Multi-suspension-centres crane

A crane and multi-hoisting point technology, applied in the direction of cranes, walking bridge cranes, clockwork mechanisms, etc., can solve the problem that the lifting points of a single group of hoisting mechanisms cannot be lifted synchronously, and the electric drive type and hoisting mechanism cannot be used. Problems such as low transmission efficiency, to achieve the effect of simple structure, improved synchronization performance, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

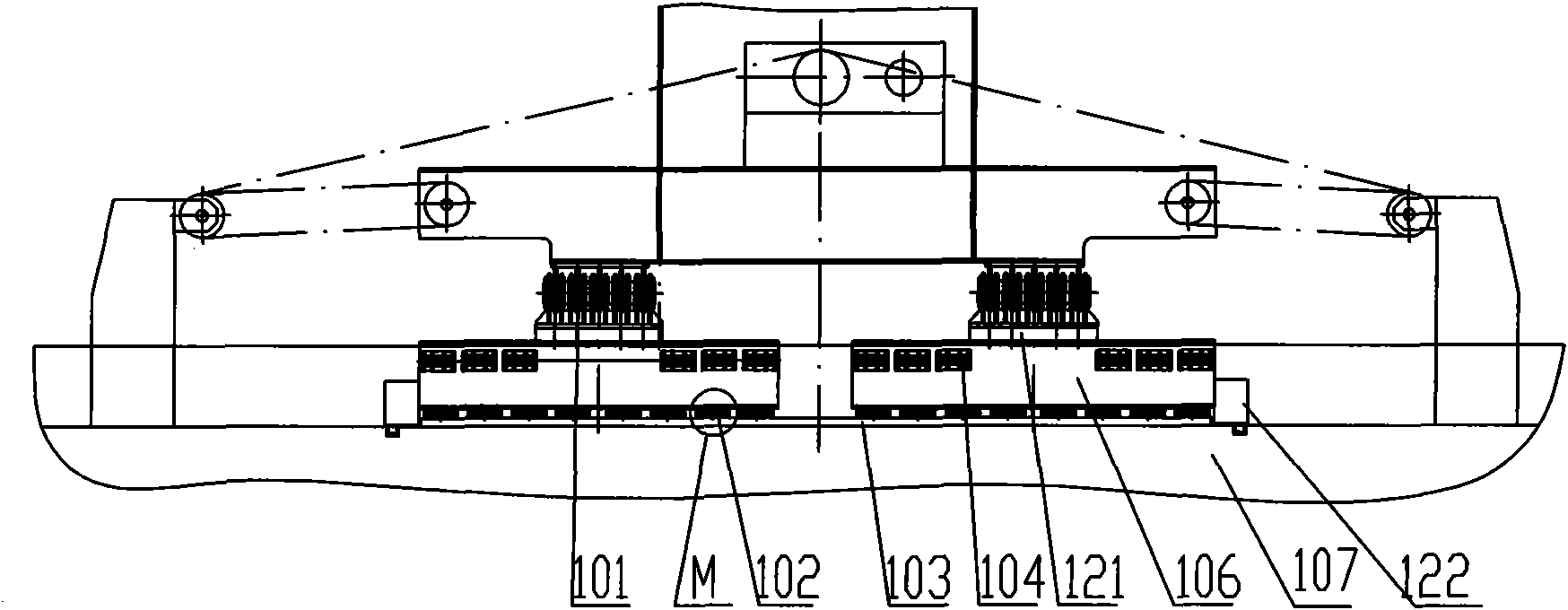

[0071] Such as figure 1 As shown, a multi-lift crane includes a main girder 3, an operating mechanism 1, a hoisting mechanism 2, and an electric control system 4, wherein the electric control system includes a lifting control system 401 composed of a frequency converter, a communication module, and an electric motor. An operation control system 402, a controller 403, a load sensor 404, a position sensor 405, and a host computer 406 composed of frequency converters, communication modules, and motors;

[0072] The controller is responsible for communicating with the upper computer, receiving control instructions, returning status information, and simultaneously controlling the operation of each hoisting mechanism and operating mechanism, and receiving feedback signals from sensors;

[0073] The load sensor and the position sensor transmit the carrying weight and lifting height of each lifting mechanism, the traction force of the operating mechanism and the stroke position to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com