Membrane material transporting device for soft bag transfusion production line

A soft bag infusion and conveying device technology, applied in the directions of packaging material feeding device, transportation packaging, transportation and packaging, etc., can solve the problems of reducing the utilization rate of film materials, increasing the risk of infusion product quality, waste bags, etc., to ensure normal The effect of running, improving production efficiency and film utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

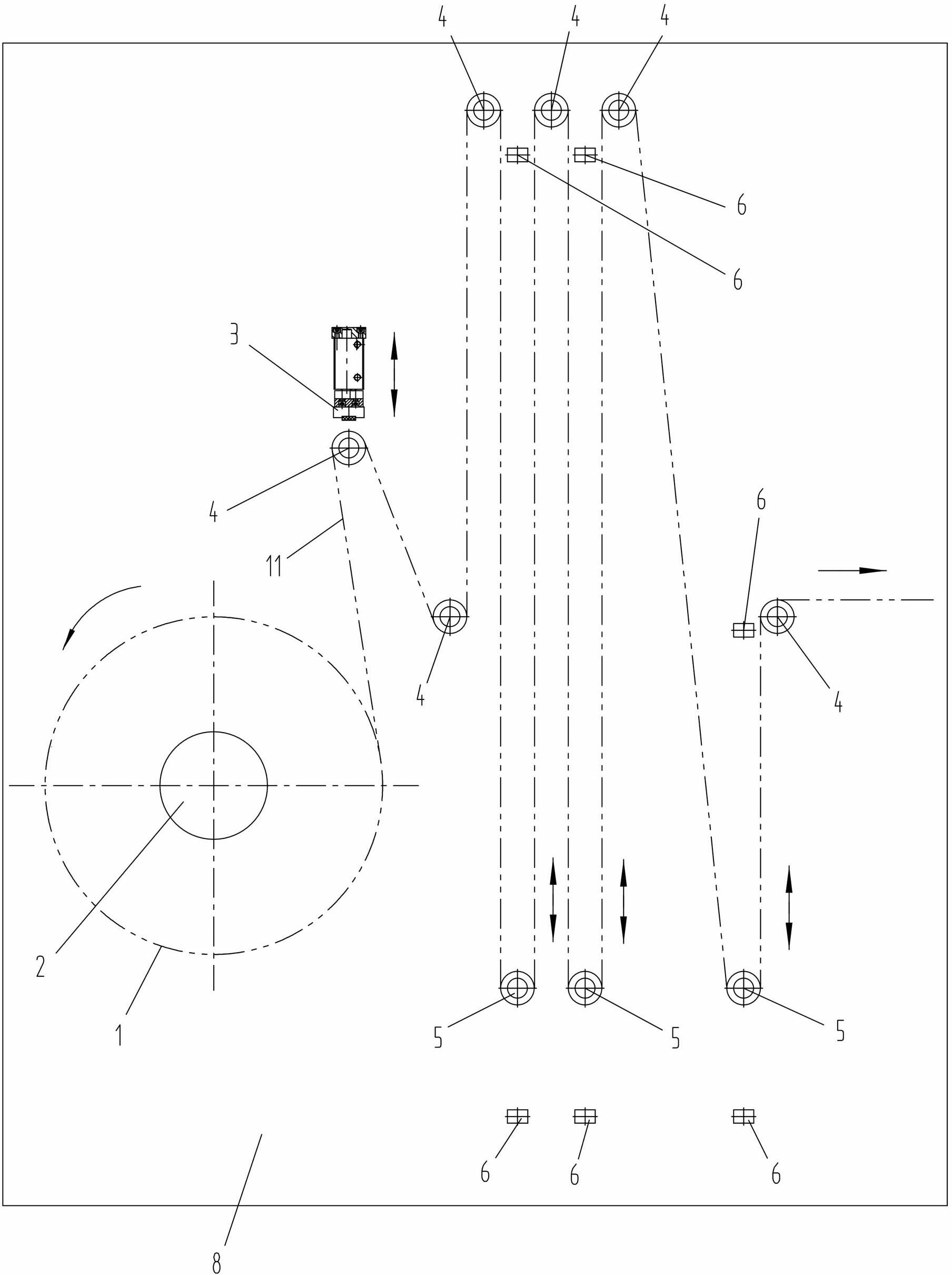

[0020] like figure 1 As shown, the film conveying device used in the soft bag infusion production line of the present invention includes a rotating film feeding mechanism 2 and a roller conveying mechanism. The rotating film feeding mechanism 2 is used to install the film material roll 1 and rotate and convey the film material 11 . The roller conveying mechanism includes more than two fixed rollers 4 and more than one moving roller 5 for winding the film material 11, and the moving roller 5 can move along the direction close to or away from the fixed roller 4, so as to change the position on the whole roller conveying mechanism. The length of the membrane material 11 is wound. Along the winding direction of the film material 11, the moving roller 5 is arranged between two adjacent fixed rollers 4, and a pressing mechanism that can stop the film material 11 from advancing is provided before the moving roller 5 closest to the rotating film feeding mechanism 2 3. like figure ...

Embodiment 2

[0025] like Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: on the premise of ensuring that the length of the reserved membrane material 11 determined according to the membrane changing time is sufficient, two fixed rollers 4 are removed, that is, along the In the winding direction of the film material 11, only one fixed roller 4 is arranged closest to the moving roller 5 of the rotating film feeding mechanism 2, and the structure is more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com