Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce winding length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

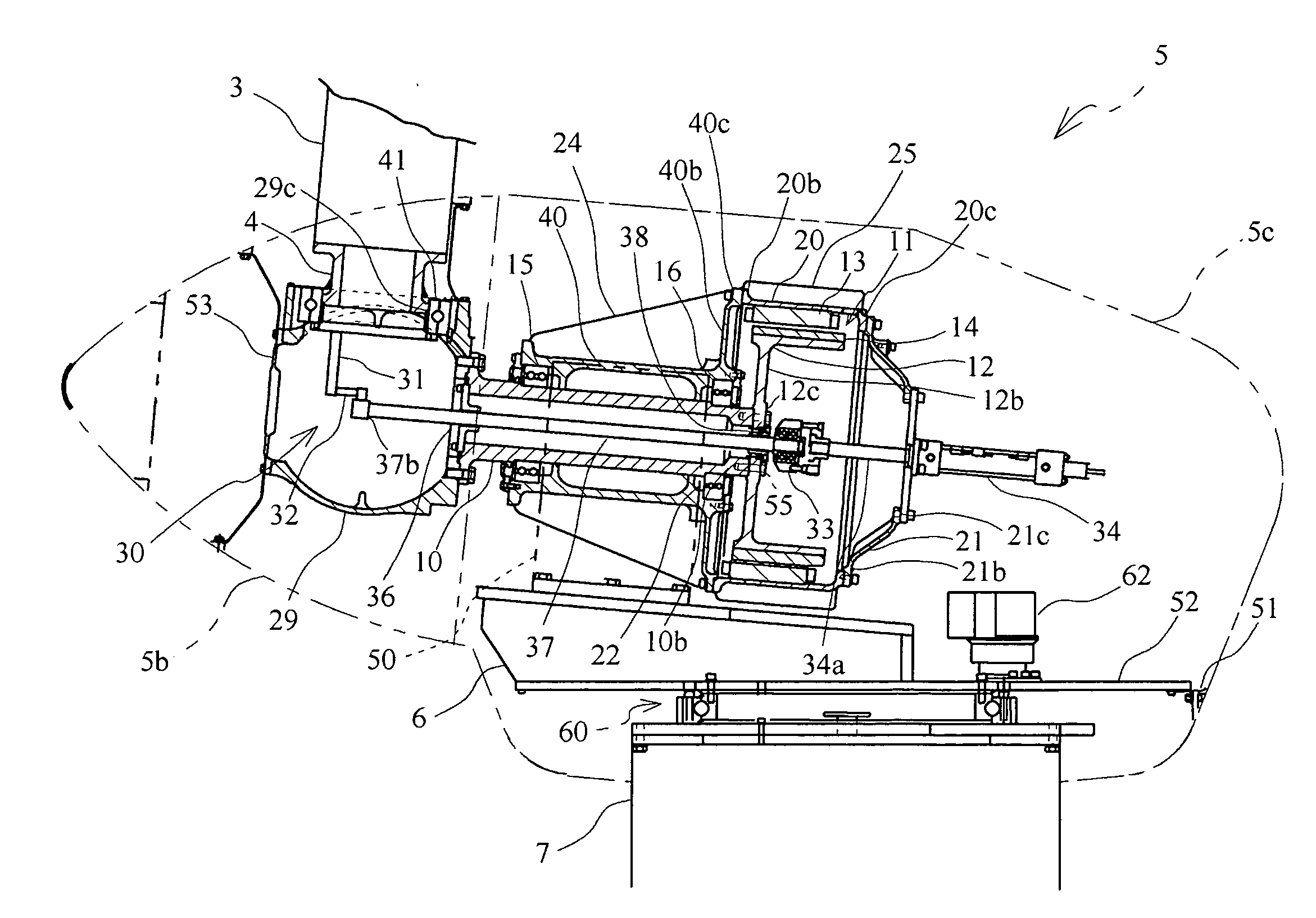

Wind turbine apparatus

InactiveUS7547985B2Reduce winding lengthShorten the lengthPropellersWind motor controlEngineeringTower

Conventionally, a main shaft of the wind turbine apparatus has awkward such as heaviness or difficulties of assembling, since the length of the main shaft must be long to support a generator rotor. It is requested originally to light heaviness of a wind turbine apparatus, since it supports a wind wheel and a generator etc. on a tower at prescribed height. A hub 29 supported on the one side of the main shaft 10, a generator rotor 12 supported on the other side of the main shaft 10, the main shaft housing 40 and the generator housing 20 are combined, the generator rotor 12 having a backward opening is fixedly provided on the rear end of the main shaft 10, the main shaft 10 and the generator rotor 12 are detachably fixed through the opening, and a rotational fitting (rod bearing 33) for a pitch control shaft 37 is at least disposed at the rear space of the generator housing 20.

Owner:YANMAR CO LTD

Wind Turbine Apparatus

InactiveUS20080309086A1Shorten the lengthReduce winding lengthPropellersFinal product manufactureTowerWind force

Conventionally, a main shaft of the wind turbine apparatus has awkward such as heaviness or difficulties of assembling, since the length of the main shaft must be long to support a generator rotor. It is requested originally to light heaviness of a wind turbine apparatus, since it supports a wind wheel and a generator etc. on a tower at prescribed height. A hub 29 supported on the one side of the main shaft 10, a generator rotor 12 supported on the other side of the main shaft 10, the main shaft housing 40 and the generator housing 20 are combined, the generator rotor 12 having a backward opening is fixedly provided on the rear end of the main shaft 10, the main shaft 10 and the generator rotor 12 are detachably fixed through the opening, and a rotational fitting (rod bearing 33) for a pitch control shaft 37 is at least disposed at the rear space of the generator housing 20.

Owner:YANMAR CO LTD

Brushless permanent magnet motor with unequal-width slots and method of producing the same

InactiveUS20080290751A1Improve motor efficiencyImprove flux linkageMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

A brushless permanent magnet motor with unequal-width slots and its manufacturing method completes a design of a regular motor with equal-width slots, employs a single-layer centralized winding, increasing the width equally on left and right sides of a first type of teeth wound with a coil until a width Wt3 of a tooth tip equals to a width Wp of a magnetic pole, such that the stator slot opening shifts towards a second type of teeth with no coil, increasing a width of a first type of teeth with a coil equally on left and right sides until a coil pitch equals to a width Wp of a magnetic pole or a motor angle equals to 180°, and decreasing a width Wt2 of a second type of teeth with no coil equally on both left and right sides until a slot area Sa2 is greater than the original slot area Sa1 of a regular motor with equal-width slots to improve the motor efficiency and reliability for a variable speed operation.

Owner:AZURE SHINE INT

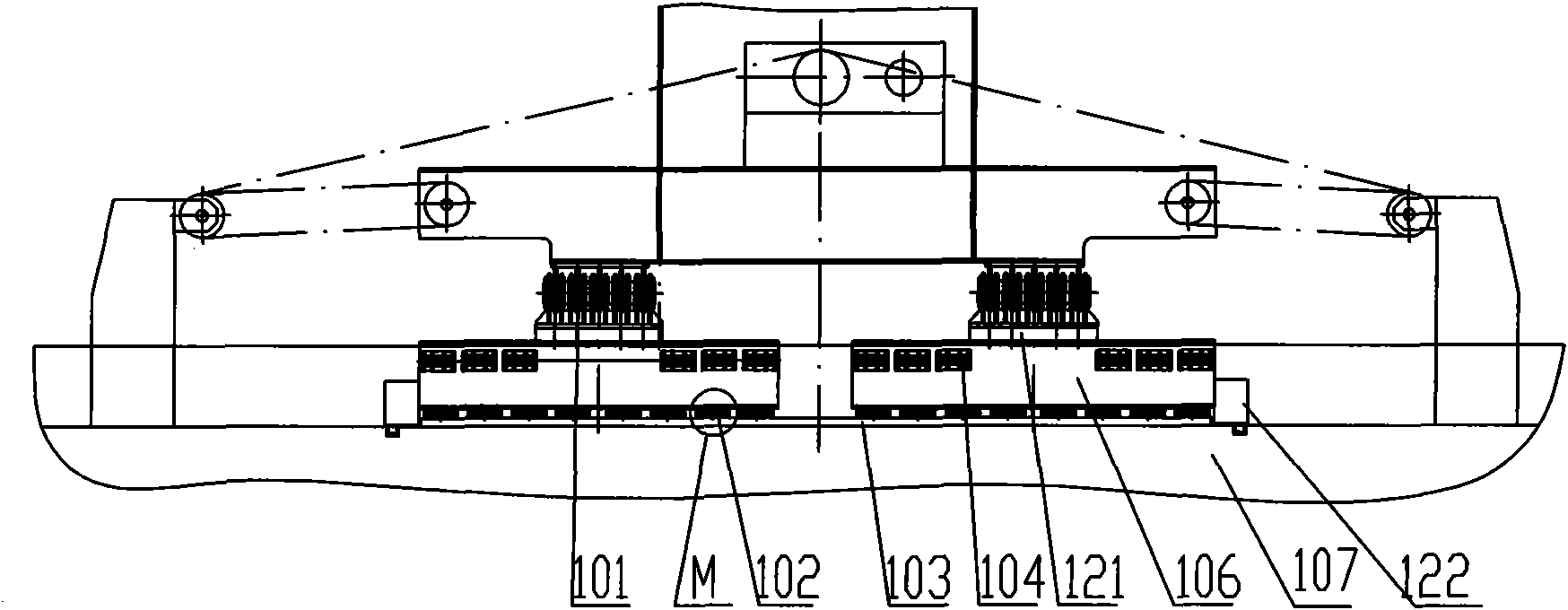

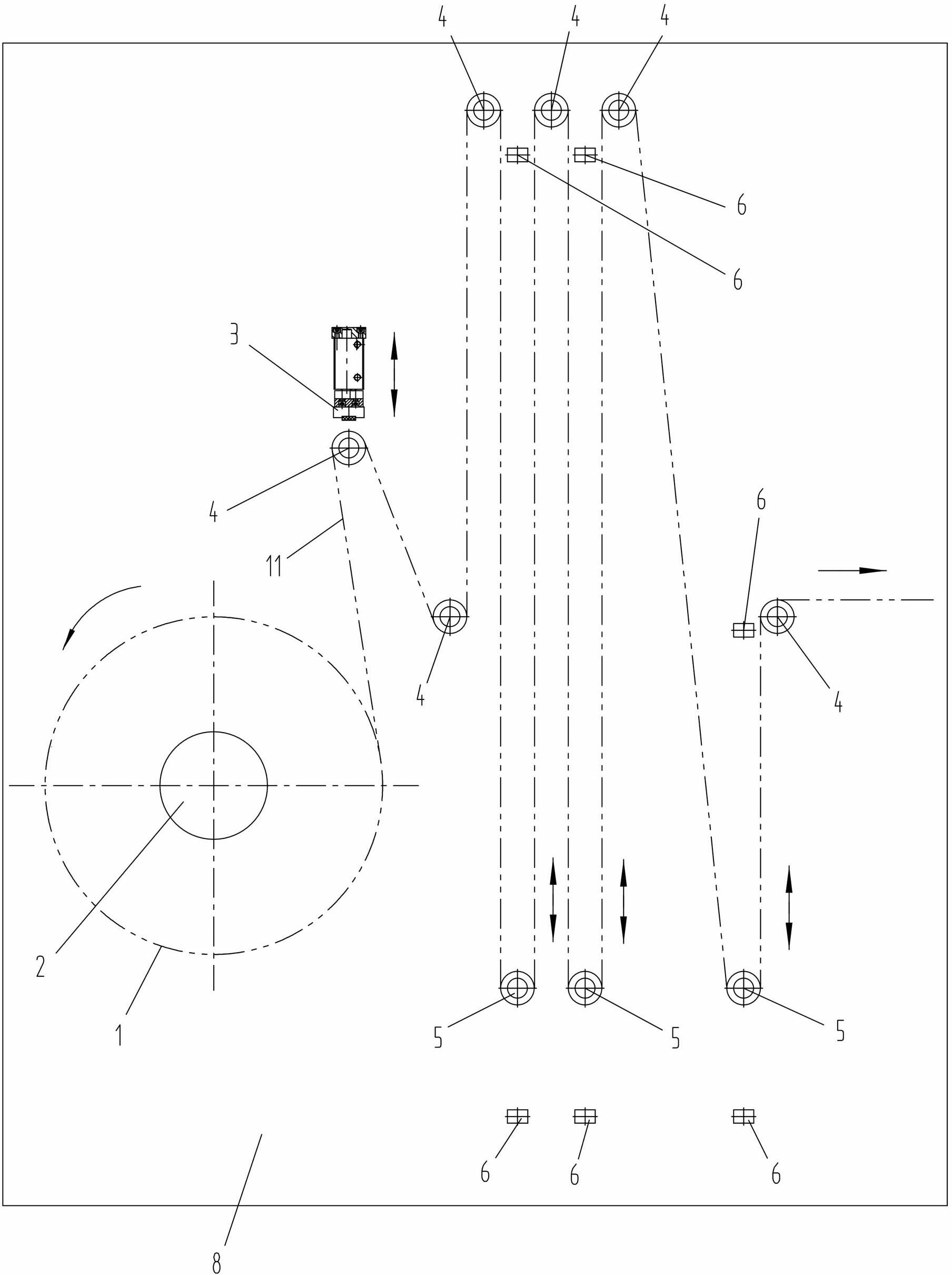

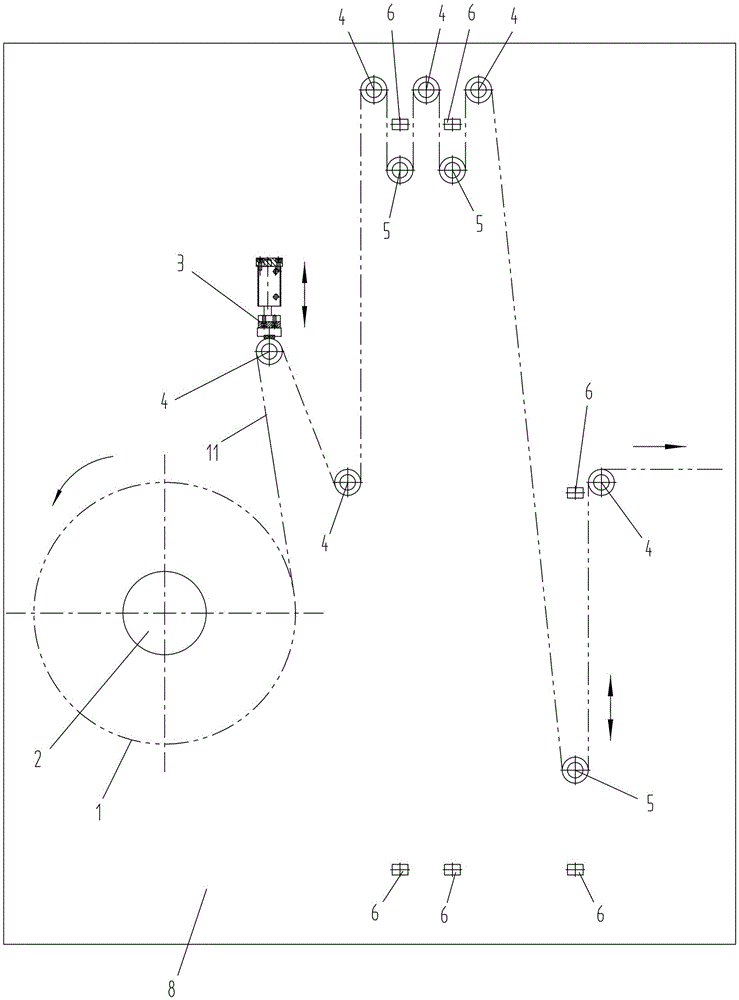

Multi-suspension-centres crane

ActiveCN101607676AImprove the forceEven by forceTravelling cranesWinding mechanismsWinding machineReduction drive

The invention discloses a multi-suspension-centres crane which comprises main beams, an operating mechanism, a lifting mechanism and an electric control system, wherein the operating mechanism comprises a bearing mechanism composed of an idle wheel device and an elastic body, and a drive mechanism composed of a motor, a reducer, a winding drum group, two groups of steel ropes, a pulley block and a pulley bracket, wherein the lifting mechanism comprises more than 2 sets of winding machines on each main beam, adopts a multilayer winding and symmetrical rope mode of duplex winding drums and steel ropes, and adopts a mode that a hook connecting piece is respectively hinged or fixedly connected with a corresponding hook group through a pin roll. The multi-suspension-centres crane has the characteristics of safety and reliability, strong practicability and the like through the self-set corresponding control method, is suitable to a crane with ultra-high lifting load, especially the multi-suspension-centres crane for lifting by sections on an offshore drilling platform.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

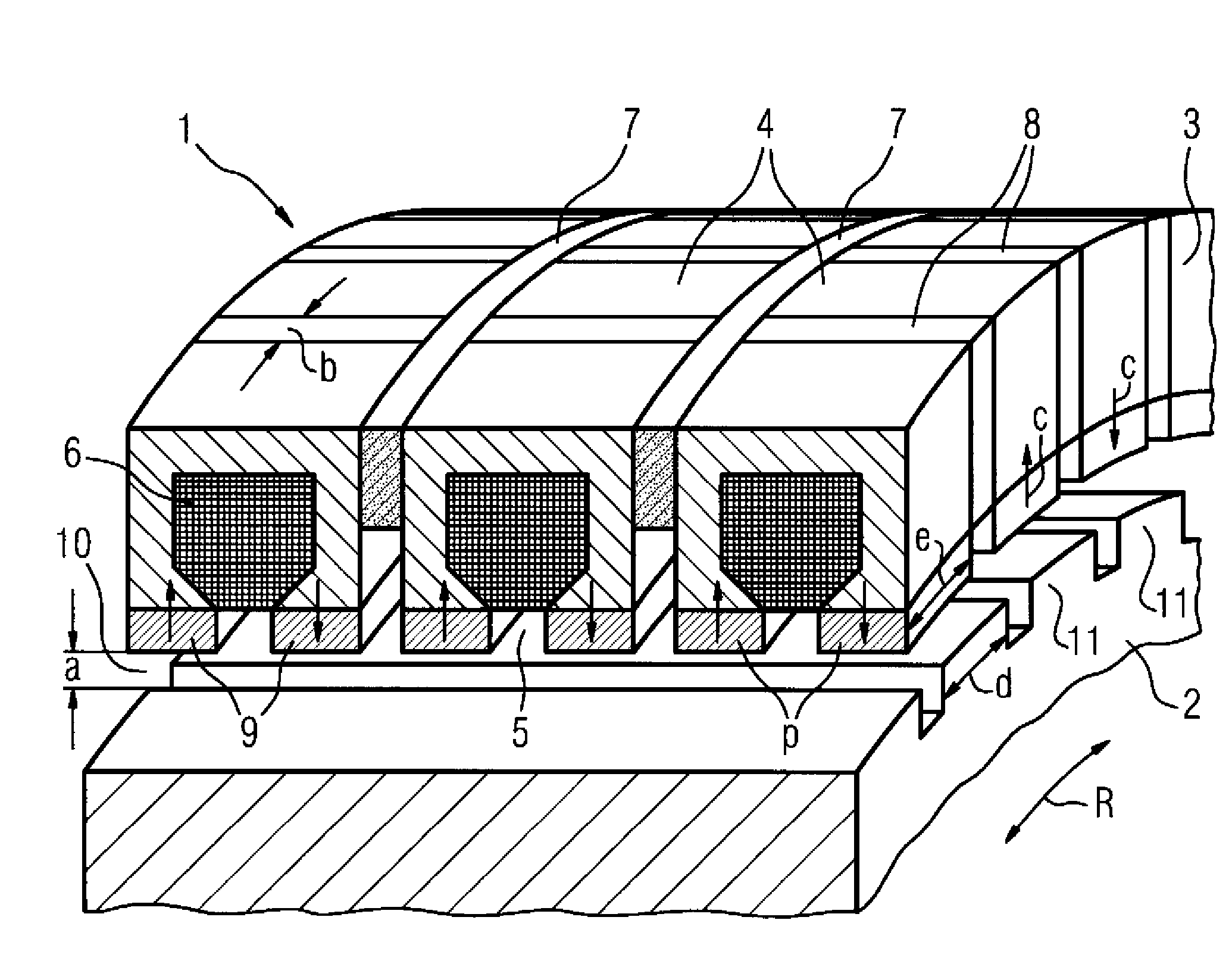

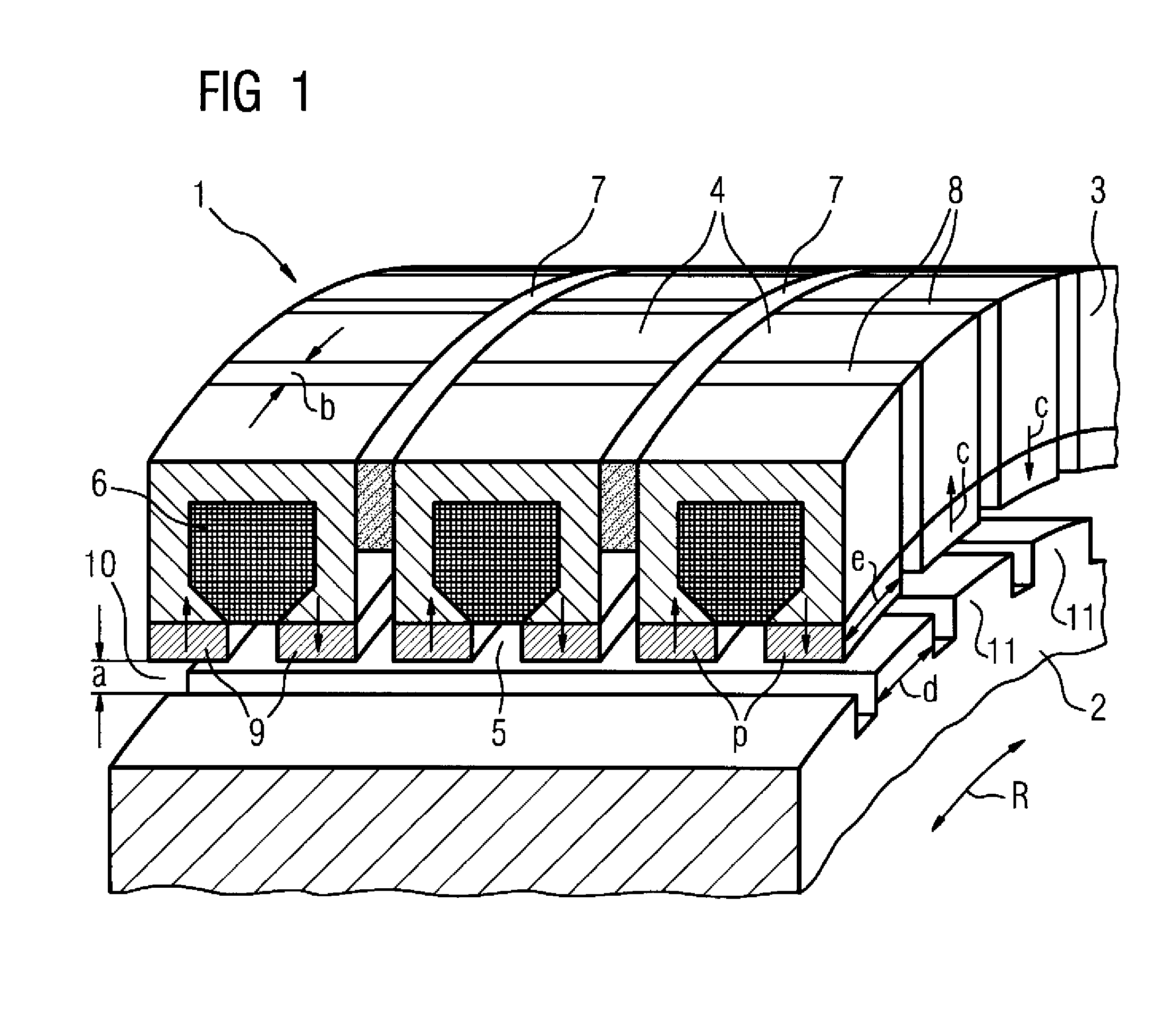

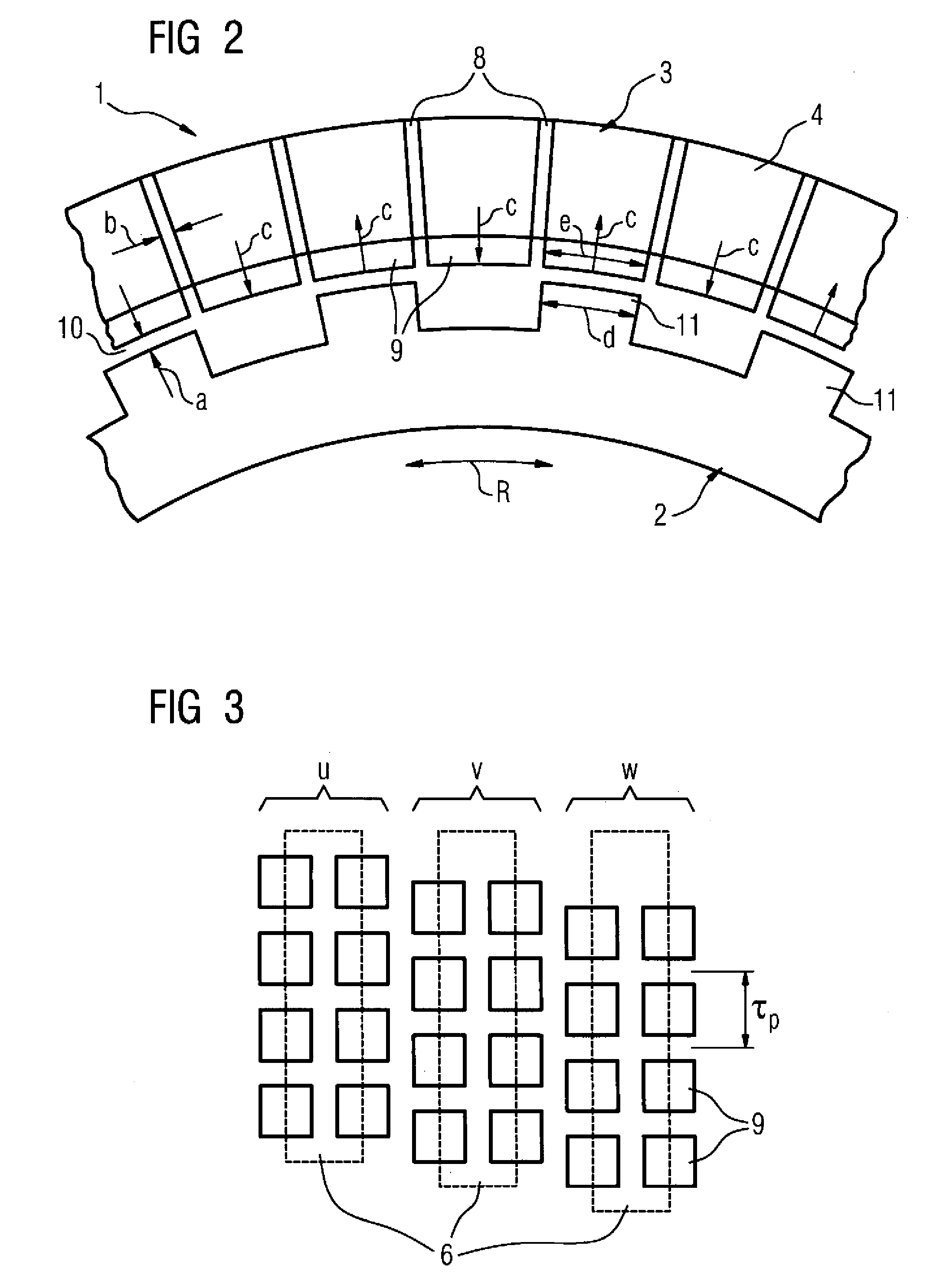

Ring coil motor

InactiveUS7915777B2Simple and cost-effective to manufactureHighly suitableSynchronous generatorsAsynchronous induction motorsElectric machineEngineering

Owner:SIEMENS AG

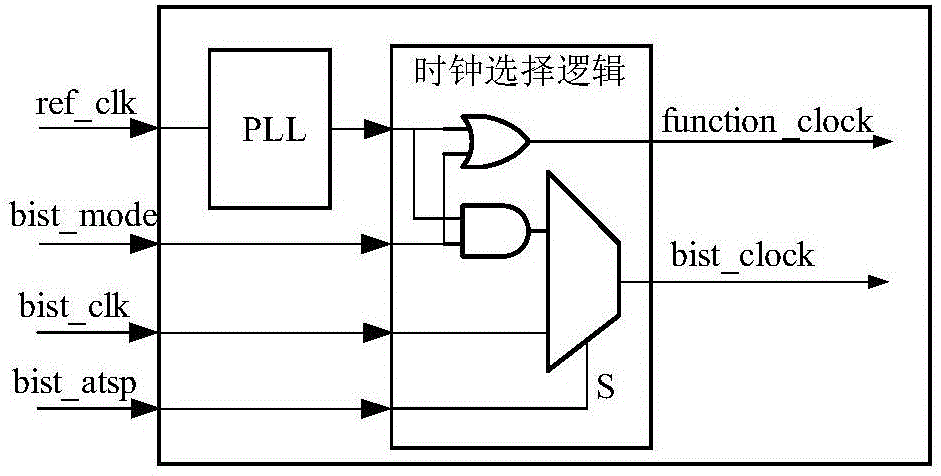

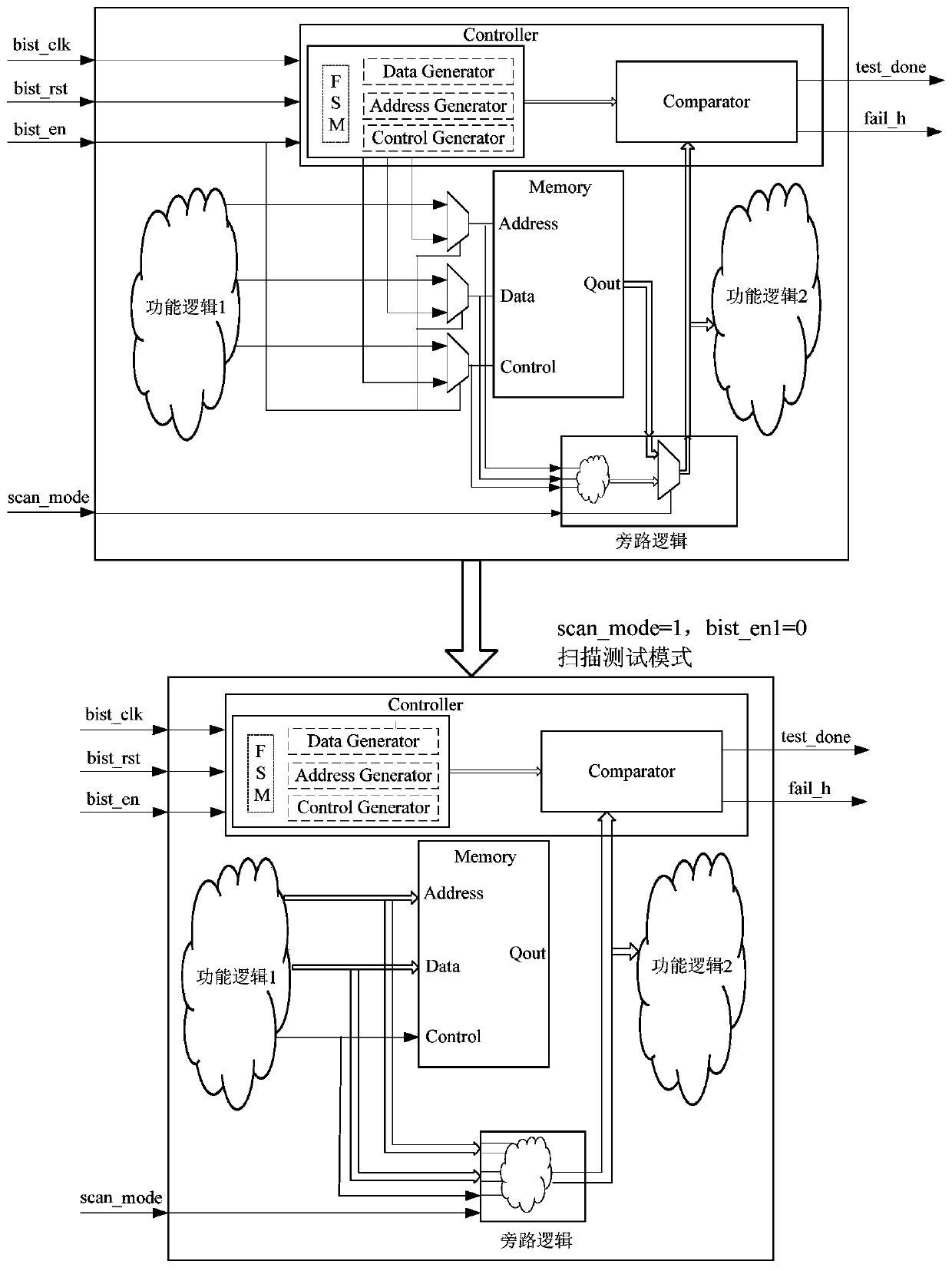

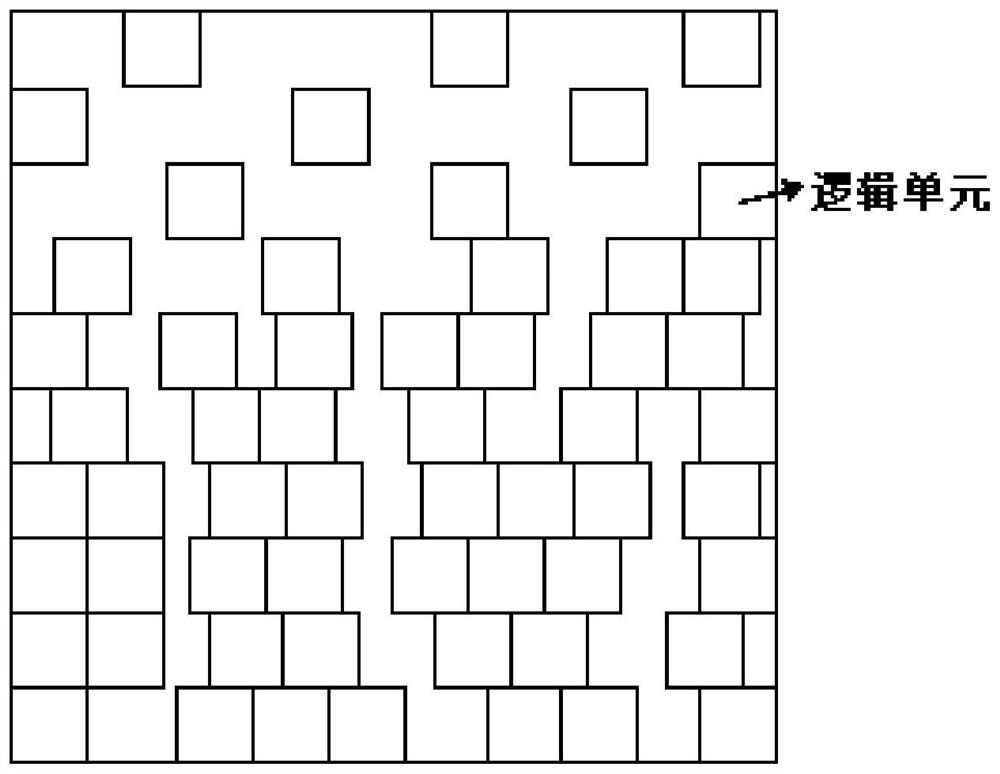

Built-in self-test designing method of multiple embedded memories on single chip

The invention discloses a built-in self-test designing method of multiple embedded memories on single chip. In the method, reasonable memory built-in self-test scheme and structure are determined according to the working frequency, size, port type, number and layout of memories on a chip; in design, multiple memory built-in self-test logics are inserted, a test way of multiple combinations of serial and parallel tests is realized, the test time, test cost, test power consumption and area increase of test logics of the memories are optimized, the test efficiency is improved, and the layout wiring and timing closure in layout design are facilitated; a clock selection logic circuit is added to realize high-speed test and low-speed test; and moreover, with additional bypass logic of the memory, the loss of test coverage in a digital logic scanning test caused by the memory shadow logic can be eliminated, and the test coverage is increased.

Owner:BEIJING MXTRONICS CORP +1

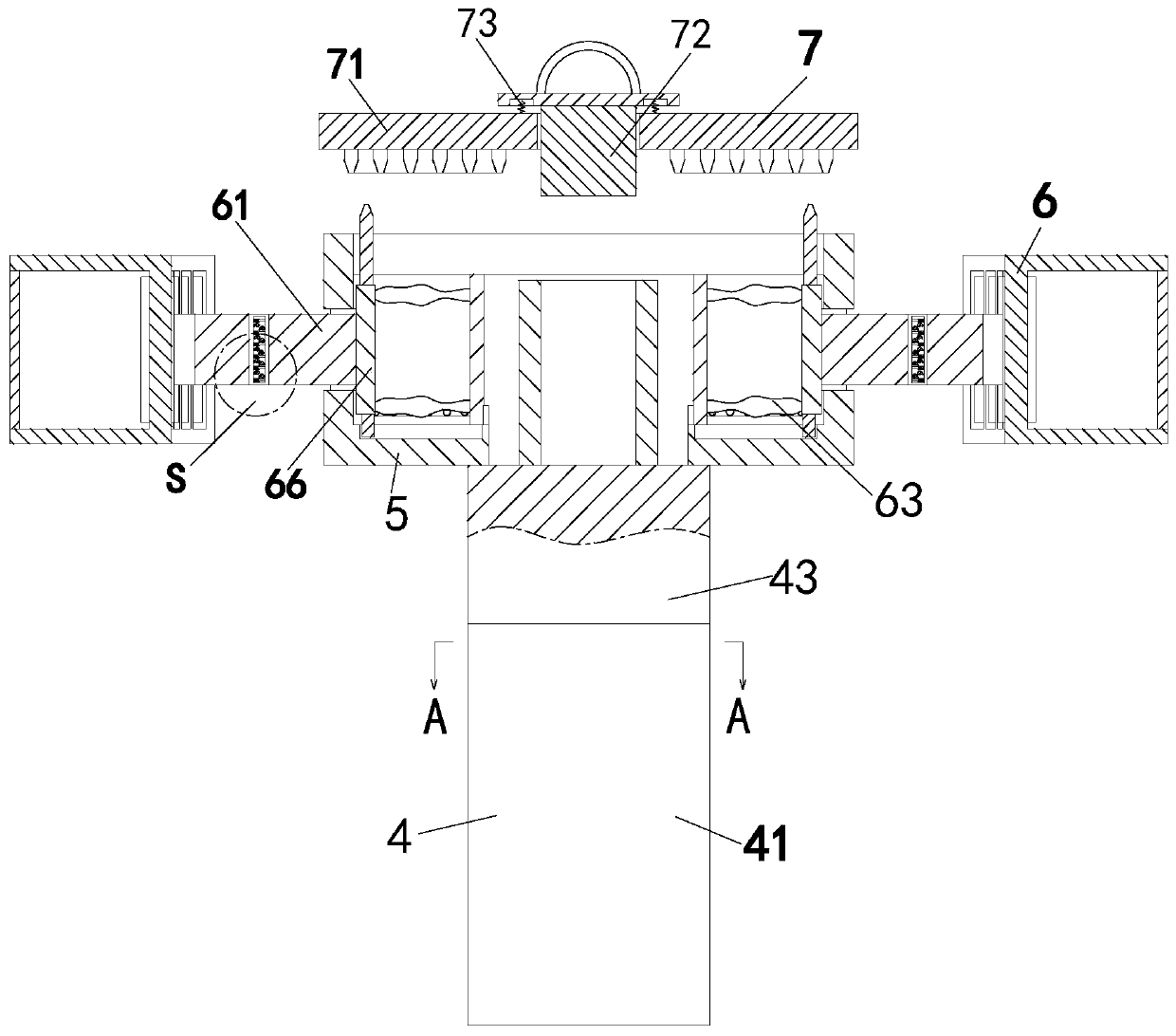

Direction changing type yarn textile working guide tensioning device and method

The invention relates to a direction changing type yarn textile working guide tensioning device and method. A bottom plate, direction changing pulley rods, an annular sliding groove, a connecting column, a connecting disc, anti-loosening devices and a rotating disc are included; the bottom plate is provided with the annular sliding groove, the annular sliding groove is connected with the directionchanging pulley rods in a sliding fit manner, the connecting column is installed in the middle portion of the bottom plate, the connecting column is located between the two direction changing pulleyrods, the upper end of the connecting column is provided with the connecting disc, the anti-loosening devices are evenly formed in the connecting disc in the circumferential direction, and the upper end of the connecting disc is provided with the rotating disc. According to the direction changing type yarn textile working guide tensioning device and method, yarns are synchronously supported to beopen through the anti-loosening devices, the winding length of the yarns is changed, and the yarns are wholly in the tightening state; and the conveying direction of the yarns is changed by position adjustment of the two direction changing pulley rods, friction generated when the yarns are subjected to direction-changing conveying, and the abrasion degree of the yarns is reduced.

Owner:福建石狮晨光化纤染织有限公司

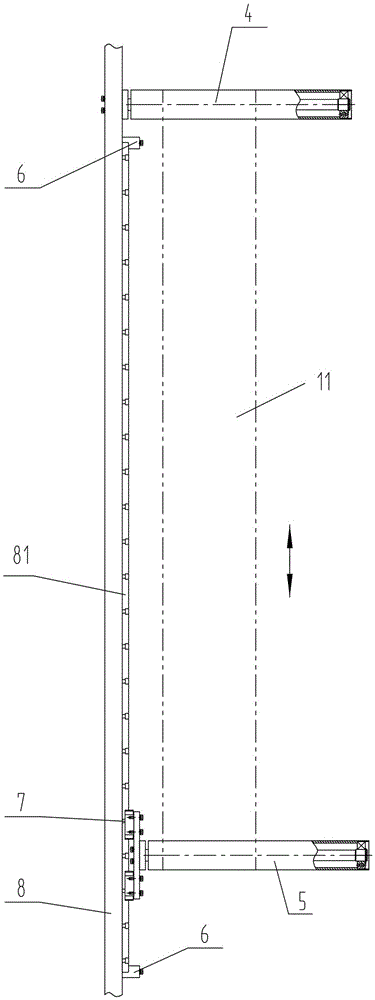

Hoisting mechanism of multi-lifting-point joint crane

The invention relates to a hoisting mechanism of a multi-lifting-point joint crane, adopting double wound roll, steel wire rope multi-layer wrapping and symmetrical rope dropping types, and adopting the type that lifting hook connecting pieces are respectively hinged or fixedly connected with corresponding lifting hook groups through pin rolls. The invention has novel structure, solves a series of problems that deflection angles of steel wire ropes of a super-heavy large-span crane is not easy to be ensured, horizontal wrapping distance of the steel wire rope is too long, the efficiency of the mechanism is tool low, self-locking is easily caused for the mechanism, lifting joints are not synchronous, construction difficulty is large, and the like, has the characteristics of security, reliability and strong practicability, can avoid fatal security risk, is suitable for the crane with 10000-ton super-large hoisting duty, and is especially suitable for the multi-lifting-point joint crane for lifting when a marine drilling platform form abutting joint with subsections.

Owner:DALIAN HUARUI HEAVY IND GROUP

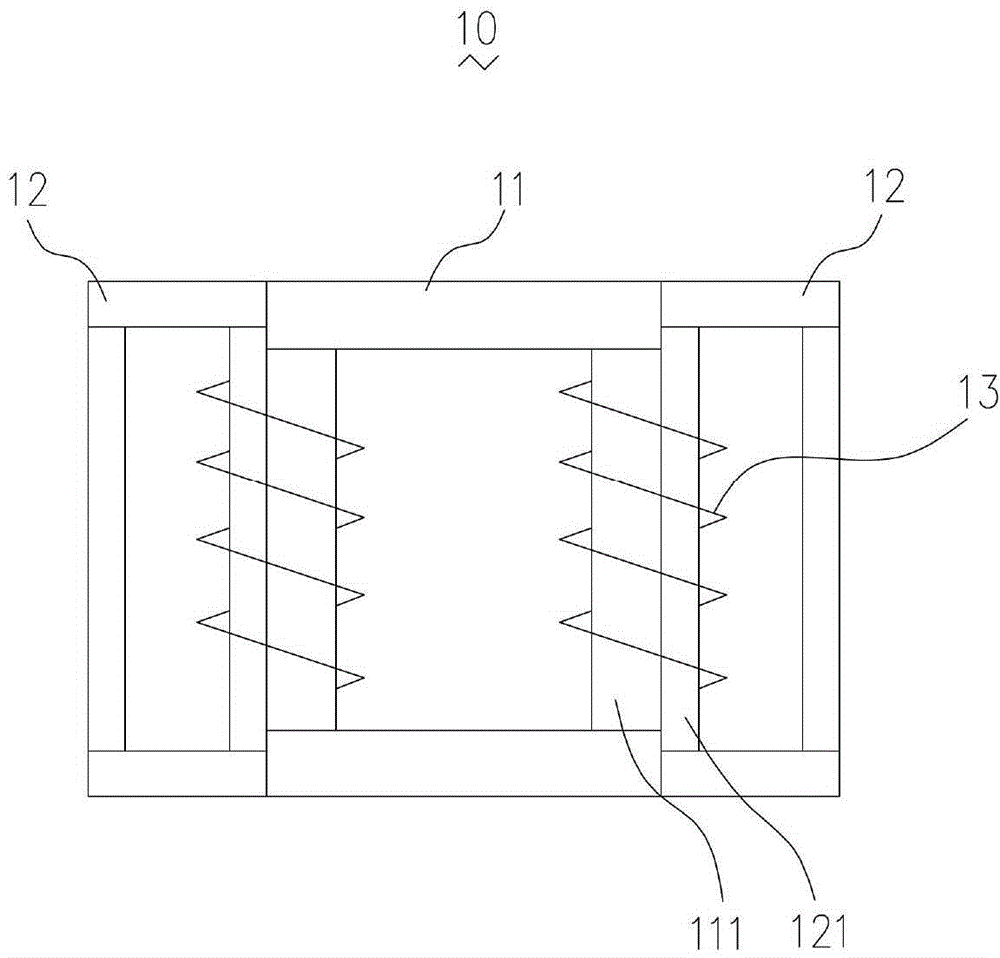

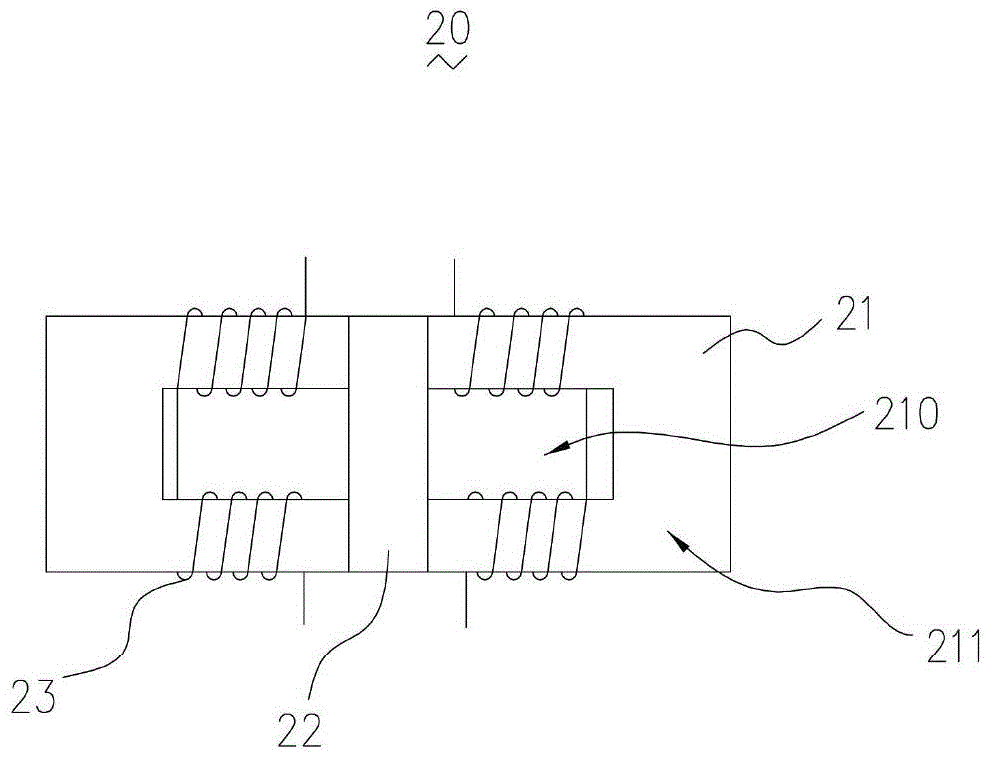

Coupling inductor

ActiveCN104064338AReduce winding lengthReduce lossTransformersTransformers/inductances coils/windings/connectionsEngineeringCoupling inductor

The invention provides a coupling inductor. The coupling inductor comprises a first magnetic core as well as a first coil group and a second coil group which are wound on the first magnetic core; the first magnetic core is a frame body magnetic core; a group of opposite edges of the frame body magnetic core comprises a first edge and a second edge; the first edge comprises a first part, a second part and a third part; the second edge also comprises three parts; the second part of the first edge is positioned between the first part and the third part; the distribution of the three parts of the second edge is consistent with that of the first edge; the first coil group is wound on the first part of the first edge and the first part of the second edge; the second coil group is wound on the third part of the first edge and the third part of the second edge; the coupling inductor also comprises a second magnetic core arranged between the first coil group and the second coil group; an air gap is formed between the second magnetic core and the second part of the first edge or the second part of the second edge.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Membrane material transporting device for soft bag transfusion production line

ActiveCN102633146AReduce winding lengthIncrease usageWrapping material feeding apparatusWebs handlingProduction lineEngineering

The invention discloses a membrane material transporting device for a soft bag transfusion production line, comprising a rotary membrane transporting mechanism and a rotary drum transporting mechanism, wherein the rotary drum transporting mechanism comprises more than two fixed rotary drums for winding a membrane material and more than one mobile rotary drum which can move relatively to the fixed rotary drums; the mobile rotary drum is arranged between the two adjacent fixed rotary drums along the winding direction of the membrane material; and a pressing mechanism for stopping forwards moving the membrane material is arranged in front of the mobile rotary drum which is the closest to the rotary membrane transporting mechanism. The membrane material transporting device for the soft bag transfusion production line can realize the purpose that a membrane can be exchanged without stopping, the production efficiency is improved, and the utilization rate of the membrane material is improved.

Owner:TRUKING TECH LTD

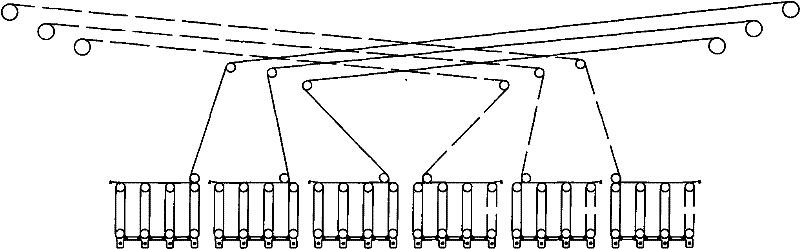

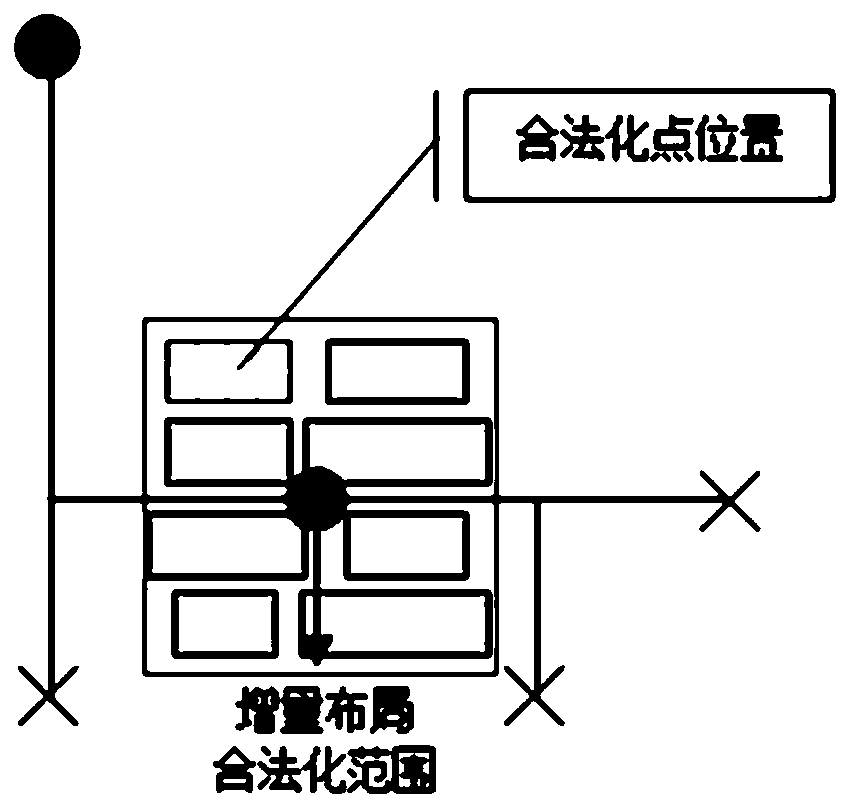

Big wire mesh splitting method for maintaining original physical routing topologies

ActiveCN107633129AReduce winding lengthEnsure consistencySpecial data processing applicationsComputer scienceWire mesh

The invention discloses a big wire mesh splitting method for maintaining original physical routing topologies. The method comprises the following steps of: converting a big wire mesh into a tree topological structure and finding a strategy point position; finding an incremental layout legalization point position of the strategy point position; finding an optimum cutting point position of originalphysical routing; and inserting a buffer unit at the incremental layout legalization point position and physically connecting the buffer unit with the optimum cutting point position. According to thebig wire mesh splitting method for maintaining original physical routing topologies, the buffer unit is inserted at the incremental layout legalization point position to split the big wire mesh into aplurality of sub-wire meshes satisfying requirements, and the newly inserted buffer unit is connected at the optimum cutting point to sufficiently reusing the original connection topology and physical routing of the wire mesh, so that the wire wrapping length can be decreased to the greatest extent and then the consistency of time delay estimation and physical realization of an optimization scheme is ensured.

Owner:北京华大九天科技股份有限公司

Design method for optimizing fishbone type clock tree metal wiring

ActiveCN111259614ASmall clock skewQuality improvementComputer aided designSpecial data processing applicationsLogic cellTree trunk

The invention discloses a design method for optimizing fishbone type clock tree metal wiring. The method comprises the following steps of: 1) before logic units in a chip are placed, dividing an integral module into squares with the side length of 30 microns, and specifying the placing density of the logic units in each square so that the logic units are uniformly distributed; 2) taking out the vertical coordinates of the adjacent fishbone branches, calculating the distance between the adjacent fishbone branches, recording the distance as a, and creating a transverse routing blockage at the central point of each adjacent branch; 3) taking the fishbone tree trunk as a starting point, taking a as an interval, and respectively creating longitudinal routing blockages leftwards and rightwards;and 4) capturing the line name of the fishbone type clock tree connected with the load of the fishbone type clock tree, preferentially performing metal routing on the connecting lines, deleting metalrouting blockages after routing is completed, and then performing global wiring. The method saves interconnection line resources, optimizes the clock structure and improves the clock quality.

Owner:PEKING UNIV

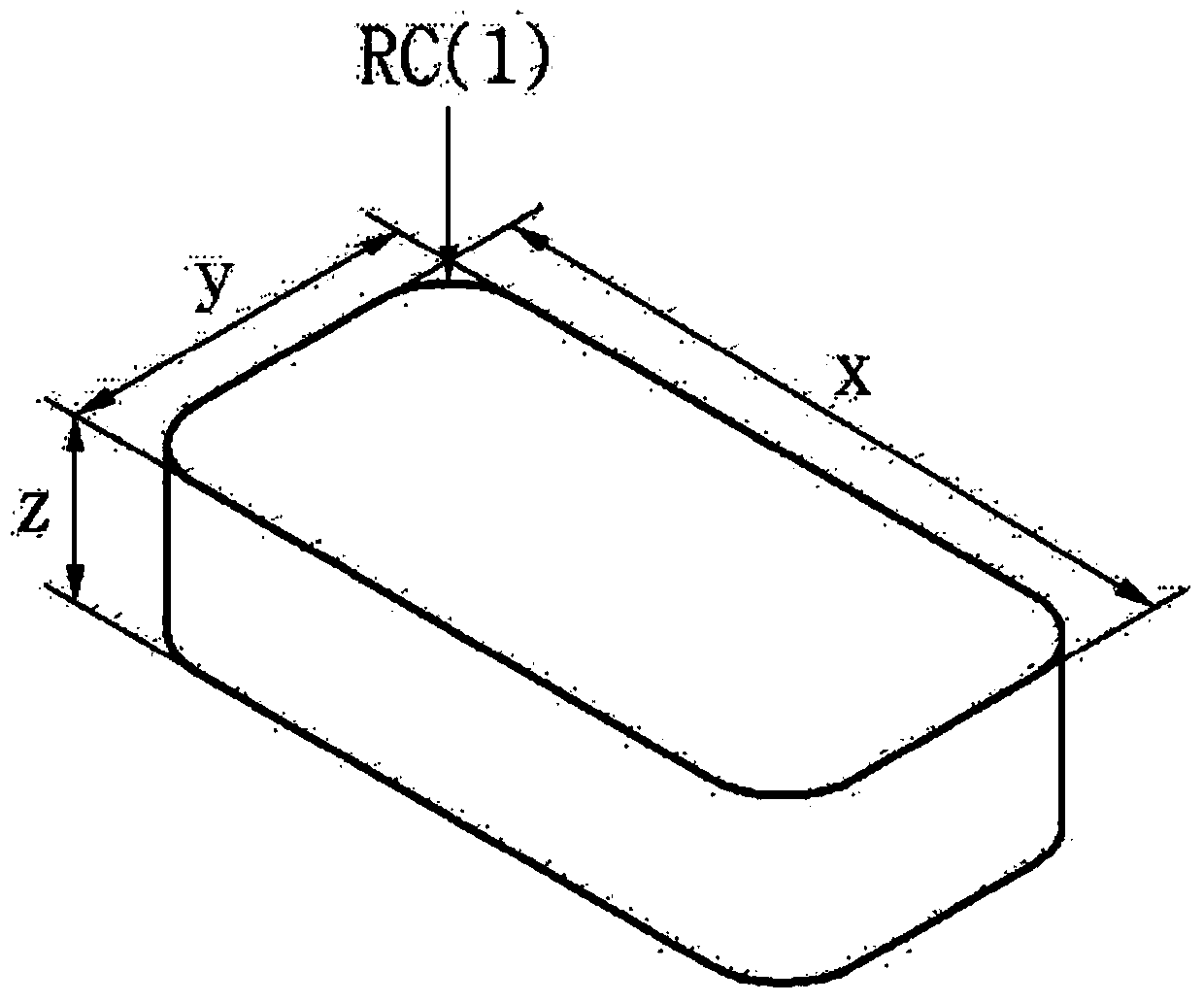

Elliptical Unit Block for Preparing Core Using Soft Magnetic Metal Powder and Magnetic Powder Core Prepared Using The Same

InactiveUS20140218144A1Reduce winding lengthImprove efficiencyPermanent magnetsInorganic material magnetismElectronMaterials science

The present invention relates to an elliptical unit block for preparing a core using soft magnetic metal powder and a core with excellent high current DC bias characteristics using the same, and more specifically, to an elliptical unit block for preparing a core using soft magnetic metal powder used in an inductor for an automotive electronic sub-assembly using a high current buck or boost inductor or a three phase line reactor or fuel cell system for power factor correction (PFC), and a powered magnetic core prepared using the same.

Owner:CHANG SUNG CO LTD

Elliptical unit block for preparing core using soft magnetic metal powder, and powdered magnetic core prepared using same

InactiveCN103797550AReduce winding lengthImprove efficiencyPermanent magnetsInorganic material magnetismPower flowFuel cells

Owner:CHANG SUNG CO LTD

Multi-suspension-centres crane

ActiveCN101607676BImprove the forceEven by forceTravelling cranesWinding mechanismsWinding machineBlock and tackle

The invention discloses a multi-suspension-centres crane which comprises main beams, an operating mechanism, a lifting mechanism and an electric control system, wherein the operating mechanism comprises a bearing mechanism composed of an idle wheel device and an elastic body, and a drive mechanism composed of a motor, a reducer, a winding drum group, two groups of steel ropes, a pulley block and a pulley bracket, wherein the lifting mechanism comprises more than 2 sets of winding machines on each main beam, adopts a multilayer winding and symmetrical rope mode of duplex winding drums and steel ropes, and adopts a mode that a hook connecting piece is respectively hinged or fixedly connected with a corresponding hook group through a pin roll. The multi-suspension-centres crane has the characteristics of safety and reliability, strong practicability and the like through the self-set corresponding control method, is suitable to a crane with ultra-high lifting load, especially the multi-suspension-centres crane for lifting by sections on an offshore drilling platform.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

A built-in self-test design method for multiple embedded memories on a single chip

Owner:BEIJING MXTRONICS CORP +1

Cable reels and construction machinery

InactiveCN104022483BReduce volumeLow costArrangements using take-up reel/drumLoad-engaging elementsEngineeringElectrical and Electronics engineering

The invention discloses a cable reel and a piece of engineering machinery. The cable reel comprises a reel housing, and a scroll spring and a planet deceleration mechanism which are arranged in the reel housing. The input end of the planet deceleration mechanism is connected with the reel housing, and the output end of the planet deceleration mechanism is connected with the free end of the scroll spring. The cable reel can reduce the number of scroll springs while ensuring the reeling length of a cable. Compared to the scroll spring, the planet deceleration mechanism is quite light in weight, quite small in size and quite low in cost. Therefore, the whole cable reel correspondingly has the advantages of low cost, light weight and small size.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

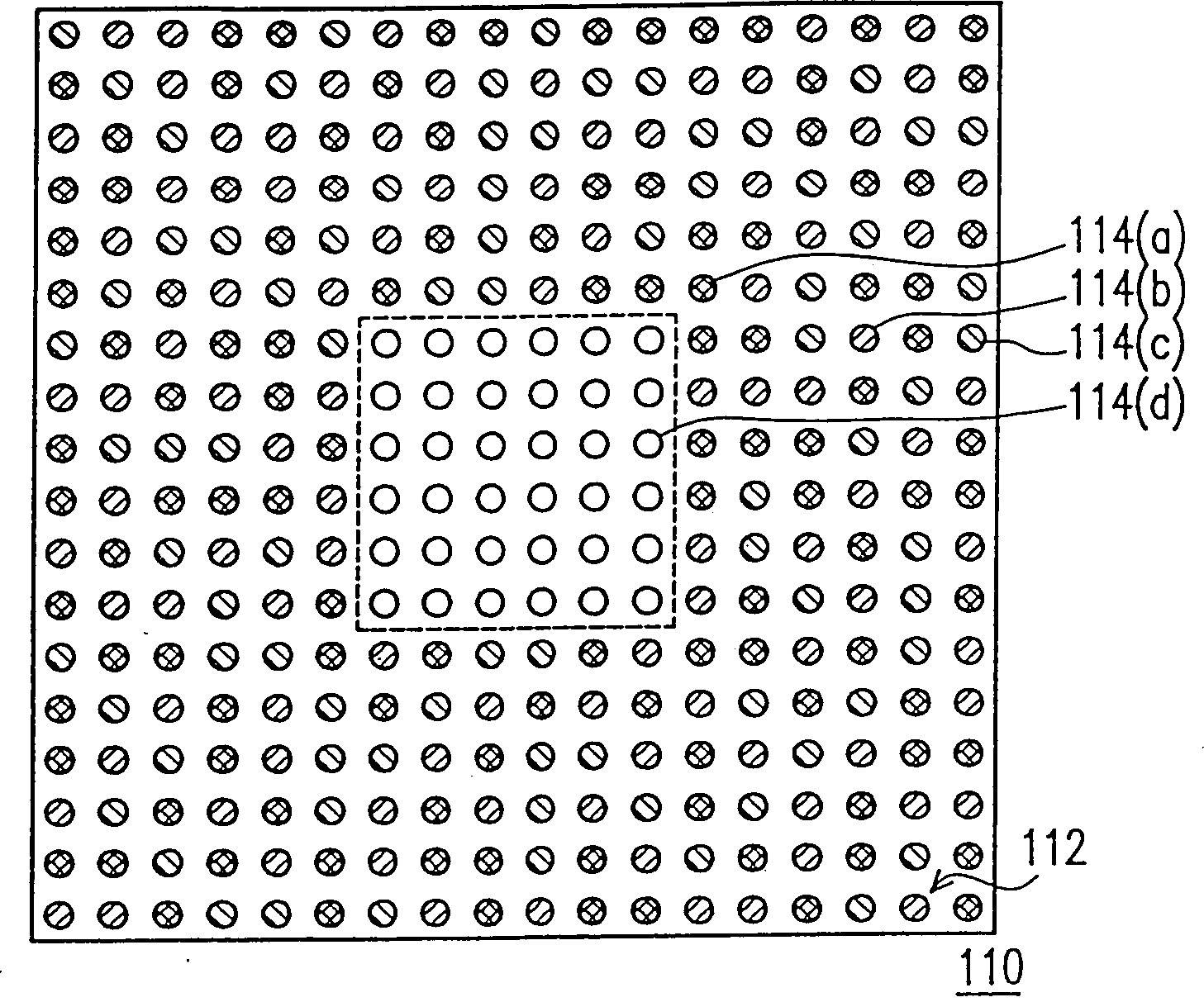

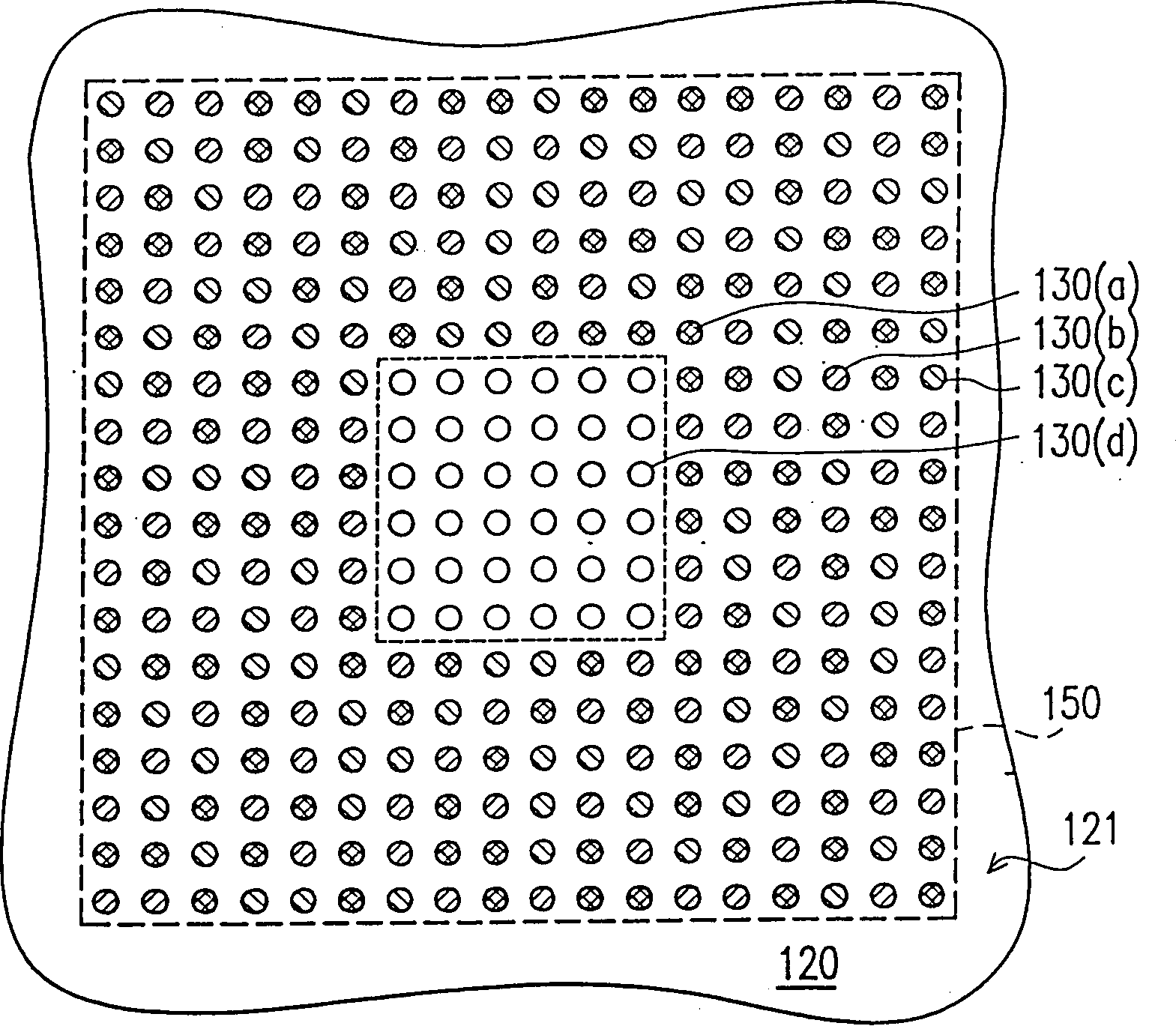

Crystal covered chip and crystal covered package substrate

InactiveCN1178295CImprove electrical performanceEasy wiringSemiconductor/solid-state device detailsSolid-state devicesActive surfaceSignal trace

A crystal covered chip consists of several core powder sources and earthing weld pads, at least one signal weld pad ring, at least one power source weld pad ring and at least one earthing weld pad ring, all of which are configurated on the active surface of the crystal covered chip and the said weld pad rings are distributed in concentric ring like around the periphery of these earthing weld pads for core powder sources by using these core power sources / earthing weld pads as a centre. In addition, a crystal covered packaging substrate has several lug pads at the most top layer of wire layers, which has the positions corresponding to the positions of weld pads for the crystal covered chip seperately. A lug pad ring of nonsignal can be configurated at the periphery of lug pad ring and a pair of power source trace or earthing trace as the protective trace for signal trace can be configurated at both sides of a signal trace separately on an any wire layer in the crystal covered packaging substrate.

Owner:VIA TECH INC

Coupled inductor

ActiveCN104064338BReduce winding lengthReduce lossTransformersTransformers/inductances coils/windings/connectionsCoupling inductorInductance

The present invention provides a coupled inductor, the coupled inductor includes a first magnetic core and a first group of coils and a second group of coils wound on the first magnetic core, the first magnetic core is a frame magnetic core, A set of opposite sides of the frame magnetic core includes a first side and a second side, the first side includes a first part, a second part and a third part, the second side also includes three parts, the first side The second part of the side is located between the first part and the third part, the distribution of the three parts of the second side is consistent with the first side, and the first group of coils surrounds the first part of the first side and the second side The first part of the side is wound, the second group of coils is wound around the third part of the first side and the third part of the second side, the coupled inductor also includes a second magnetic core, so The second magnetic core is arranged between the two groups of coils, and an air gap is formed between the second magnetic core and the second part of the first side or the second part of the second side.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Refrigerator supporting piece with stacking function

InactiveCN113108541AEasy slide connectionImprove cleanlinessDomestic cooling apparatusLighting and heating apparatusIceboxStructural engineering

The invention relates to the technical field of refrigerator supporting pieces, in particular to a refrigerator supporting piece with a stacking function. The refrigerator supporting piece comprises a supporting structure, a first fixing structure, a moving structure, a driving structure, a second fixing structure, a limiting structure and a winding structure, the second fixing structure is detachably connected with the moving structure and sliding of the moving structure is facilitated; after the moving structure and the supporting structure are mostly staggered, the second fixing structure and the moving structure are driven by the driving structure to slide, the height and the position of a refrigerator on the second fixing structure are reduced, and then articles in the refrigerator on the second fixing structure can be conveniently taken; and furthermore, two refrigerators can be conveniently stacked when the articles are not taken, so that the space utilization efficiency is greatly improved; and the winding structure used for winding an electric wire is arranged in the supporting structure, the arrangement of the winding structure facilitates winding of the electric wire, winding of the electric wire is more convenient, and the electric wire is effectively prevented from being knotted.

Owner:杭州沫兮日用百货有限公司

Touch display driving circuit, computing circuit, display device and operating method thereof

ActiveCN110147167BSmall footprintImprove area utilizationInput/output processes for data processingComputer hardwareSensing data

Owner:HIMAX TECH LTD

An Exhaust Gas Turbine Driven Electrically Excited Generator

ActiveCN105896820BStable outputNo cogging torqueMagnetic circuit rotating partsInternal combustion piston enginesExhaust gasStator poles

An exhaust gas turbine-driven electric excitation generator of the present invention is composed of a shaft, an exhaust gas turbine, an exhaust gas turbine shell, two sets of excitation windings, two stator cores, two sets of armature windings, a rotor core and a motor shell. An exhaust gas turbine and a rotor core are respectively fixed on the shaft, and there are rotor poles protruding axially on the two end faces of the rotor core. The stator core is fixed on the inner wall of the casing; the end face of the stator core facing the rotor core has axially protruding stator poles. The armature windings are wound around the stator poles. The excitation winding is wound around the radial direction of the stator core and embedded in the magnetic isolation groove of the stator core. The technical rotor of the present invention is manufactured in one piece and has no excitation winding, which can adapt to the high temperature and high speed working environment of the exhaust gas turbine; it adopts electrified coil excitation, has no positioning torque, and can accelerate rapidly; both ends of the rotor have armatures Winding, the motor has high specific power.

Owner:SHANDONG UNIV OF TECH

Connection conversion device for computer mainboard interface

InactiveCN112688133AReduce winding lengthIncrease winding lengthFlexible lead accommodationMechanical engineeringBackplane

The invention discloses a connection conversion device for a computer mainboard interface which comprises a connector, a buckle, a wire, an adapter and a telescopic mechanism. The telescopic mechanism is arranged at the upper end of the wire, the wire is wound at the upper end of a roller in an S-shaped distribution manner, and then the wire can be borne through a bottom plate; a connecting wire can be prevented from being rubbed with the ground and being bent by external force to be damaged; a rotating mechanism and a rotating knob are arranged at the upper end of the telescopic mechanism, the knob drives a worm wheel to rotate clockwise through a worm, so that a first connecting plate and a second connecting plate are driven to move in opposite directions, the wire winding length is shortened, similarly, the worm wheel rotates anticlockwise, and the winding length can be increased; and the advantage of quickly adjusting the length of the wire is achieved.

Owner:WUHAN DONGHU UNIV

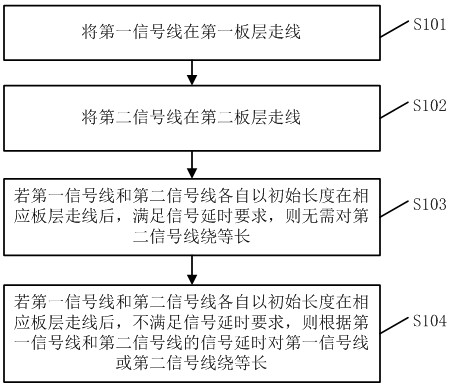

PCB wiring method for compensating signal delay, PCB and electronic equipment

PendingCN114282489AReduce winding lengthSmall footprintCAD circuit designSpecial data processing applicationsSignal linesWire wrap

The invention relates to the field of PCB wiring, and particularly discloses a PCB wiring method for compensating signal delay, a PCB and electronic equipment, and the method comprises the steps: enabling a first signal line to be wired on a first board layer; routing a second signal line on a second board layer; if the first signal line and the second signal line meet the signal delay requirement after being wired on the corresponding board layer at the initial length, the second signal line does not need to be wound at the same length; if the signal delay requirement is not met after the first signal line and the second signal line are wired on the corresponding board layers with the initial lengths respectively, the first signal line or the second signal line is wound to be equal in length according to the signal delay of the first signal line and the second signal line. According to the invention, the signal lines in the same group are wired in different board layers, the signal delay is compensated by utilizing different unit length delays of different board layers, the winding length is shortened or winding is not needed, the occupied space is saved, and the time sequence requirement of signals is met.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Hoisting mechanism of multi-lifting-point joint crane

InactiveCN101613057BReduce winding lengthShorten the installation cycleTrolleysSelf lockingEngineering

The invention relates to a hoisting mechanism of a multi-lifting-point joint crane, adopting double wound roll, steel wire rope multi-layer wrapping and symmetrical rope dropping types, and adopting the type that lifting hook connecting pieces are respectively hinged or fixedly connected with corresponding lifting hook groups through pin rolls. The invention has novel structure, solves a series of problems that deflection angles of steel wire ropes of a super-heavy large-span crane is not easy to be ensured, horizontal wrapping distance of the steel wire rope is too long, the efficiency of the mechanism is tool low, self-locking is easily caused for the mechanism, lifting joints are not synchronous, construction difficulty is large, and the like, has the characteristics of security, reliability and strong practicability, can avoid fatal security risk, is suitable for the crane with 10000-ton super-large hoisting duty, and is especially suitable for the multi-lifting-point joint crane for lifting when a marine drilling platform form abutting joint with subsections.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

A reversible yarn textile operation guide tensioning device and method

Owner:福建石狮晨光化纤染织有限公司

Design Method for Optimizing the Metal Routing of Fishbone Clock Tree

ActiveCN111259614BSmall clock skewQuality improvementComputer aided designSpecial data processing applicationsLogic cellParallel computing

Owner:PEKING UNIV

A method of splitting large wire nets while maintaining the original physical wiring topology

ActiveCN107633129BReduce winding lengthEnsure consistencyComputer aided designSpecial data processing applicationsEngineeringWire wrap

The invention discloses a big wire mesh splitting method for maintaining original physical routing topologies. The method comprises the following steps of: converting a big wire mesh into a tree topological structure and finding a strategy point position; finding an incremental layout legalization point position of the strategy point position; finding an optimum cutting point position of originalphysical routing; and inserting a buffer unit at the incremental layout legalization point position and physically connecting the buffer unit with the optimum cutting point position. According to thebig wire mesh splitting method for maintaining original physical routing topologies, the buffer unit is inserted at the incremental layout legalization point position to split the big wire mesh into aplurality of sub-wire meshes satisfying requirements, and the newly inserted buffer unit is connected at the optimum cutting point to sufficiently reusing the original connection topology and physical routing of the wire mesh, so that the wire wrapping length can be decreased to the greatest extent and then the consistency of time delay estimation and physical realization of an optimization scheme is ensured.

Owner:北京华大九天科技股份有限公司

Membrane conveying device for soft bag infusion production line

ActiveCN102633146BReduce winding lengthIncrease usageWrapping material feeding apparatusWebs handlingProduction lineMembrane configuration

The invention discloses a film material conveying device used in a soft bag transfusion production line, which includes a rotating film conveying mechanism and a roller conveying mechanism, the roller conveying mechanism includes more than two fixed rollers and more than one movable roller for winding the film material The moving roller that moves relative to the fixed roller is arranged between two adjacent fixed rollers along the winding direction of the film material, and there is a pressure plate that can stop the film material from advancing before the moving roller that is closest to the rotating film feeding mechanism. tight body. The invention can realize membrane replacement without stopping the machine, and improve production efficiency and membrane material utilization rate.

Owner:TRUKING TECH LTD

A heat dissipation device and method for an M.2 solid state disk of a server

InactiveCN109445553AAffect the air volumeIncrease air volumeDigital data processing detailsEnergy efficient computingSolid-state driveTurbofan

The invention discloses a heat dissipation device and method for an M.2 solid state disk of a server. An independent heat dissipation device is arranged on one side of an M.2 solid-state hard disk; the system independently controls the heat dissipation device according to the temperature of the M.2 solid state disk; an air outlet of the heat dissipation device faces the M.2 solid state disk, and an air inlet of the heat dissipation device faces the main board. The heat dissipation device comprises a fan shell, a vortex fan is arranged in the fan shell; an air outlet is formed in the side faceof the fan shell, a shell air inlet is formed in the bottom of the shell, a base air inlet matched with the shell air inlet is formed in the shell base, and the shell base is installed on the side, close to the M.2 solid state disk, of the main board. According to the present invention, the bottom air inlet and the side face air outlet mode are adopted, so that the height space occupied by the heat dissipation device is reduced, the turbofan under the same power can provide larger air outlet speed and larger air outlet amount, the system power consumption is reduced, the noise is reduced, andmeanwhile the heat dissipation effect is greatly improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com