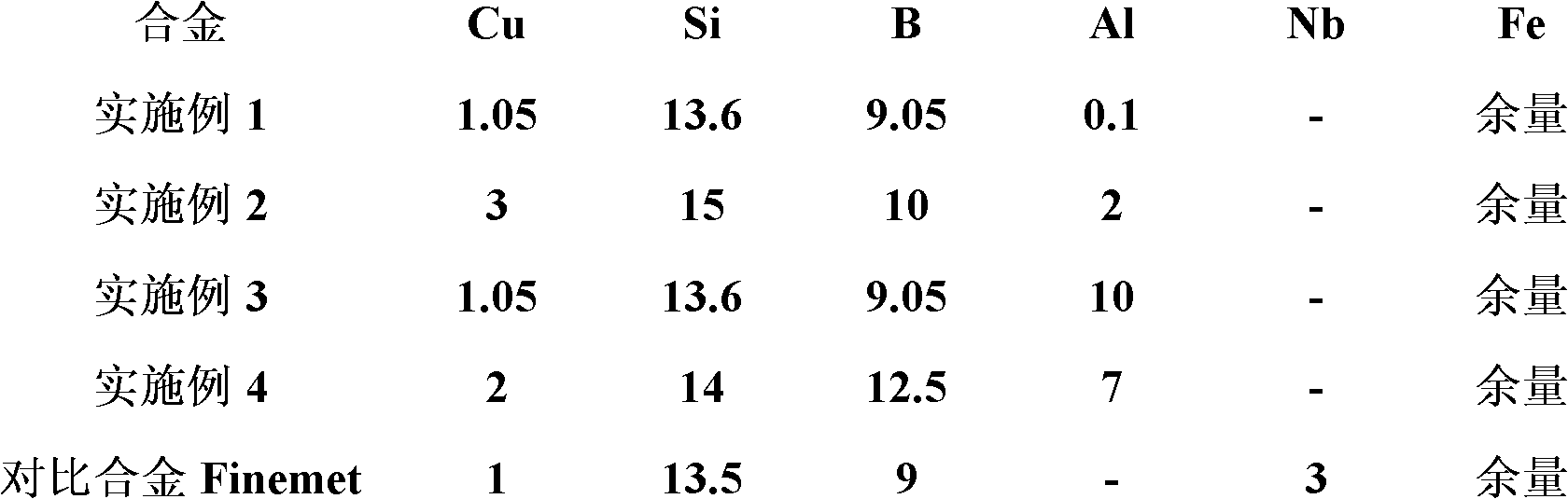

Embodiment 1

[0031] Preparation of Fe 76.2 Cu 1.05 Si 13.6 B 9.05 al 0.1 Amorphous / Nanocrystalline Ribbons

[0032] Step 1: Press Fe 76.2 Cu 1.05 Si 13.6 B 9.05 al 0.1 Atomic percentages are used for batching.

[0033] According to Fe 76.2 Cu 1.05 Si 13.6 B 9.05 al0.1 Chemical composition, respectively weighing 22.0273 grams of iron with a purity of 99.9%, 0.3454 grams of copper with a purity of 99.9%, 1.9772 grams of silicon with a purity of 99.9%, 0.5064 grams of boron with a purity of 99.9%, and 0.0140 grams of aluminum with a purity of 99.9%. .

[0034] The second step: preparation of Fe 76.2 Cu 1.05 Si 13.6 B 9.05 Al 0.1 Master Alloy

[0035] Wash the ingredients of the first step with alcohol and put them into a vacuum intermediate frequency induction melting furnace, and adjust the vacuum degree to 5×10 -3 Pa, then filled with 0.05MPa argon protective gas, adjusted current 15A, melting temperature 1600°C, smelting for 60 minutes and then cooling with the furnace...

Embodiment 2

[0042] Preparation of Fe 70 Cu 3 Si 15 B 10 Al 2 Amorphous / Nanocrystalline Ribbon

[0043] Step 1: Press Fe 70 Cu 3 Si 15 B 10 Al 2 Atomic percentages are used for batching.

[0044] According to Fe 70 Cu 3 Si 15 B 10 Al 2 Chemical composition, weighing 22.7034 grams of iron with a purity of 99.9%, 1.1072 grams of copper with a purity of 99.9%, 2.4467 grams of silicon with a purity of 99.9%, 0.6279 grams of boron with a purity of 99.9%, and 0.3135 grams of aluminum with a purity of 99.9%. .

[0045] The second step: preparation of Fe 70 Cu 3 Si 15 B 10 Al 2 Master Alloy

[0046] Wash the ingredients of the first step with alcohol and put them into a vacuum intermediate frequency induction melting furnace, and adjust the vacuum degree to 1×10 -2 Pa, then filled with 0.1MPa argon protective gas, adjusted current 20A, melting temperature 2400°C, smelting for 7 minutes and cooling with the furnace. The alloy was repeatedly smelted 4 times and then taken out....

Embodiment 3

[0053] Preparation of Fe 66.3 Cu 1.05 Si 13.6 B 9.05 Al 10 Amorphous / Nanocrystalline Ribbon

[0054] Step 1: Press Fe 66.3 Cu 1.05 Si 13.6 B 9.05 Al 10 Atomic percentages are used for batching.

[0055] According to Fe 66.3 Cu 1.05 Si1 3.6 B 9.05 Al 10 Chemical composition, respectively weighing 25.2437 grams of iron with a purity of 99.9%, 0.4549 grams of copper with a purity of 99.9%, 2.6042 grams of silicon with a purity of 99.9%, 0.6671 grams of boron with a purity of 99.9%, and 1.8400 grams of aluminum with a purity of 99.9% .

[0056] The second step: preparation of Fe 66.3 Cu 1.05 Si 13.6 B 9.05 Al 10 Master Alloy

[0057] Wash the ingredients of the first step with alcohol and put them into a vacuum intermediate frequency induction melting furnace, and adjust the vacuum degree to 6×10 -3 Pa, then filled with 0.06MPa argon protective gas, adjusted current 20A, smelting temperature 2000°C, smelting for 30 minutes and cooling with the furnace. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com