Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

544 results about "Tennis racket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

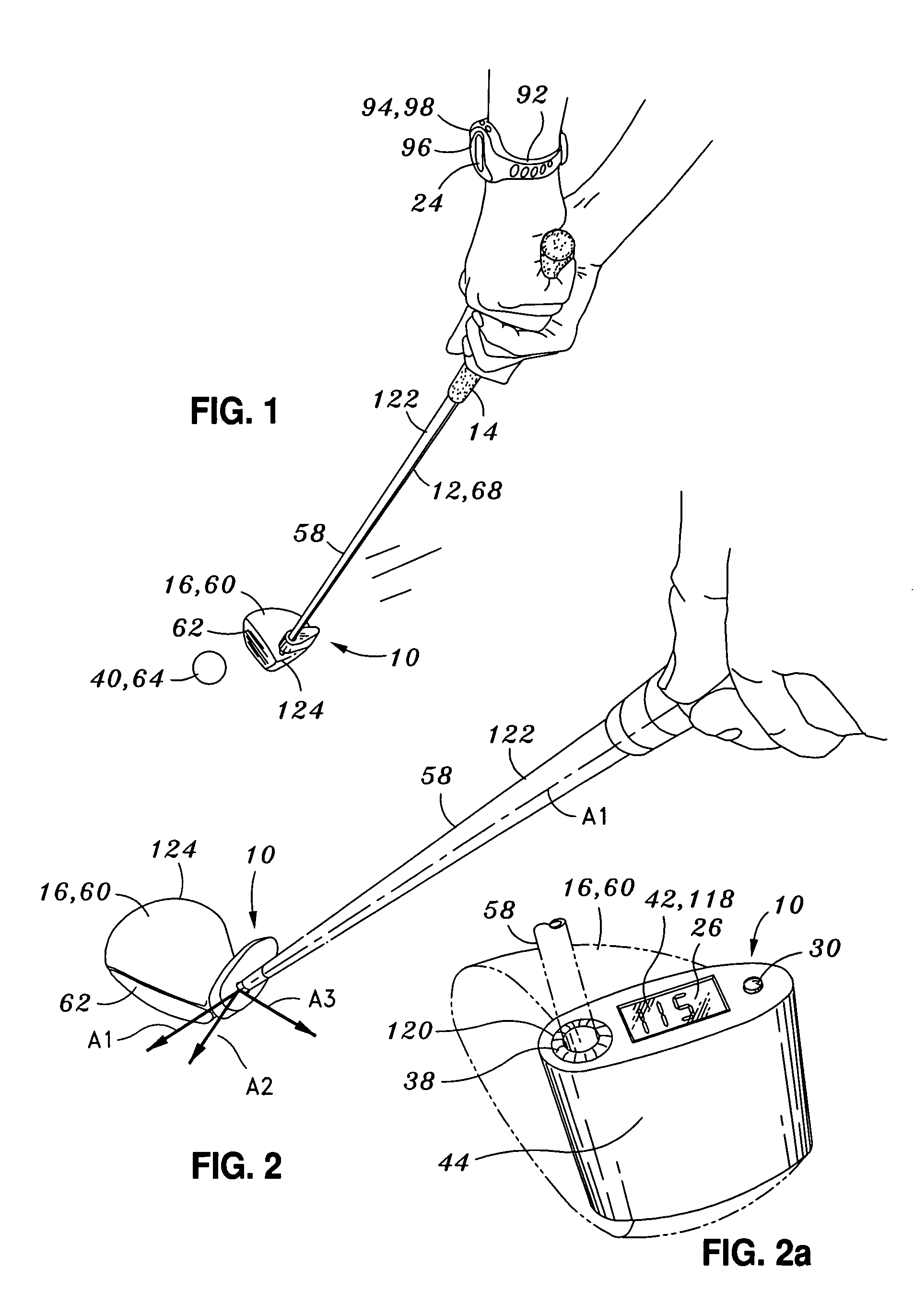

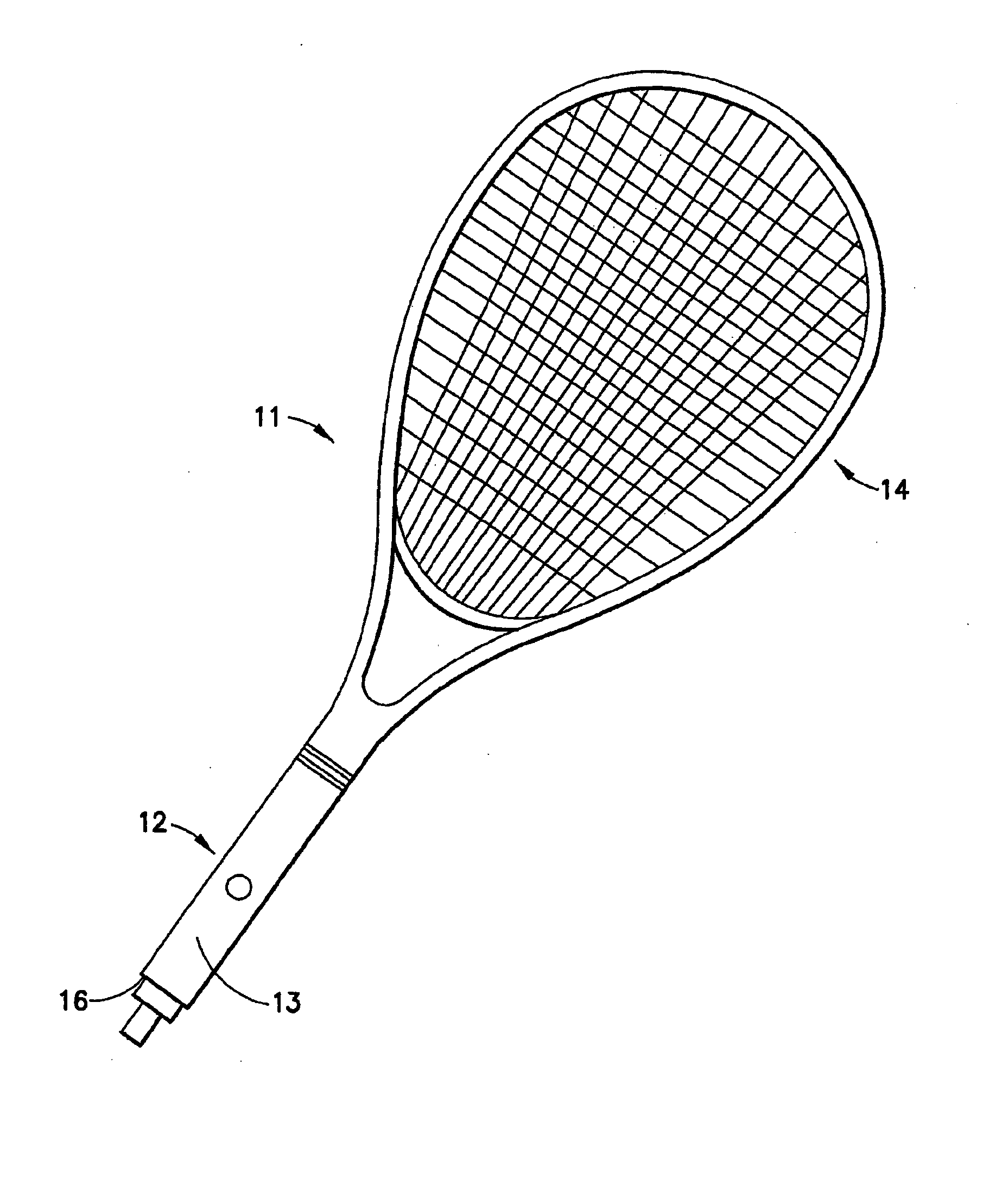

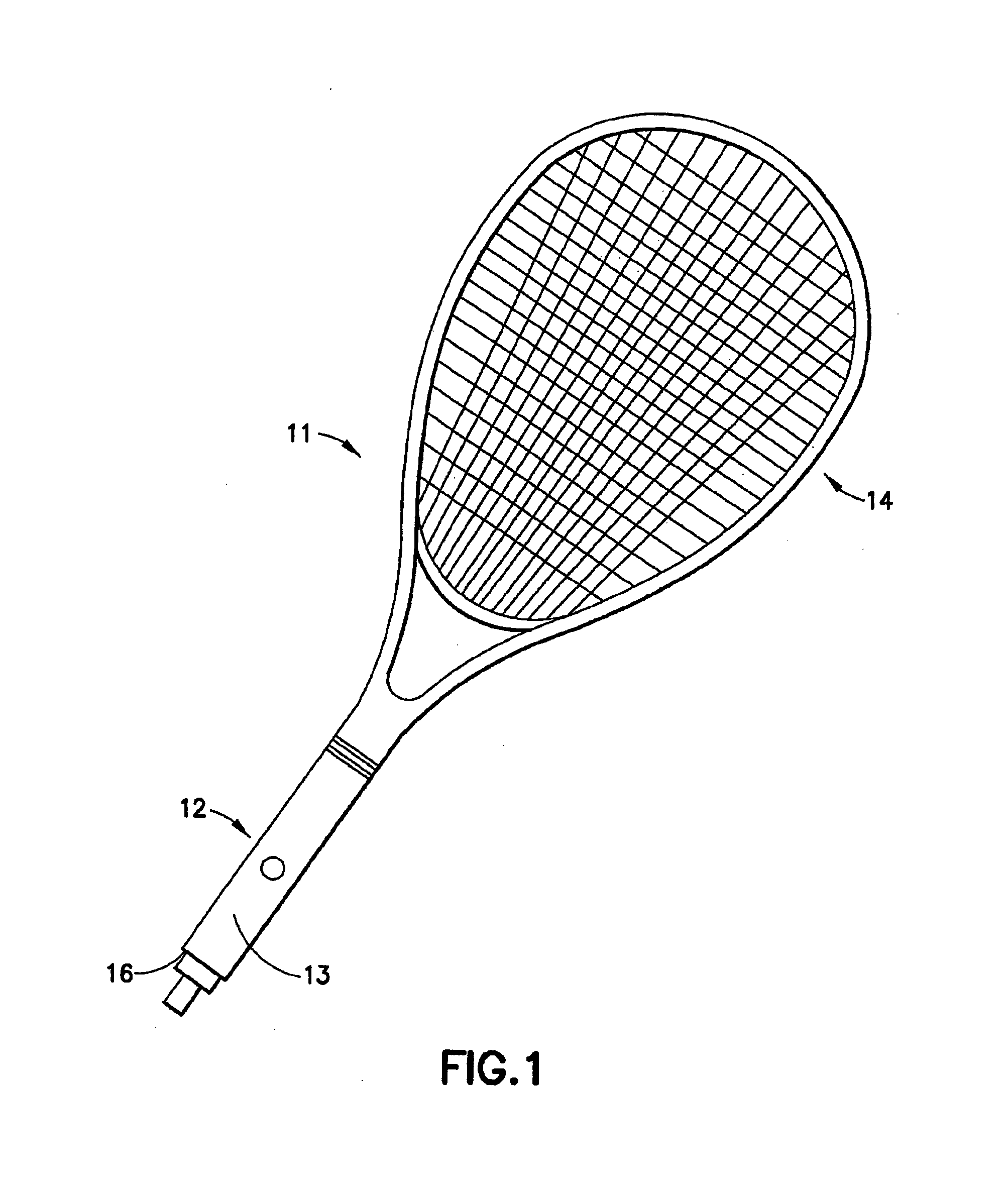

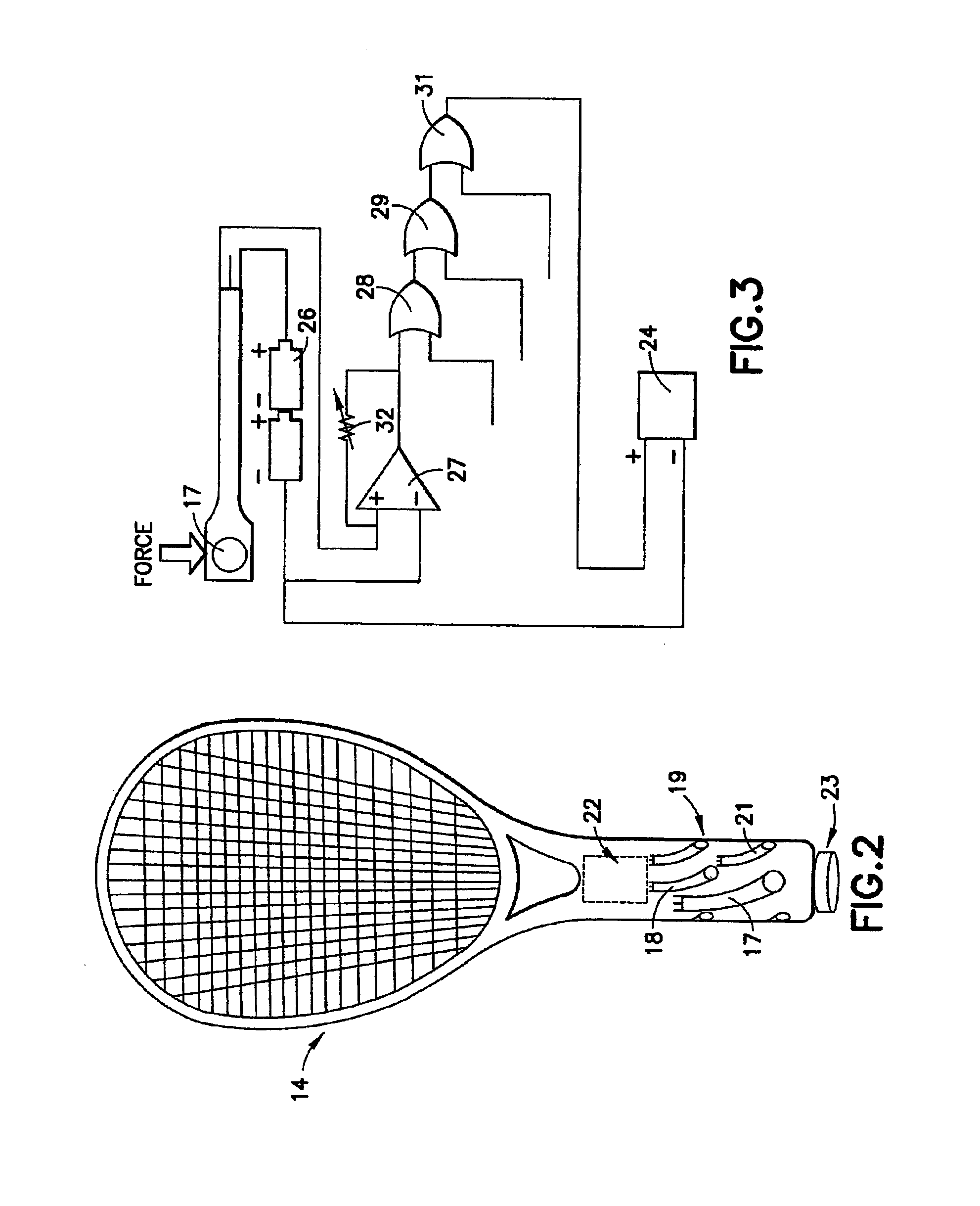

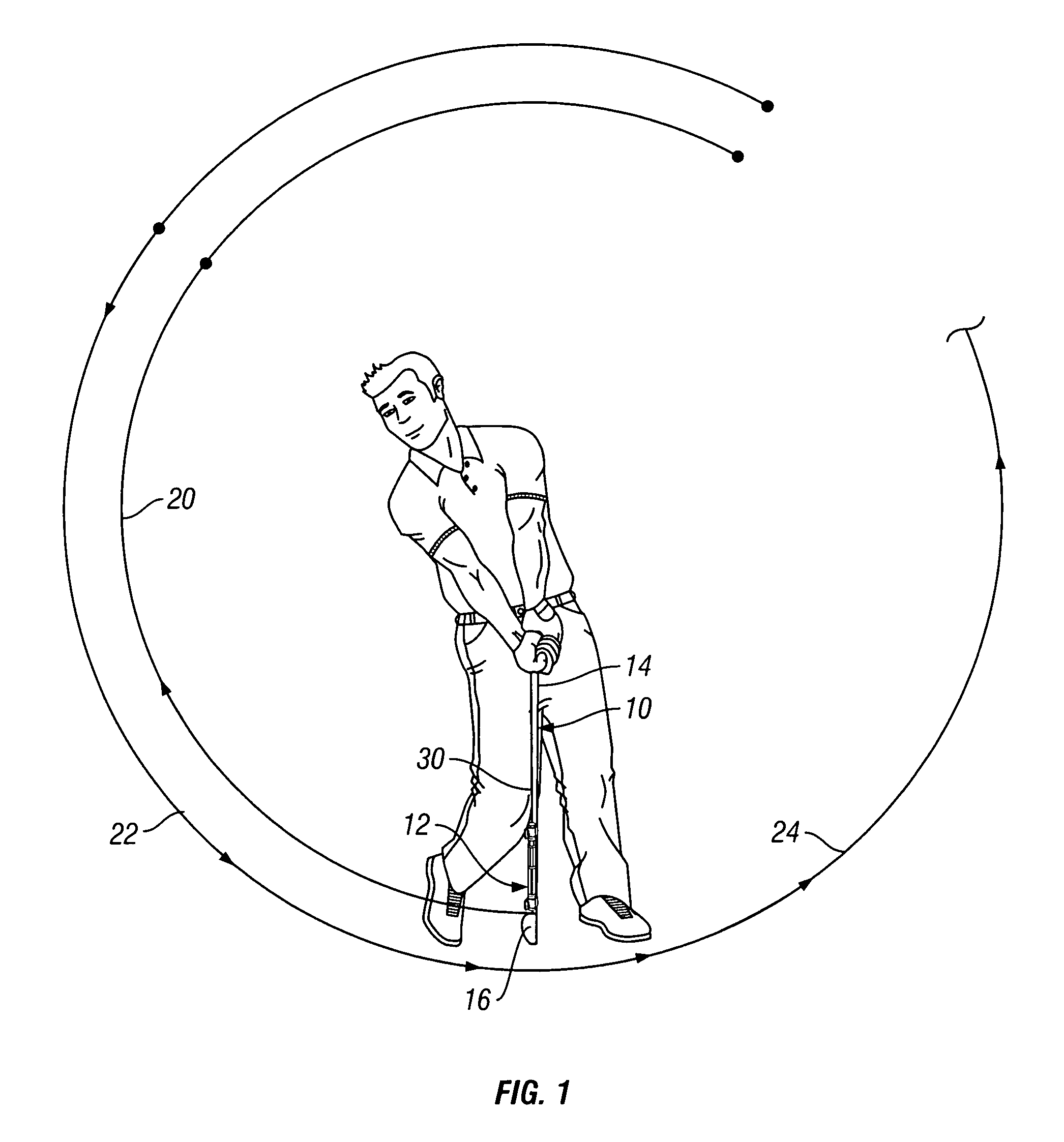

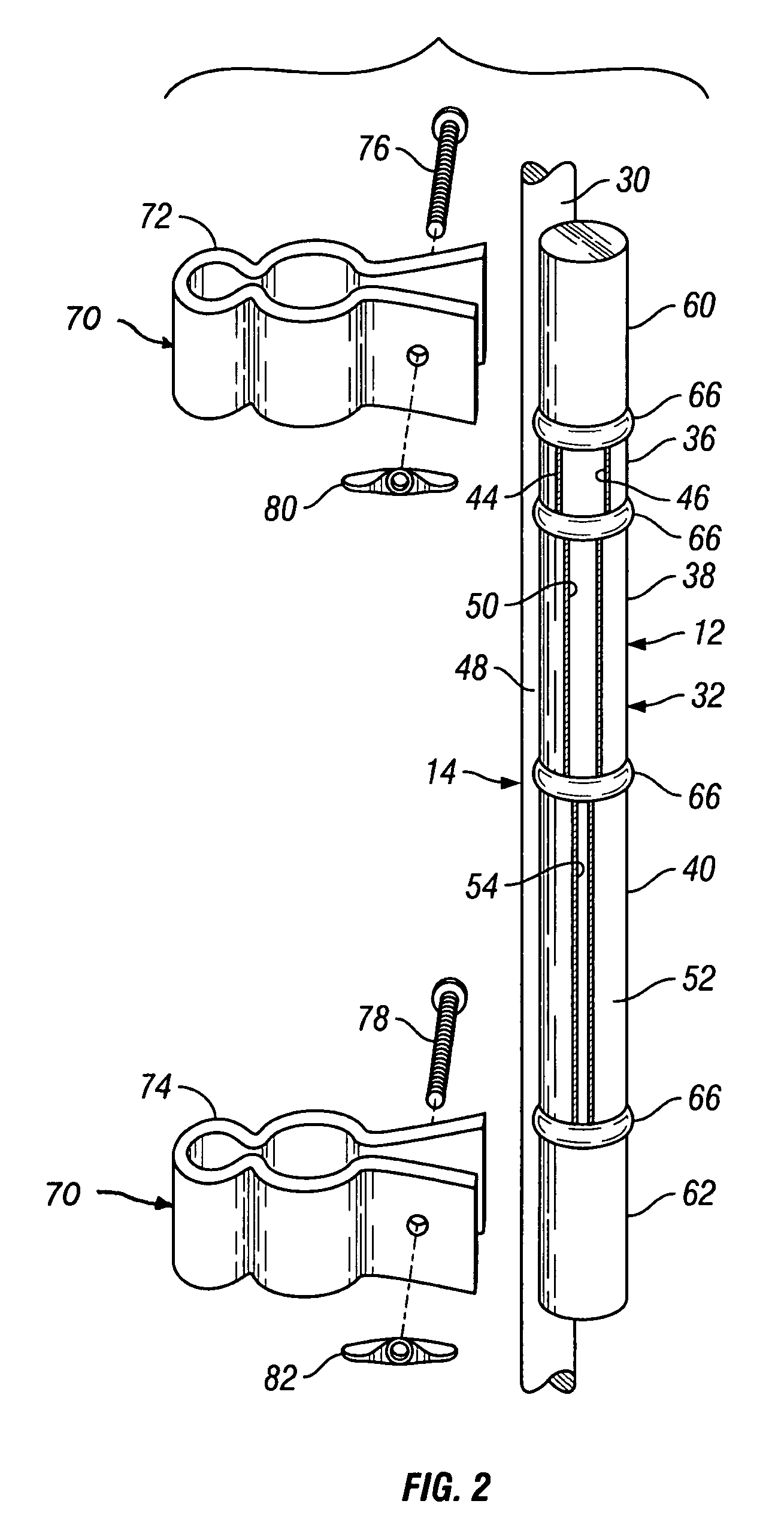

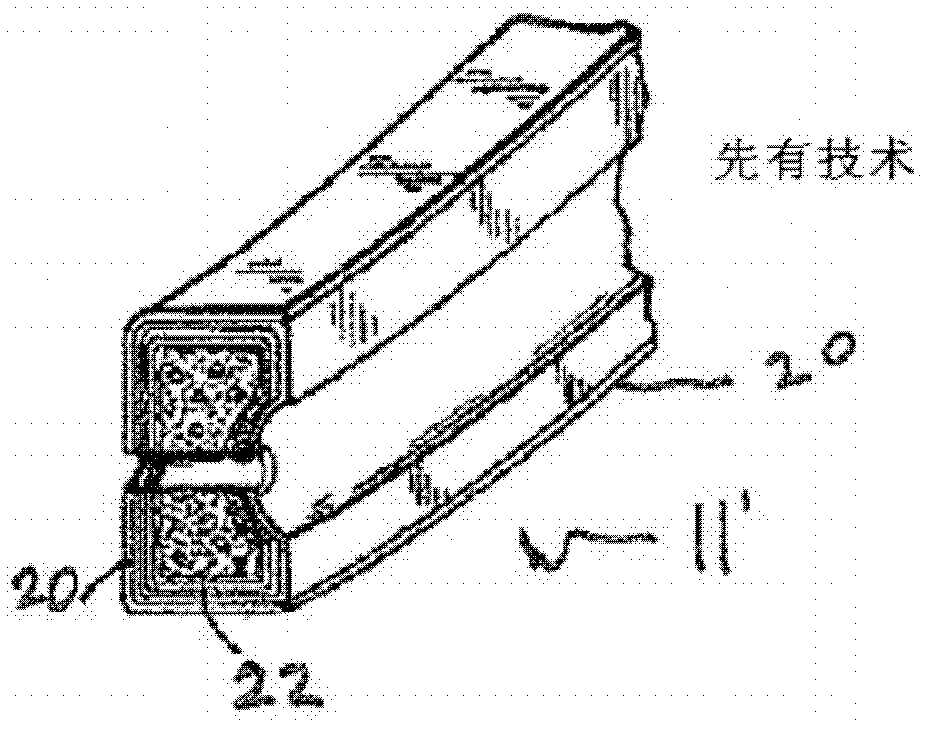

Portable swing speed analyzer

InactiveUS20060052173A1Easy to measureImprove accuracyGymnastic exercisingAcceleration measurementShock waveAccelerometer

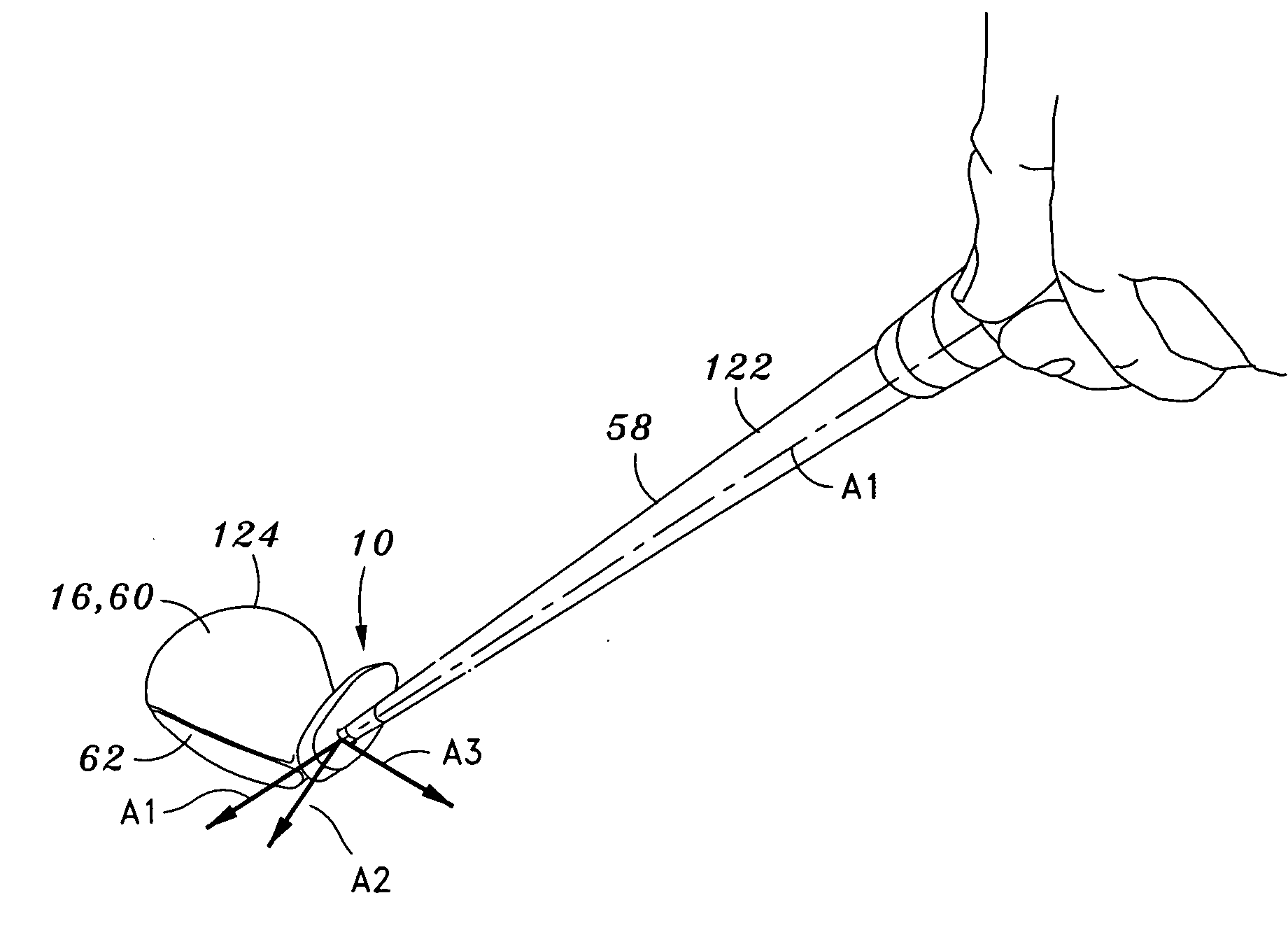

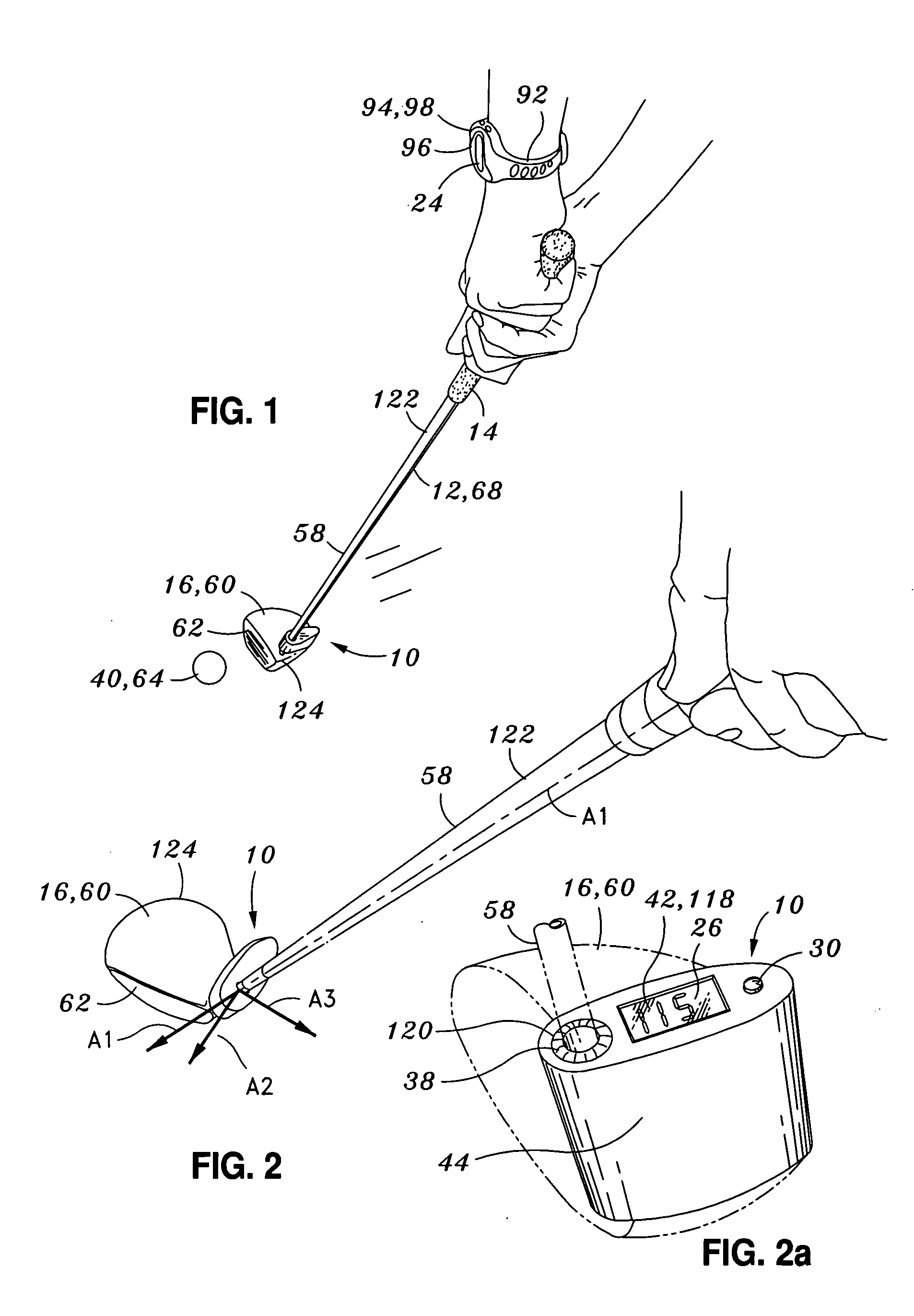

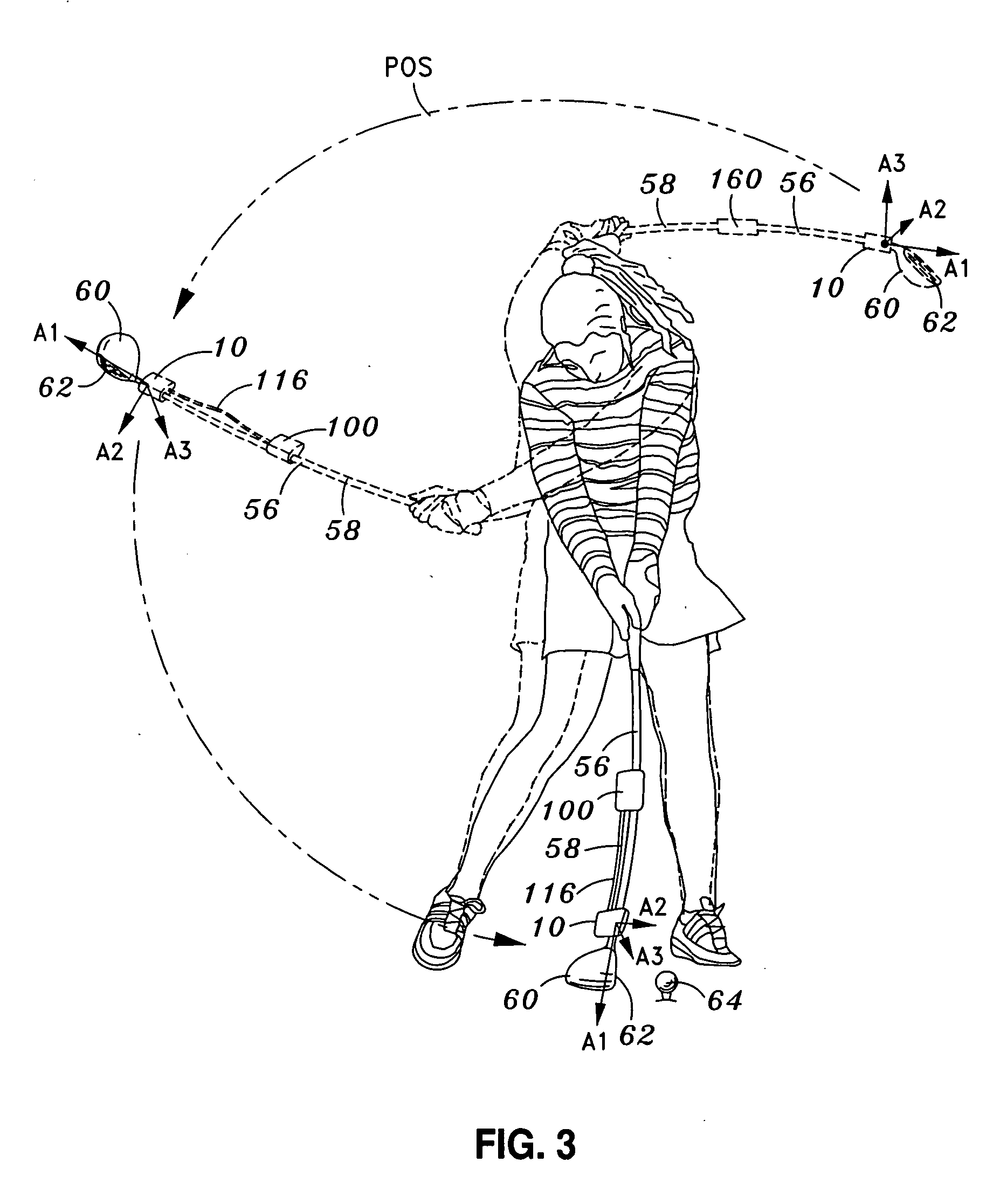

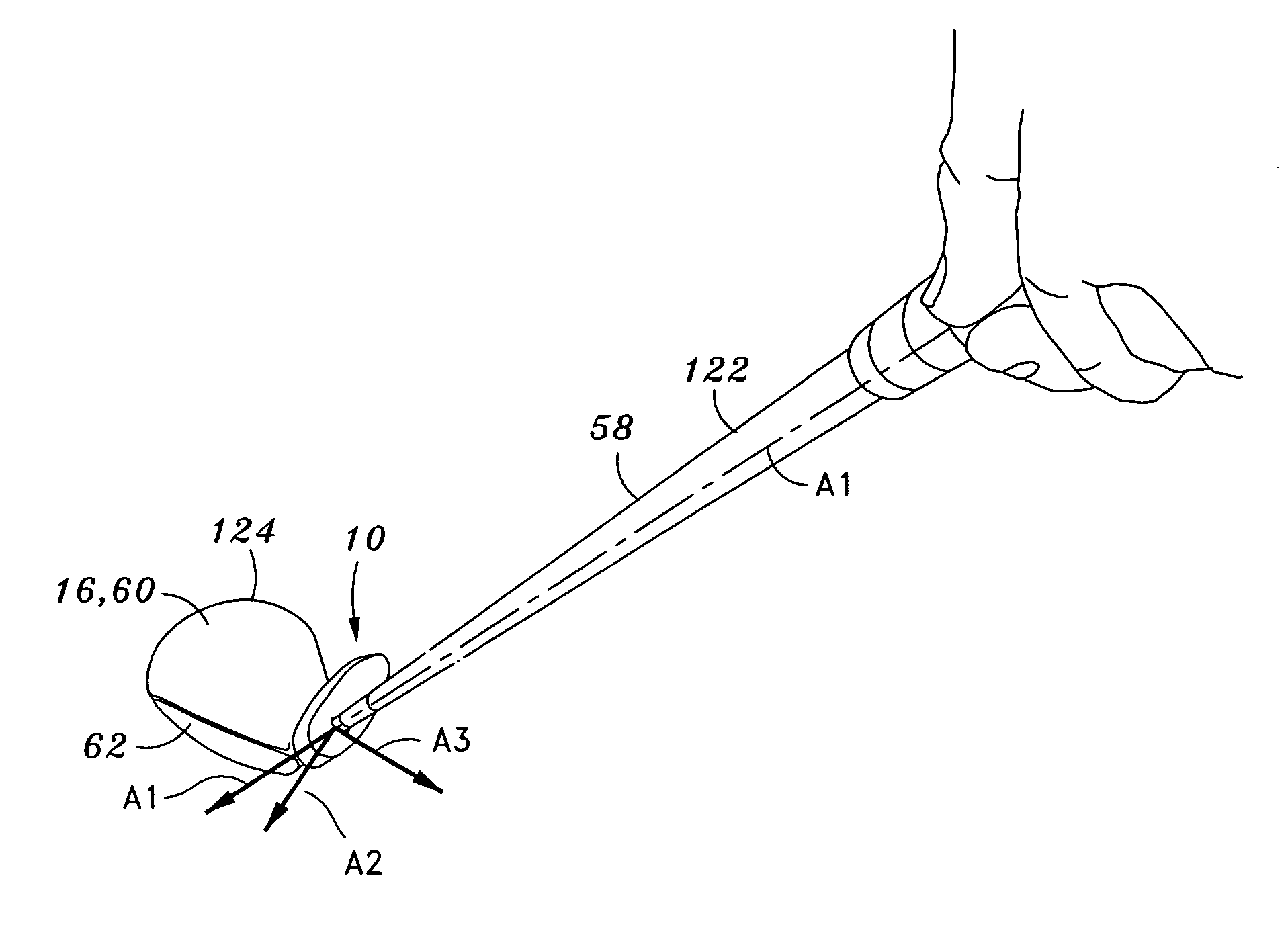

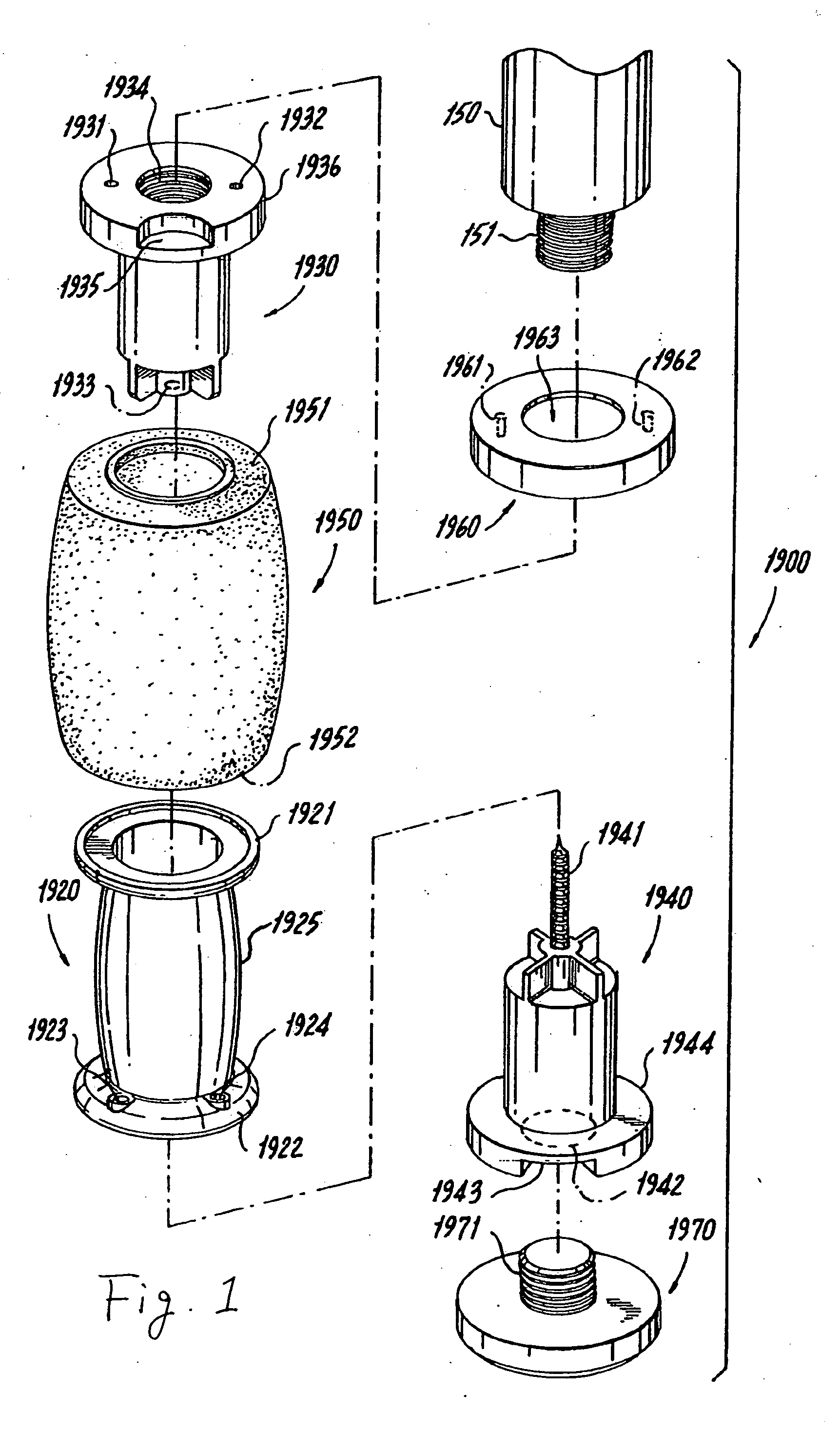

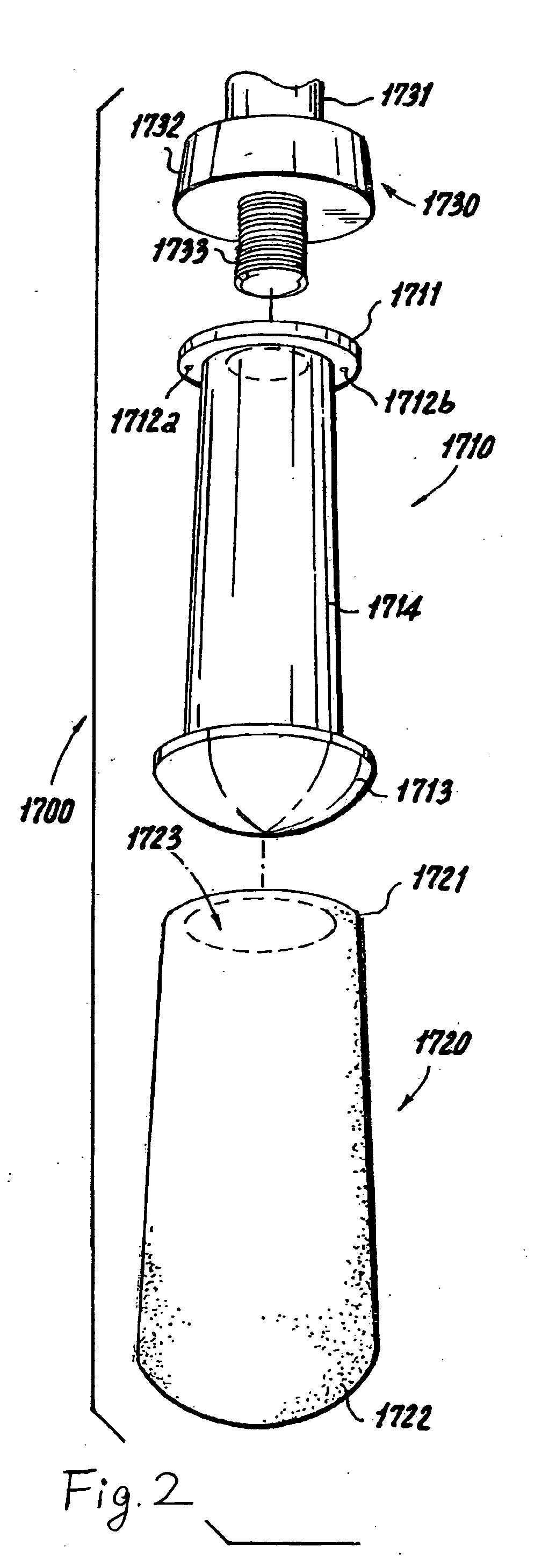

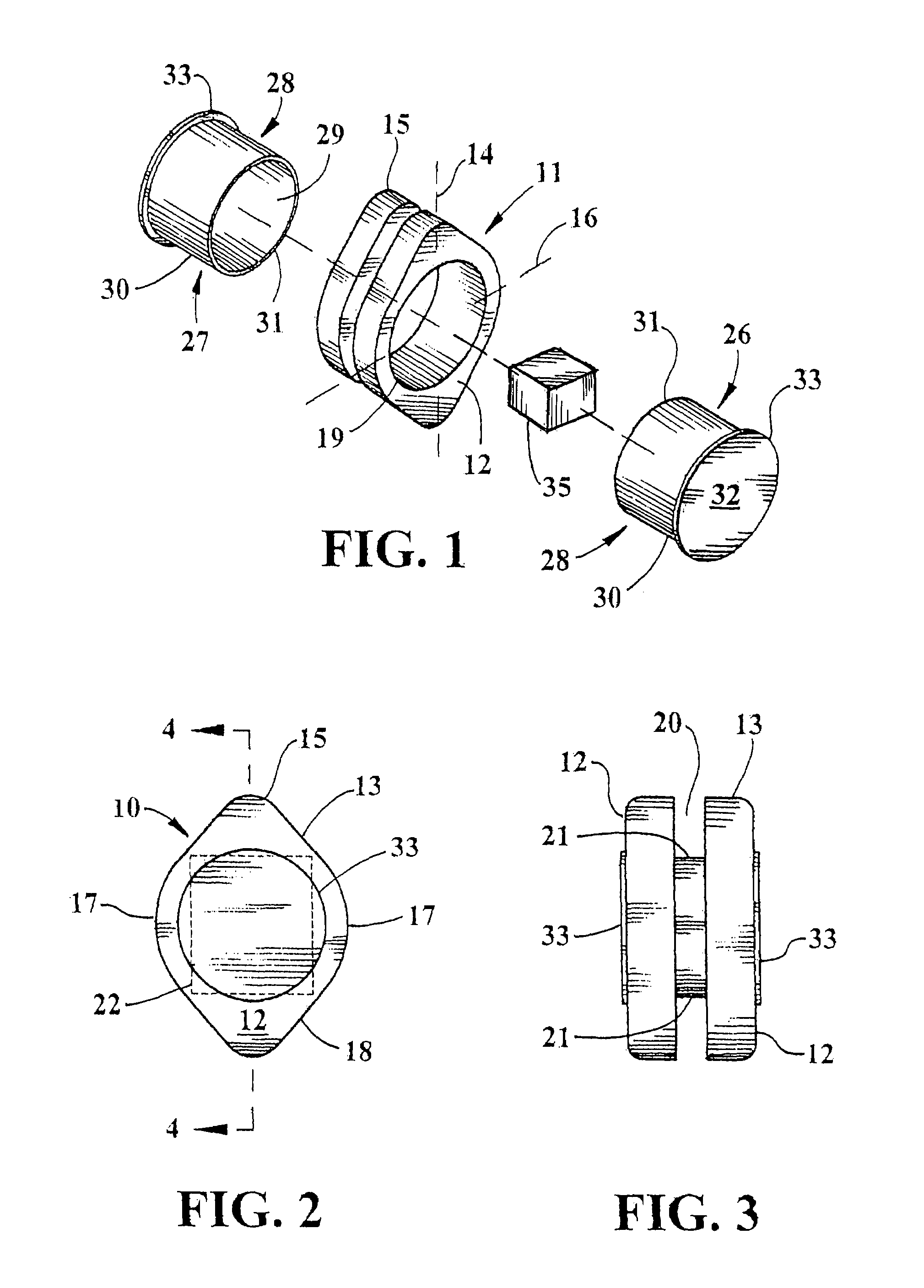

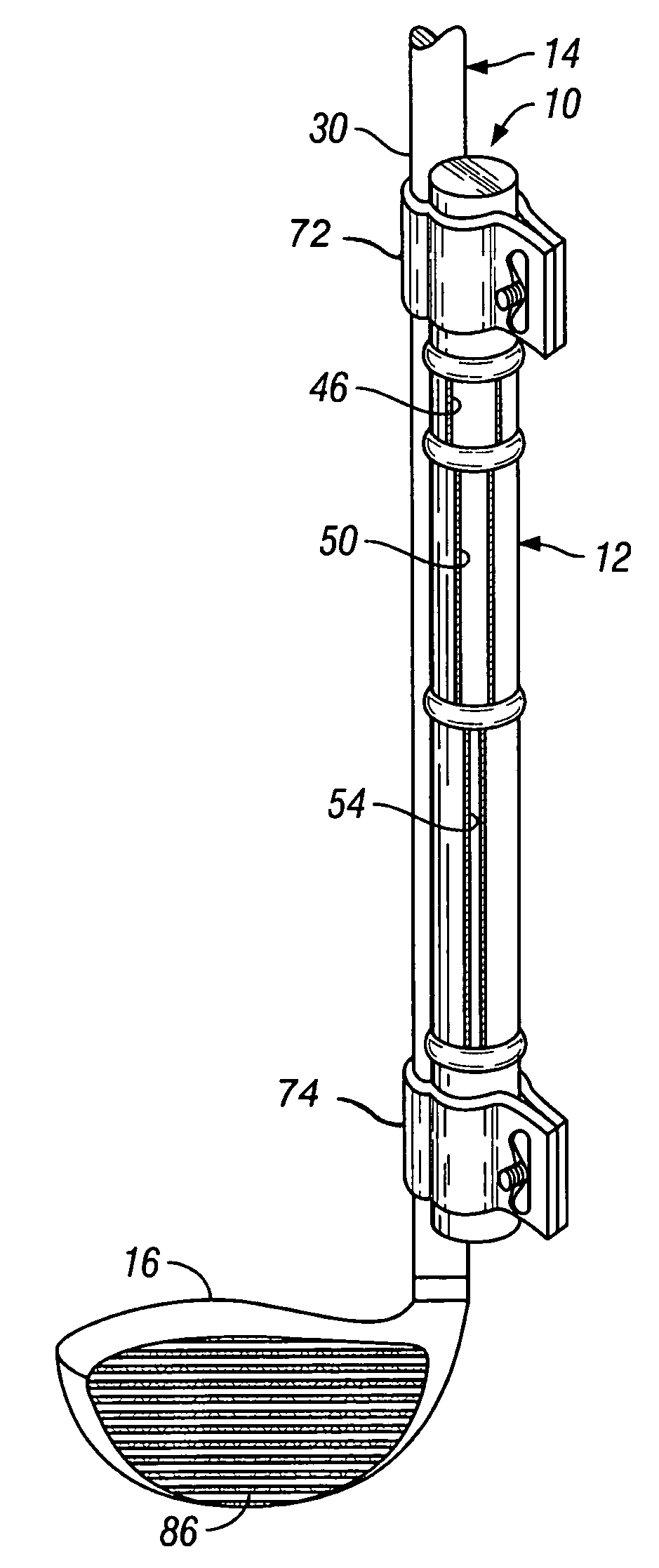

Provided is a swing speed analyzer for mounting on a swinging implement and comprising a first accelerometer, a processor and a shock attenuator. The processor uses an output from the first accelerometer to compute a swing speed of the swinging implement. The shock attenuator is comprised of a material that is sized and dimensioned to dampen an impact shock wave by more than 50% at 125 Hz. The material is preferably sized and dimensioned to dampen the impact shock wave from more than 1000 g to less than 500 g. Suitable attenuators can include viscoelastomeric materials such as foam. The swing speed analyzer can advantageously include any of a releasable attachment mechanism, a liquid crystal or other visual display, a second accelerometer, and a strain gauge. The analyzer can advantageously be attached to a golf club, a tennis racket, a baseball bat, or a hockey stick.

Owner:TELFORD GOLF ENTERPRISES

Portable swing speed analyzer

InactiveUS7771263B2Easy to measureImprove accuracyGymnastic exercisingAcceleration measurementShock waveAccelerometer

Provided is a swing speed analyzer for mounting on a swinging implement and comprising a first accelerometer, a processor and a shock attenuator. The processor uses an output from the first accelerometer to compute a swing speed of the swinging implement. The shock attenuator is comprised of a material that is sized and dimensioned to dampen an impact shock wave by more than 50% at 125 Hz. The material is preferably sized and dimensioned to dampen the impact shock wave from more than 1000 g to less than 500 g. Suitable attenuators can include viscoelastomeric materials such as foam. The swing speed analyzer can advantageously include any of a releasable attachment mechanism, a liquid crystal or other visual display, a second accelerometer, and a strain gauge. The analyzer can advantageously be attached to a golf club, a tennis racket, a baseball bat, or a hockey stick.

Owner:TELFORD GOLF ENTERPRISES

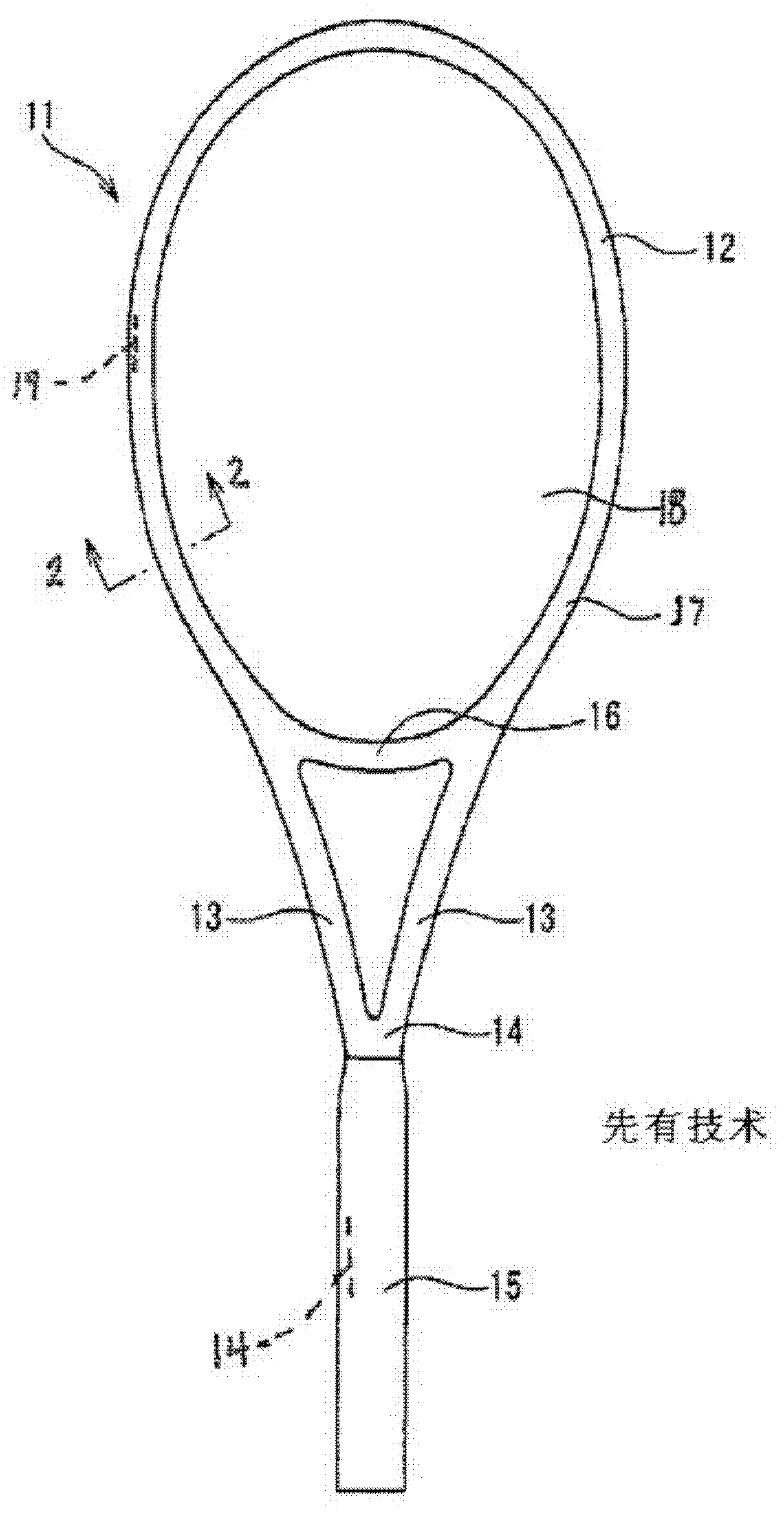

Device and method for improved tennis racket damping and weight adjustment

Owner:HK INNOVATIONS

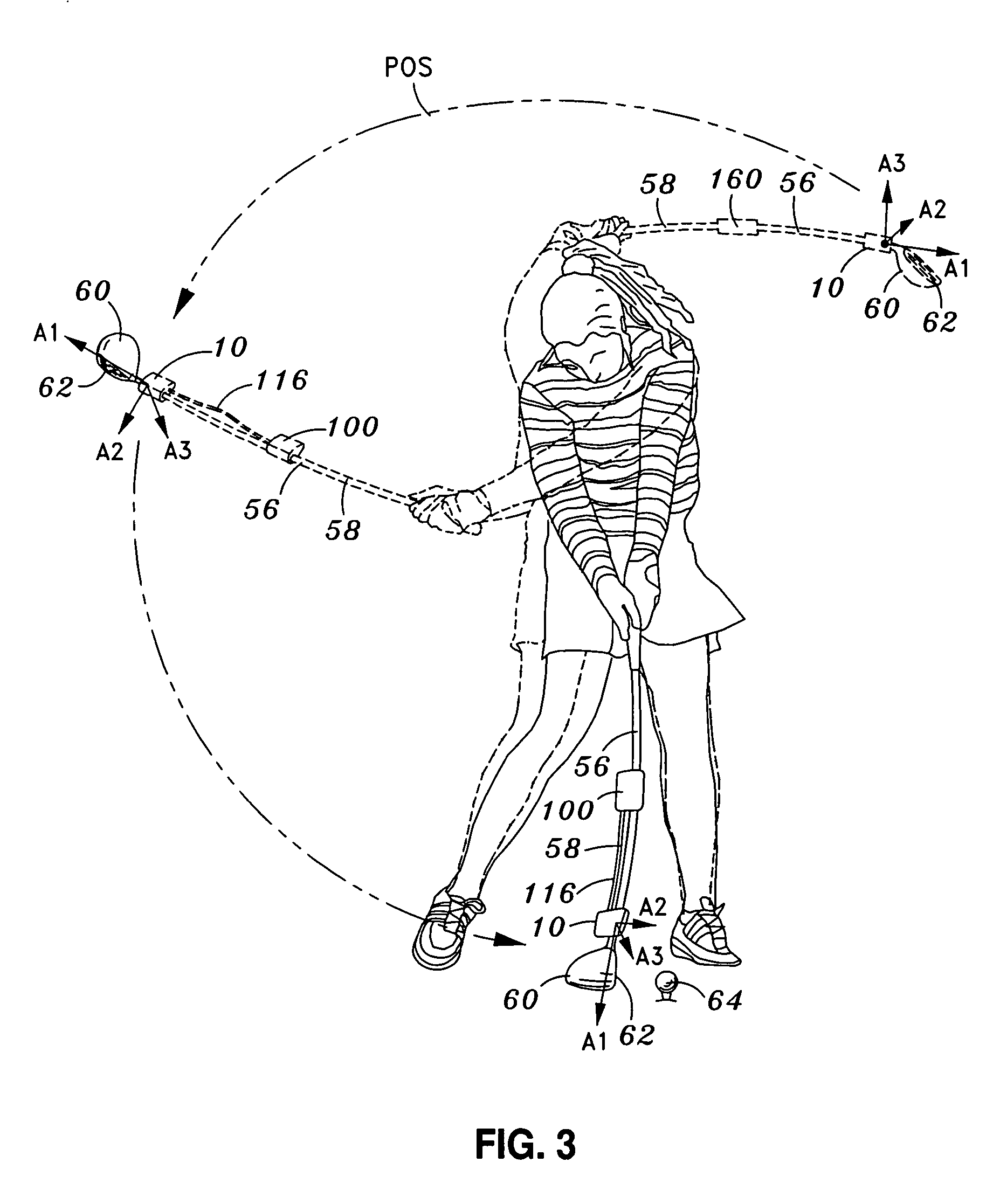

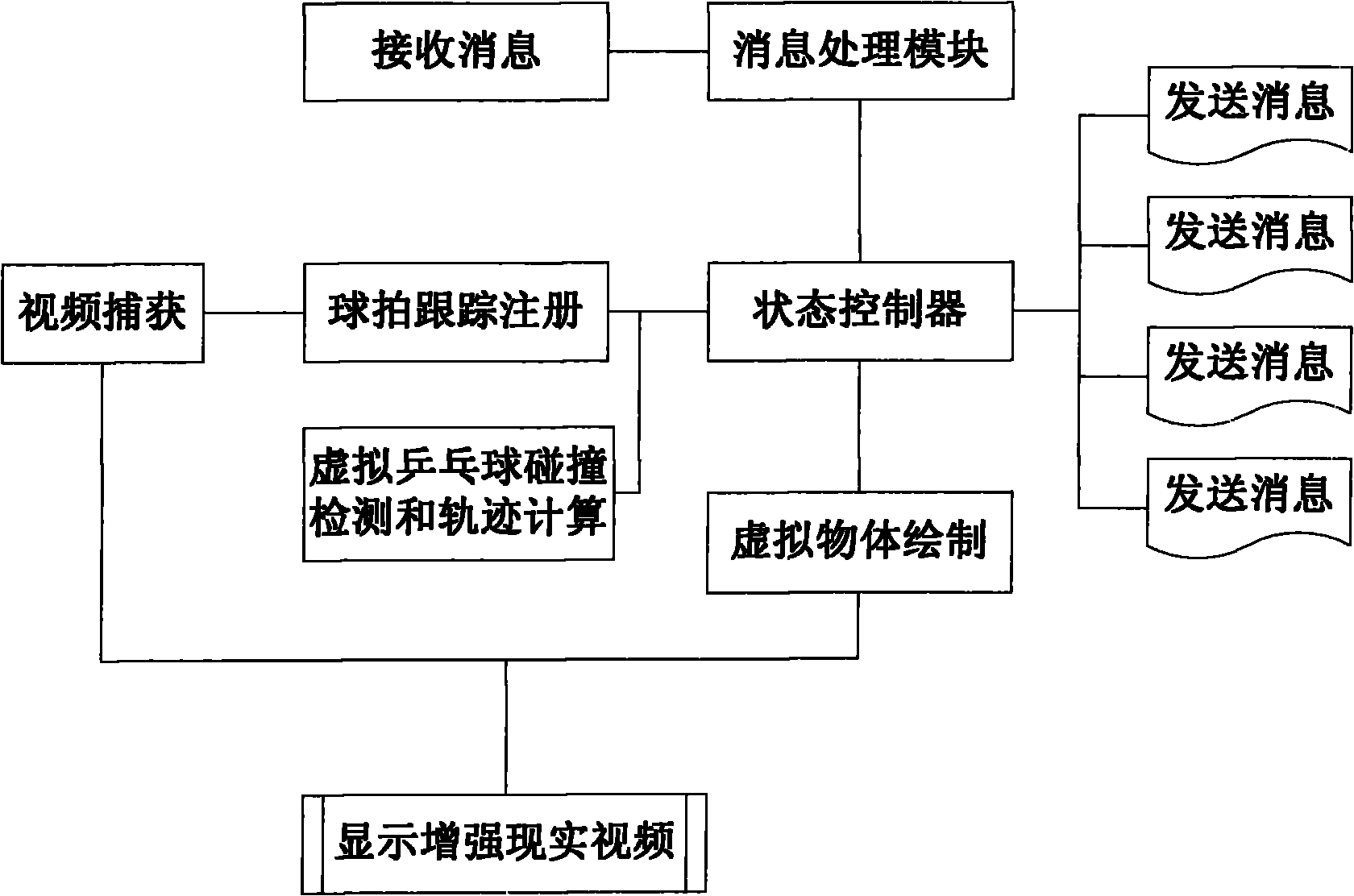

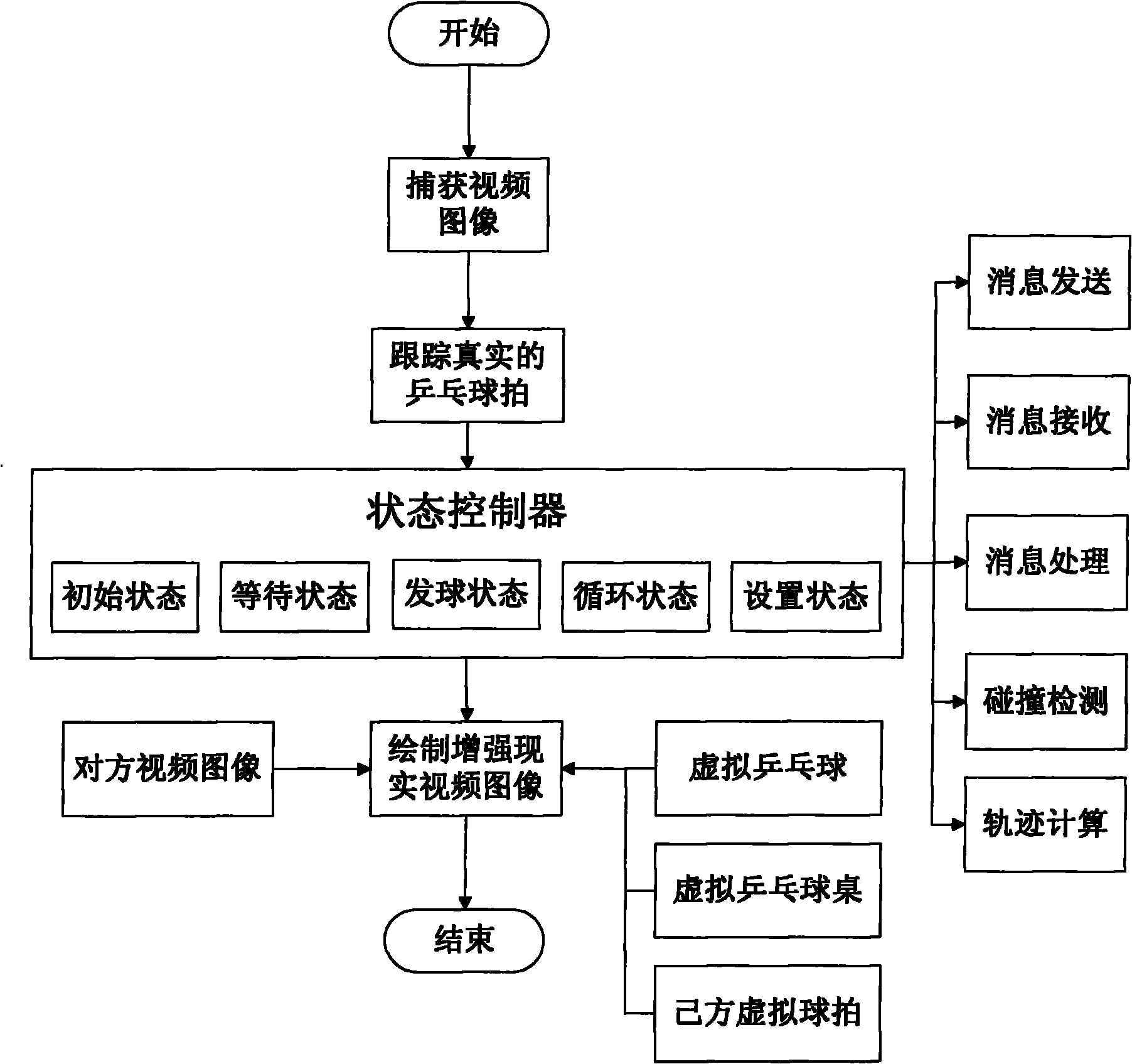

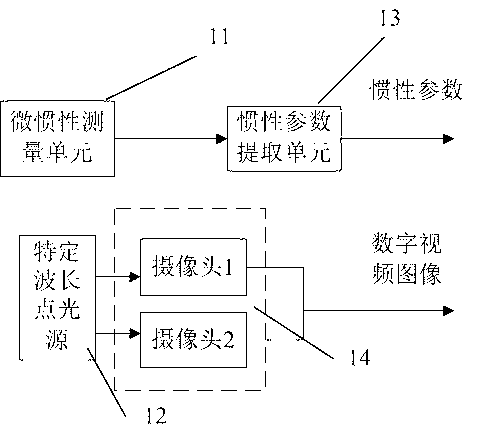

Cooperative construction method for enhancing realistic table-tennis system based on real rackets

InactiveCN101893935AImprove developmentSimplify the development processInput/output for user-computer interactionTelevision systemsComputer graphics (images)Collision detection

The invention relates to a cooperative construction method for enhancing a realistic table-tennis system based on real rackets. The method comprises the following steps of: detecting and tracking a real table-tennis racket by utilizing the color characteristics according to a video image acquired by the system; designing and realizing the virtual-real three-dimensional registration of a virtual scene and a real scene, mapping the virtual scene to a video image coordinate system of the real rackets, participator users and real environment; designing and realizing the collision detection between a virtual table-tennis ball and objects, such as the real rackets, a virtual table-tennis table, a virtual table-tennis net, and the like according to the motion information of the real rackets and confirming and representing the motion trajectory of the virtual table-tennis ball after collision; and providing a finite state machine and a message-processing mechanism, controlling the conversion of various states of the table-tennis system in the operation process and ensuring a plurality of users to have the same table-tennis motion experience. The cooperative construction method can be widely applied to the fields, such as interactive digital entertainment, sports research, training simulation, remote education and training, and the like.

Owner:BEIHANG UNIV

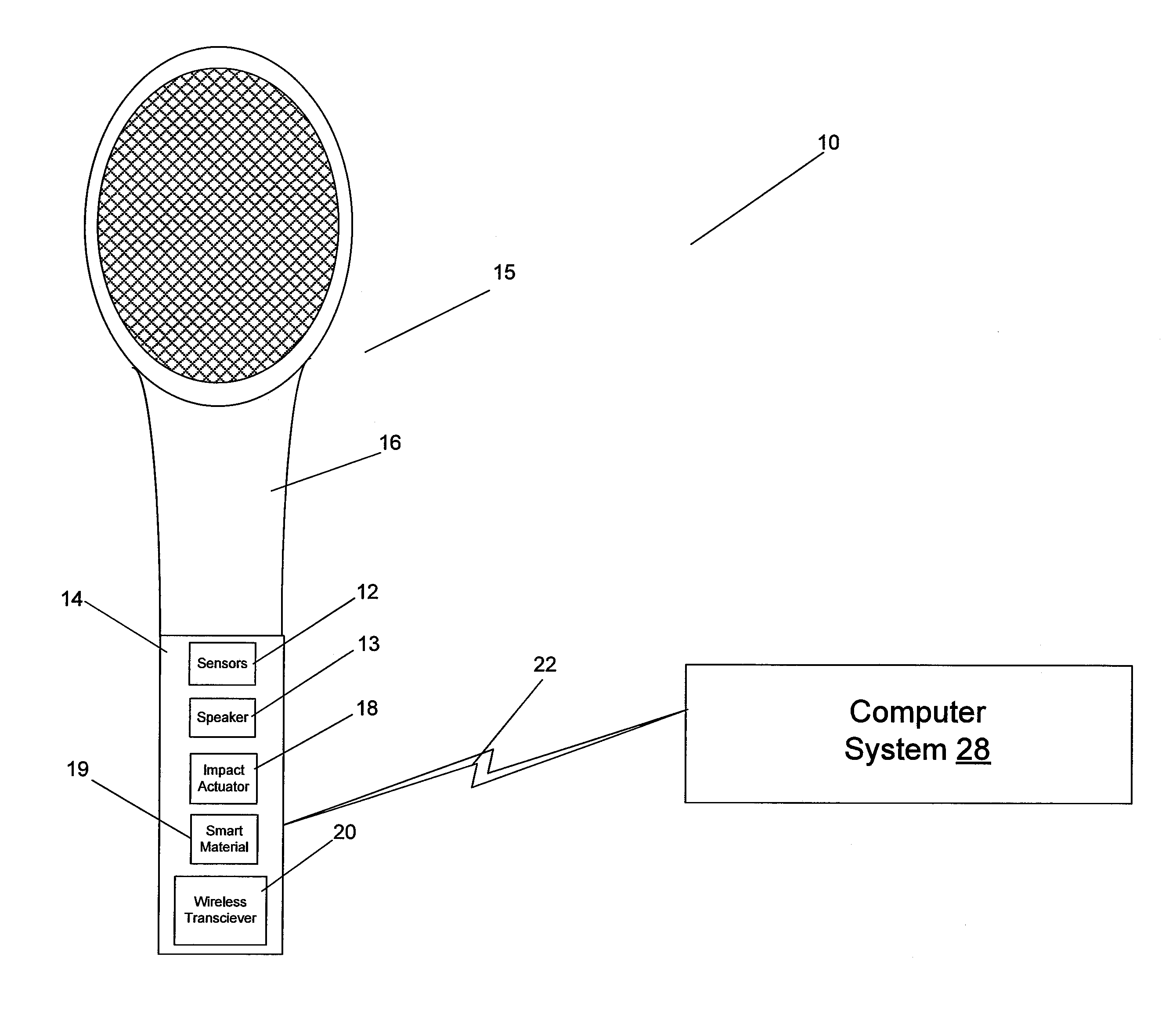

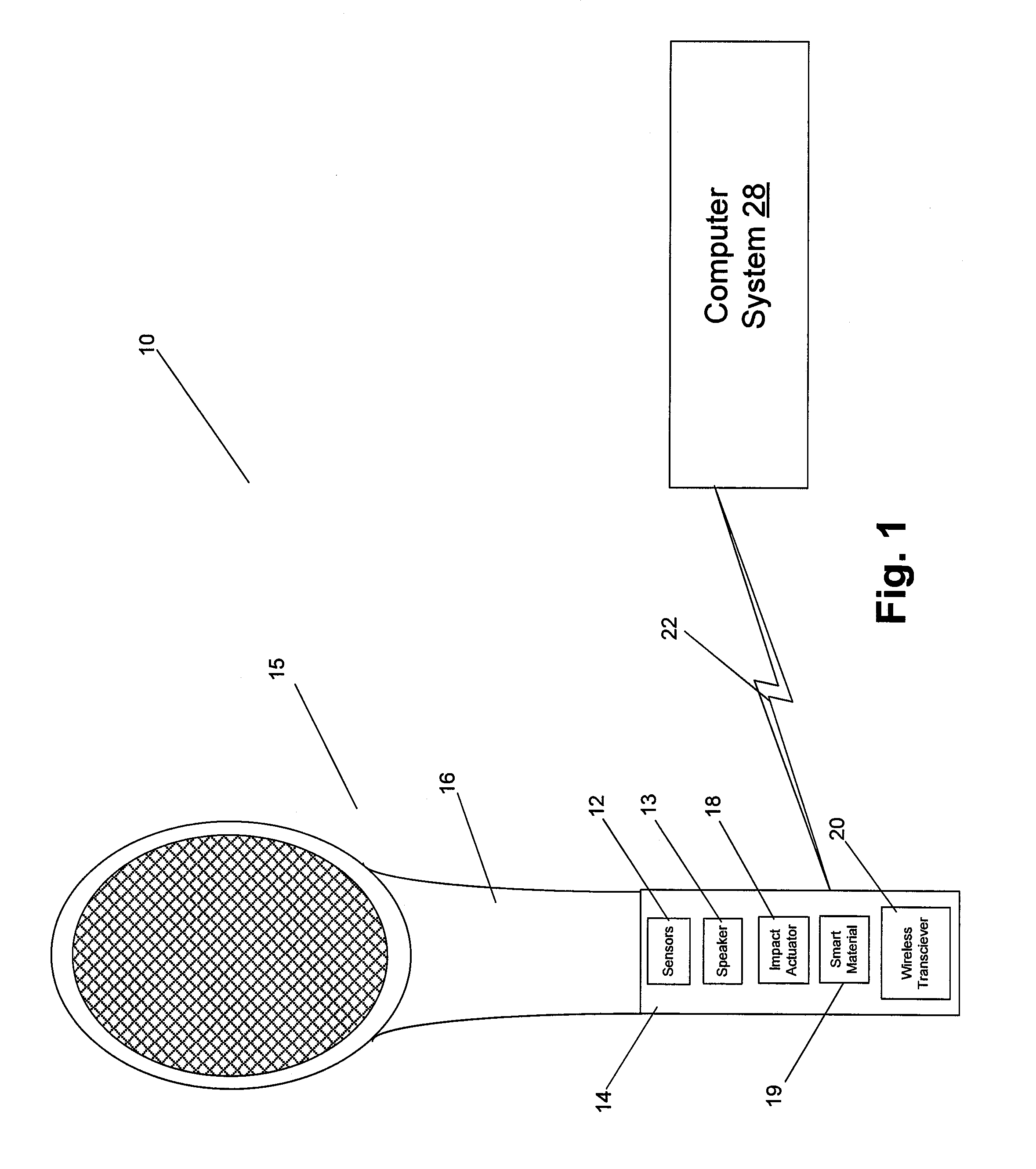

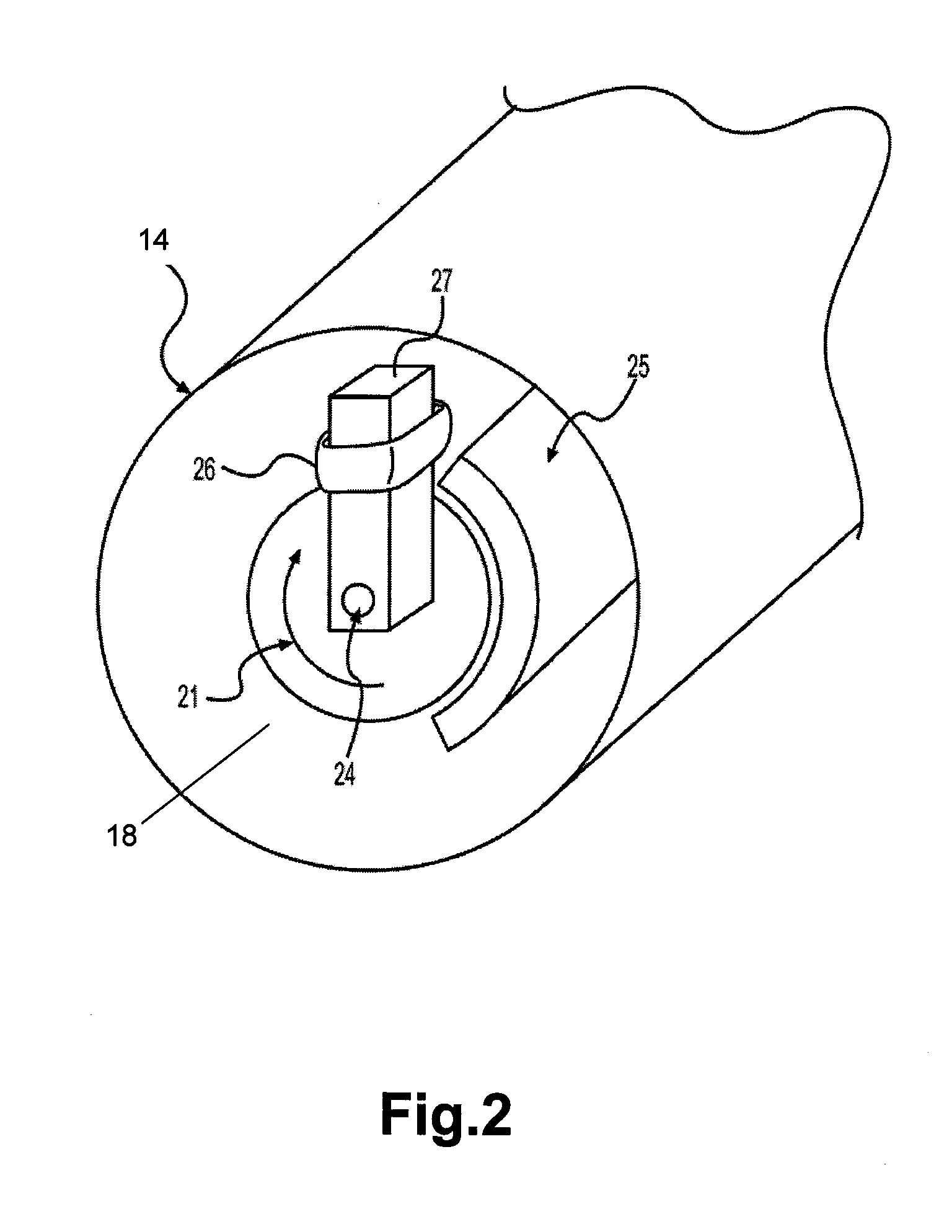

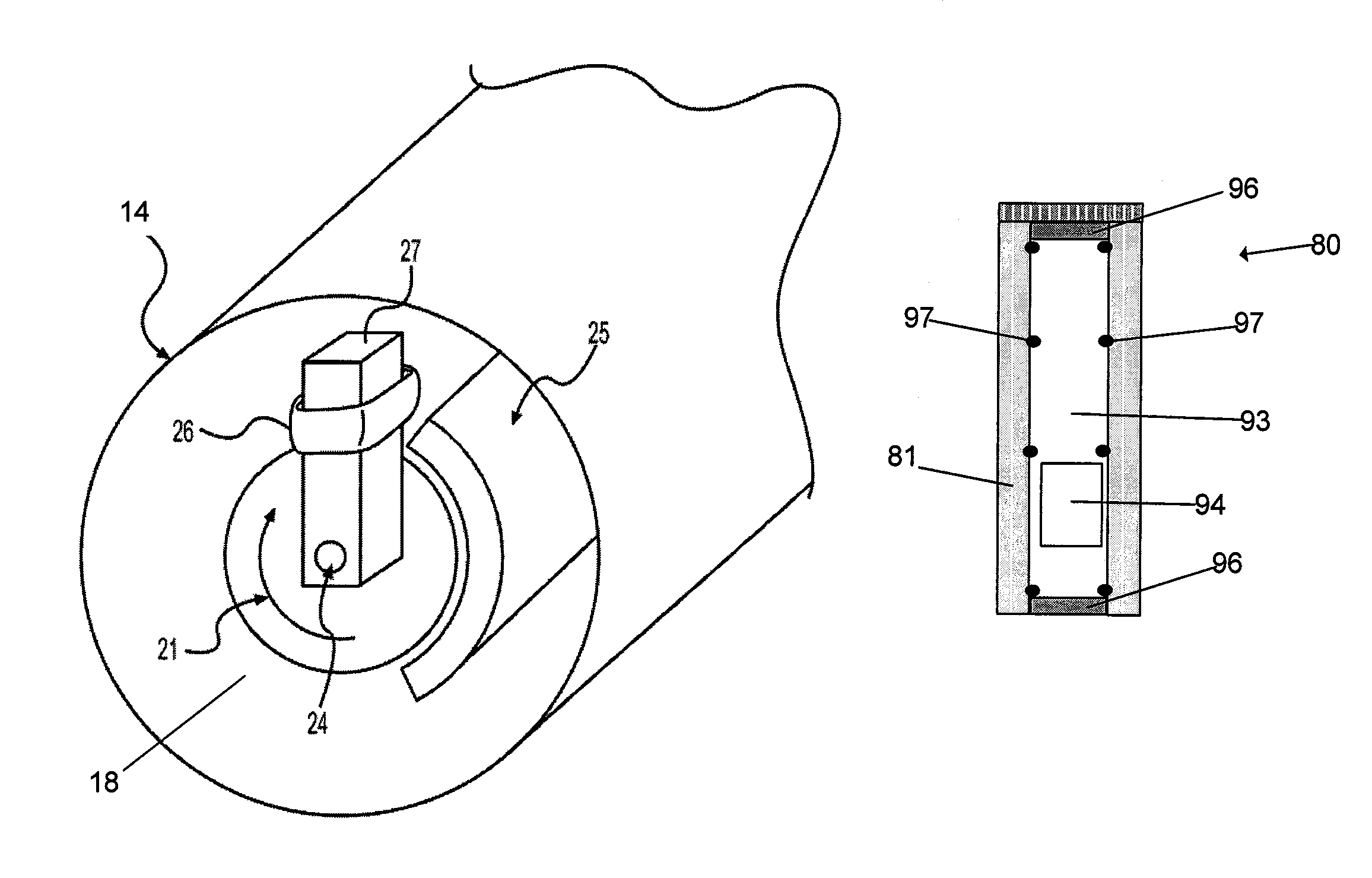

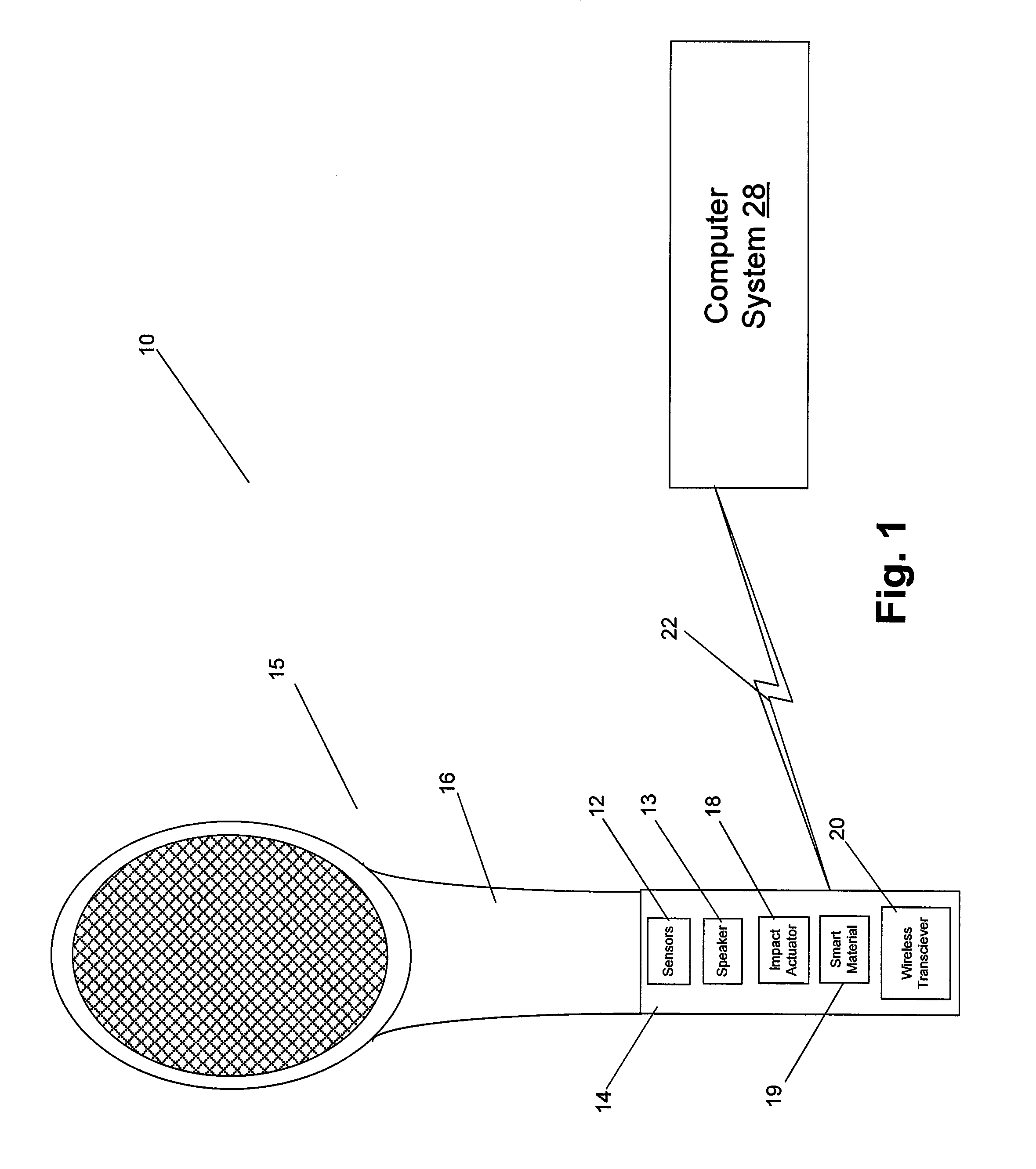

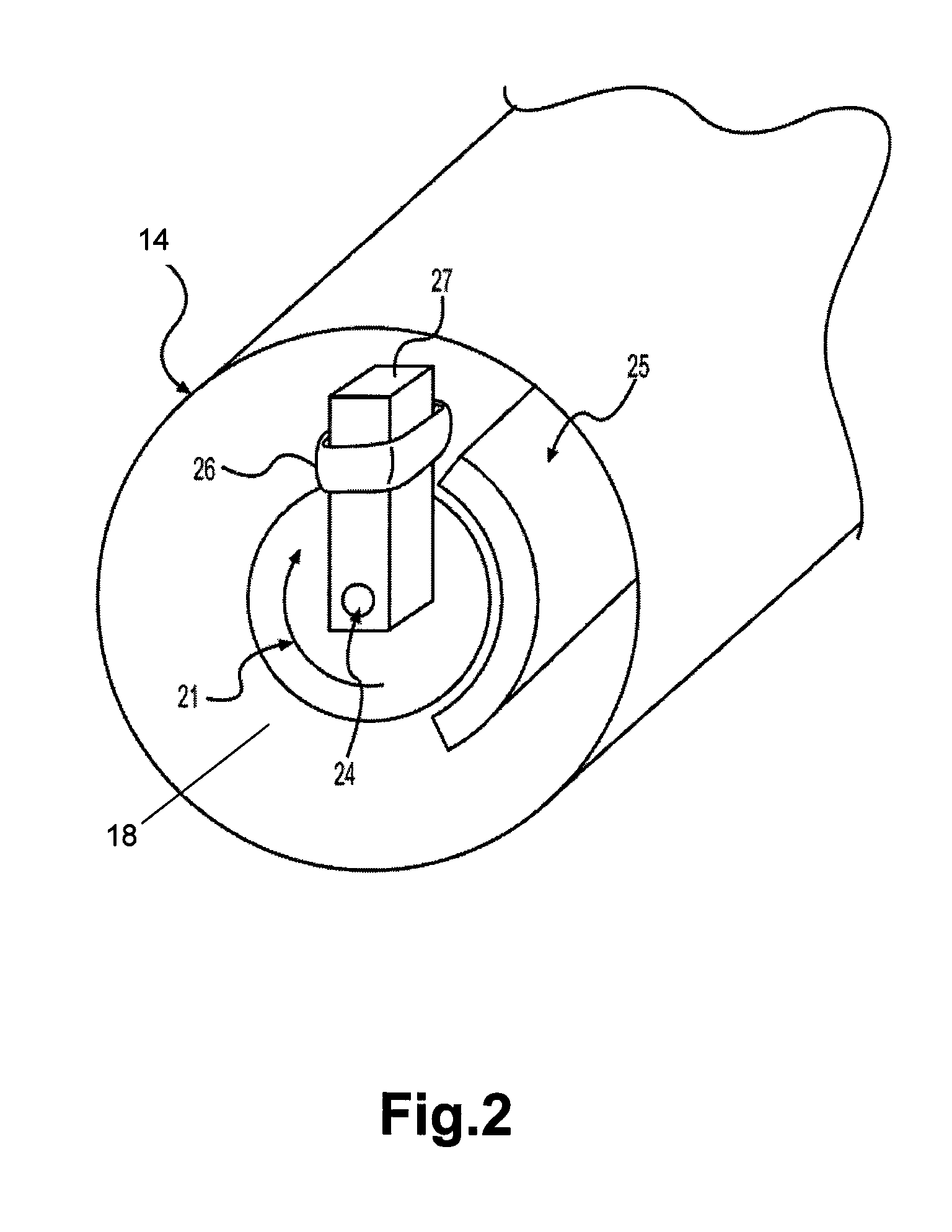

Handheld Computer Interface with Haptic Feedback

InactiveUS20110121953A1Input/output for user-computer interactionIndication apparatusHand Held ComputerEngineering

Various systems, devices, and methods are provided for generating an impact and / or surface haptic effect for a handheld computer interface such as a video game controller. For example, the handheld computer interface may include a handle coupled to an impact actuator. The impact actuator includes a movable mass and an end stop. The impact actuator may receive a haptic effect signal and in response cause the mass to contact the end stop to generate a haptic effect. A smart material that outputs a surface haptic effect may be coupled to a surface of the handle such that the surface haptic effect is output substantially from the smart material rather than the handle. The handle may be coupled to an end piece having a shape that simulates an object such as a tennis racket, golf club, or other object.

Owner:IMMERSION CORPORATION

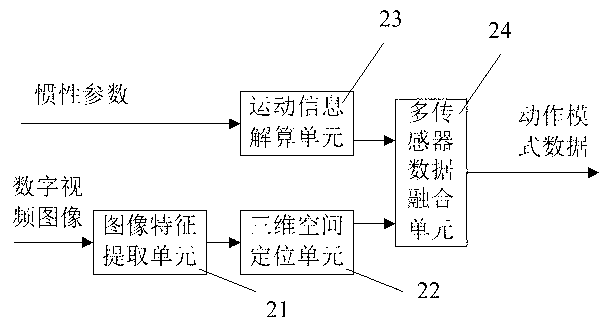

Tennis motion capturing and analyzing method

InactiveCN103106411AExtended TrackingHigh precisionCharacter and pattern recognitionSport apparatusDigital videoMultiple sensor

A tennis motion capturing and analyzing method is characterized by comprising the steps of binding a mark point and a tennis racket, installing a camera on the dead ahead of a motion area, wherein the camera is used for capturing images of a motion area and obtaining inertia parameters of motion of the tennis racket mark point, collecting a digital image of the tennis racket, inputting the digital image to a general-purpose computer, obtaining a digital video image of motion of the tennis racket, collecting the inertia parameters of the motion of the tennis racket mark point, resolving the collected inertia parameters and the digital video image, fusing data of multiple sensors, obtaining a motion mode of the tennis racket mark point, identifying a motion pattern according to the motion mode of the tennis racket mark point, and identifying and analyzing captured motions.

Owner:徐玉文

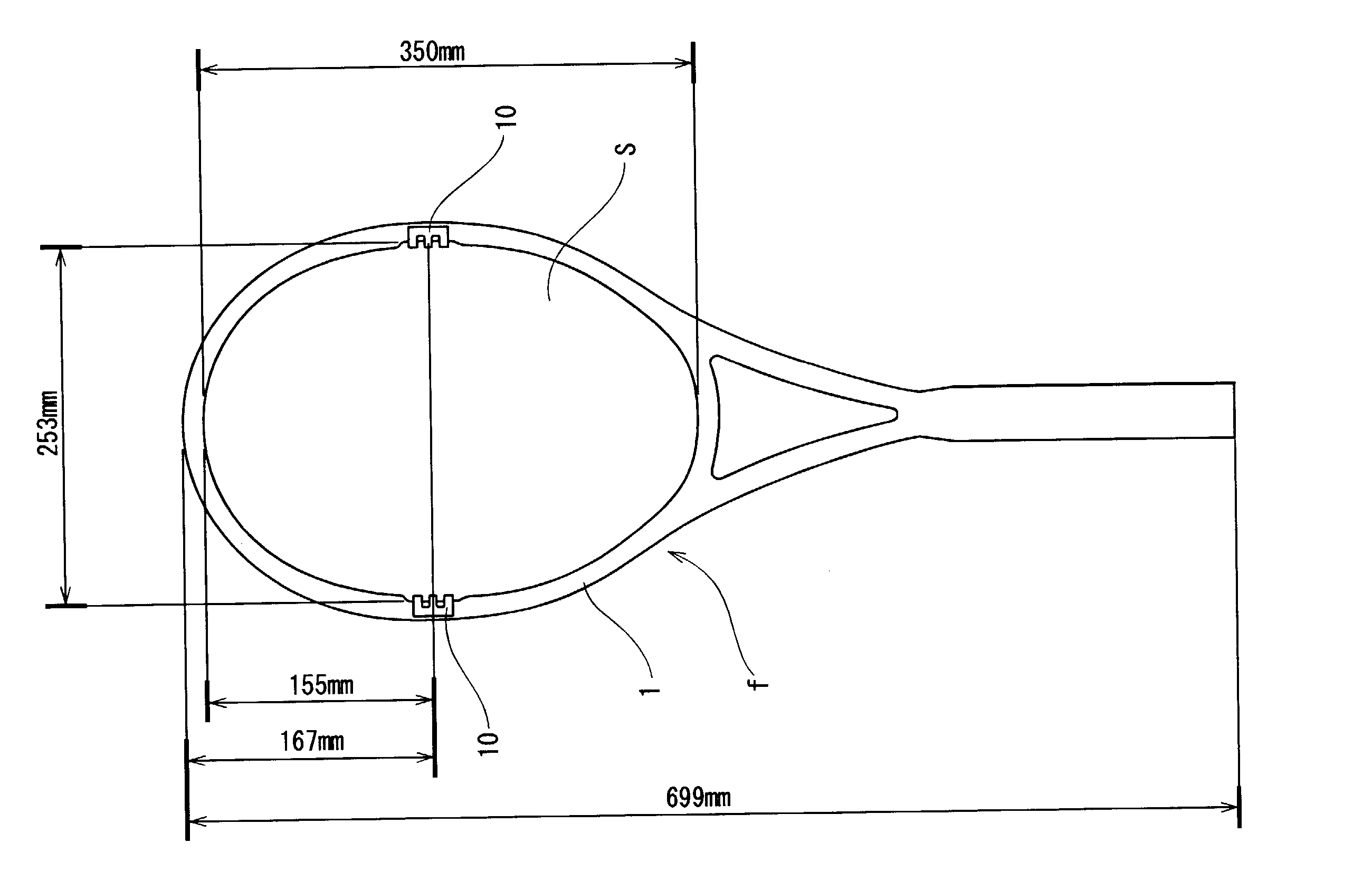

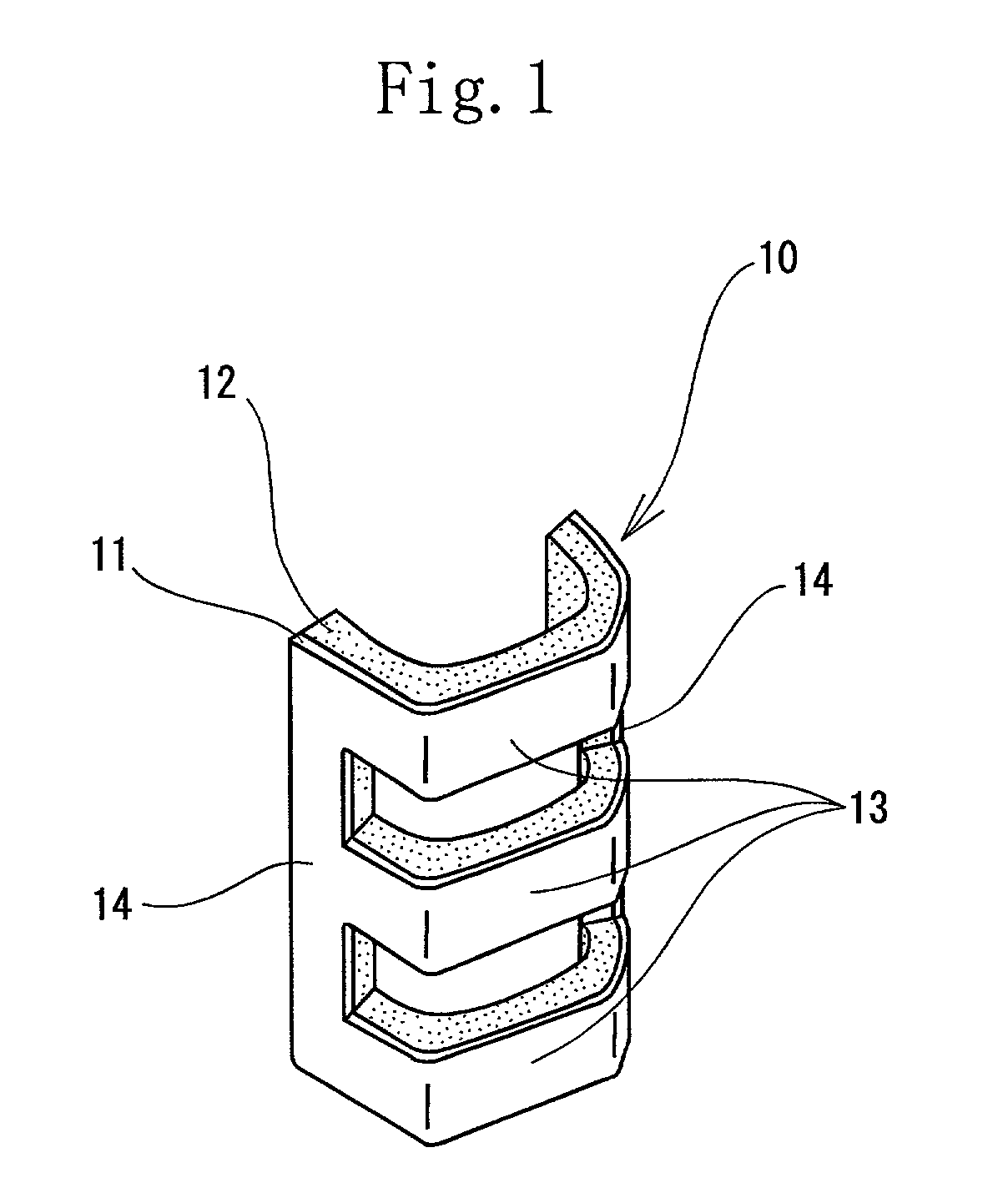

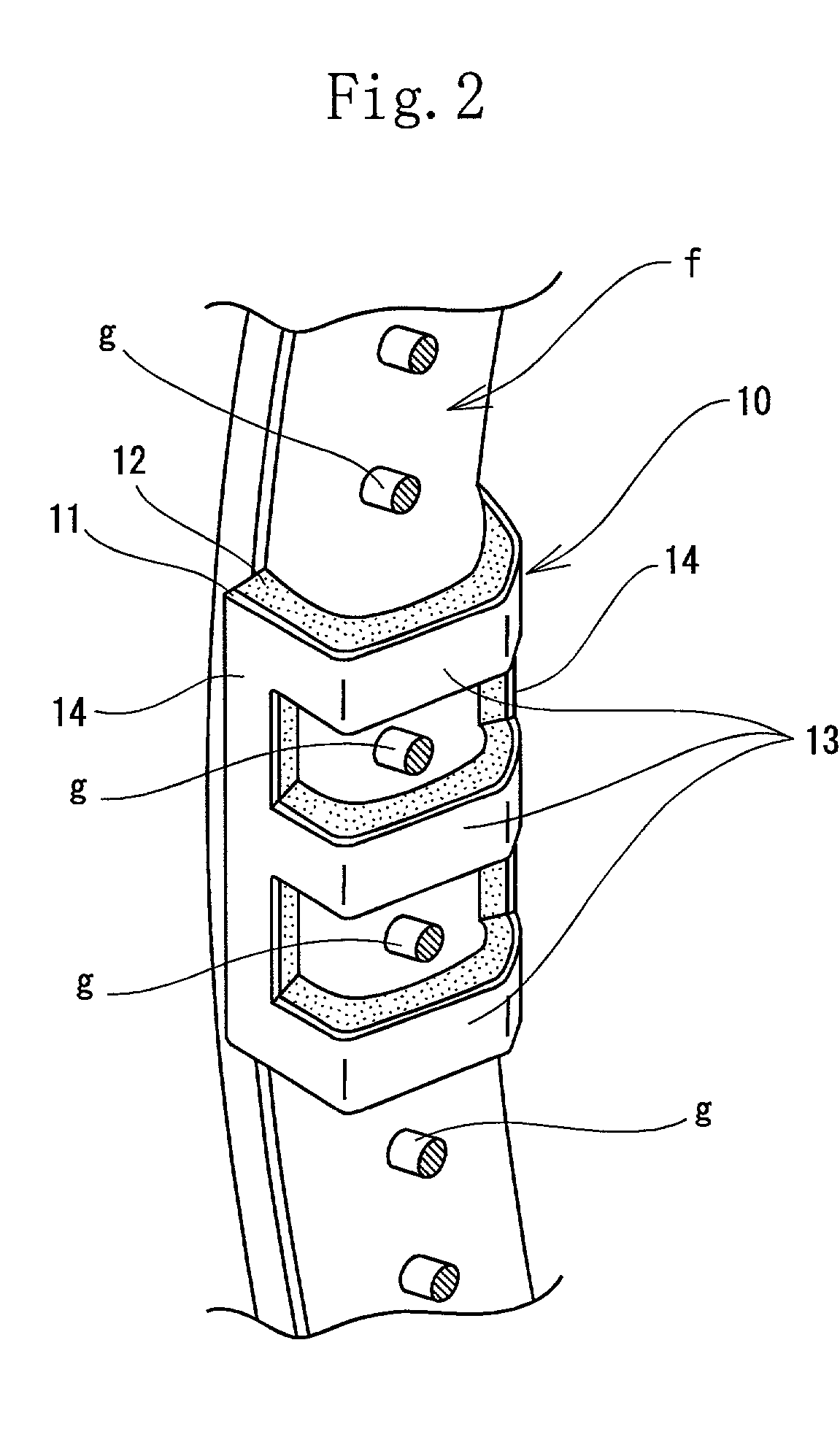

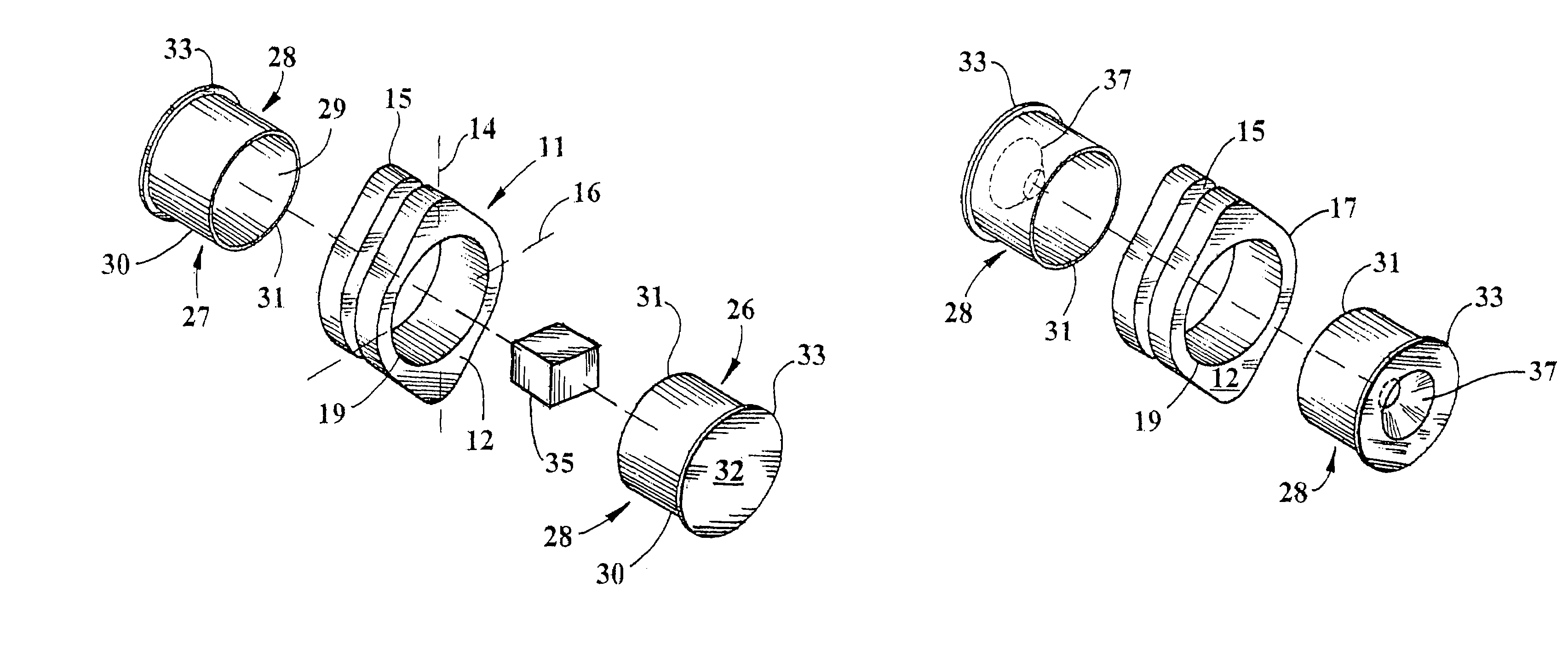

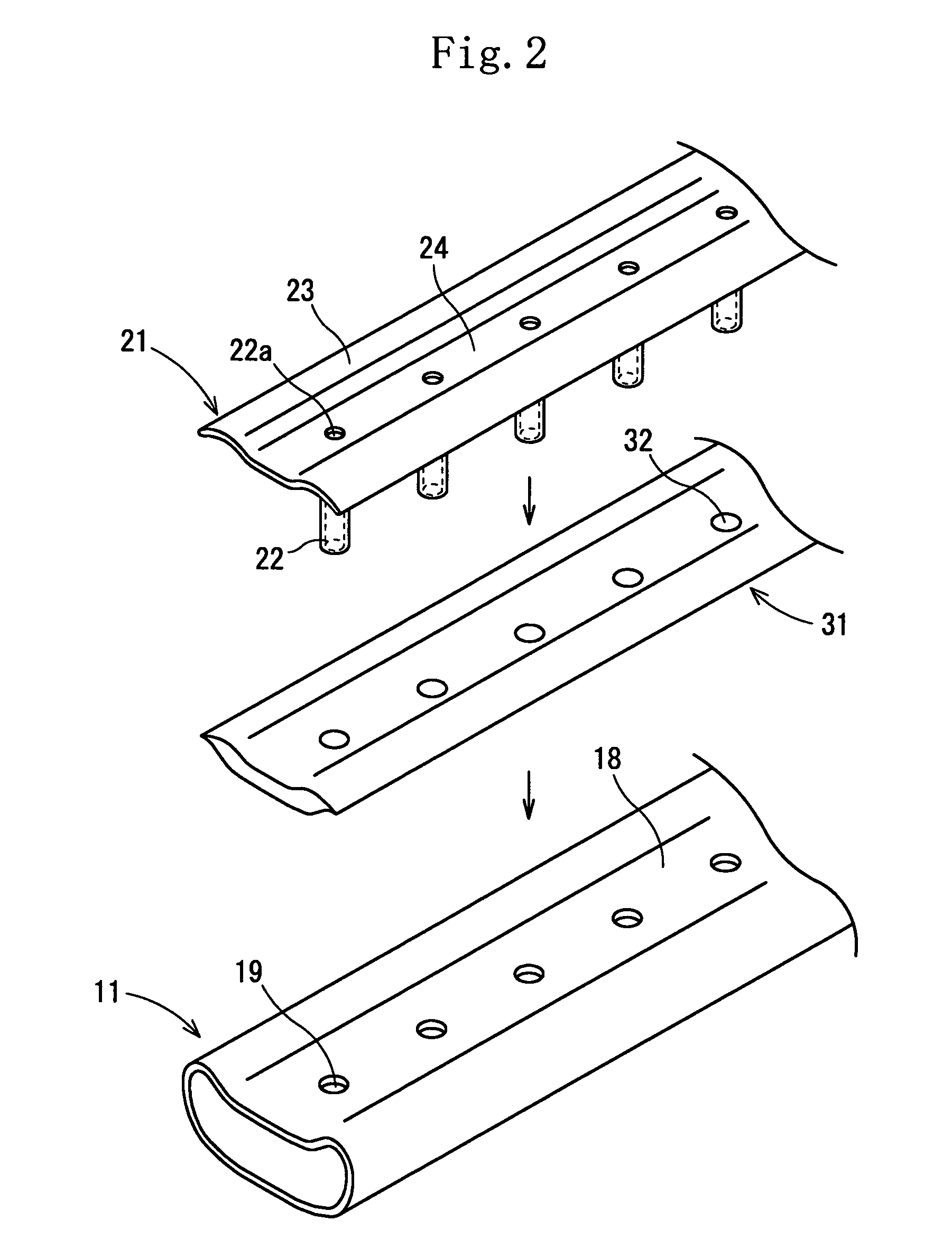

Dynamic damper and dynamic damper-installed tennis racket

InactiveUS20020058557A1Reduce the burden onFeel goodNon-rotating vibration suppressionStringed racketsClassical mechanicsTennis racket

A dynamic damper (10) having a viscoelastic part (12) and a mass-adding part (11) laminated on the viscoelastic part (12). The dynamic damper (10) has a horizontal frame (13) and a vertical frame (14) disposed at both sides of the horizontal frame (13) in such a way that the horizontal frame (13) and the vertical frame (14) continuous with the horizontal frame (13) in the shape of a lattice. The horizontal frame (13) and the vertical frame (14) are integral with each other or separately provided in the shape of a lattice.

Owner:DUNLOP SPORTS CO LTD

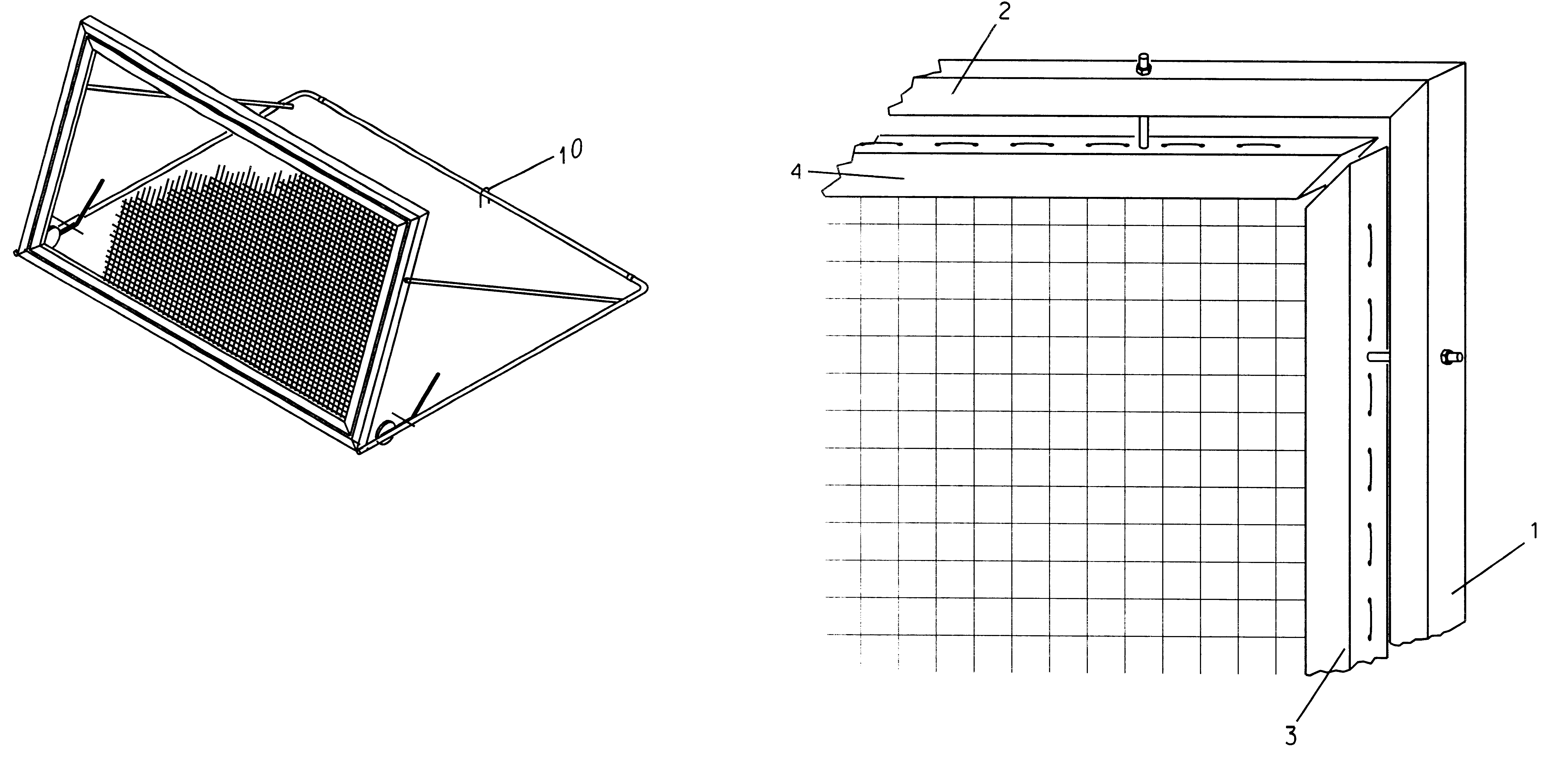

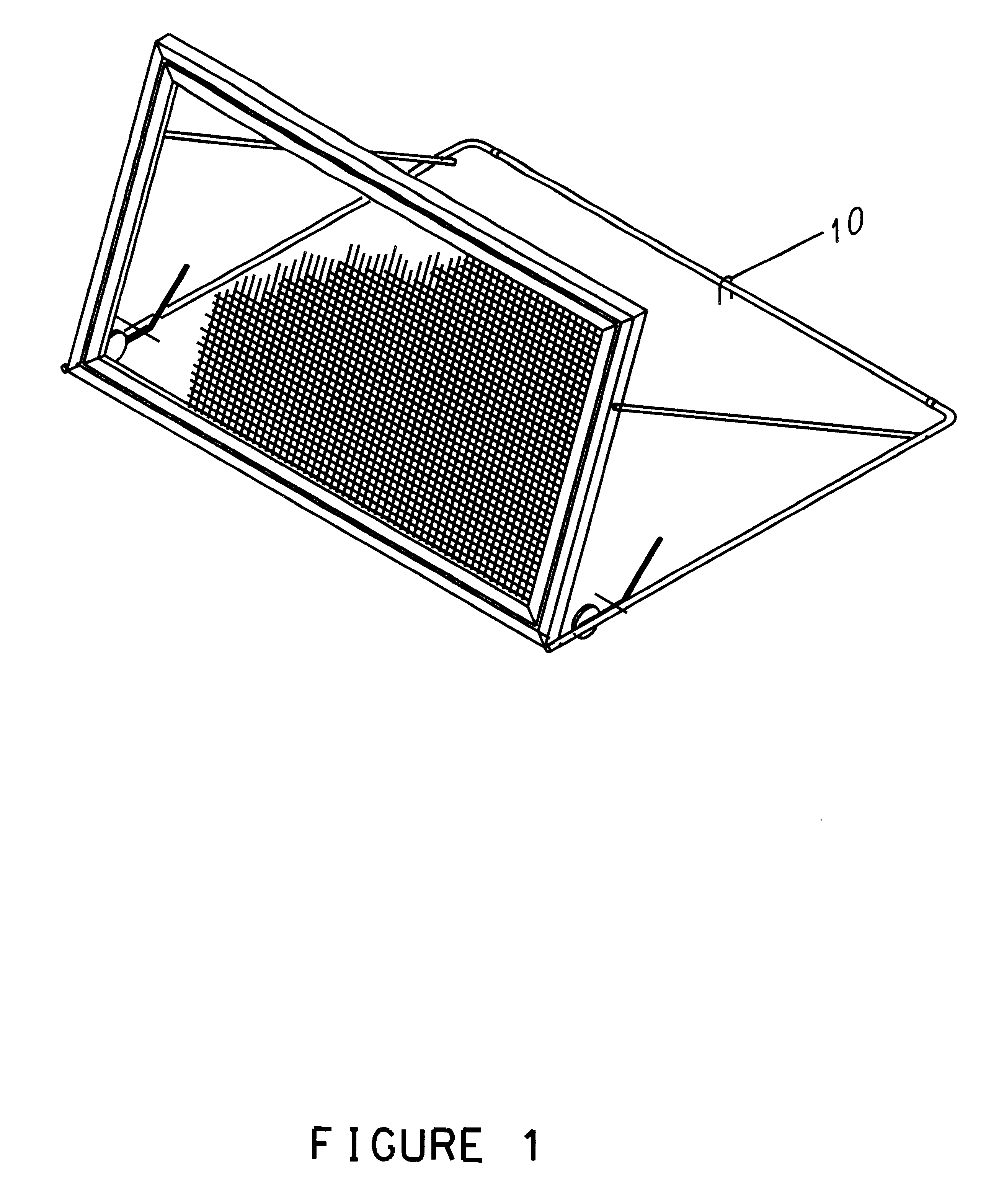

Ball rebound device

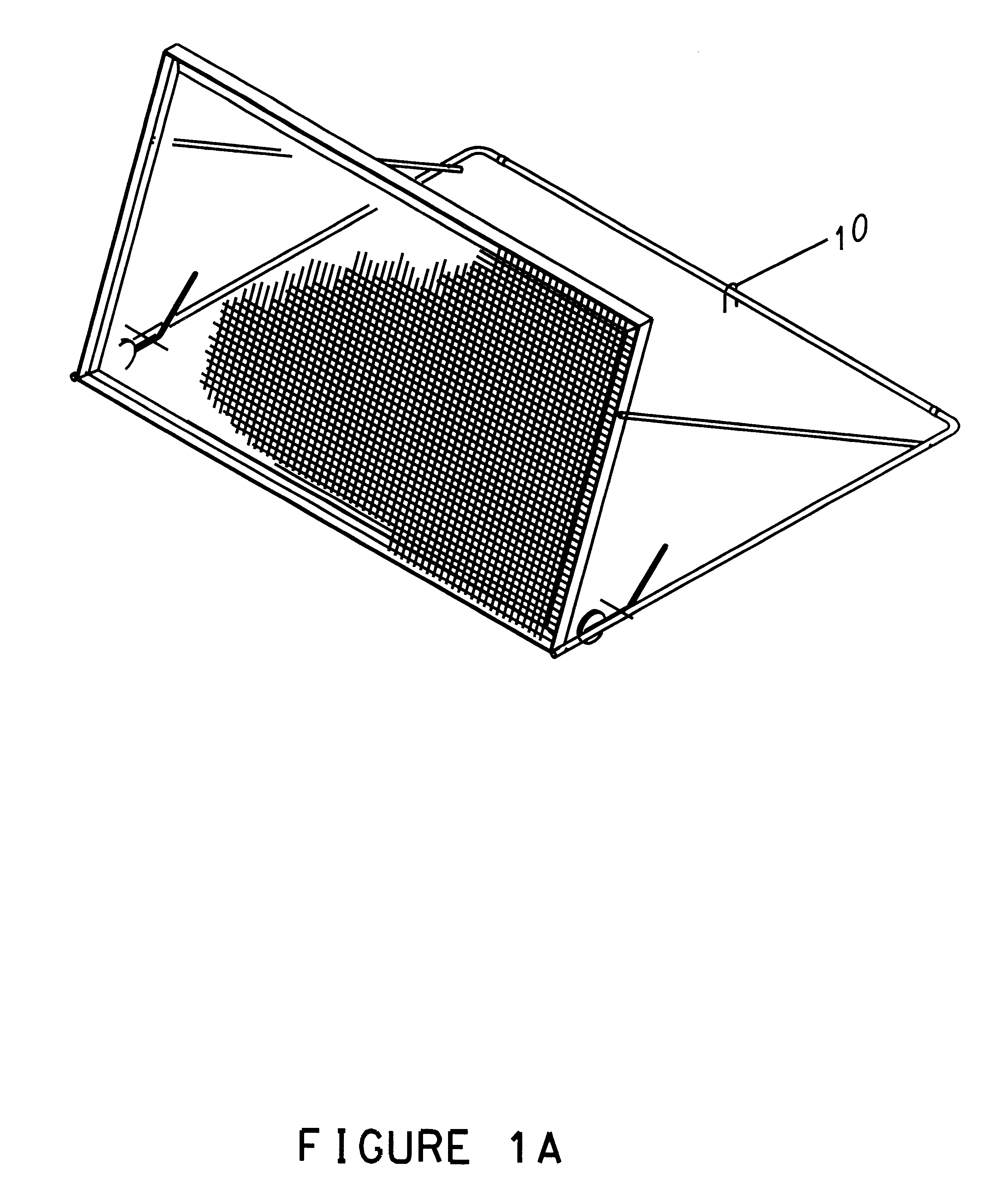

An improved ball rebound device which will deliver a playground type ball such as a soccer ball, basketball, or kick ball which is propelled against the device, back to the user with surprising speed and distance. This ball rebound device utilizes a series of monofilament nylon elastic cords which are independently stung back and forth in a basket-weave fashion within a rectangular frame as a tennis racket is strung. This enables the device to more efficiently convert the kinetic energy of the ball into a powerful rebound back to the user. One embodiment of the device has within its frame the capability for adjustment of the tension of the cords to keep them operating at the desired tension. Another embodiment of the device has the capability for its frame to be adjustably oriented at various angles to the user to better suit the individual practice needs of the user.

Owner:WARNICK BRUCE D

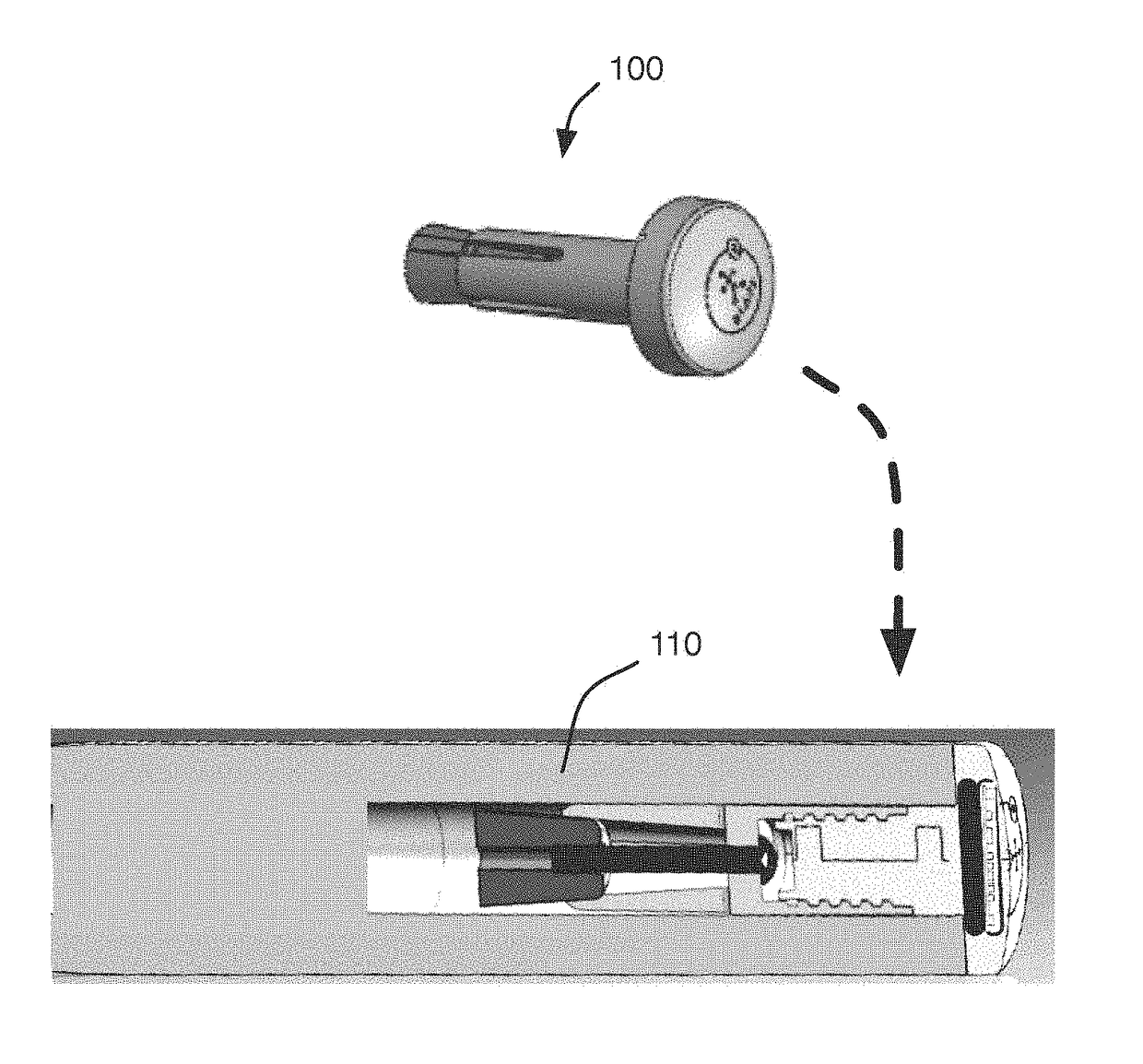

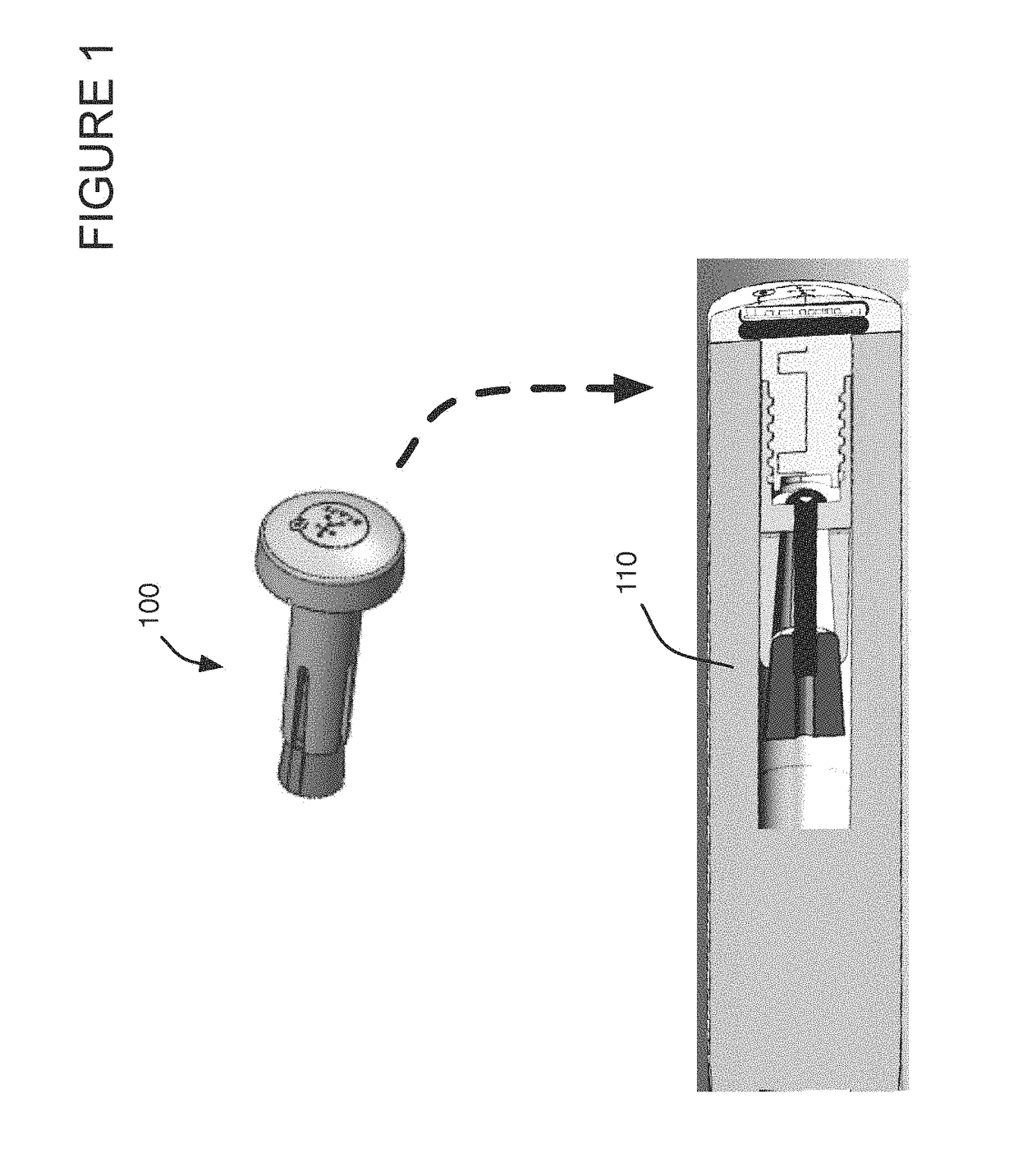

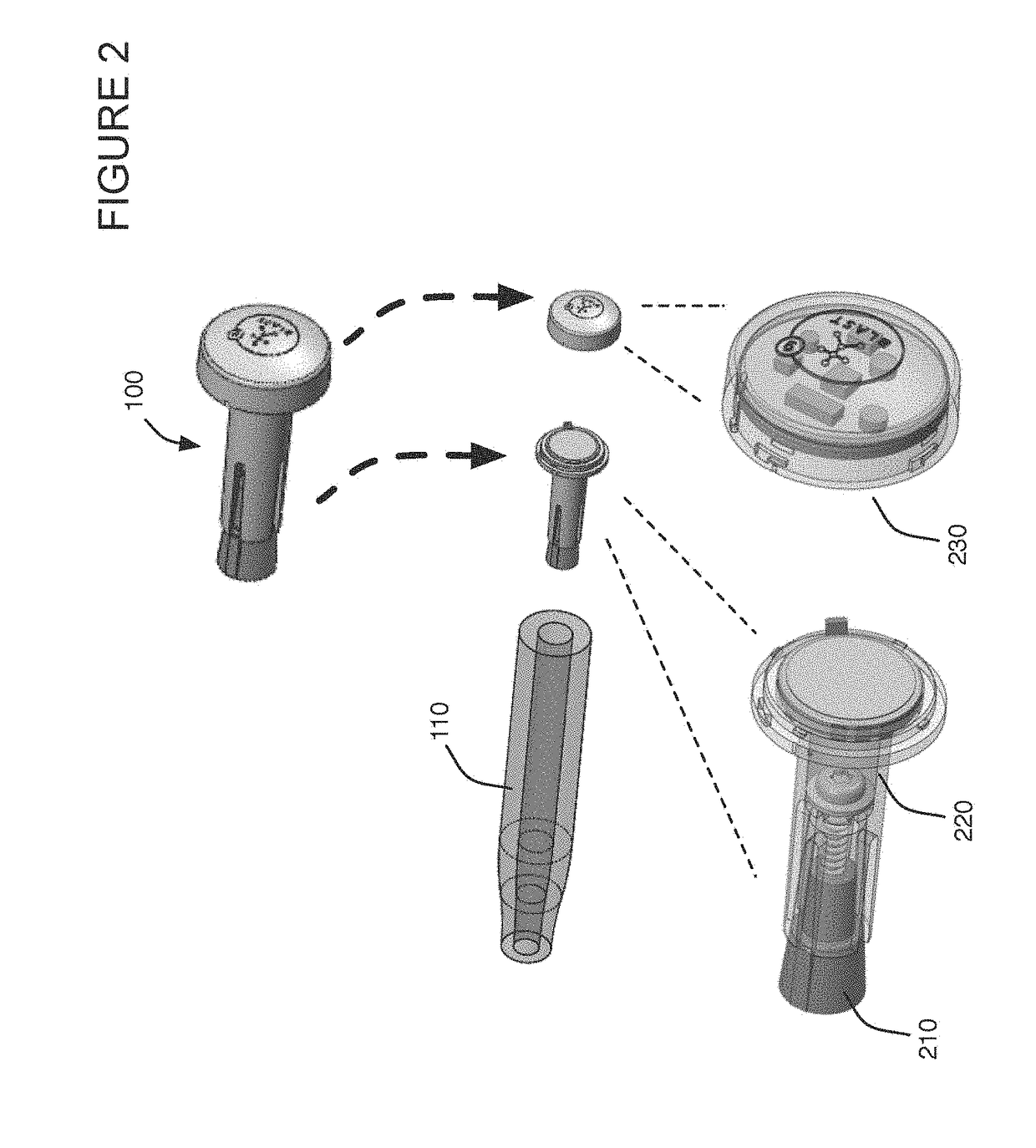

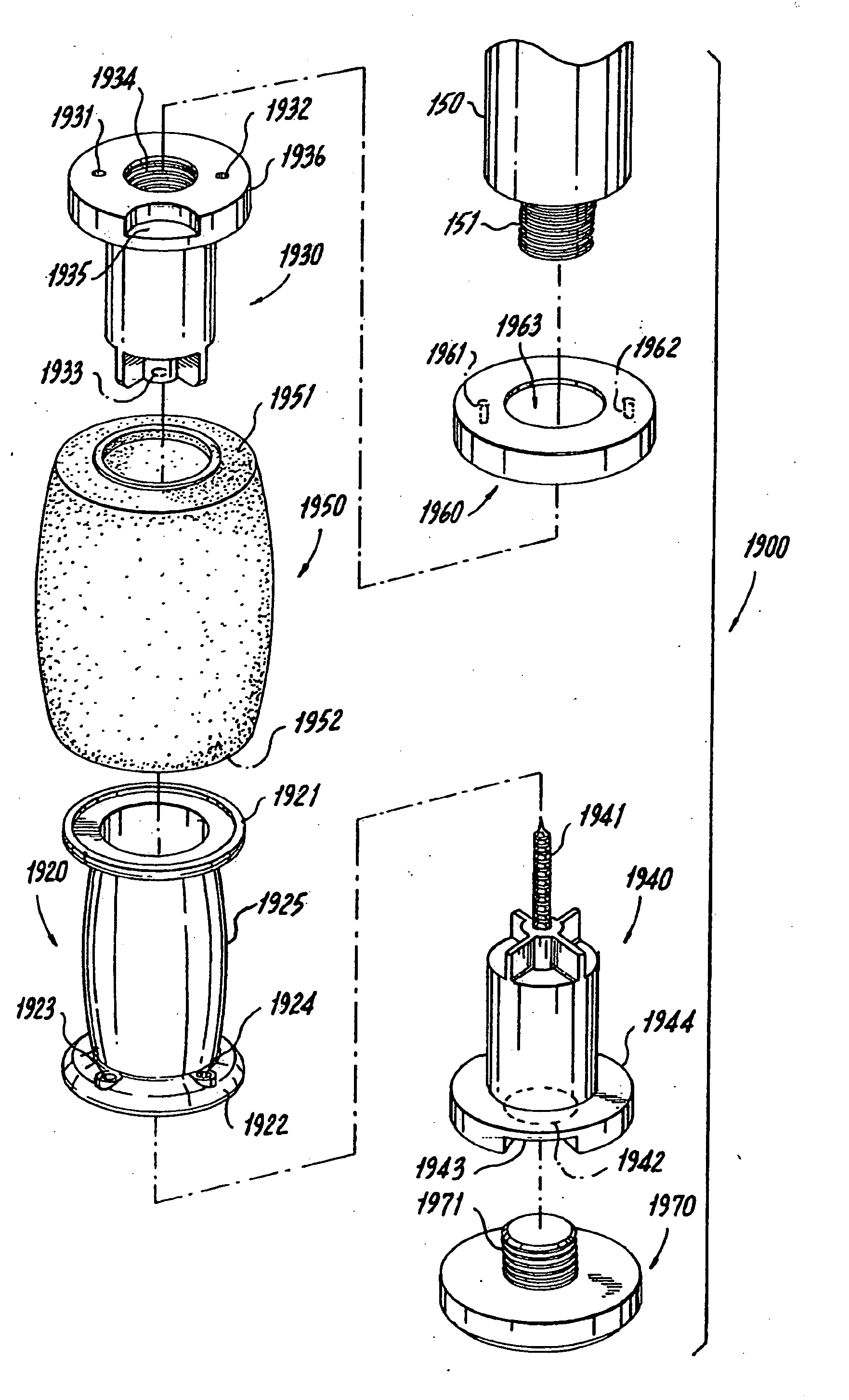

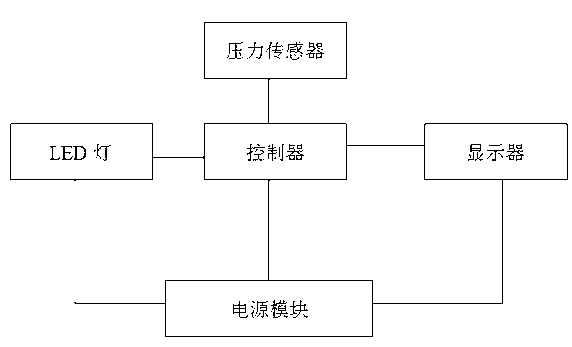

Method of coupling a motion sensor to a piece of equipment

ActiveUS20170234706A1Easy to removeEasy to replaceInertial sensorsNavigation instrumentsDegrees of freedomEngineering

Method for coupling a sensor to a piece of equipment, such as a golf club, baseball bat, or tennis racket, that ensures that the sensor is in a known position and orientation relative to the equipment. Compensates and calibrates for degrees of freedom introduced in manufacturing and installation. The method may include manufacturing a sensor receiver that aligns with equipment in a fixed orientation, and that holds a sensor housing in a fixed orientation relative to the receiver. Remaining uncertainties in sensor position and orientation may be addressed using post-installation calibration. Calibration may include performing specific calibration movements with the equipment and analyzing the sensor data collected during these calibration movements.

Owner:NEWLIGHT CAPITAL LLC

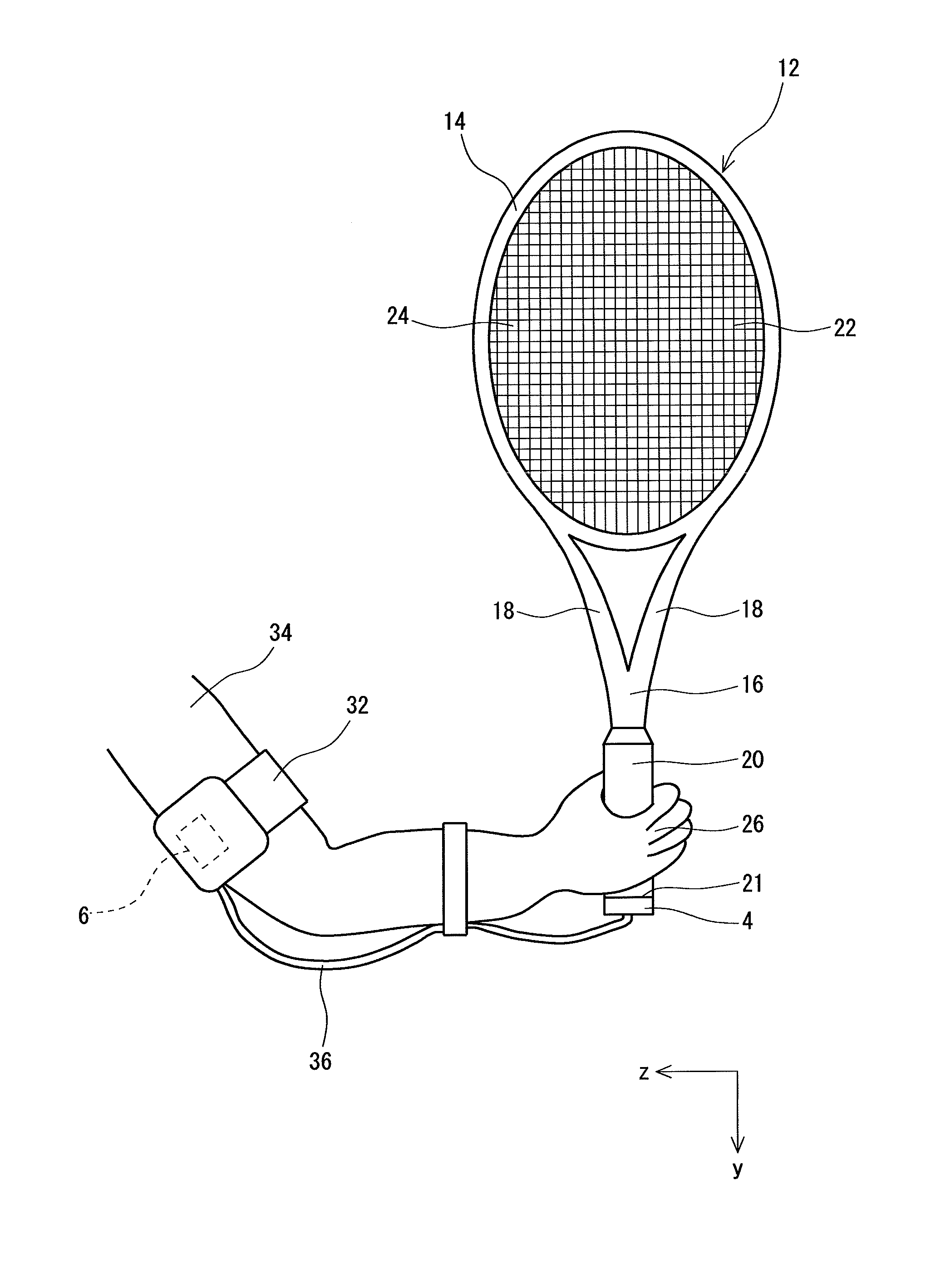

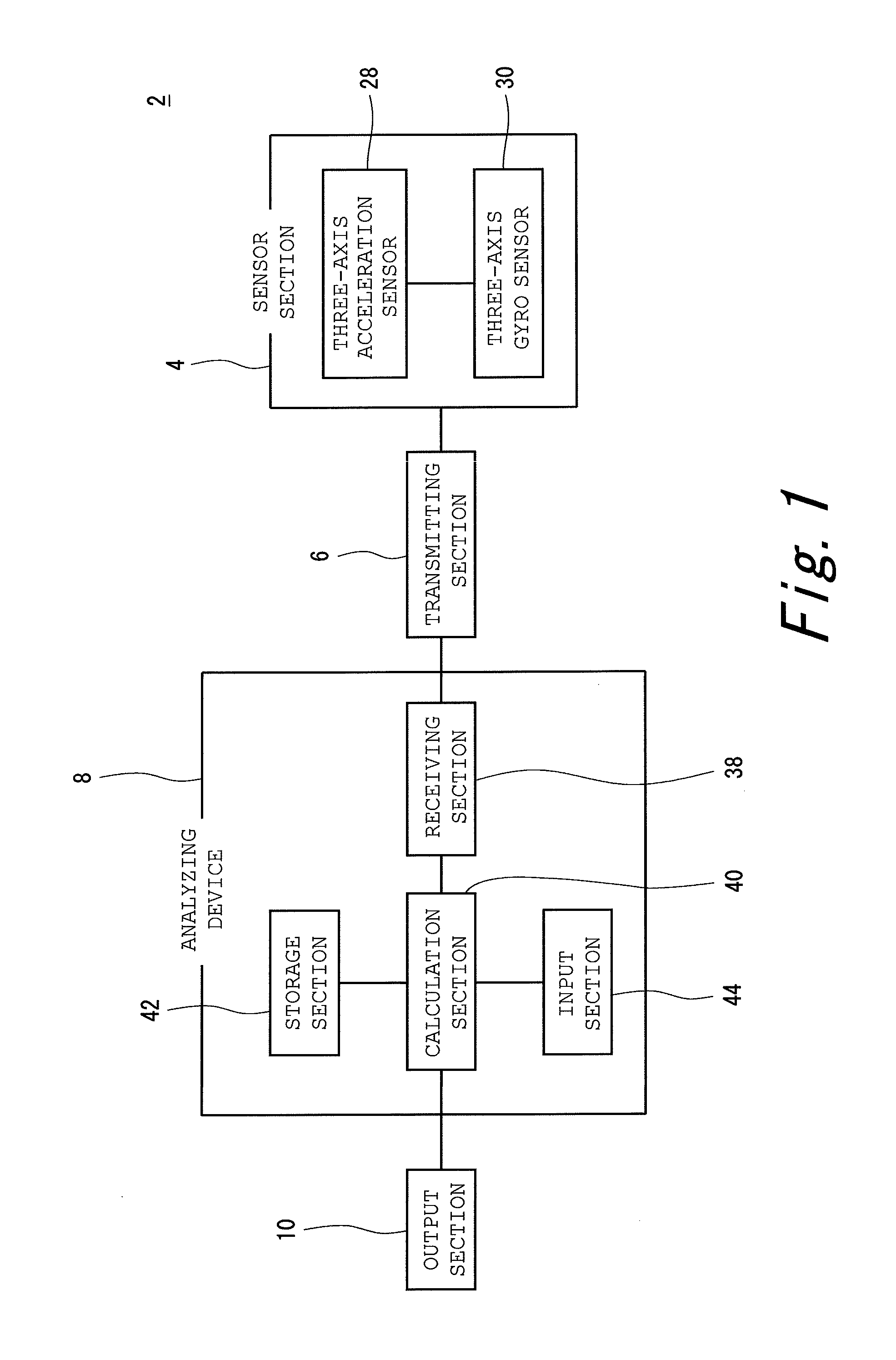

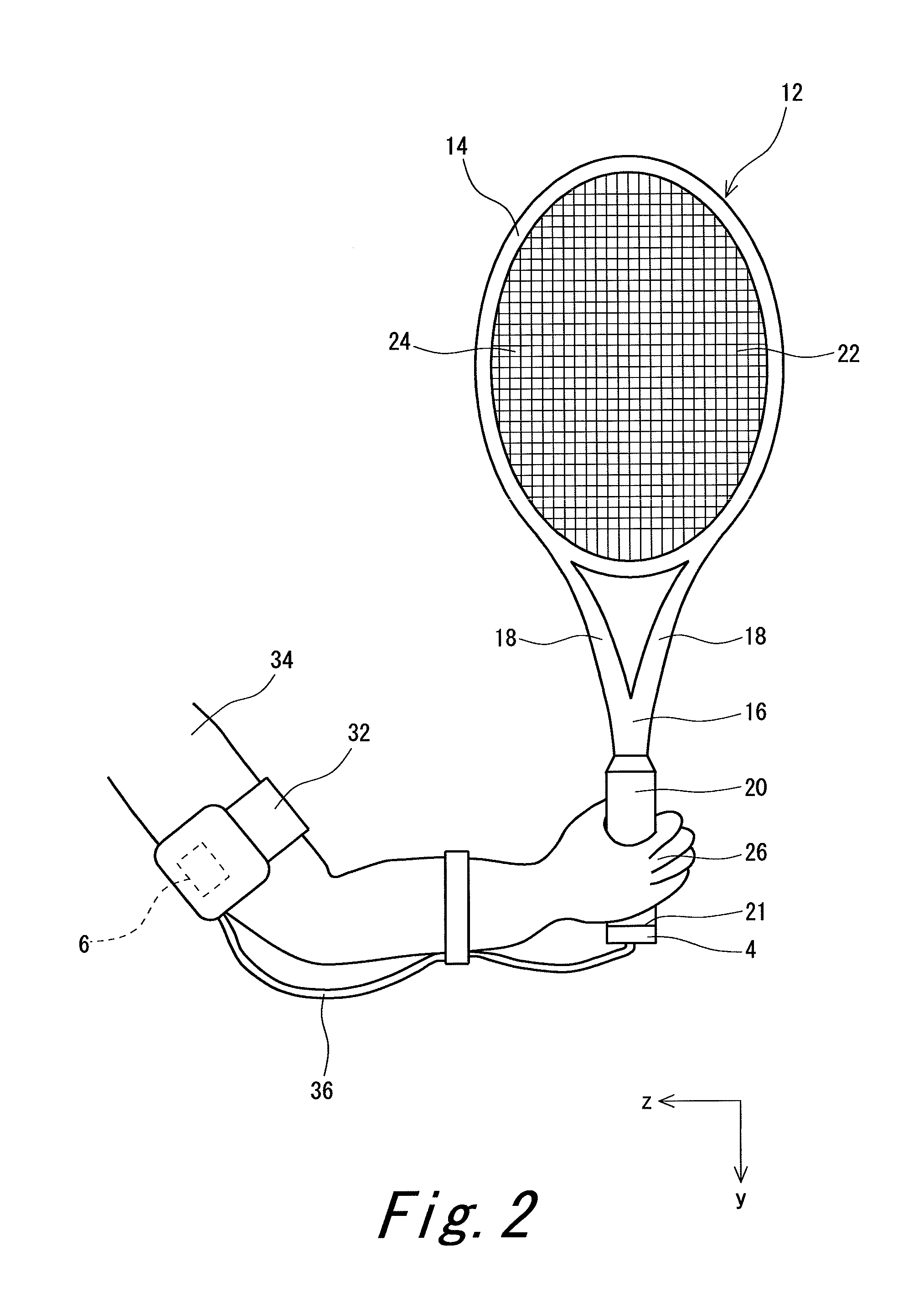

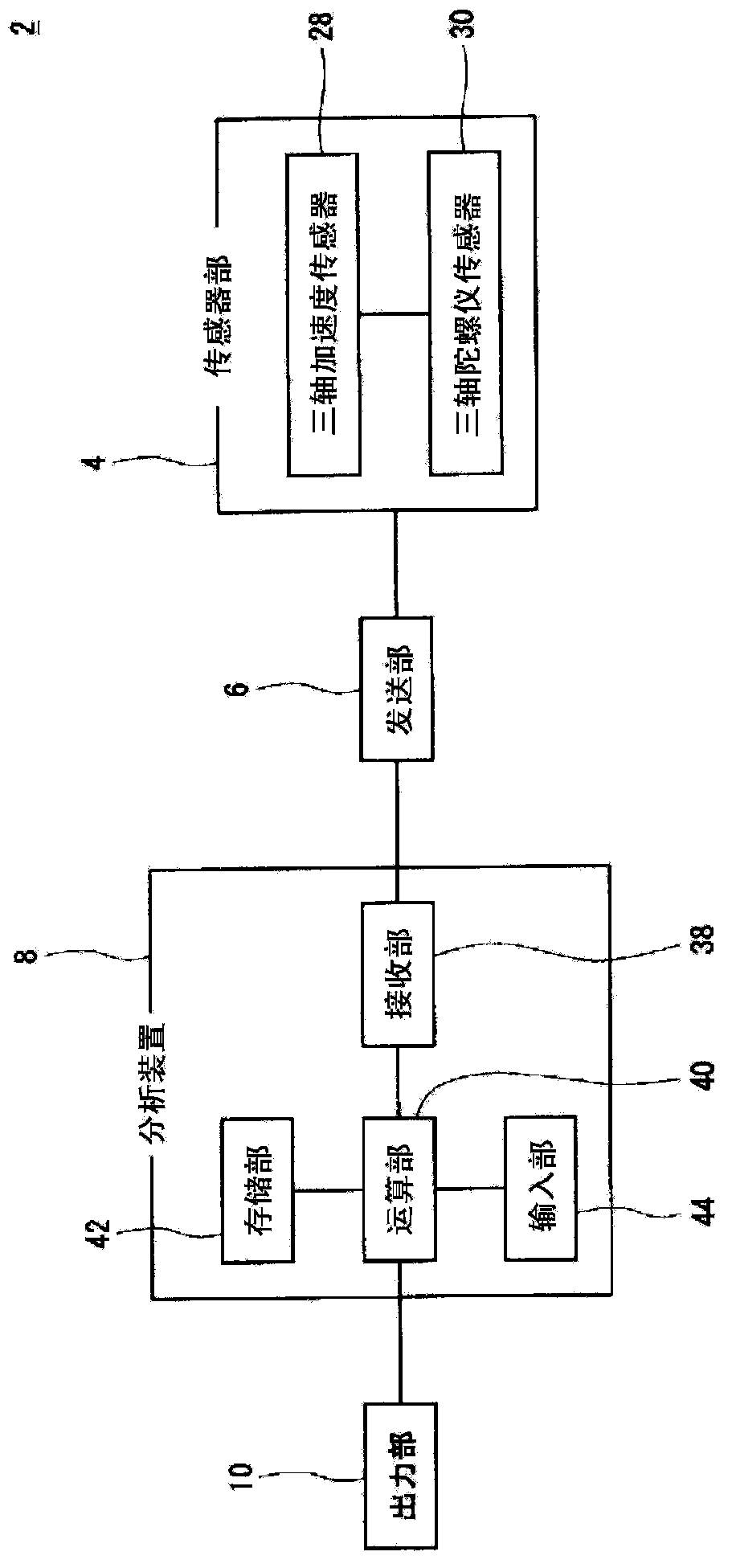

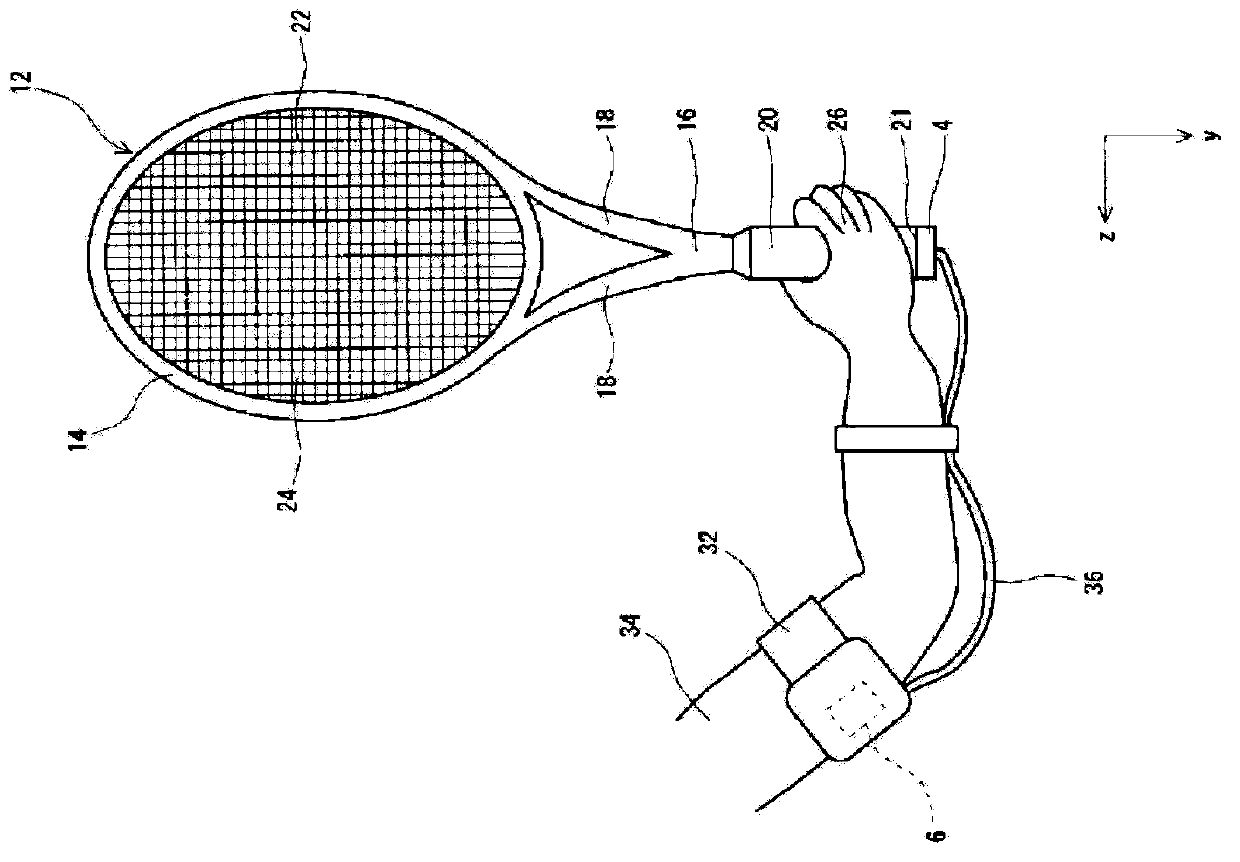

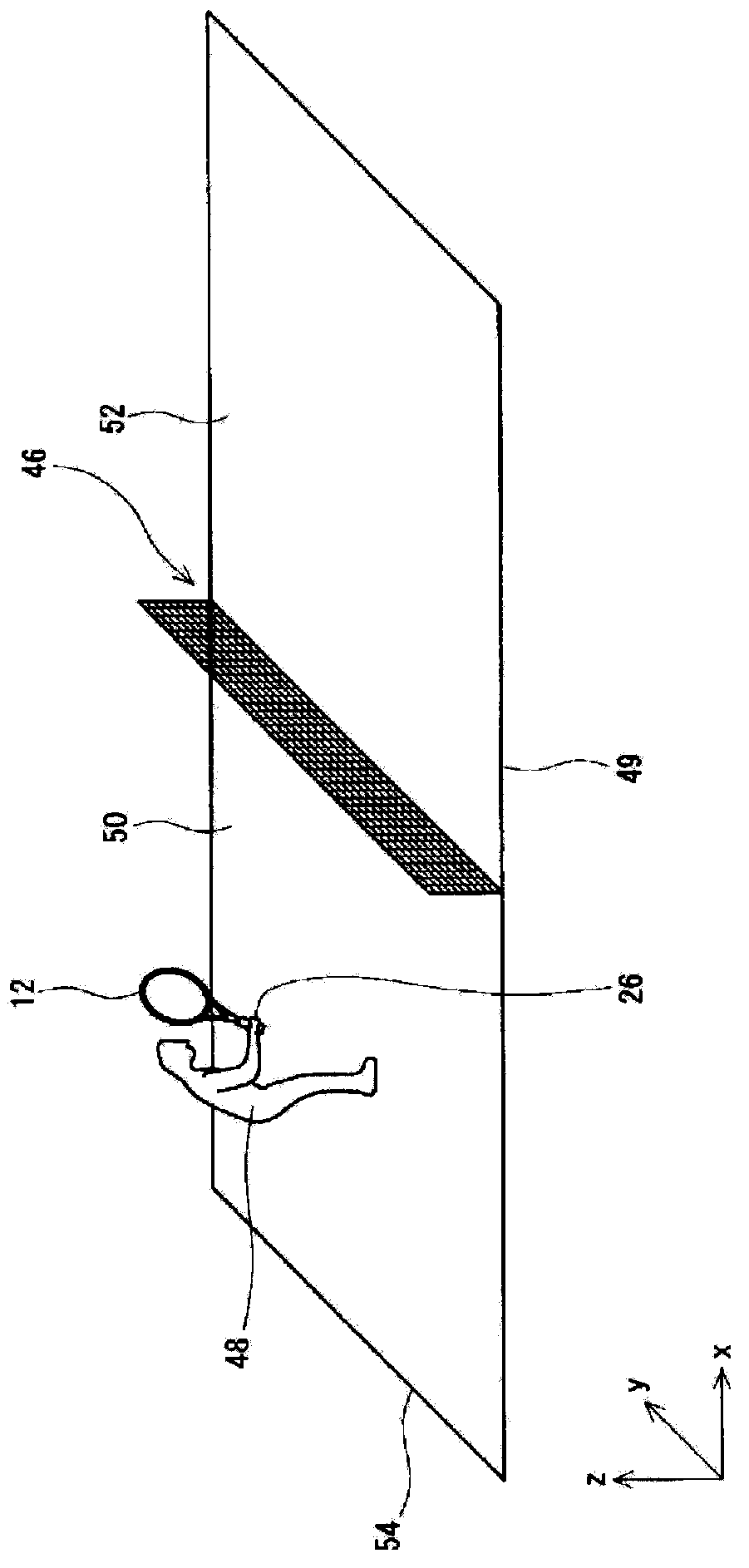

Tennis swing analysis method

ActiveUS20130095962A1Accurately analyze swingCharacter and pattern recognitionStringed racketsGyroscopeEngineering

A swing analyzing apparatus 2 includes:a three-axis acceleration sensor 28 attached to a tennis racket, for measuring accelerations in the directions of three axes when a swing for hitting a tennis ball is taken with the tennis racket;a three-axis gyro sensor 30 attached to the tennis racket, for measuring angular speeds about the three axes; andan analyzing device 8. The analyzing device 8 has a receiving function to receive data regarding the accelerations and the angular speeds from the three-axis acceleration sensor 28 and the three-axis gyro sensor 30; a coordinate axis conversion function to convert relative coordinate axes that are the three axes for the accelerations into absolute coordinate axes on the basis of the angular speeds; and a calculation function to calculate an index of the swing on the basis of accelerations resulting from the coordinate axis conversion.

Owner:SUMITOMO RUBBER IND LTD

Tennis racket with vibration damping member

A tennis racket including a vibration damping member located in the vicinity of a position of a racket frame at which a large amplitude is generated when the tennis racket hits a tennis ball. The vibration damping member includes a mass adding part, such as a bracket assembly, having a portion extending in a widthwise direction of the tennis racket and a portion extending in a thickness direction thereof such that both portions are either integral or unintegral with each other; a viscoelastic material; a spring; or / and a damper each for connecting the mass adding part to the racket frame. The vibration damping member absorbs a vibration in an in-plane and an out-of-plane direction of the racket frame, and longitudinal and rotational impacts to be applied to a handle portion of the tennis racket.

Owner:IWATSUBO TAKUZO

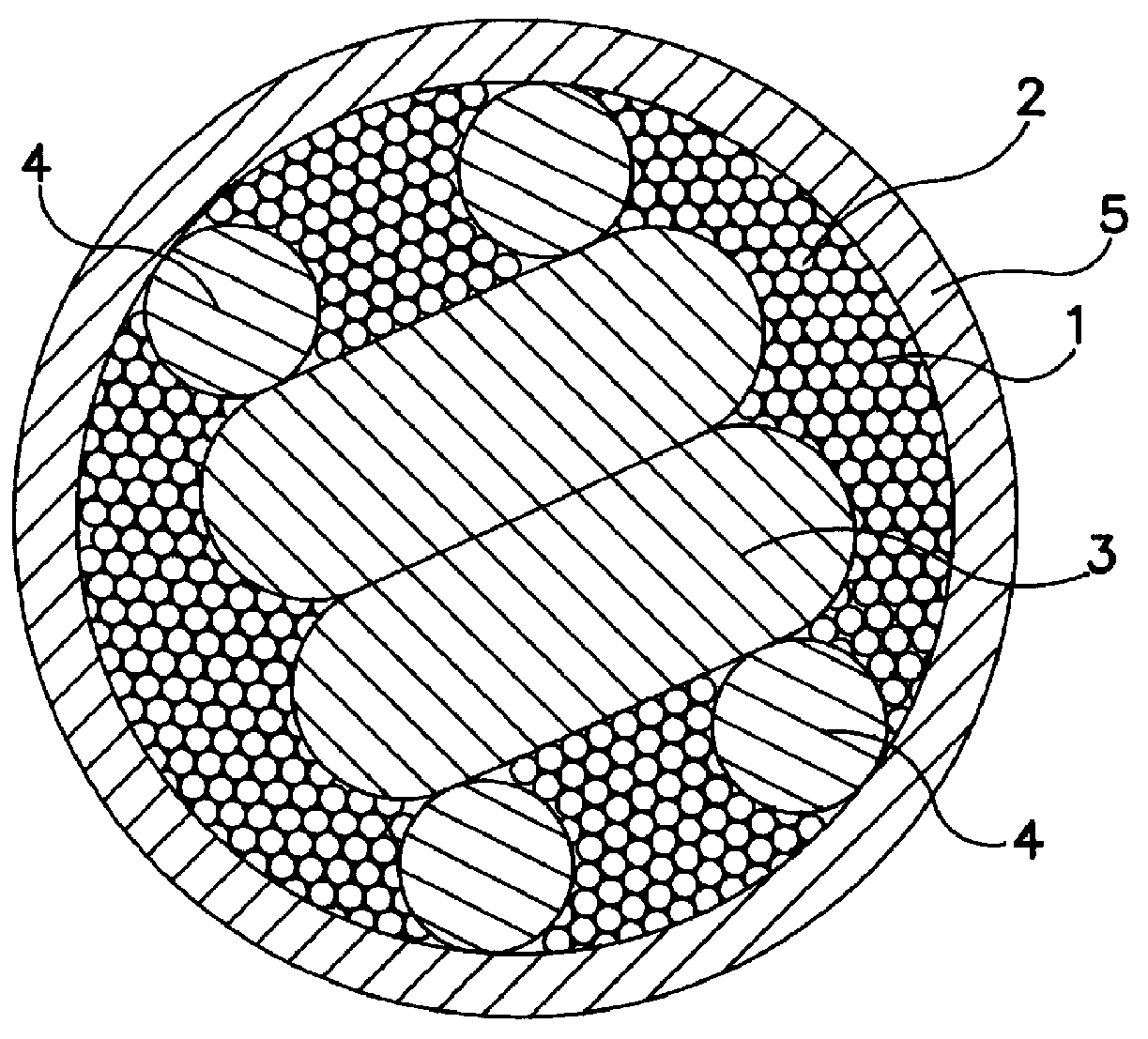

Composite synthetic string for a tennis racket

Composite synthetic string, in particular for a tennis racket. According to the invention, the string is made up of central monofilaments surrounded by mono-filament threads and by multifilament threads, the assembly being impregnated and covered in polyurethane. The string is applicable to tennis rackets having increased lifetime and that react in lively manner under the impact of a ball.

Owner:COUSIN BIOTECH R L

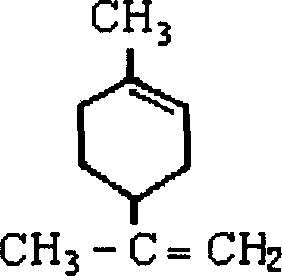

Binder in use for jointing covering rubber on table tennis bat

InactiveCN101003711AImprove solubilityShort manufacturing timeNatural rubber adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceTennis racket

This invention discloses a pressure-sensitive adhesive for rubber layer on table tennis racket. The adhesive is composed of: solvent 60-90 wt. %, rubber 8-20 wt. %, and thickening resin 2-20 wt. %. The solvent is 1, 8-terpadiene, or a mixture of 1, 8-terpadiene and one or two of ethyl acetate, methanol and ethanol. The rubber is one or two of nonpolar rubbers such as natural rubber, and polar rubbers such as polychlorobutadiene, or rubber compound. 1, 8-terpadiene used as the solvent has high solvency for rubber layer on table tennis racket, and is harmless and environmentally friendly. The adhesive, when used on rubber layer on table tennis racket, has such advantages as rapid swelling, long elasticity-enhancing effect, and simple process.

Owner:徐昊为

Black table tennis racket inverted rubber composition with high viscosity and high elasticity

The invention discloses a black table tennis racket inverted rubber composition with high viscosity and high elasticity. The composition comprises a matrix material composed of a blend of 50-100 parts by mass of a natural rubber and 0-50 parts by mass of a butadiene rubber, 1-3 parts by mass of an anti-aging agent, 1-10 parts by mass of a filler, 6-13 parts by mass of a vulcanizing activator, 1-5 parts by mass of a vulcanizing accelerator, 0.5-3.5 parts by mass of sulfur and 10-30 parts by mass of a tackifier. The composition is simple in preparation process and low in cost; the prepared table tennis racket inverted rubber has good rebound resilience and relatively high viscosity that can be kept for a long time, thereby guaranteeing fast tennis ball speed, high rotation ball-making efficiency and high control ability for the tennis balls; and at the same time, the rubber has smooth appearance without blooming phenomenon, so that the table tennis racket can be well balanced in both performance and appearance and be beneficial to athlete health.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Handheld computer interface with haptic feedback

InactiveUS8542105B2Input/output for user-computer interactionIndication apparatusHand heldHand Held Computer

Owner:IMMERSION CORPORATION

Pliable handle

InactiveUS20070074374A1Simple structureSealing is reliableTravelling carriersHoldersEngineeringTennis racket

A pliable handle includes a core member, an outer sheath, and gel disposed between the core member and the outer sheath. There is an outer annular flange around its top. The outer sheath has an opening on its top and a closed bottom, an inner annular flange on its top; and the outer sheath is disposed about the core member. Below the inner annular flange of the outer sheath and the outer annular flange of the core member define the gap portion, which is filled with gel. There is an annular flange which corresponds with the annular groove on the core member below the inner annular flange of the outer sheath. The present pliable handle can be secured to walking sticks, golf clubs, ski poles, tennis rackets, battledores, and umbrellas.

Owner:XIAMEN JUNDIAN HOUSE OMAMENTS

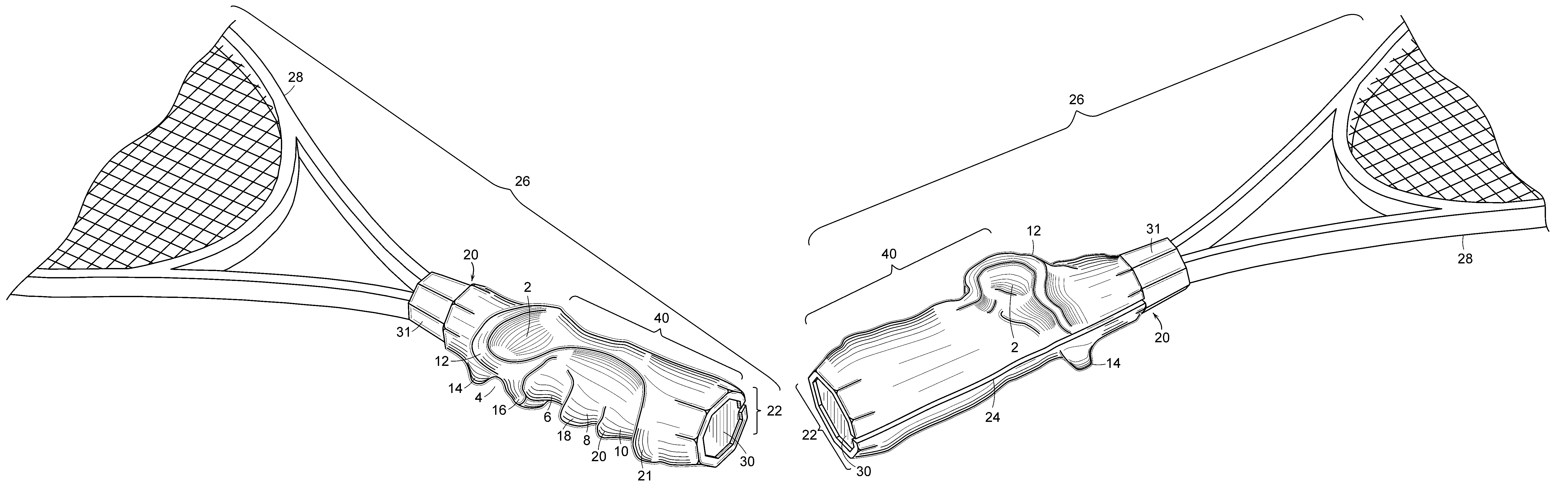

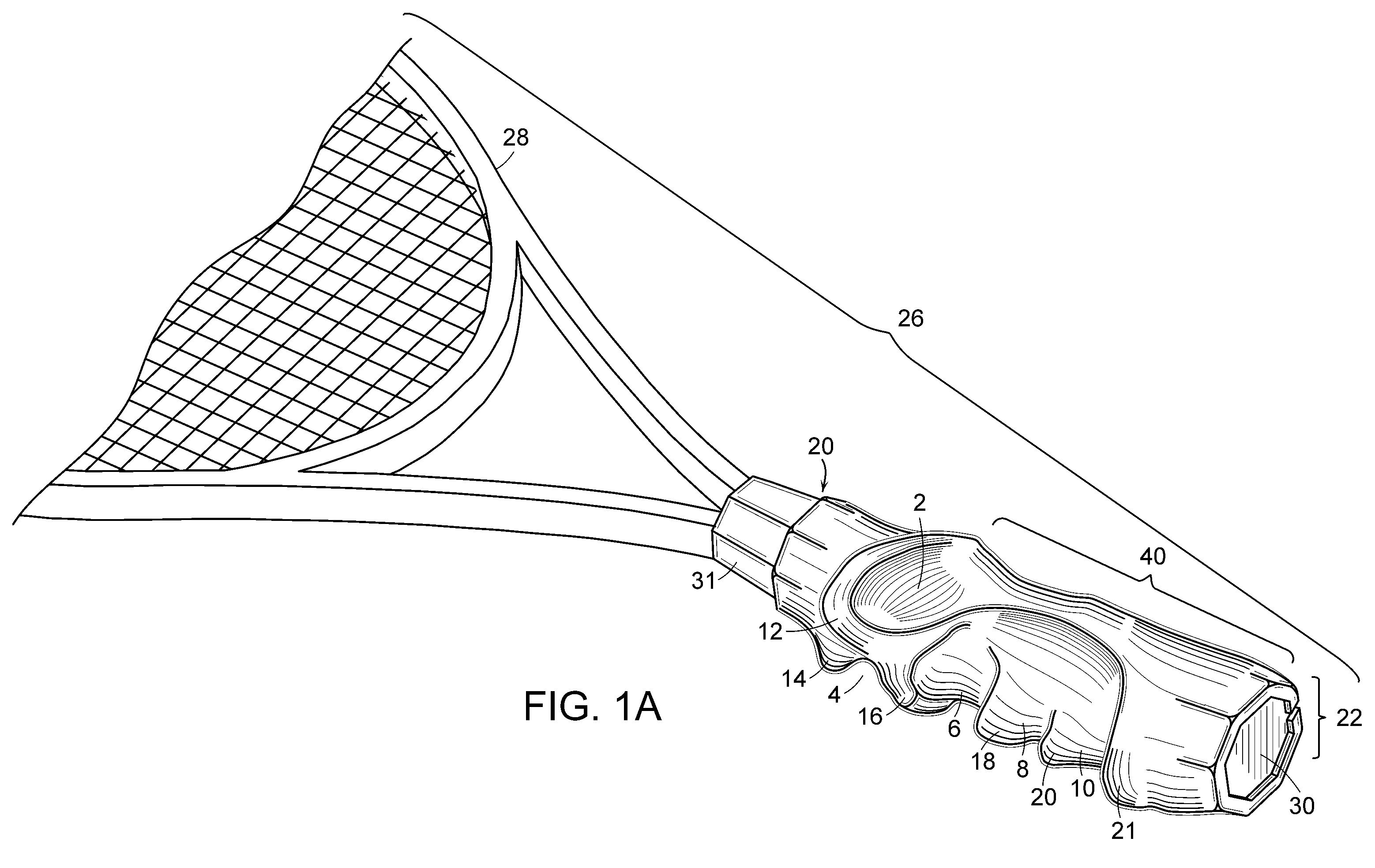

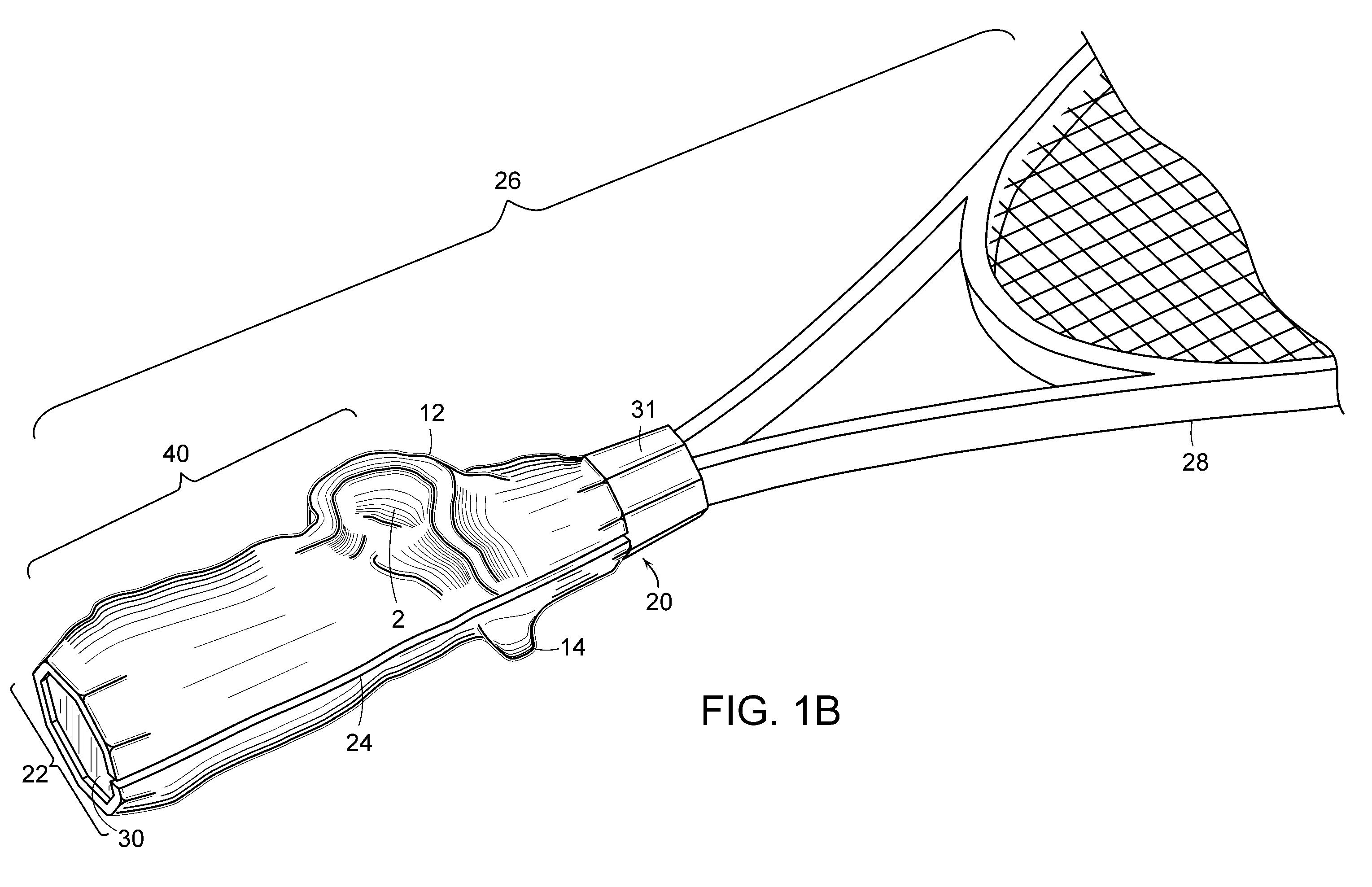

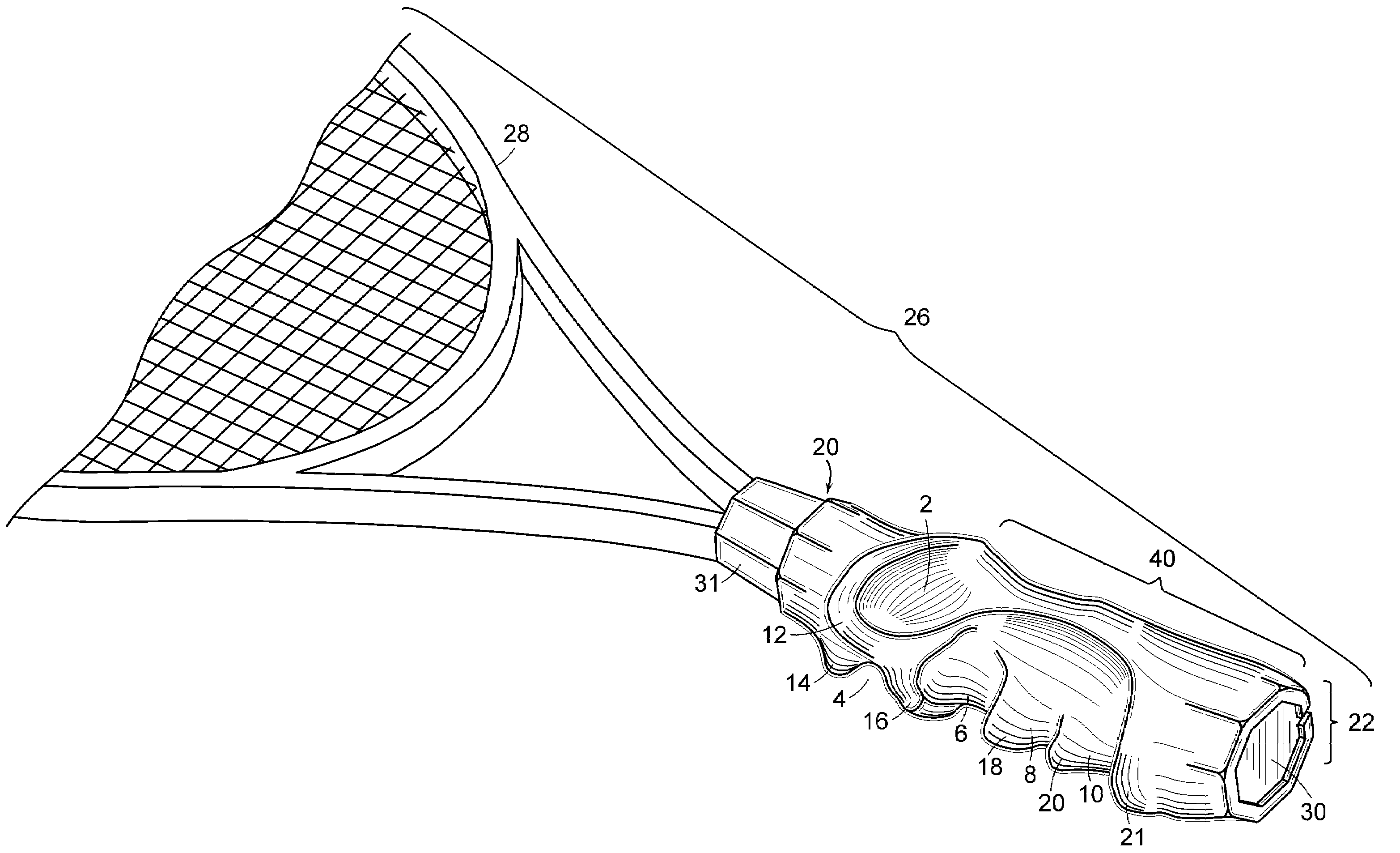

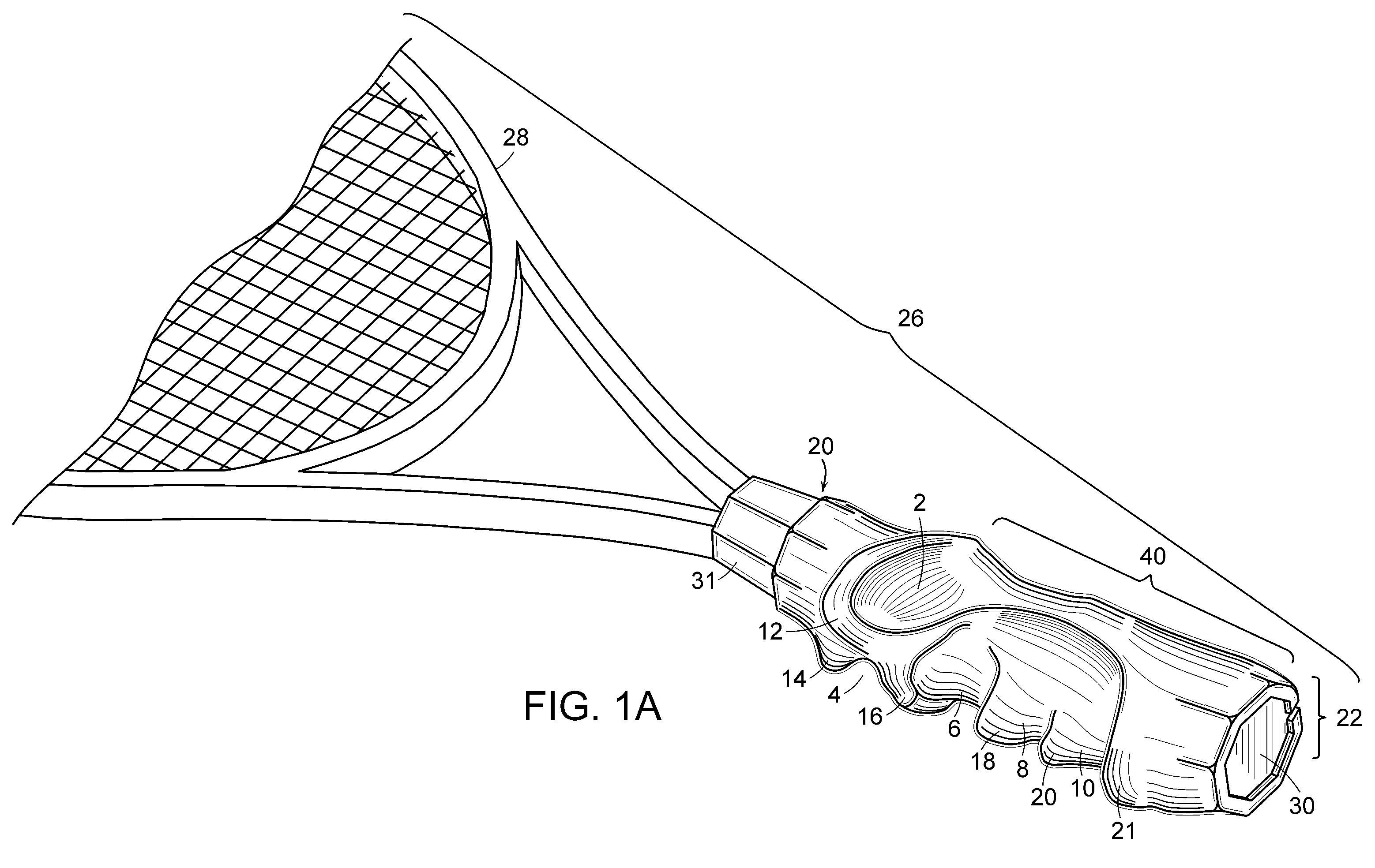

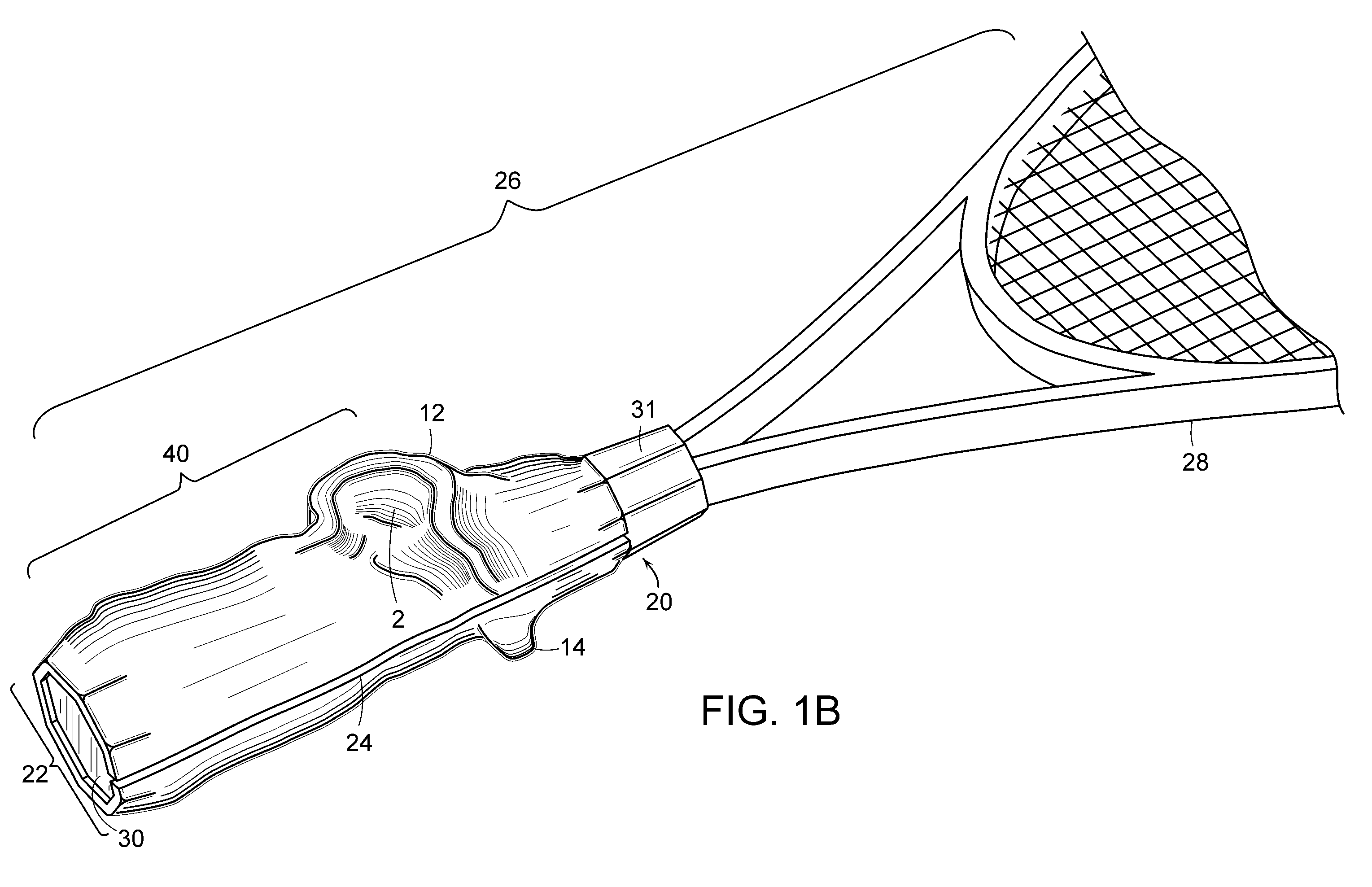

Tennis training grip and methods of use thereof

The present invention relates to a training grip for a tennis racket. The training grip has a series of protrusions and recesses that receive a user's hand and place it in proper position for a particular grip type. The present invention, in one embodiment, includes a universal training grip that allows the grip to be used for more than one grip type. The present invention includes methods, systems and kits that encompass such a tennis training grip.

Owner:THOMAS CARL A

Sports grip sensor

Owner:KAUFMAN ALEXANDER

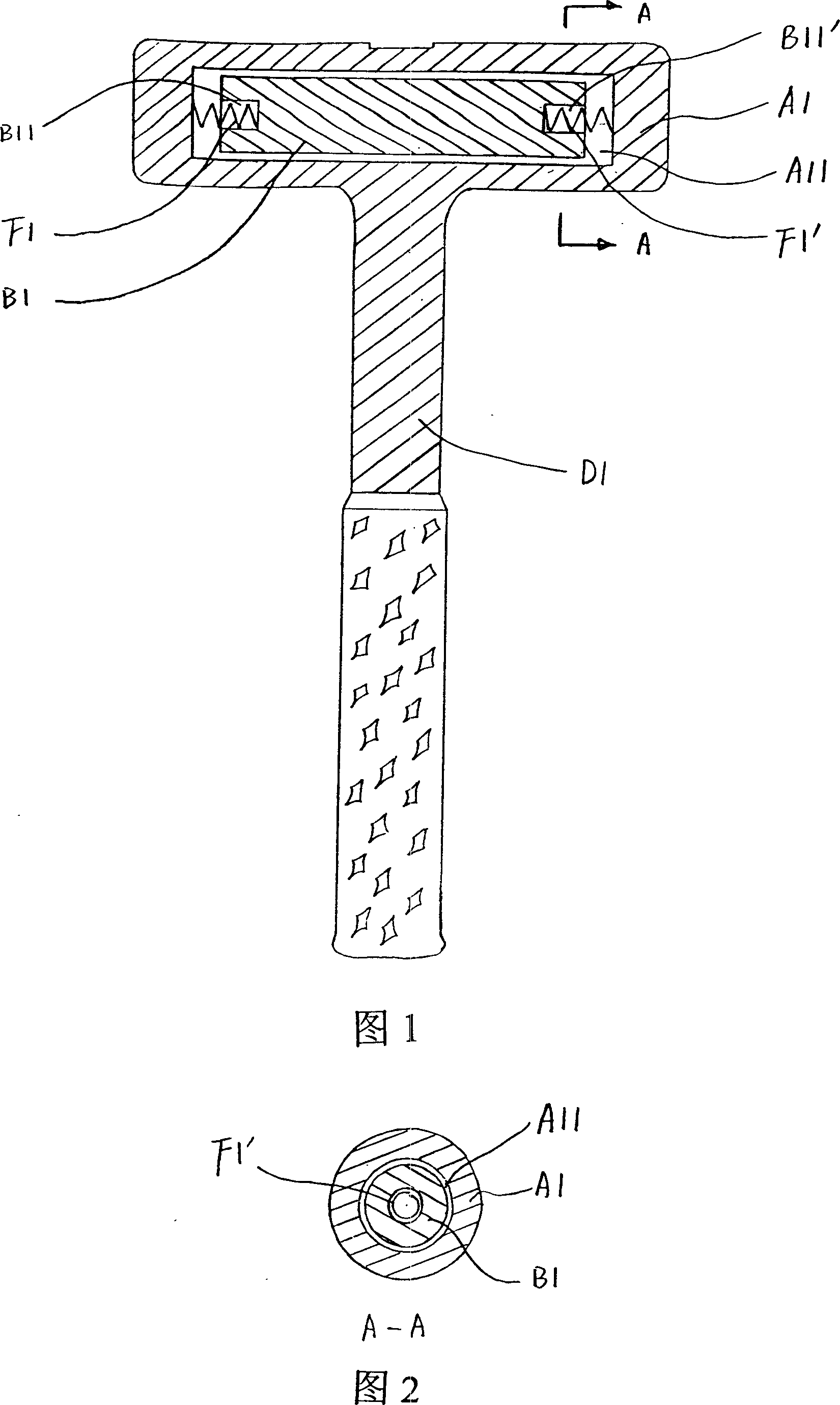

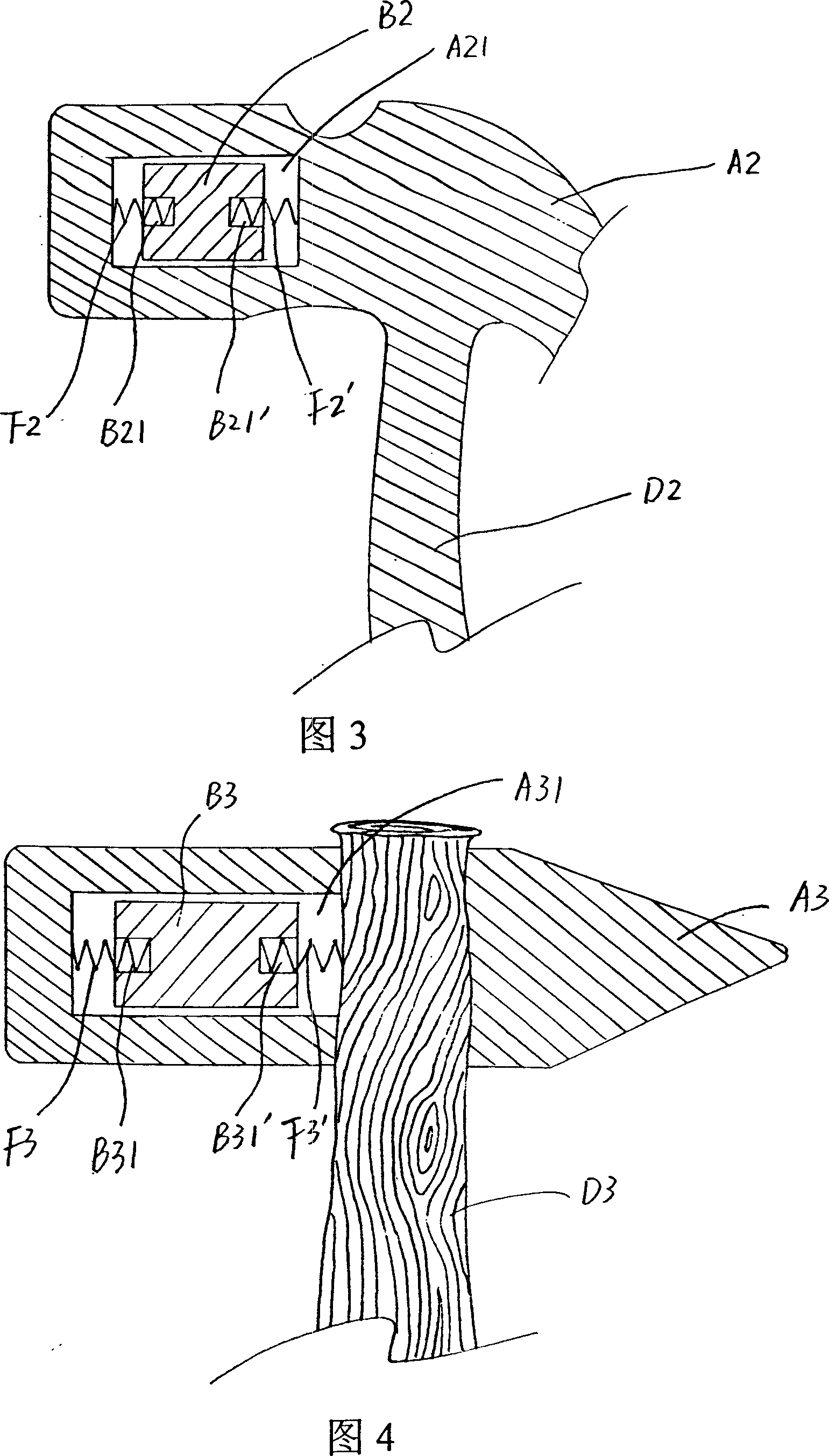

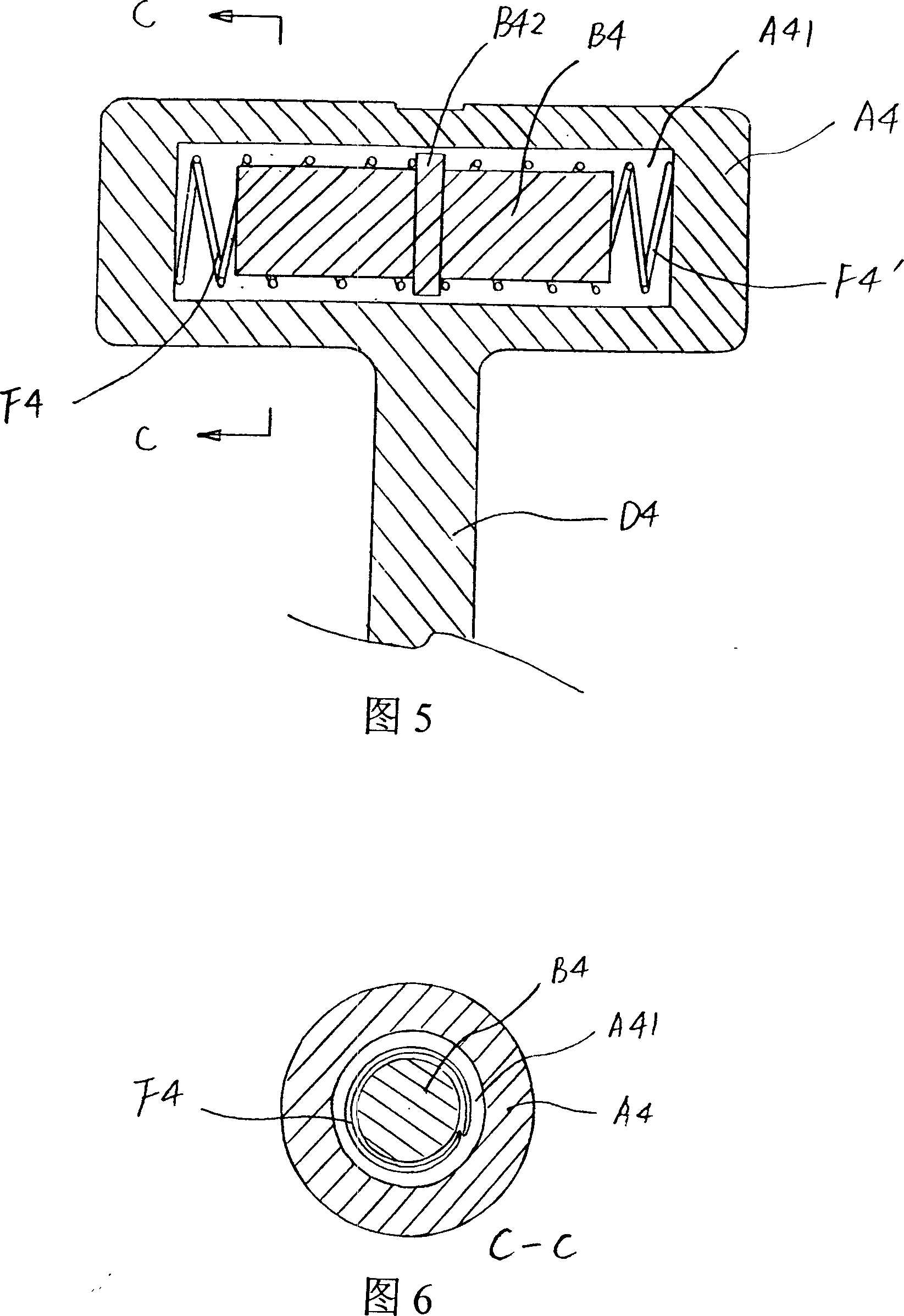

Double-beat hammer mechanism

InactiveCN1970238AImprove percussionReduce or eliminate elasticityHoesHand cultivatorsEngineeringGolf Ball

It relates to a dual acting hammer modified from ordinary hammers. It comprises the hammer head and hammer handle, with the head contained with sealed and movable blocks. It features in the once time for time hammering with improved hammering effect, being more accurate, reduced or illuminated vibration resulted from counteraction, simple structure, same shape with the ordinary hammer after quick resetting of blocks. It can be used for hammering tools like hack, handle axe, axe, tennis racket, and golf pole and so on.

Owner:弗兰克·当泰·埃多莱·克罗那

Tennis Training Grip and Methods of Use Thereof

The present invention relates to a training grip for a tennis racket. The training grip has a series of protrusions and recesses that receive a user's hand and place it in proper position for a particular grip type. The present invention, in one embodiment, includes a universal training grip that allows the grip to be used for more than one grip type. The present invention includes methods, systems and kits that encompass such a tennis training grip.

Owner:THOMAS CARL A

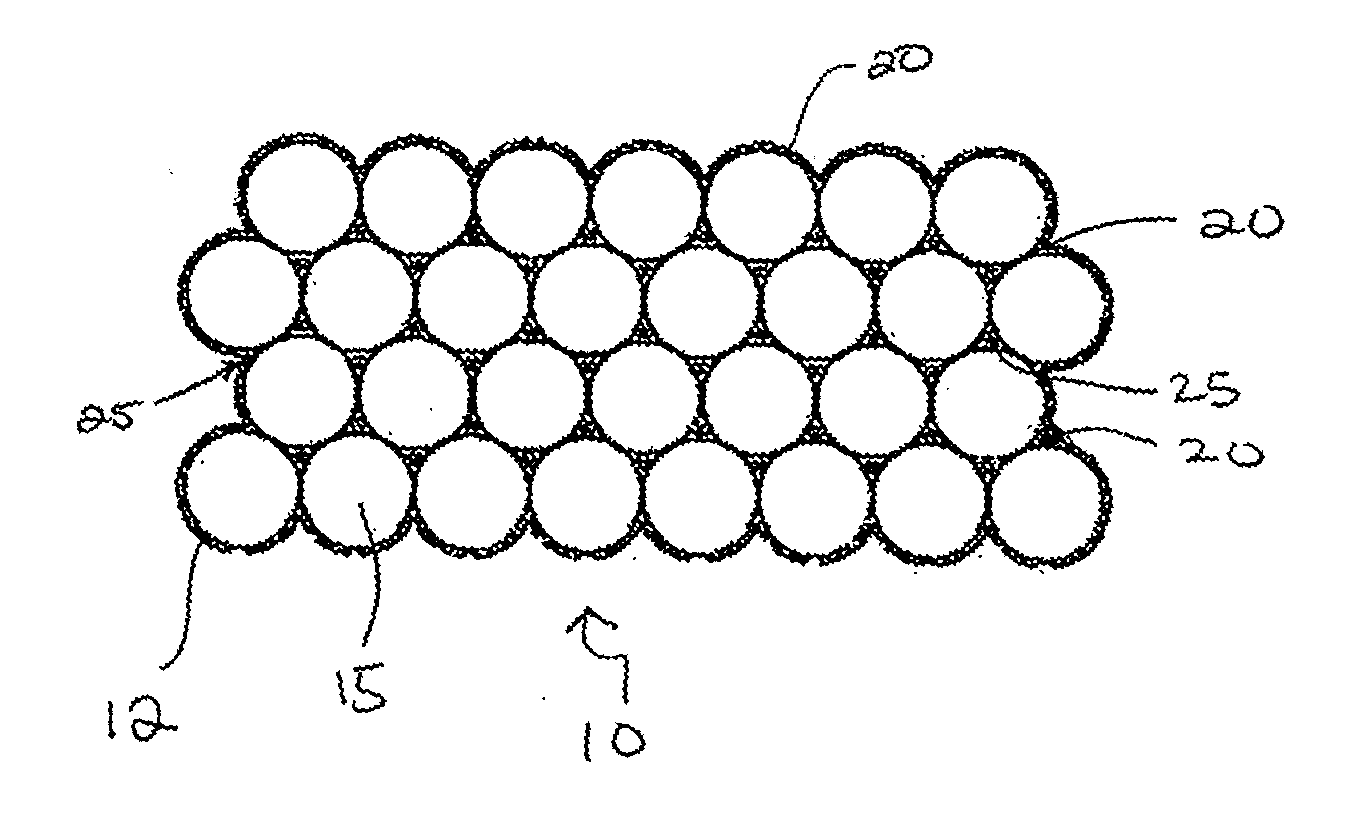

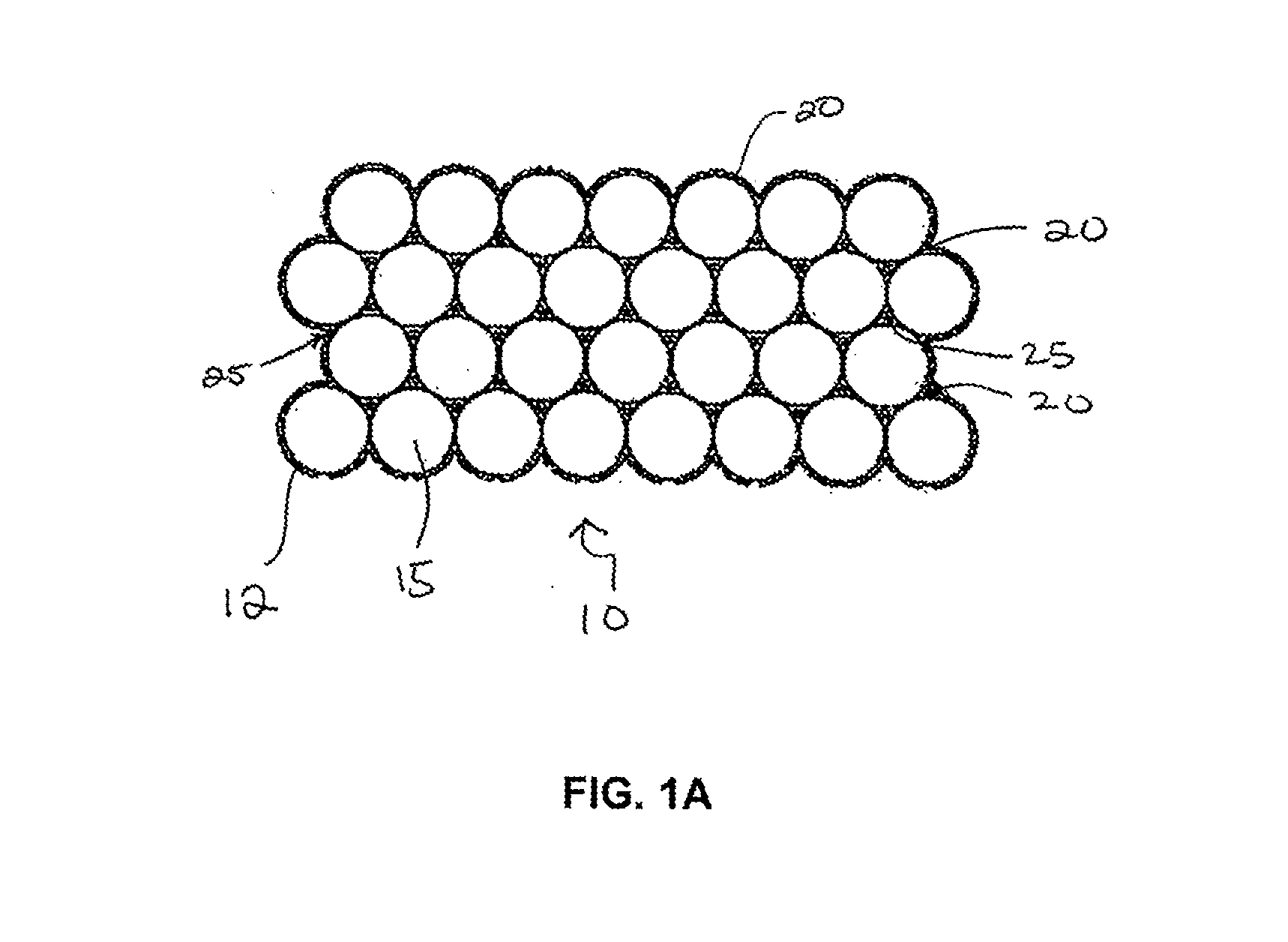

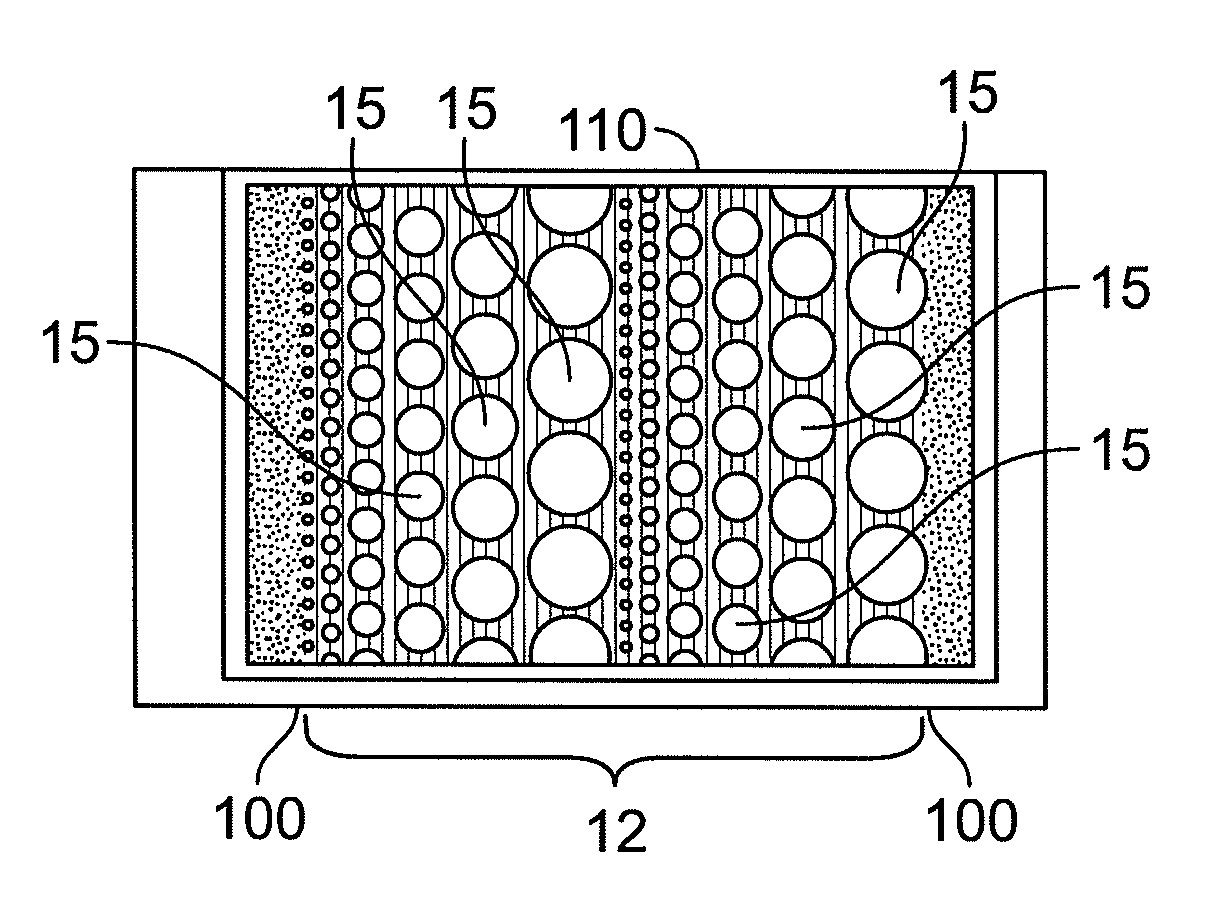

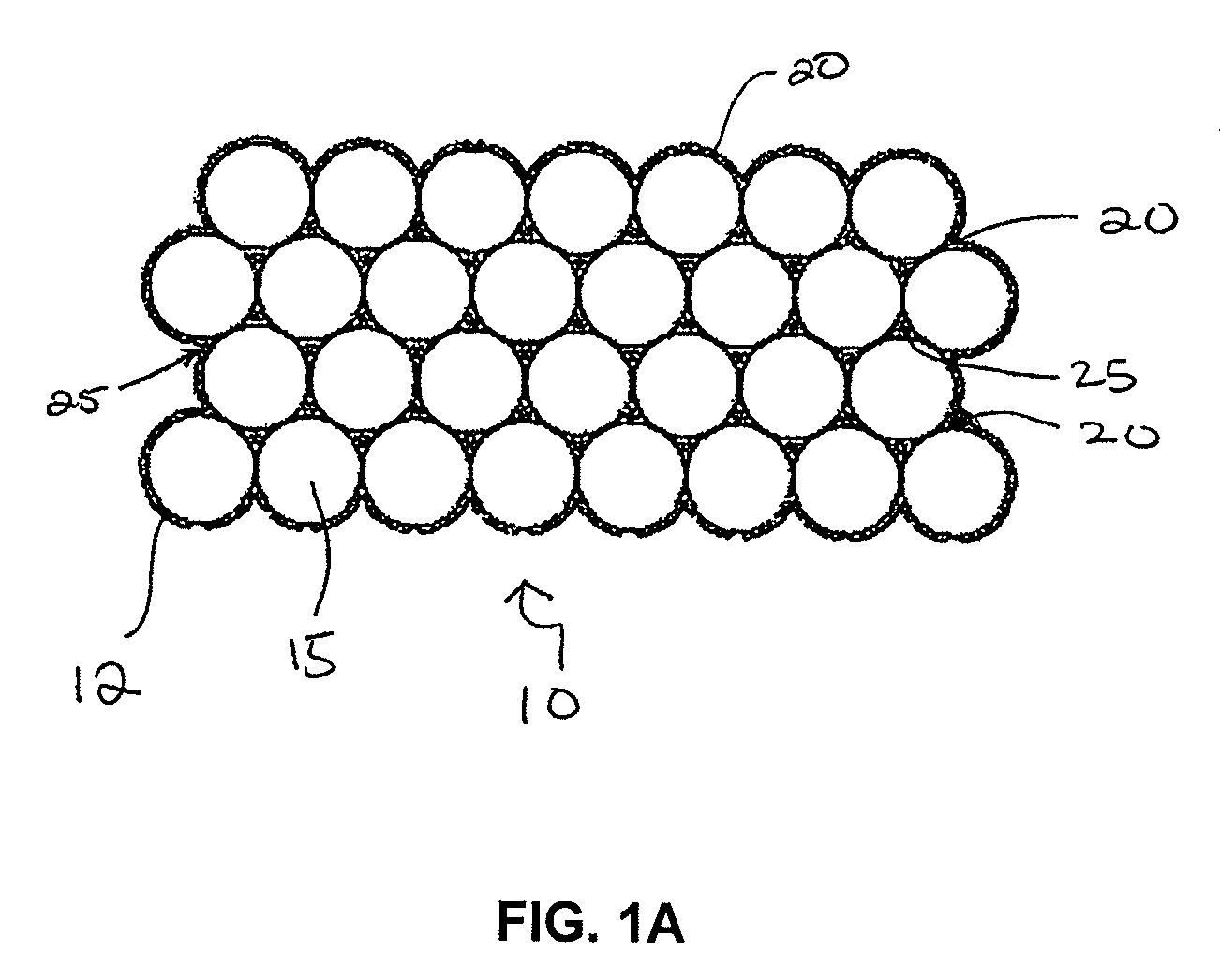

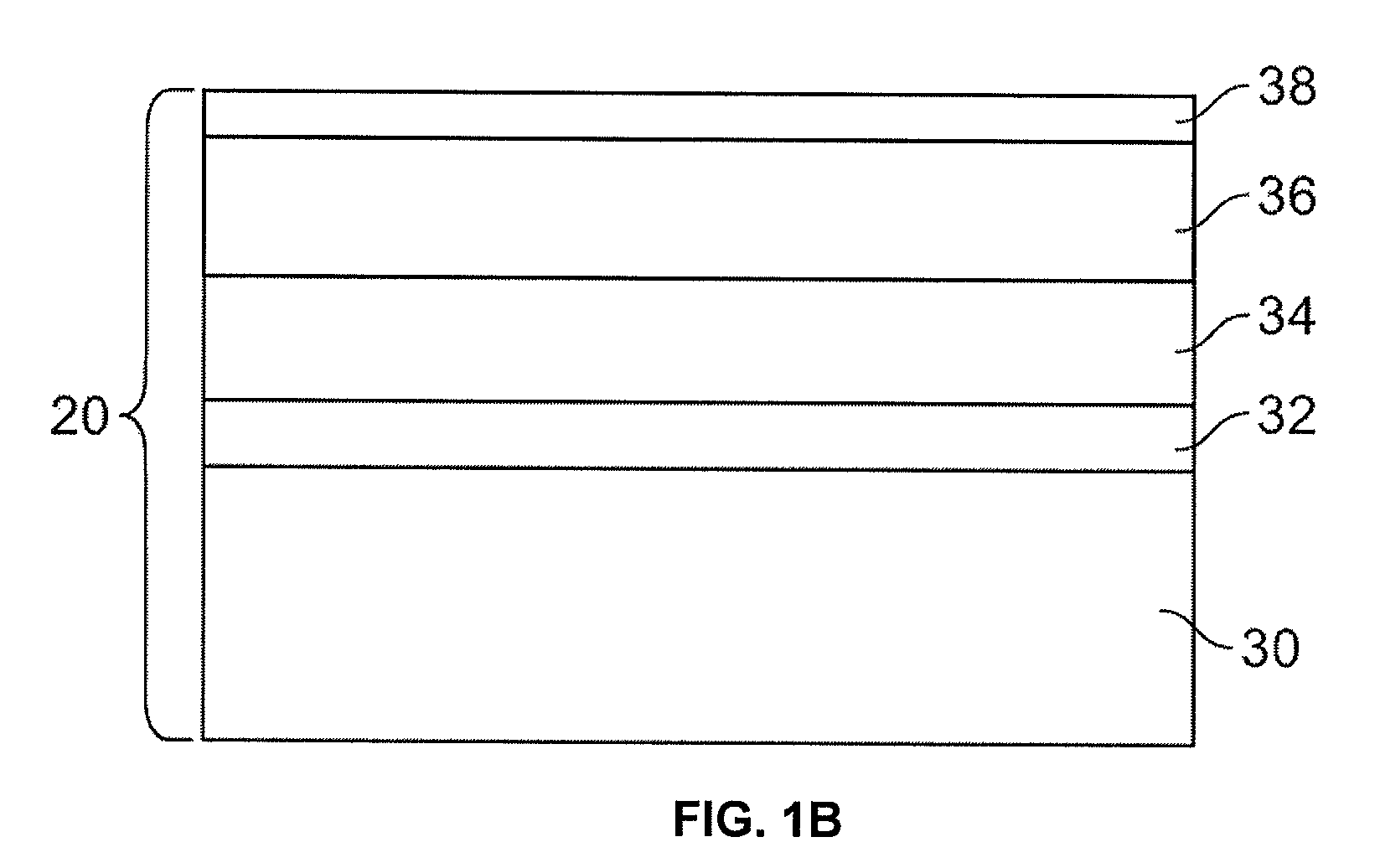

Compositionally Modulated Composite Materials and Methods for Making the Same

ActiveUS20150315716A1DiscontinuityEnhanced and increased structural propertyElectrolytic coatingsDuplicating/marking methodsPorous substrateElectricity

A light-weight composite material with enhanced structural characteristics includes, in one embodiment, a compositionally modulated nanolaminate coating electrically deposited into an open, accessible void structure of a porous substrate. As a result of including a nanolaminate within the void structure, the composite can include a greater amount of nanolaminate material per unit volume than can be achieved by depositing a nanolaminate material solely on a two-dimensional surface. In addition, the nanolaminate material as well as other material electrodeposited to form the composite is compositionally modulated so that discontinuities between layers are minimized and potentially eliminated. The light-weight but structurally enhanced composite material can be used in a number of different applications including, but not limited to, ballistic applications (e.g., armor panels or tank panels), automotive protection applications (e.g., car door panels, racing shells) and sporting equipment applications (e.g., golf club shafts and tennis racket frames).

Owner:MODUMETAL LLC

Tennis swing analyzing device and method

ActiveCN103721393ASimple and high-precision analysisEvaluation StabilitySport apparatusGyroscopeEngineering

The invention refers to a tennis swing analyzing device which is used for knocking down a ground ball, intercepting or serving a ball. The swing analyzing apparatus includes: a three-axis acceleration sensor attached to a tennis racket including a handle and a head, for measuring accelerations in the directions of three axes when a swing for hitting a tennis ball is taken with the tennis racket; a three-axis gyro sensor attached to the tennis racket, for measuring angular speeds about the three axes when a swing for hitting a tennis ball is taken; and an analyzing device. The analyzing device has a receiving function to receive data regarding the accelerations and the angular speeds from the three-axis acceleration sensor and the three-axis gyro sensor; a coordinate axis conversion function to convert relative coordinate axes that are the three axes for the accelerations into absolute coordinate axes on the basis of the angular speeds; and a calculation function to calculate an index of the swing on the basis of accelerations resulting from the coordinate axis conversion.

Owner:SUMITOMO RUBBER IND LTD

Compositionally modulated composite materials and methods for making the same

ActiveUS9115439B2DiscontinuityEnhanced and increased structural propertyElectrolytic coatingsArmour platesPorous substrateElectricity

Owner:MODUMETAL LLC

Vibration dampening device for a strung sports racquet

A device adapted to be emplaced in a self-securing manner between adjacent strings of a tennis racquet for dampening vibrations caused by impact with a tennis ball produces beneficial sensory effects such as a whistling sound and flashing light.

Owner:NIKSICH GENE +1

Tennis grip reference aid

An aid for teaching players specific proper tennis grips is provided in two form factors. The aid can be provided in a wrap or a band form factor. The aid comprises a reference for each of the following grips: Continental, Eastern, Semi-Western, and Western. The references are spatially located on the aid, such that when installed onto a neck of a tennis racket, each reference aligns with the “V” formed between player's thumb and forefinger when holding the racket with the respective grip. The references can be color coded, provided in differing fonts, include unique graphical representations, and the like.

Owner:MONTALVO CARLOS

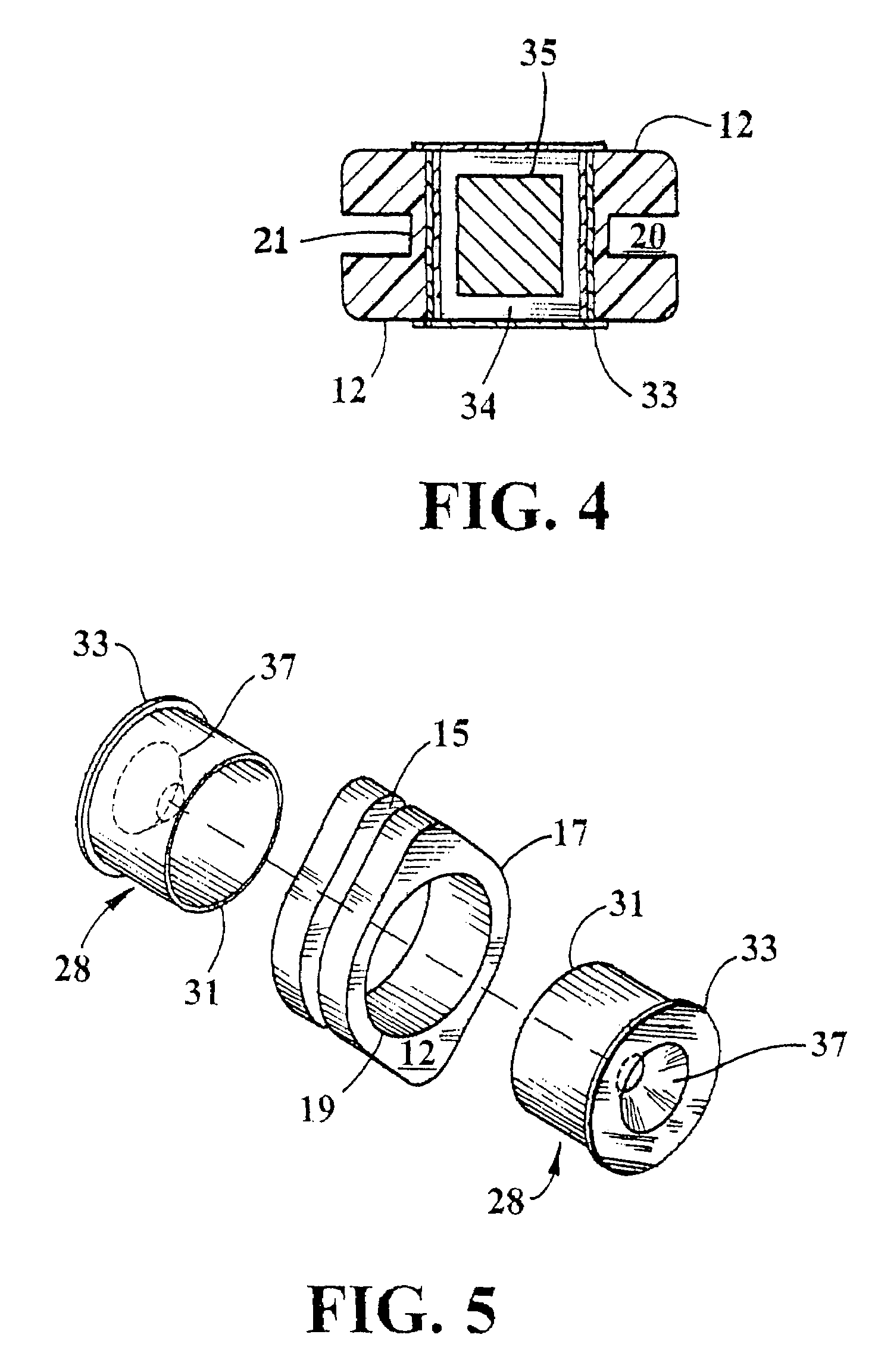

Table tennis racket with counting function

The invention discloses a table tennis racket with a counting function. The table tennis racket with the counting function comprises a pressure sensor, a controller, a displayer and a power module, wherein the pressure sensor, the controller, the displayer and the power module are all situated inside the table tennis racket, the pressure sensor is connected with the controller and transmits detected pressure signals to the controller, the controller is connected with the displayer and enables a counting value to be displayed on the displayer, and the power module provides electricity for the pressure sensor, the controller and the displayer. The table tennis racket with the counting function can count automatically, each time a ping pong ball contacts the table tennis racket, the pressure sensor detects a pressure and transmits the detected pressure signals to the controller, and the controller can automatically count, and enables the count value to be displayed on the displayer. Therefore, a user can see the times of ball knocking at any time.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Apparatus for generating a complex acoustic profile representing the acceleration pattern of an object moving through a path of travel

An apparatus for generating an acoustic profile representing the acceleration pattern of an object moving through a path of travel. The apparatus comprises a flute assembly attachable to a golf club. Preferably, the flute assembly comprises three cross flutes with three different fundamental frequencies aligned axially on the shaft of the club. The swinging motion of the club creates a complex, multi-tone acoustic profile indicative of the acceleration pattern of the club throughout the down swing. The golfer can then compare his profile to the swing of a known, great golfer, and then practice until he duplicates the sound of the model swing. While the apparatus is especially useful for golfers, the apparatus may be adapted to a wide variety of other sports implements, such as baseball bats, hockey sticks and tennis rackets, for example. An assembly comprising the apparatus in combination with the sports implement is also provided.

Owner:KIENZLE JOHN A

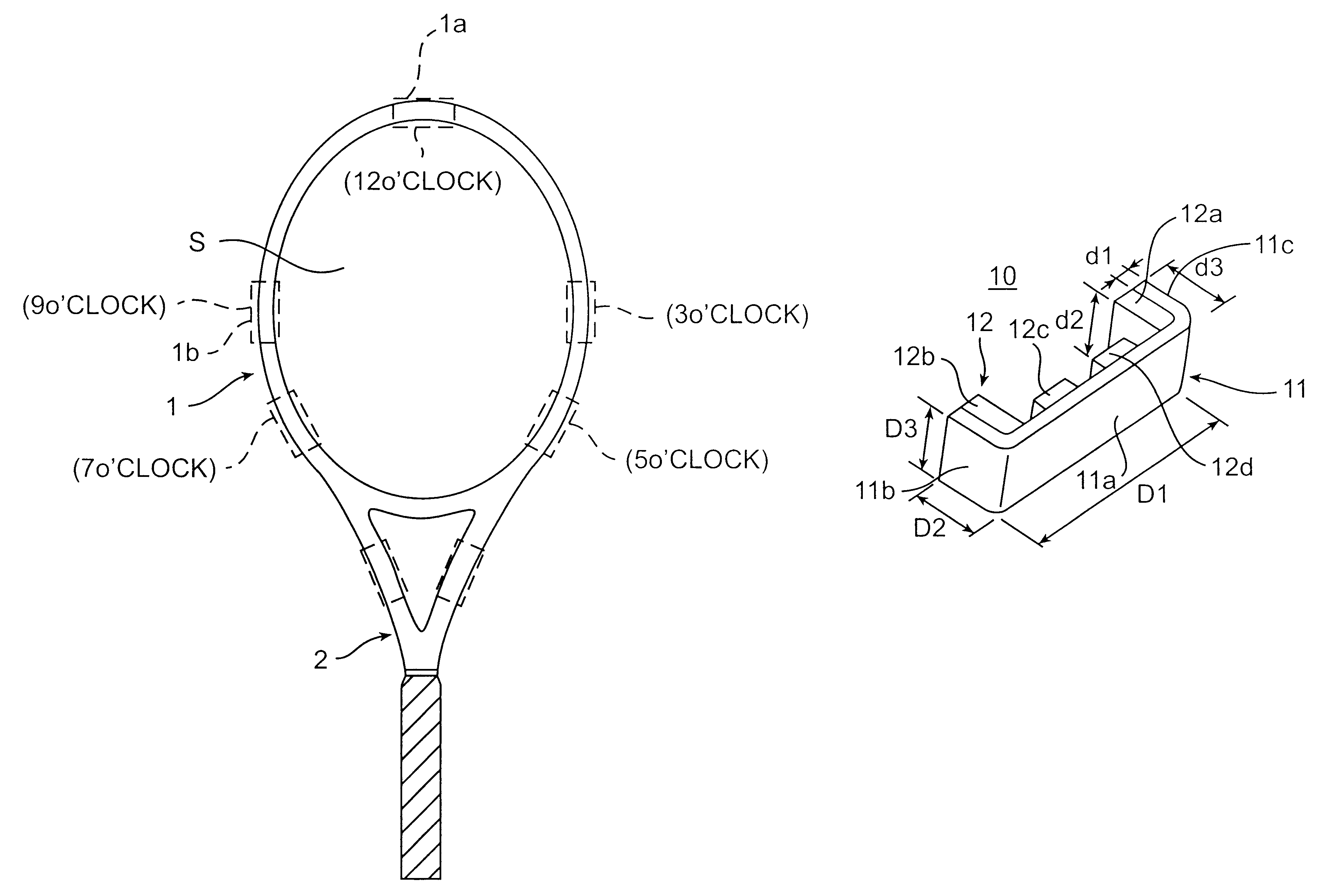

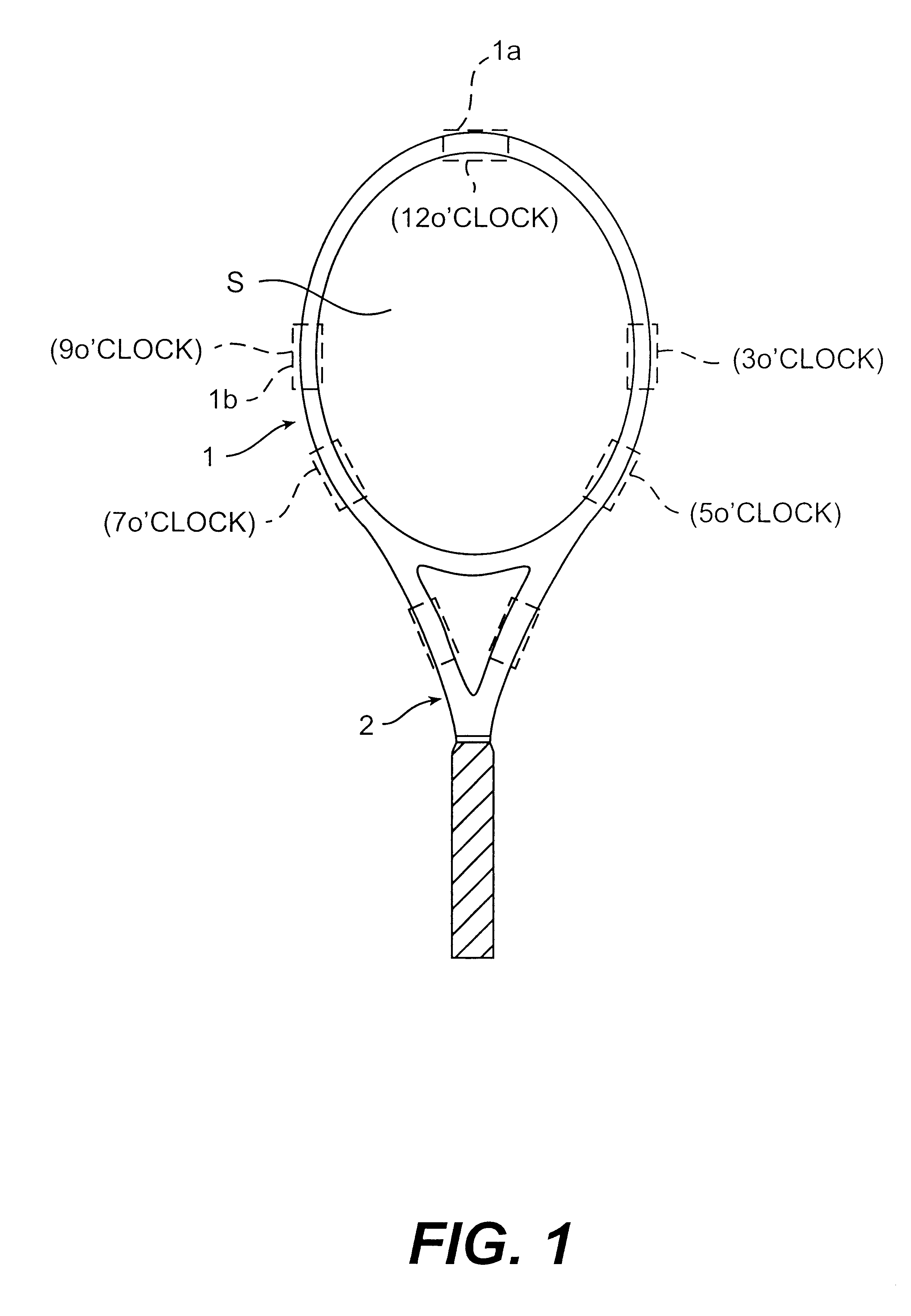

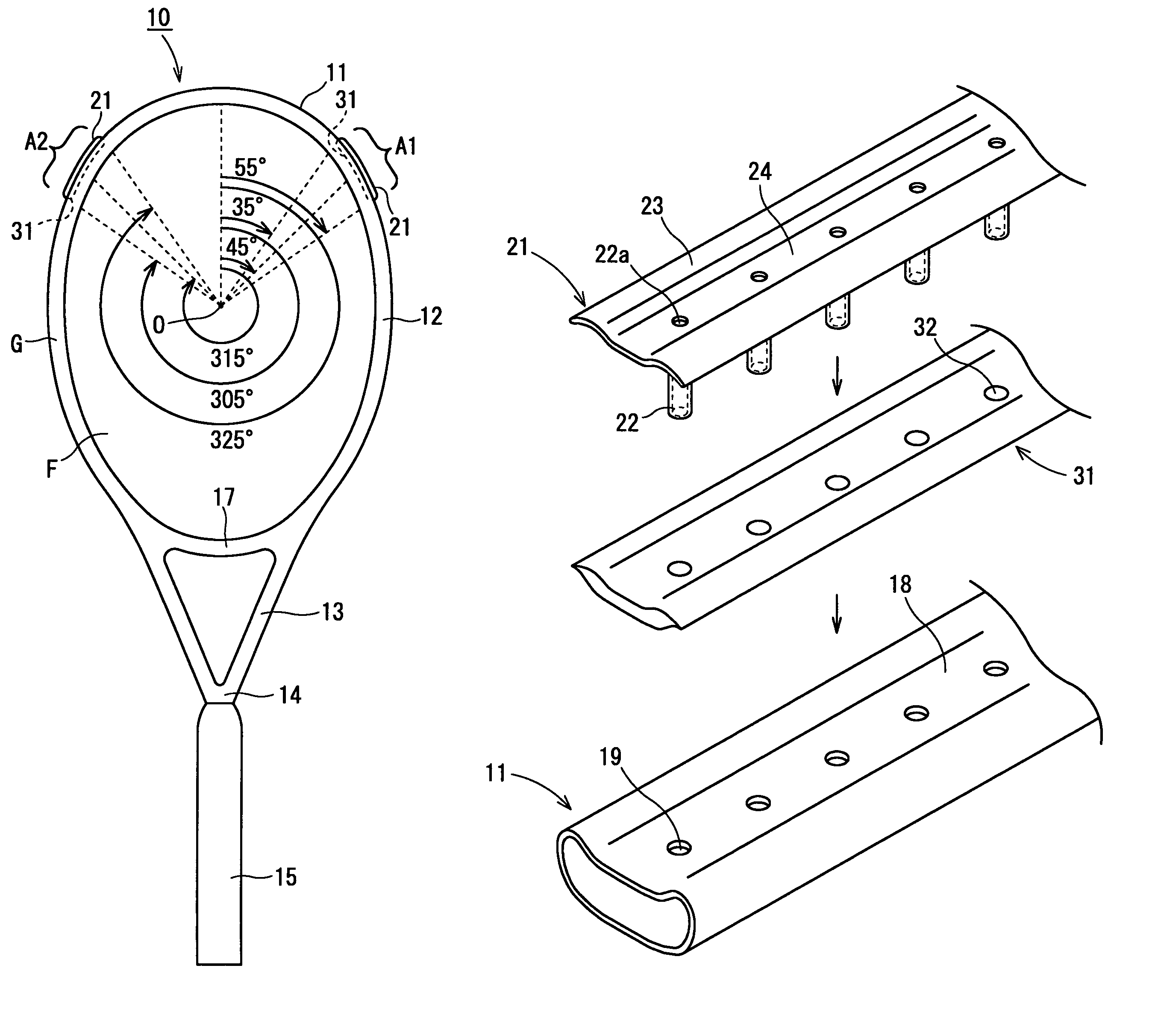

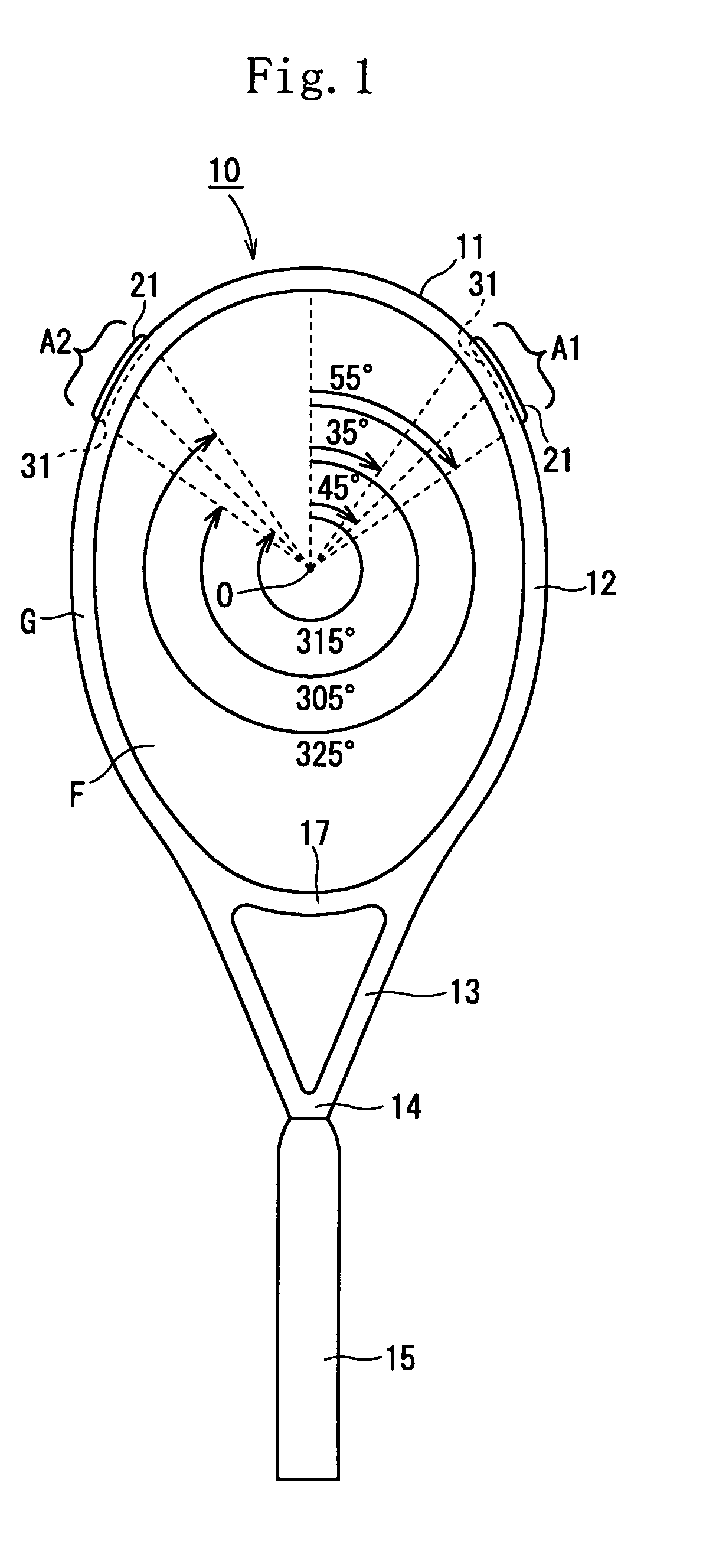

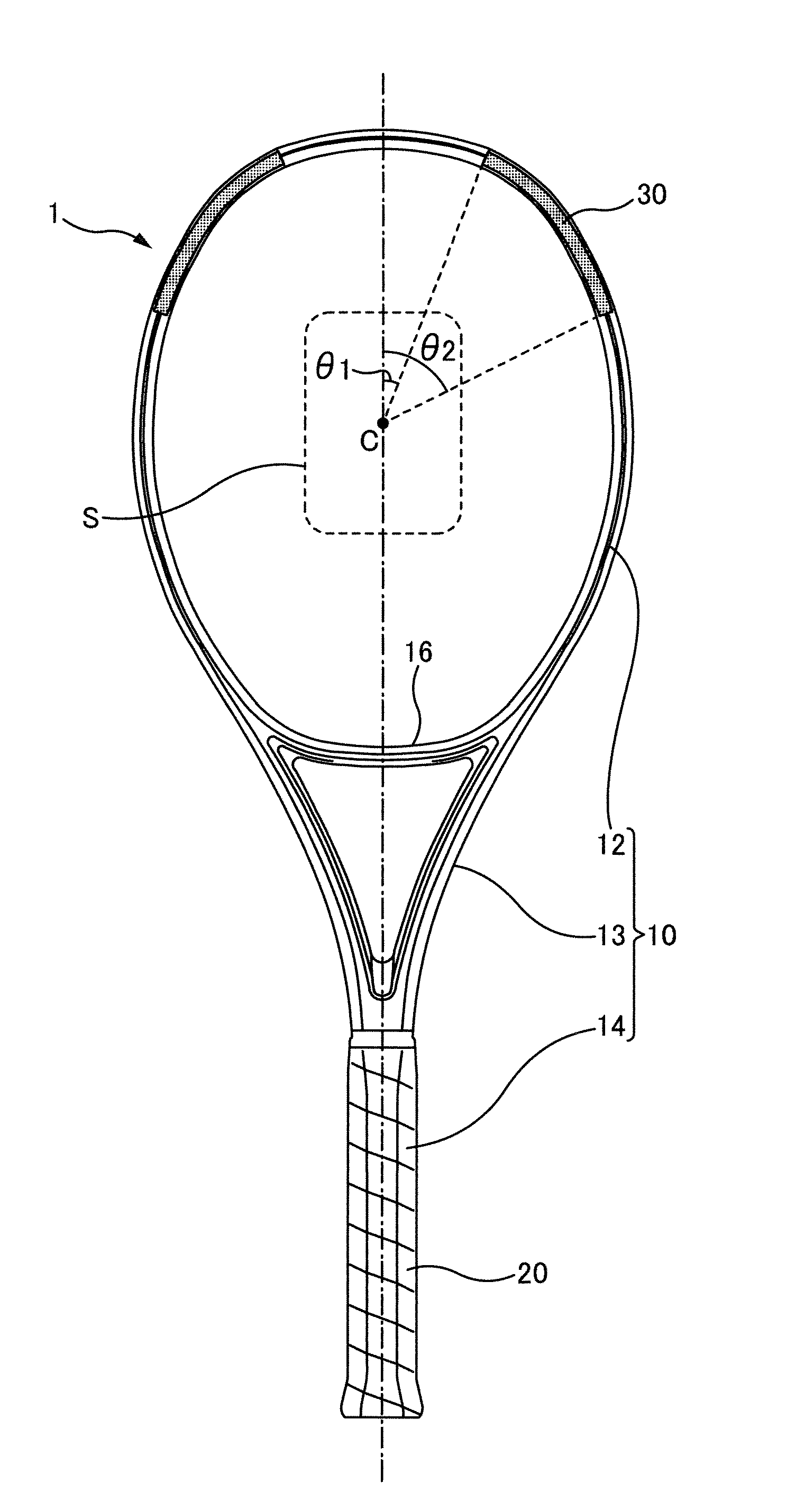

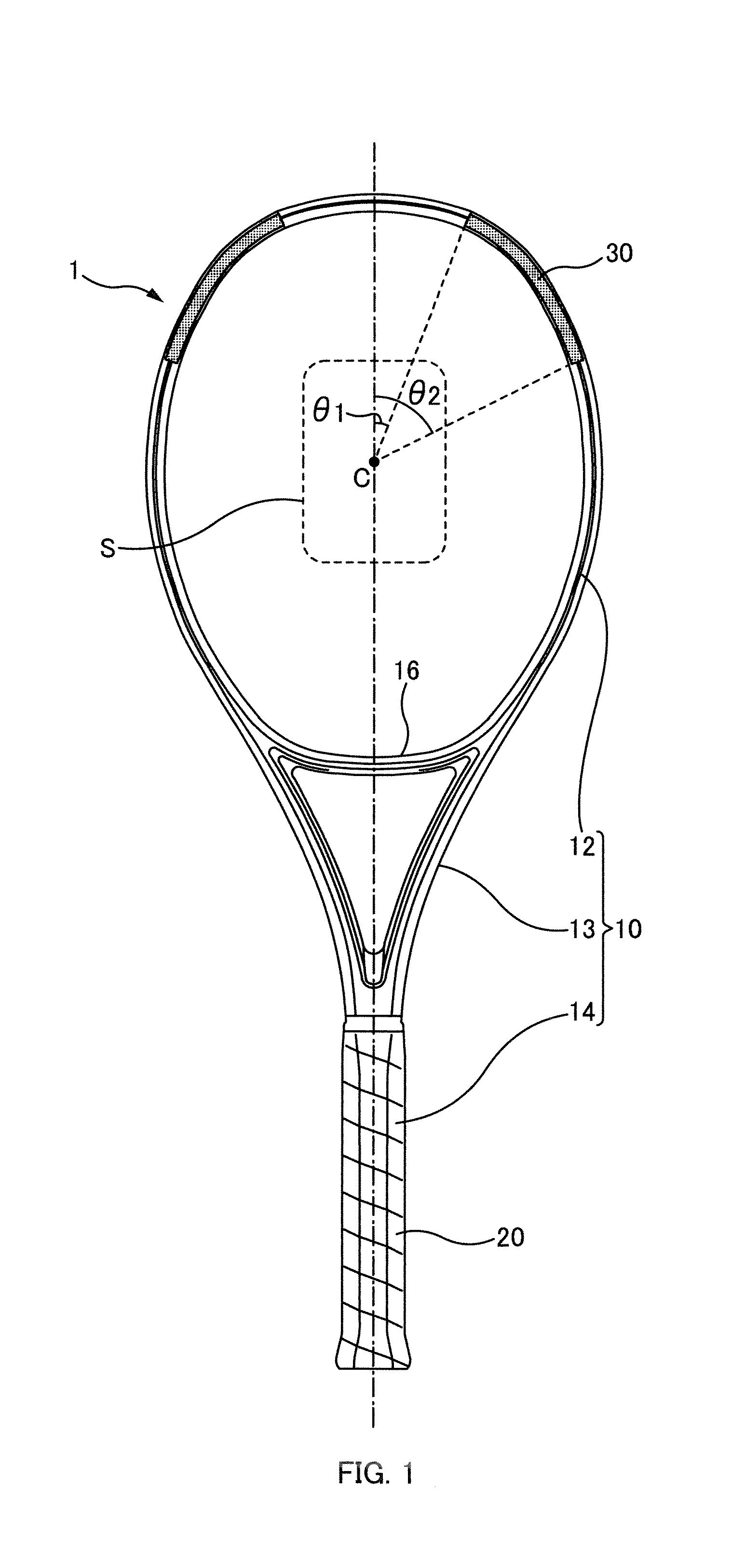

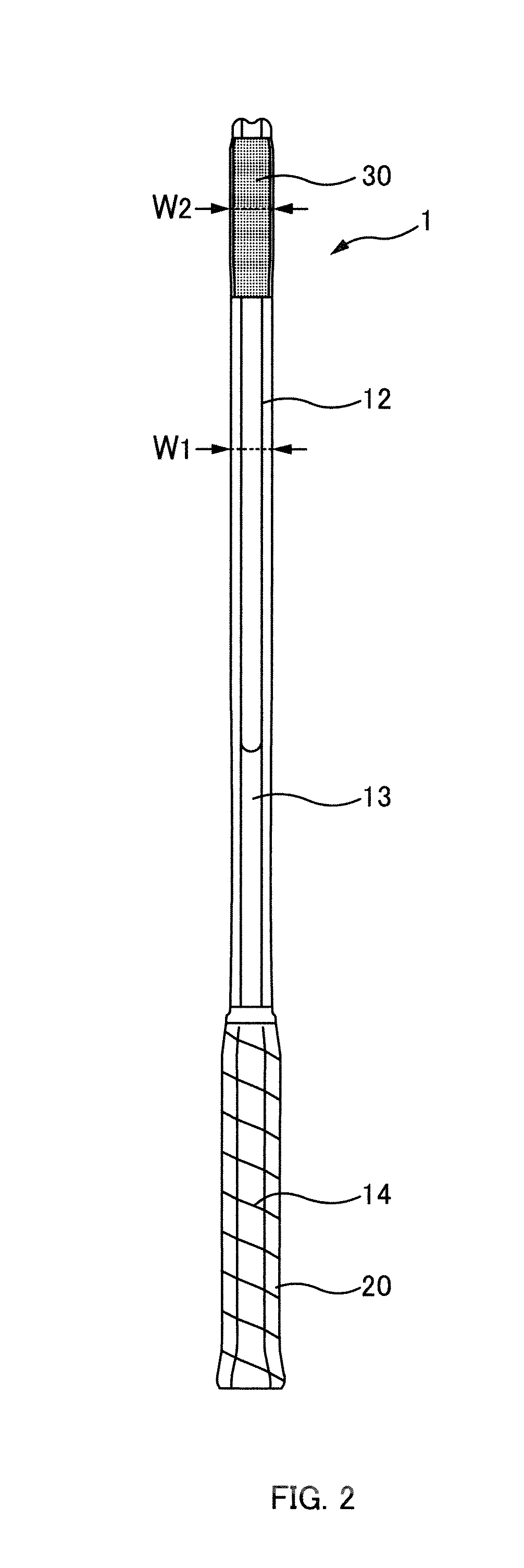

Tennis racket

A tennis racket having a racket frame defining a ball-hitting face, wherein if the upper part of the ball-hitting face is set as a 0-degree position, a string protection member is mounted on at least one portion of a head part of the racket frame in a range from a clockwise 45-degree position to a clockwise 135-degree position and in a range from a clockwise 225-degree position to a clockwise 315-degree position by interposing a viscoelastic member between the string protection member and the racket frame. The moment (Is) of inertia of the tennis racket in a swing direction is set to not less than 450,000 g / cm2 nor more than 490,000 g / cm2, when strings are not tensionally mounted thereon. The moment (Ic) of inertia of the tennis racket in a center direction is set to not less than 15,000 g / cm2 nor more than 19,000 g / cm2, when the strings are not tensionally mounted thereon.

Owner:DUNLOP SPORTS CO LTD

Tennis racket and method for manufacturing the same

InactiveUS20130244817A1Improve rigidityIncrease vibrationDomestic articlesAdhesivesTennis racketUltimate tensile strength

A tennis racket includes a frame that surrounds a hitting face for hitting a ball, wherein a foam material is provided inside two side portions of the frame on opposite sides of a predetermined area of the hitting face, and the two side portions of the frame have a strength that is higher than a strength of another portion of the frame.

Owner:YONEX CO LTD

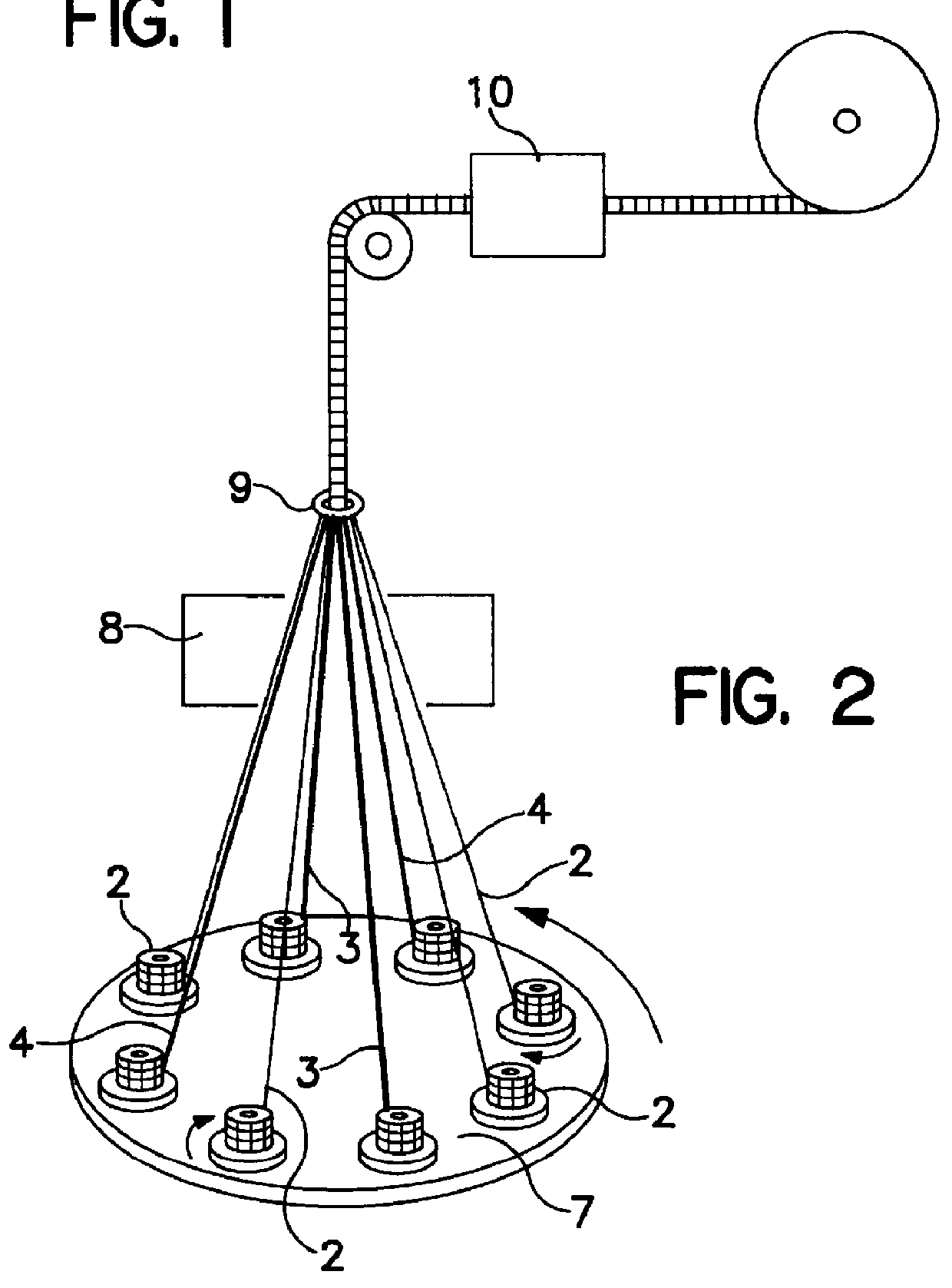

Fiber composite and process of manufacture

ActiveCN102612427AImprove performanceReduce the effect of centrifugal blowsEngineeringFibrous composites

The inventive fiber manufacturing process is particularly adapted for demanding applications such as sports racquets, including tennis racquets, badminton racquets and other sports applications. Because of the improved strength to weight ratio of components formed using the inventive method, a wide range of flexibility is achieved, allowing use of the inventive process to manufacture, for example, a fiber reinforced (for example, graphite) modular sports racquet, optionally provided with user- selectable weights and / or handle replacements. From the standpoint of the player, this allows a racquet frame featuring self customization. From the standpoint of a retailer, the benefit provided is reduction of inventory.; The inventive fiber, for example graphite fiber) racquet frame is filled with a plastic foam and is formed using, for example, microencapsulation technology to time, generate and apply the pressure used to form the graphite composite material of which the racquet is comprised. This compares to the standard industry technique of air injection. The racquet is thus not hollow like conventional graphite racquets, and the walls therefore can be made thinner than those of existing graphite racquets still being of the same strength or being stronger, which gives the racquet exceptional performance. In addition, the overall dimensions of, for example the cross-section, of the racquet can also be reduced while still maintaining performance characteristics.

Owner:XENE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com