A kind of nanocrystalline soft magnetic composite material and preparation method thereof

A technology of nanocrystalline soft magnetic and composite materials, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the complex process of nanocrystalline soft magnetic composite materials, large eddy current loss of soft magnetic composite materials, magnetic Low conductivity and other issues, to achieve the effect of excellent DC bias characteristics, guaranteed performance, and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

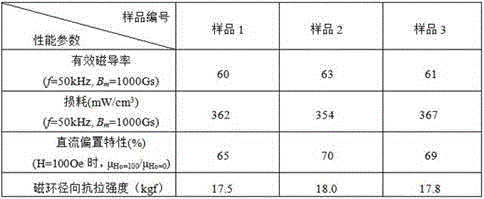

Embodiment 1

[0023] In this embodiment, the molecular formula of the alloy that constitutes the nanocrystalline soft magnetic composite material is Fe 71 Cu 1 Nb 2.9 Si 14 B 11 Dy 0.1 , the following are the specific preparation steps:

[0024] (1) Alloy melting: soft magnetic alloys are melted in a vacuum melting furnace;

[0025] (2) Atomized powder making: Spray the smelted alloy directly with nitrogen gas to obtain amorphous soft magnetic powder, and sieve to obtain a powder of less than 100 mesh;

[0026] (3) Particle size ratio: The obtained amorphous powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage of the mixed powder is: -100~+200 mesh 30%, -200~+300 mesh accounted for 50%, -300~+400 mesh accounted for 15%, -400 mesh accounted for 5%;

[0027] (4) Passivation treatment: Mix the amorphous powder with a good particle size ratio and phosphoric acid alcohol diluent evenly. The amount of phosphoric acid alcohol diluent is 10...

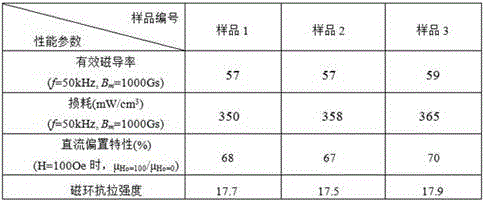

Embodiment 2

[0034] In this embodiment, the molecular formula of the alloy that constitutes the nanocrystalline soft magnetic composite material is Fe 75 Cu 2 Nb 2 P 3 Si 10 B 5 Dy 1 La 1 PR 1 , the following are the specific preparation steps:

[0035] (1) Alloy melting: soft magnetic alloys are melted in a vacuum melting furnace;

[0036] (2) Atomized powder making: Spray the smelted alloy directly with nitrogen gas to obtain amorphous soft magnetic powder, and sieve to obtain a powder of less than 100 mesh;

[0037] (3) Particle size ratio: The obtained amorphous powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage of the mixed powder is: -100~+200 mesh 40%, -200~+300 mesh accounted for 25%, -300~+400 mesh accounted for 10%, -400 mesh accounted for 25%;

[0038] (4) Passivation treatment: Mix the amorphous powder with a good particle size ratio and acetone phosphate diluent evenly. The amount of acetone phosphate diluent is 5...

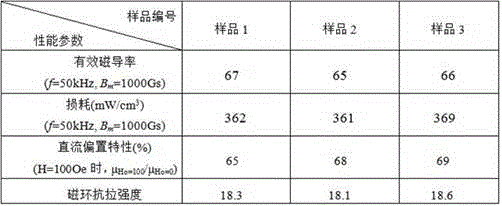

Embodiment 3

[0045] In this embodiment, the molecular formula of the alloy that constitutes the nanocrystalline soft magnetic composite material is Fe 75 Cu 3 P 1 Si 10 B 10 Ho 0.5 Yb 0.5 , the following are the specific preparation steps:

[0046] (1) Alloy melting: soft magnetic alloys are melted in a vacuum melting furnace;

[0047] (2) Atomized powder making: Spray the smelted alloy directly with nitrogen gas to obtain amorphous soft magnetic powder, and sieve to obtain a powder of less than 100 mesh;

[0048] (3) Particle size ratio: The obtained amorphous powder is classified into -400 mesh, -300 mesh, -200 mesh, -100 mesh and then mixed. The mass percentage of the mixed powder is: -100~+200 mesh 20%, -200~+300 mesh accounted for 30%, -300~+400 mesh accounted for 30%, - 400 mesh accounted for 20%;

[0049] (4) Passivation treatment: Mix the amorphous powder with a good particle size ratio and phosphoric acid aqueous solution evenly. The amount of phosphoric acid aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com