High-permeability, high-frequency, high-impedance and high-Curie-temperature manganese-zinc ferrite material and preparation method thereof

A technology of manganese zinc ferrite and high magnetic permeability, which is applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem that the magnetic permeability is lower than 10000, achieve high magnetic permeability, improve Effects of Curie temperature and grain size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] will be proportioned as Fe 2 o 3 52.80mol%, MnO 26.90mol%, ZnO 20.30mol% (converted to mass percentage as Fe 2 o 3 : 69.48wt%, Mn 3 o 4 : 16.91wt%, ZnO: 13.62wt%) three main raw materials are mixed by ball milling once, then calcined at 850°C, and the auxiliary component CaCO is added to the calcined material 3 200ppm, Bi 2 o 3 400ppm, Co 2 o 3 500ppm, MoO 3 200ppm, mixed through secondary ball milling, drying, granulation, pressing and molding, and finally sintered in a pusher kiln. The sintering process is: heating to 1000°C at a heating rate of 2°C / min, and the sintering atmosphere at this stage is air , and then heated to 1410°C at a heating rate of 0.8°C / min, and held for 6 hours. Slow down to room temperature.

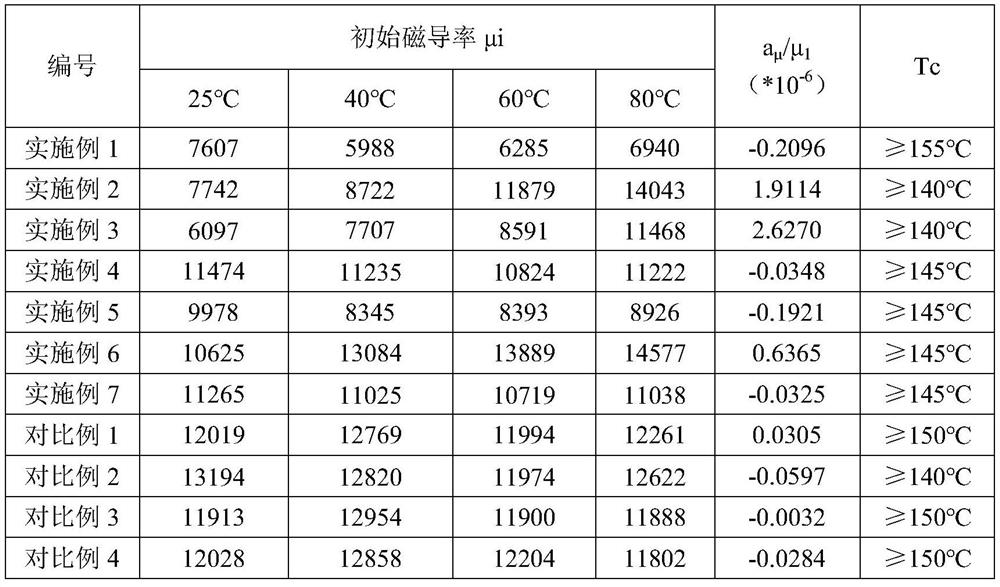

[0039] Using 10 turns of winding, the temperature characteristics of the permeability at a voltage of 0.25v and a frequency of 10KHz are measured on the 3302 instrument, and the frequency characteristics of the permeability and impedance at ...

Embodiment 2

[0041] will be proportioned as Fe 2 o 3 52.00mol%, MnO 27.60mol%, ZnO 20.40mol% (converted to mass percentage as Fe 2 o 3 : 68.80wt%, Mn 3 o 4 : 17.44wt%, ZnO: 13.76wt%) three main raw materials are ball milled and mixed once, and then calcined at 850°C, and the auxiliary component CaCO is added to the calcined material 3 200ppm, Bi 2 o 3 400ppm, Co 2 o 3 500ppm, MoO 3 200ppm, mixed through secondary ball milling, drying, granulation, pressing and molding, and finally sintered in a pusher kiln. The sintering process is: heating to 1000°C at a heating rate of 2°C / min, and the sintering atmosphere at this stage is air , and then heated to 1410°C at a heating rate of 0.8°C / min, and held for 6 hours. Slow down to room temperature.

[0042] Using 10 turns of winding, the temperature characteristics of the permeability at a voltage of 0.25v and a frequency of 10KHz are measured on the 3302 instrument, and the frequency characteristics of the permeability and impedance...

Embodiment 3

[0044] The blank with the same formula as in Example 2 is used for debinding and sintering in a pusher kiln. The sintering process is: heating to 1000°C at a heating rate of 2°C / min, the sintering atmosphere at this stage is air, and then at a temperature of 1.5°C / min The heating rate was heated to 1360°C, and the temperature was maintained for 6 hours. The oxygen partial pressure concentration was controlled at 5vol%. After cooling to 1100°C, the oxygen partial pressure concentration was controlled below 0.03vol%.

[0045] Using 10 turns of winding, the temperature characteristics of the permeability at a voltage of 0.25v and a frequency of 10KHz are measured on the 3302 instrument, and the frequency characteristics of the permeability and impedance at a voltage of 0.25v are measured on the 3302 instrument. The test results are shown in Table 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com