Elliptical unit block for preparing core using soft magnetic metal powder, and powdered magnetic core prepared using same

A powder preparation, soft magnetic metal technology, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, permanent magnet, etc., can solve the problem of low degree of freedom of shape, achieve low core loss characteristics, and improve inductor characteristics , The effect of power density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

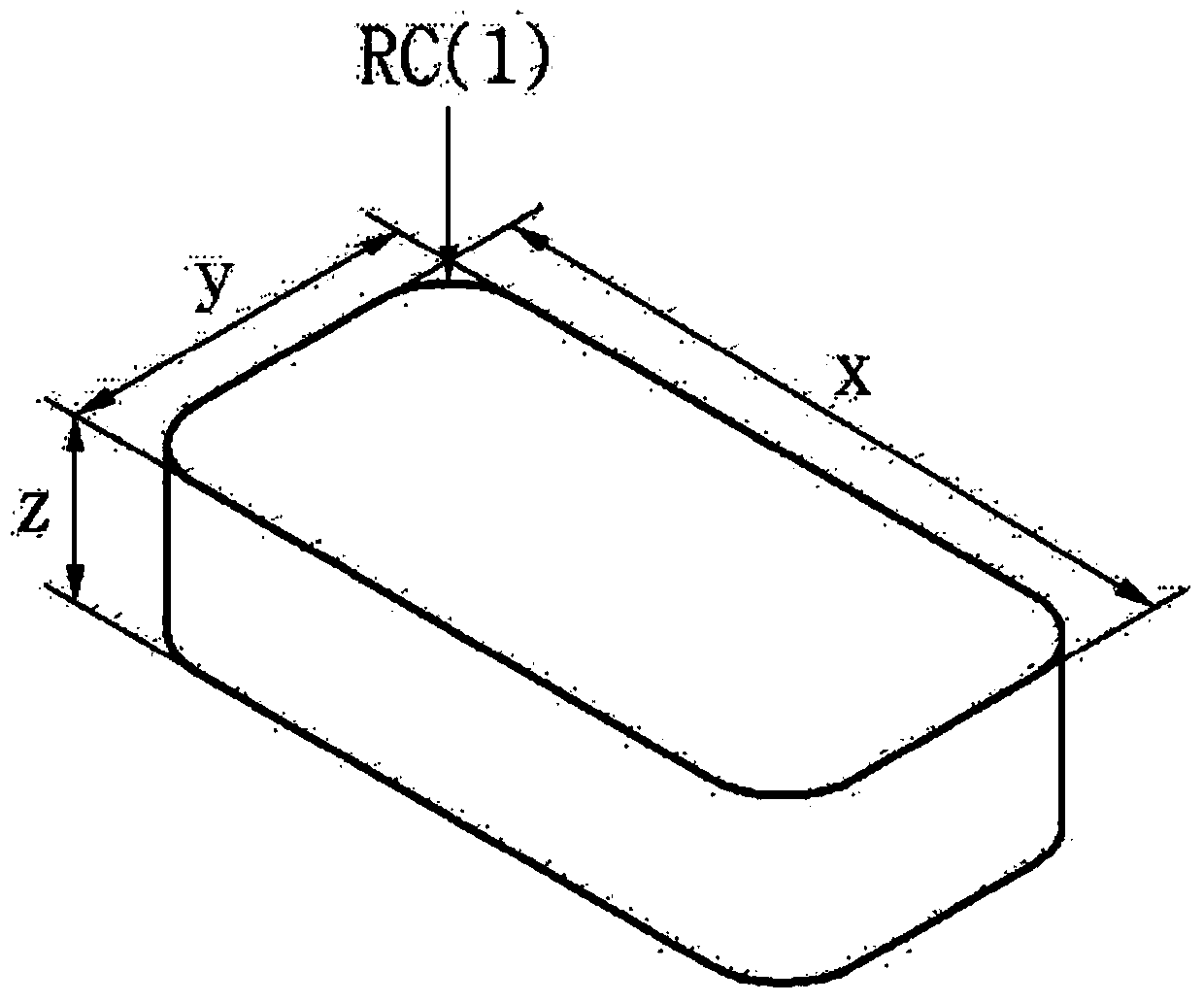

[0025] The present invention relates to an elliptical unit block for preparing a core using soft magnetic metal powder. The elliptical unit block can be formed by selectively molding one or more of sendust powder, high flux powder or MPP powder and Mega Flux (silicon steel powder) with a particle size less than or equal to 180 μm , and subsequently heat-treated it. The elliptical unit block has such as figure 1 and 2 Dimensions and shapes shown in .

[0026] Furthermore, the present invention relates to an elliptical unit block for producing a core using a soft magnetic metal powder having a composition comprising: 9% by weight to 10% by weight of silicon (Si), 4% by weight -8% by weight of aluminum (Al) and the balance of the total weight of the composition iron (Fe). The high-flux powder has a composition comprising 45% to 55% by weight of nickel (Ni) and the balance of iron (Fe) in the total weight of the composition. The MPP powder has a composition including 80 to 81...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com