Binder in use for jointing covering rubber on table tennis bat

A table tennis racket and covering technology, applied in the direction of natural rubber adhesives, adhesives, adhesive types, etc., can solve the problems of short retention time of elastic effect, fast solvent volatilization, difficulty in producing elastic effect, etc. The effect of preparation time, simple preparation process, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

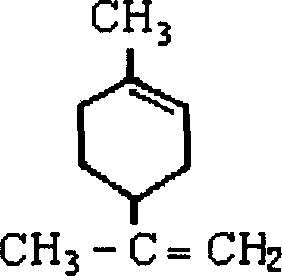

[0018] Natural rubber: 85g; Butadiene styrene copolymer: 15g; Rosin 10g; White carbon black: 20g; 2,6-di-tert-butyl-4-methylphenol (antiaging agent 264): 1g Mix in a rubber mixer, then take 28g of the mixed rubber and place it in 172g of 1,8-terpene, let it stand for 5 to 8 hours, and stir continuously for 2 to 4 hours to obtain a uniform, translucent pressure-sensitive type adhesive.

[0019] Drying time and tack retention time test. Take an appropriate amount of the prepared adhesive and apply it evenly on a glass sheet. The thickness of the coating is controlled at about 0.2-0.4mm. The time for the adhesive coating to touch dry at room temperature is taken as the drying time, and the adhesion is observed at the same time. The time from touch drying to the time when most of the coating surface loses its viscosity is taken as the viscosity retention time. Peel test. Use the same material and surface state as the adherend (in this case, plywood and cricket cover), cut it in...

Embodiment 2

[0023] With 230 type chloroprene rubber: 100g; Zinc oxide: 5g; Magnesium oxide: 4g; Stearic acid: 1g; ): 1g; operating oil: 3g; vinylthiourea (accelerator EUR): 2g; Put 36g of the mixed rubber into 200g of 1,8-terpene: 89g; ethyl acetate: 11g; in a mixed solvent, let it stand for 5 hours, and keep stirring until the mixed rubber is completely dissolved.

[0024] Peel test. Take an appropriate amount of vulcanized adhesive, apply it evenly on a 25×200mm table tennis racket cover rubber and sponge, and paste it after it is fully dried, as a sample, and then use the same adhesive to glue two pieces of the same size as the sample. The size of 2×2 canvas is pasted on both sides of the specimen. Put this sample in an environment of 80°C for 30 minutes to vulcanize, and then park it at room temperature for 12 hours, and perform a 90° peel test on it with a tensile testing machine.

[0025] The drying time of the product is 52 minutes, the viscosity retention time is > 9 hours, the...

Embodiment 3

[0027] Regenerated styrene-butadiene rubber: 85g; polyisoprene: 15g; terpene resin: 20g, mixed on an open rubber mixer, then took 26g of mixed rubber and placed it in 170g of 1,8-terpene two In the mixed solvent of alkene and ethanol, let it stand for 3 hours, and continue to stir for 5 hours, and the obtained glue is uniformly dissolved.

[0028] The sample preparation and testing methods were the same as in Example 1. The test results showed that the drying time was 60 minutes, the viscosity retention time was >15 hours, the peeling test was 2.3N / 25mm, the elasticity retention time was >1 hour, and the swelling was rapid and extremely raised.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com