Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1223 results about "Central unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Central Unit was the only state prison within the city limits of Sugar Land which, since 1960, has been highly developed as a suburban, upscale residential and business city. In August 2011, the TDCJ announced that the Central Unit would be the first prison in Texas to close without being replaced.

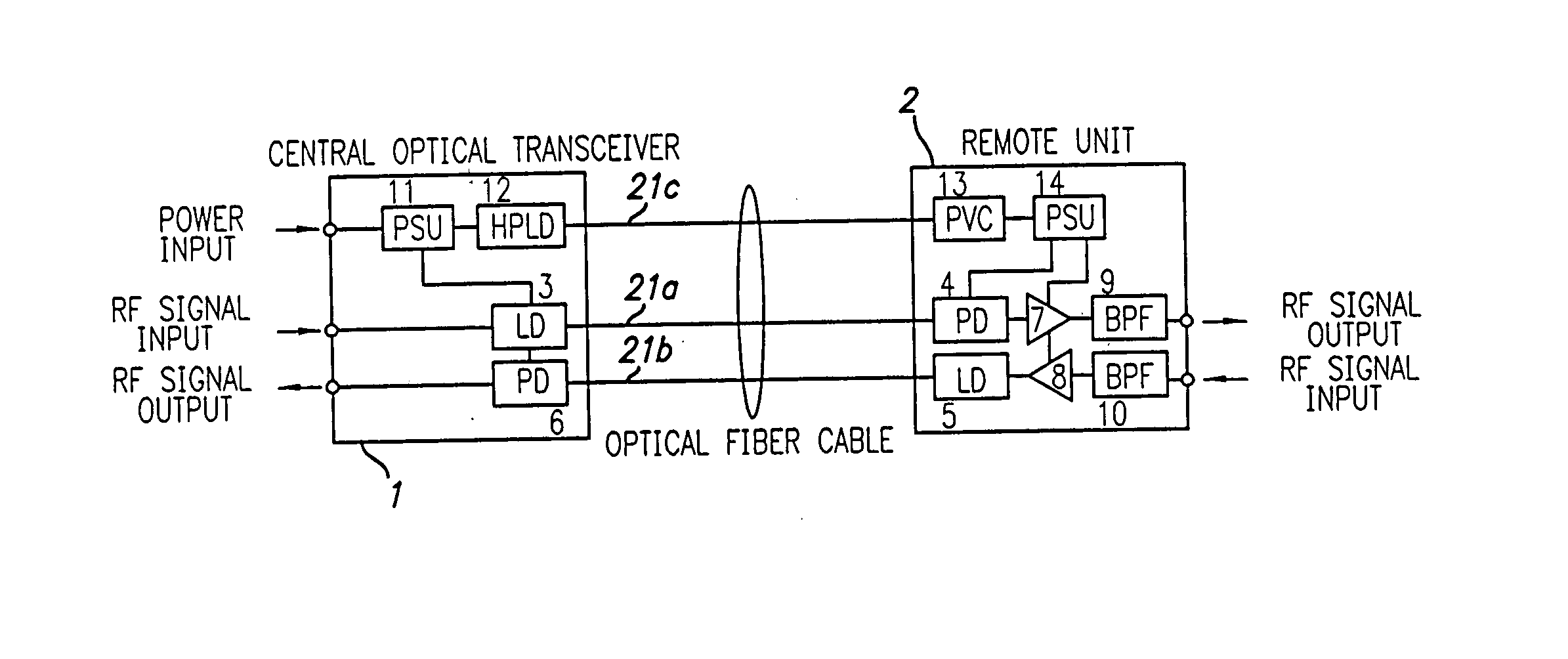

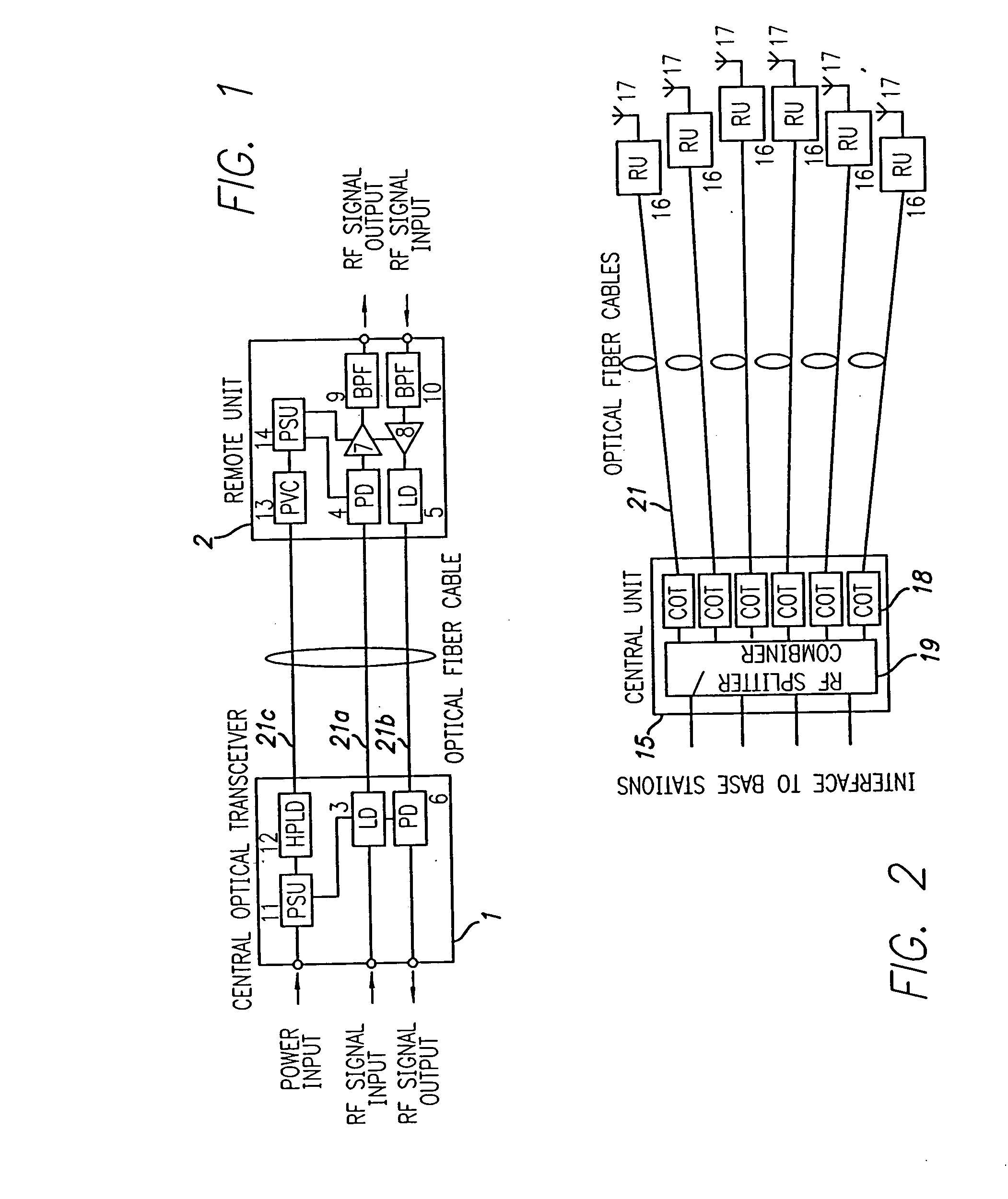

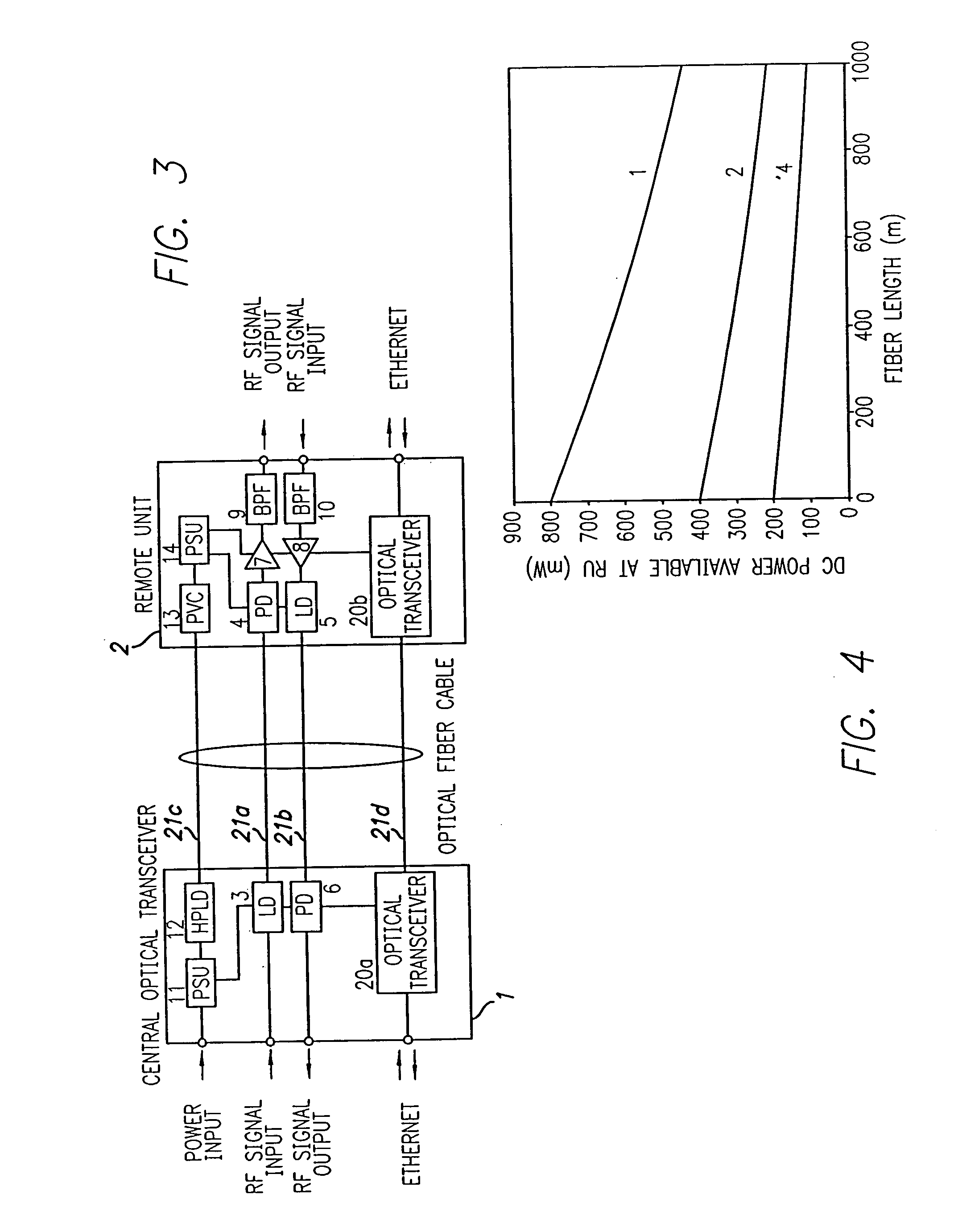

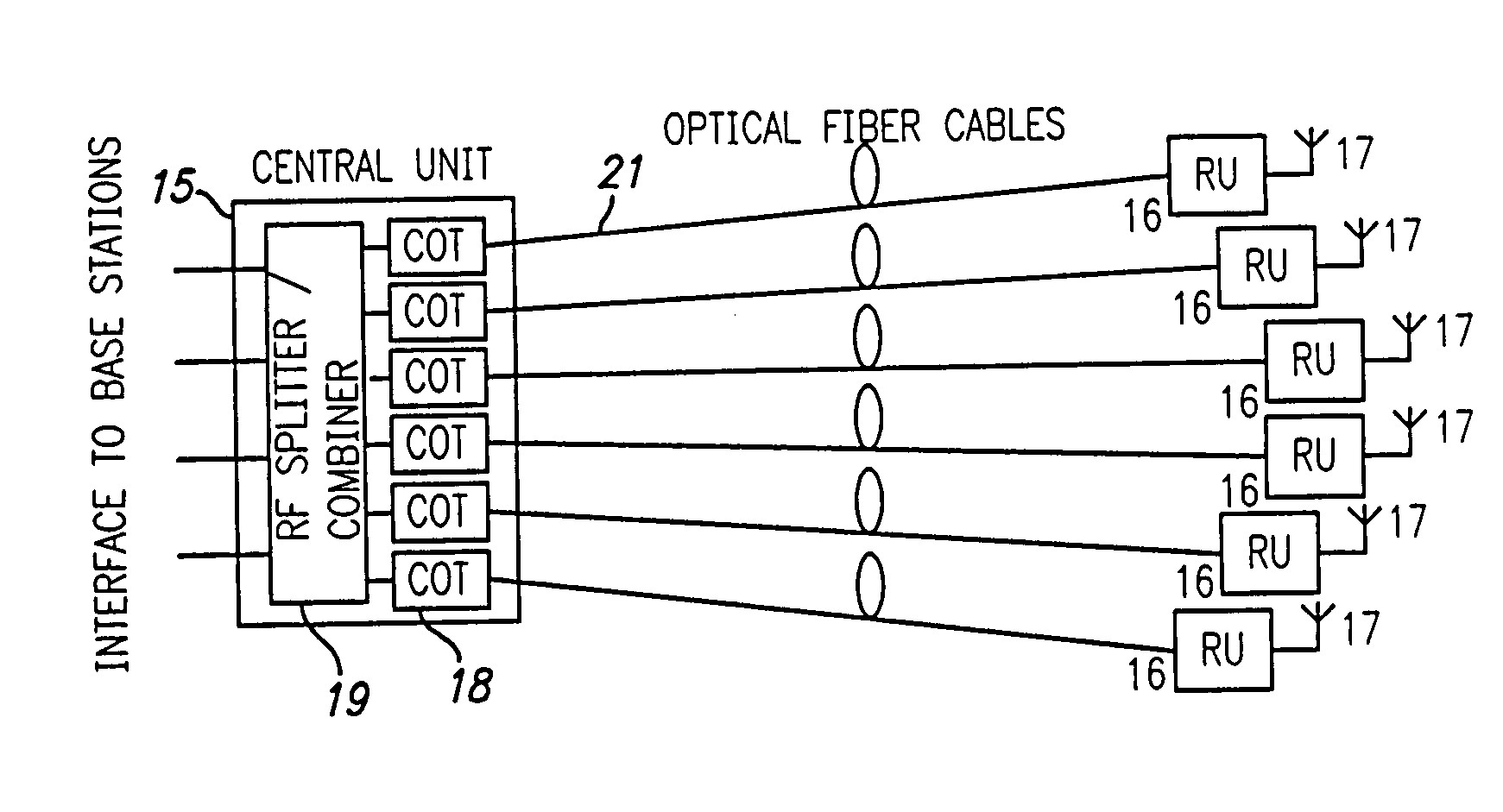

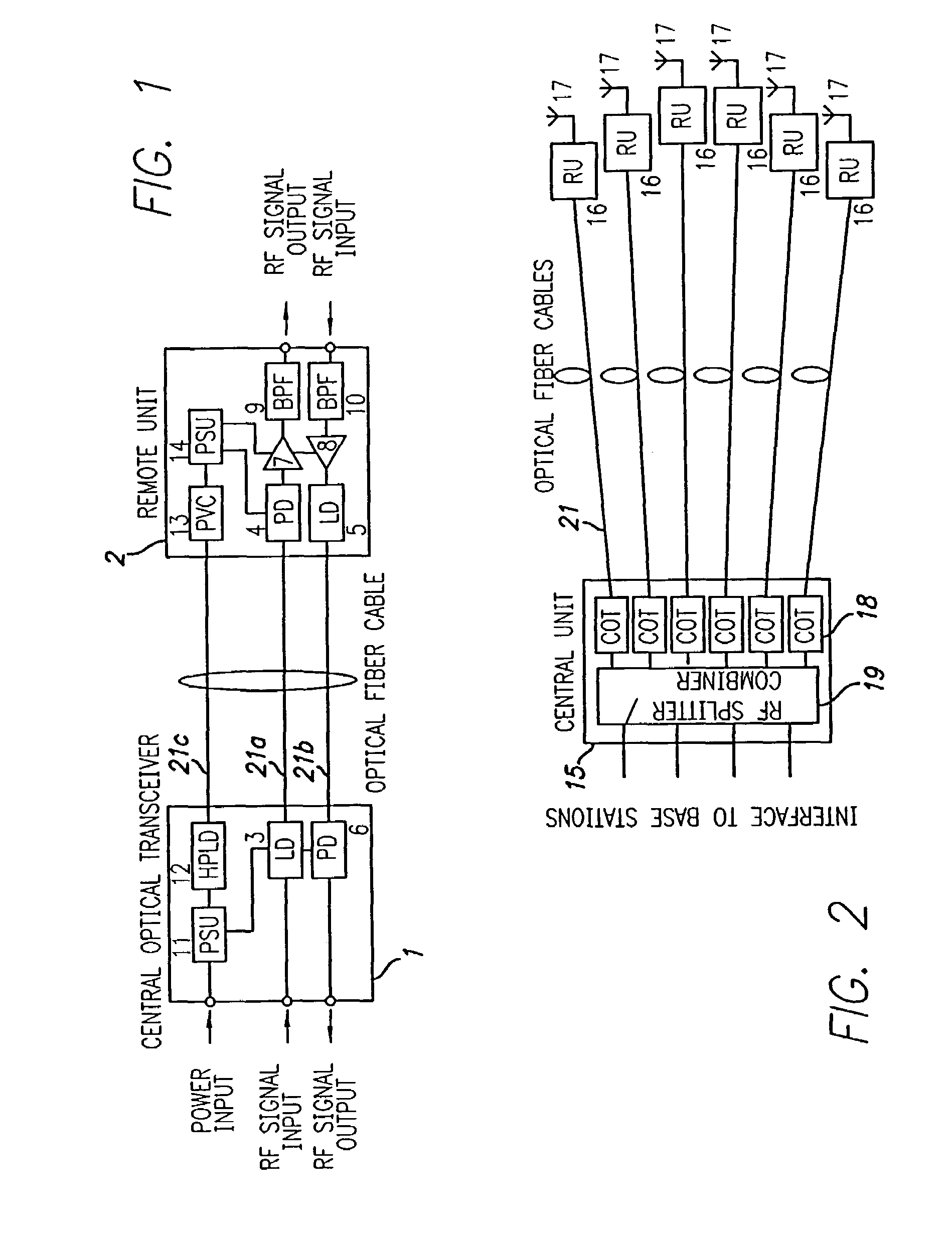

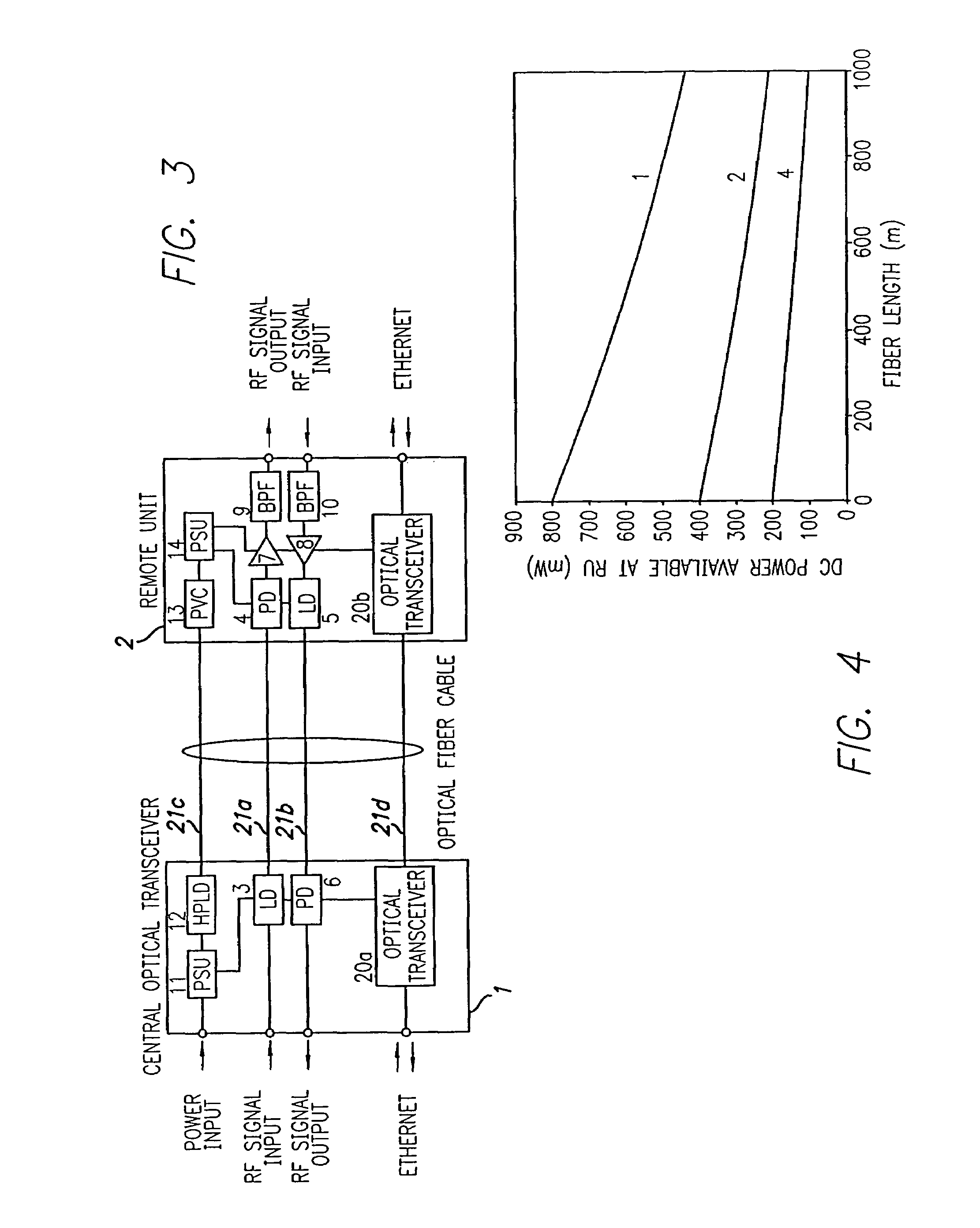

Optical fiber communications method and system without a remote electrical power supply

ActiveUS20050226625A1Reduce power consumptionReduced Power RequirementsElectromagnetic transmissionWireless communicationElectrical conductorOptical communication

The present invention allows remote antenna units for radio frequency signal transmission and receipt to operate without the requirement for remote electrical power supplies or for connecting cables that incorporate electrical conductors. According to an aspect of the present invention, an optical communications system employing radio frequency signals comprises a central unit; at least one remote unit having at least one optoelectronic transducer for converting optical data signals to radio frequency signals and converting radio signals to optical signals and at least one antenna to receive and send radio frequency signals; at least one optical fiber data link between the central unit and the remote unit for transmitting optical data signals therebetween; and at least one optical fiber power link between the central unit and the remote unit for providing electrical power at the remote unit.

Owner:NEXTG NETWORKS INC

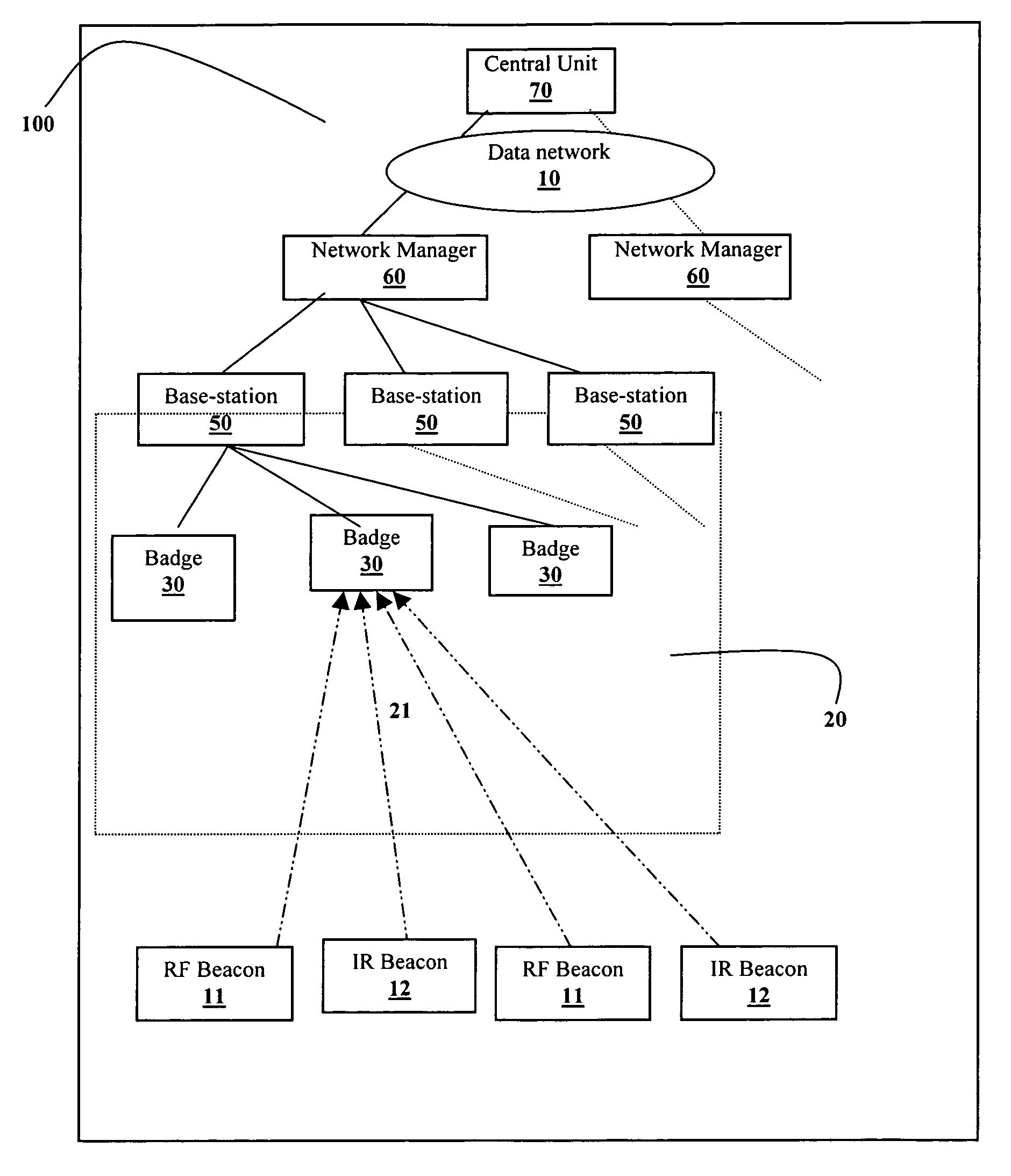

Two-way wireless monitoring system and method

InactiveUS20060290519A1Increase ping rateIncrease ratingsIndividual entry/exit registersAlarmsMonitoring systemCentral unit

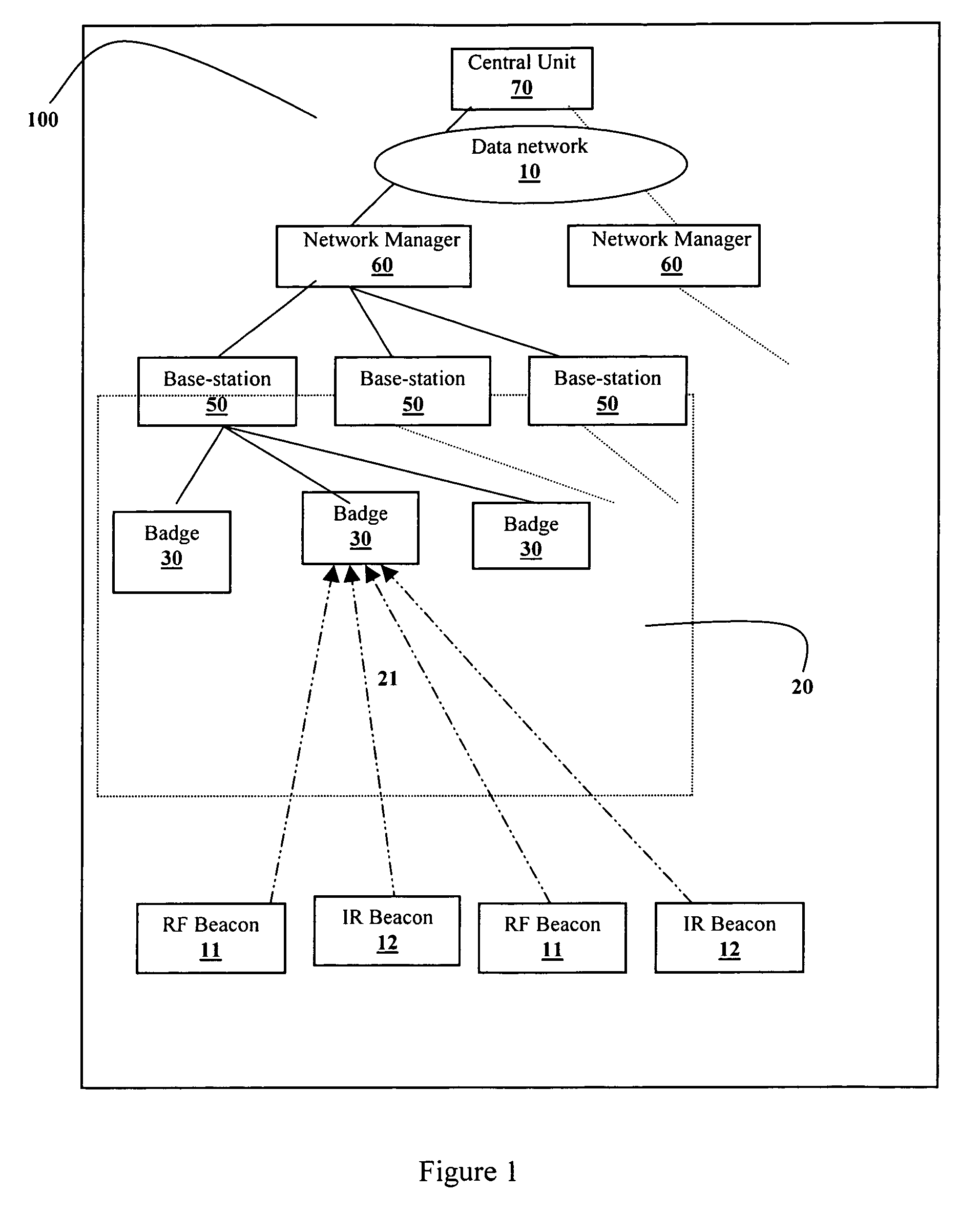

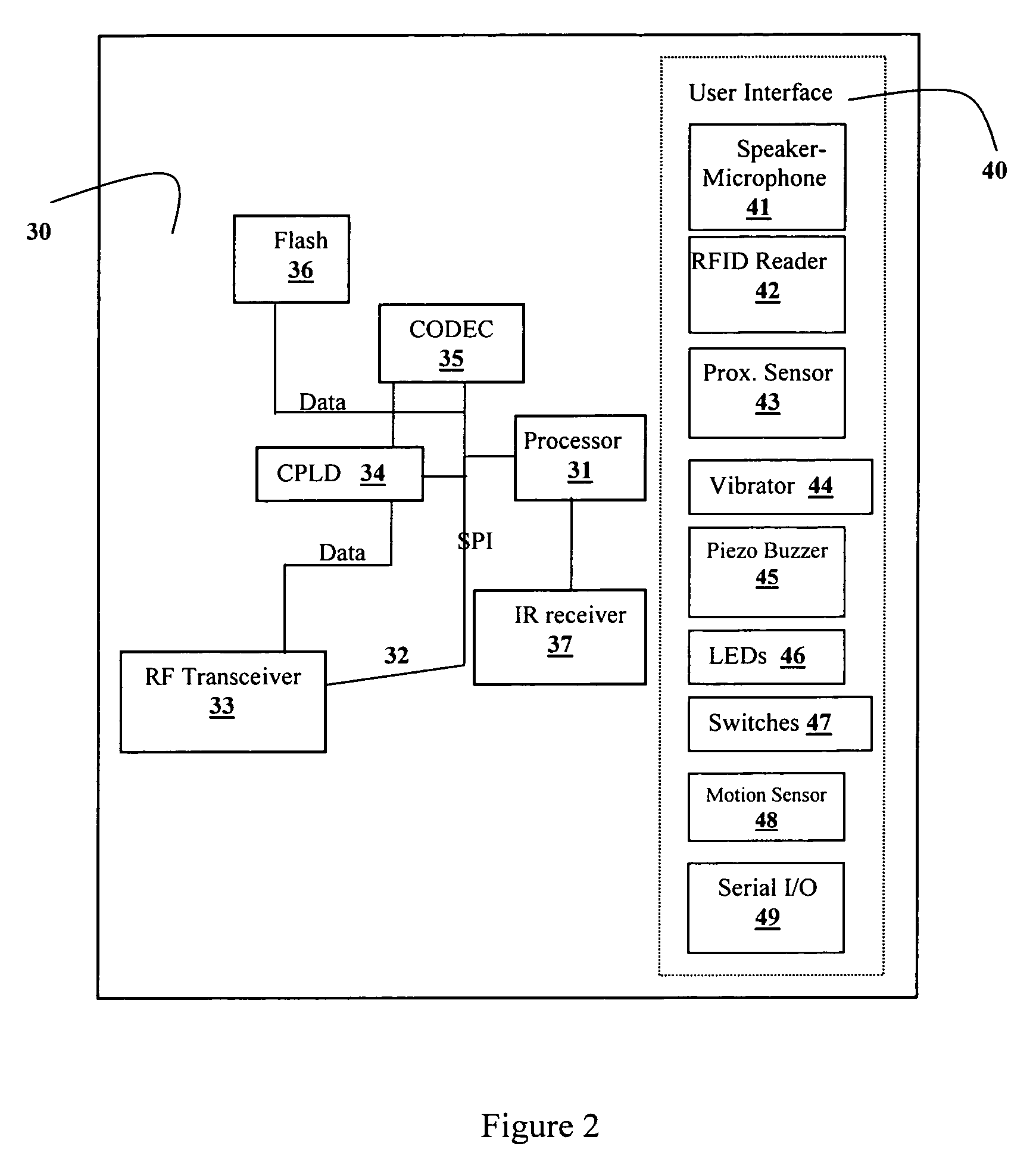

A two-way wireless monitoring system tracks the location of badged users or objects within a facility, and accordingly provides a variety of services relevant to the badge location and ID. The system comprises a plurality of beacons bearing beacon IDs distributed throughout the facility, a portable badge having a badge address, a base-station having access to a central unit via a data network. Each beacon periodically broadcasts the respective beacon ID, for being picked up by the badge when being nearby. The base-station polls the badge to receive the beacon IDs of the nearby beacons, and then uploads such beacon IDs to the central unit via the data network. Finally, the central unit estimates the badge location and decides on triggering an event within the facility based on the estimated badge location.

Owner:IGEACARE SYST

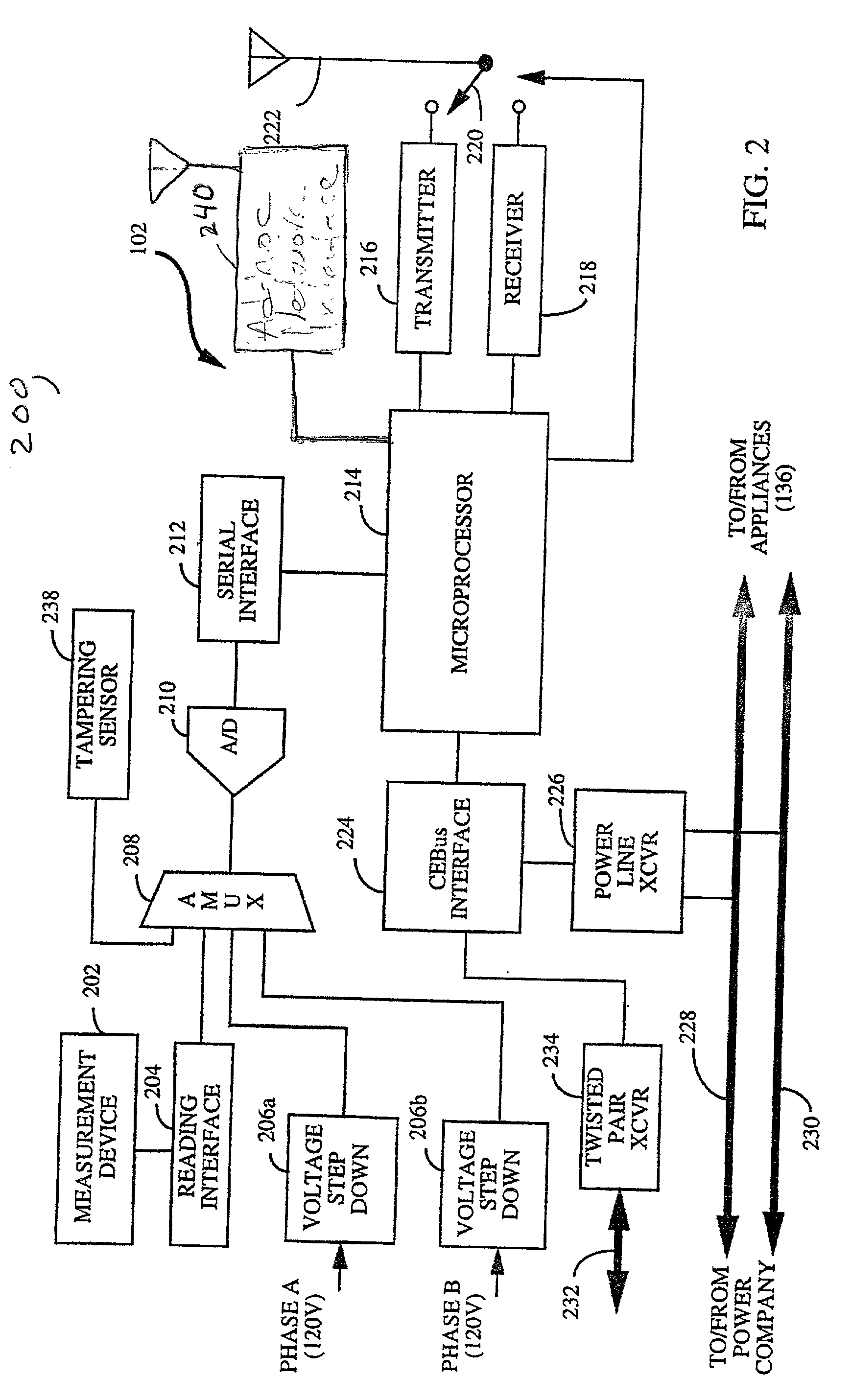

Method and apparatus for wireless remote telemetry using ad-hoc networks

InactiveUS6985087B2Use minimizedLow costElectric signal transmission systemsTariff metering apparatusIntelligent planningCommunication unit

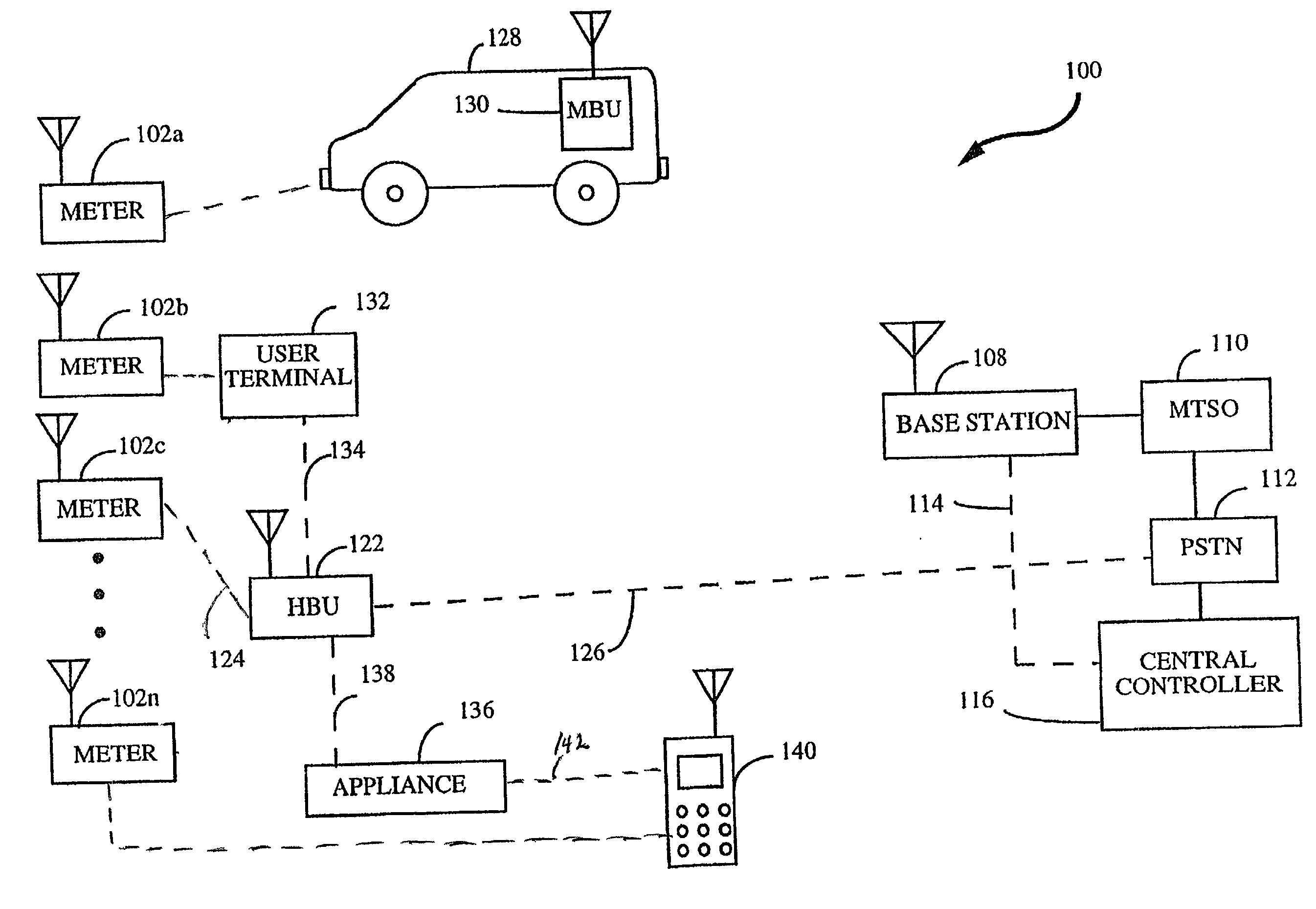

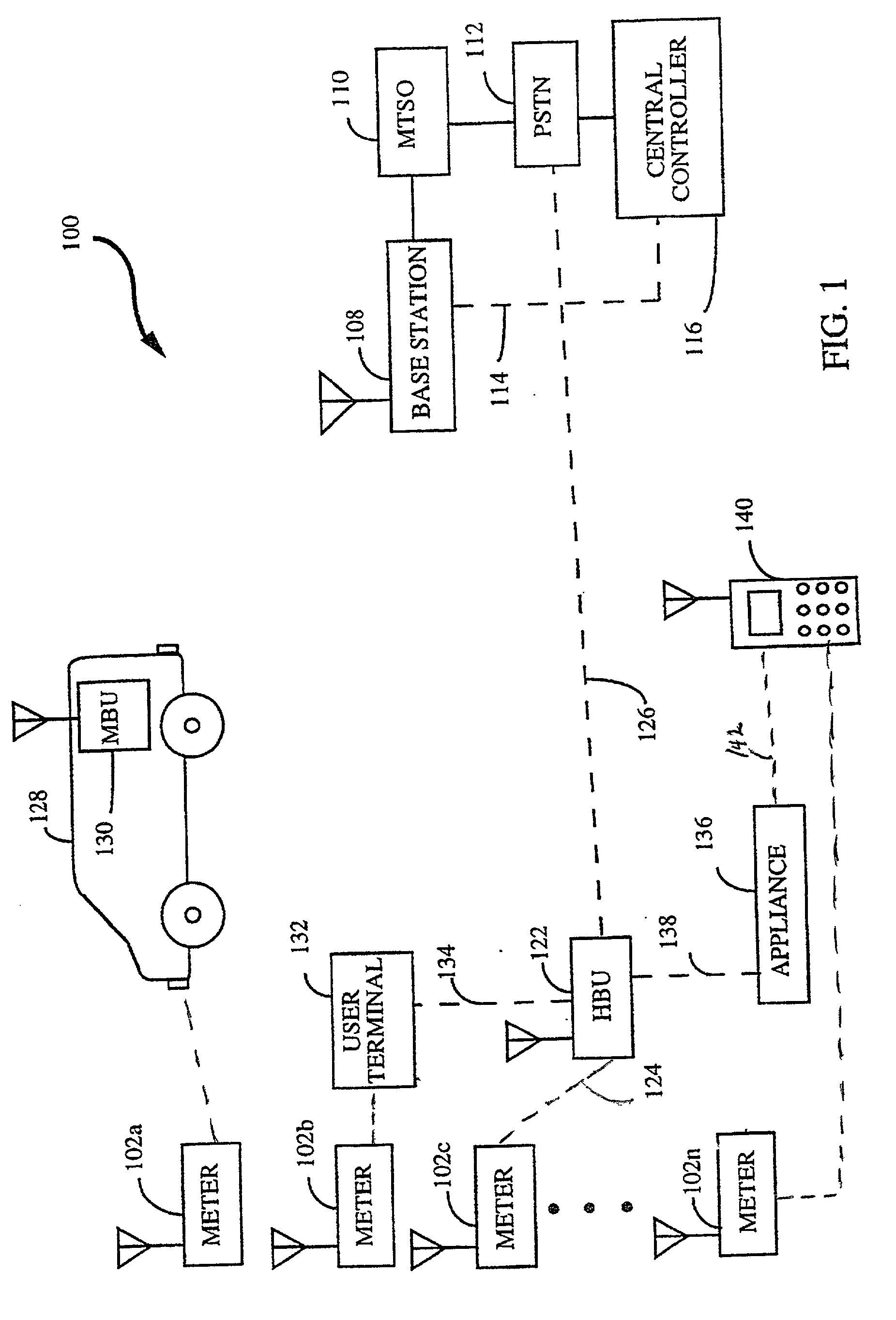

A wireless remote telemetry system uses low-cost, low-power ad-hoc networks to provide flexible reading and control of remote devices. In an embodiment applicable to a utility service, consumption of electrical power among a population of customers is measured by a utility metering system having ad-hoc network communication capability. The remote metering unit transmits information over an ad-hoc network to one or more intermediate communication units or hops. The intermediate communication units or hops include a mobile unit, a mobile base unit, a subscriber home computer, and a home base unit. Each of these hops may co-exist in the same large-scale system. The intermediate communication units transfer the received information to a central controller through multi-hop ad-hoc networks or cellular networks, according to intelligent planning by the wireless infrastructure or the central unit.

Owner:QUALCOMM INC

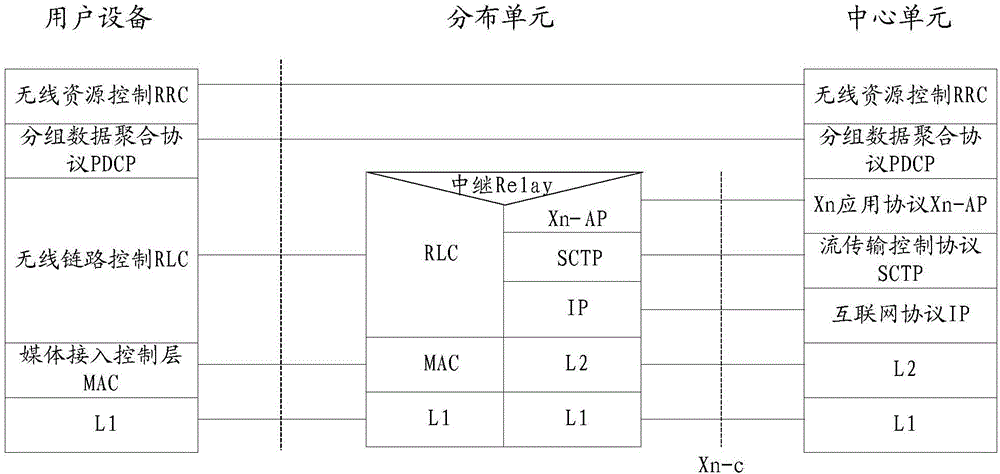

Communication method, equipment and system

ActiveCN106162730AFacilitate communicationNetwork traffic/resource managementAssess restrictionTelecommunicationsResource information

An embodiment of the invention discloses a communication method. The communication method is used for defining the signaling interaction flow between a central unit and a distribution unit. The method includes: the distribution unit receives a wireless link building request transmitted by the central unit, wherein the wireless link building request comprises resource information for building a wireless link; the distribution unit builds the wireless link according to the resource information; the distribution unit transmits the wireless link building response to the central unit.

Owner:SHANGHAI HUAWEI TECH CO LTD

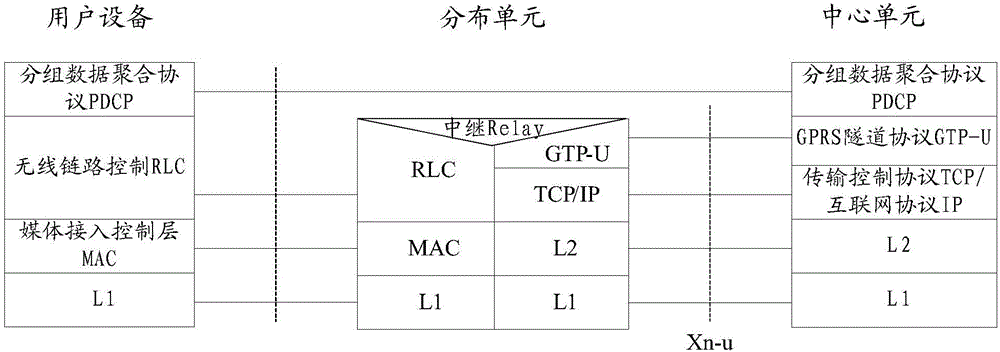

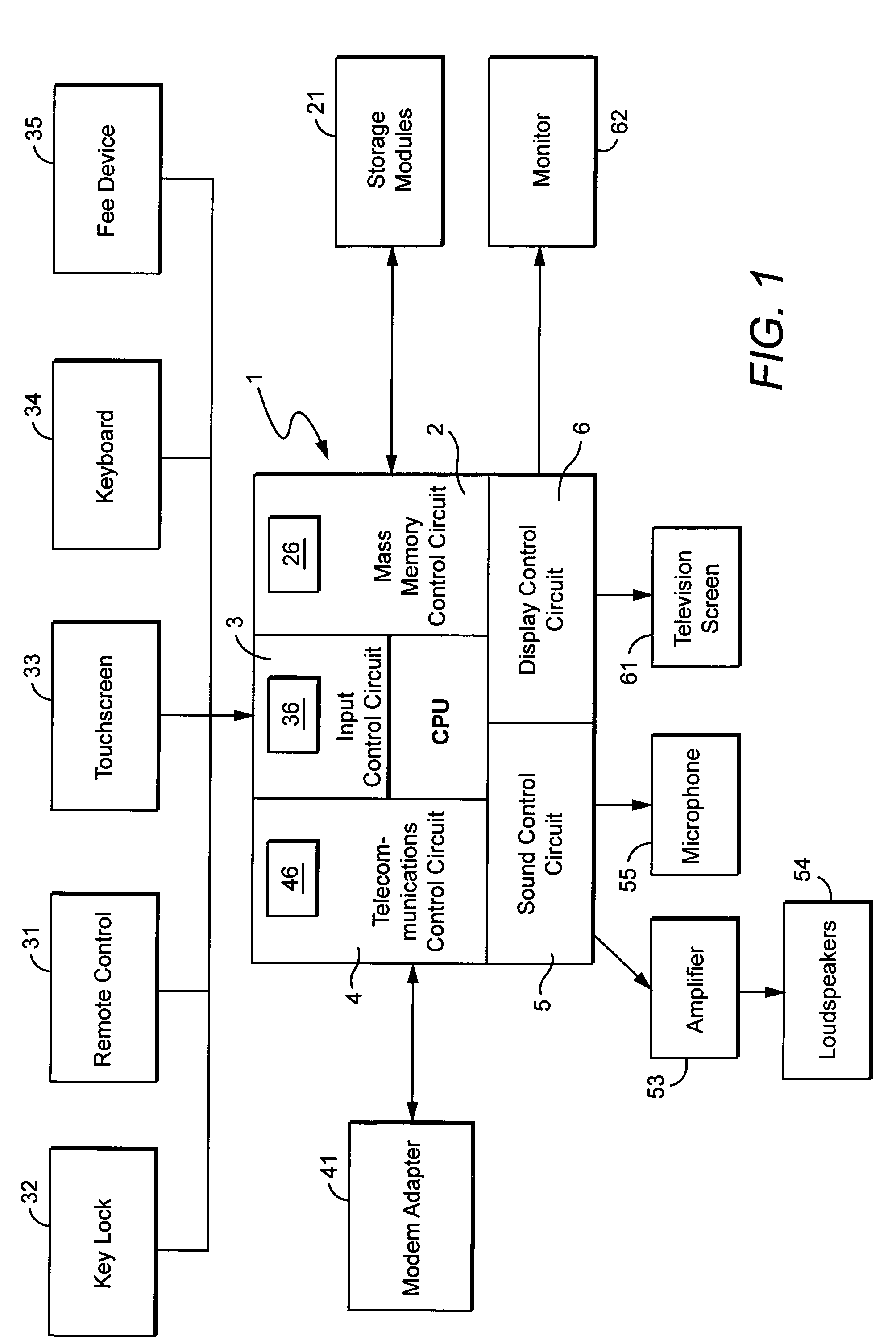

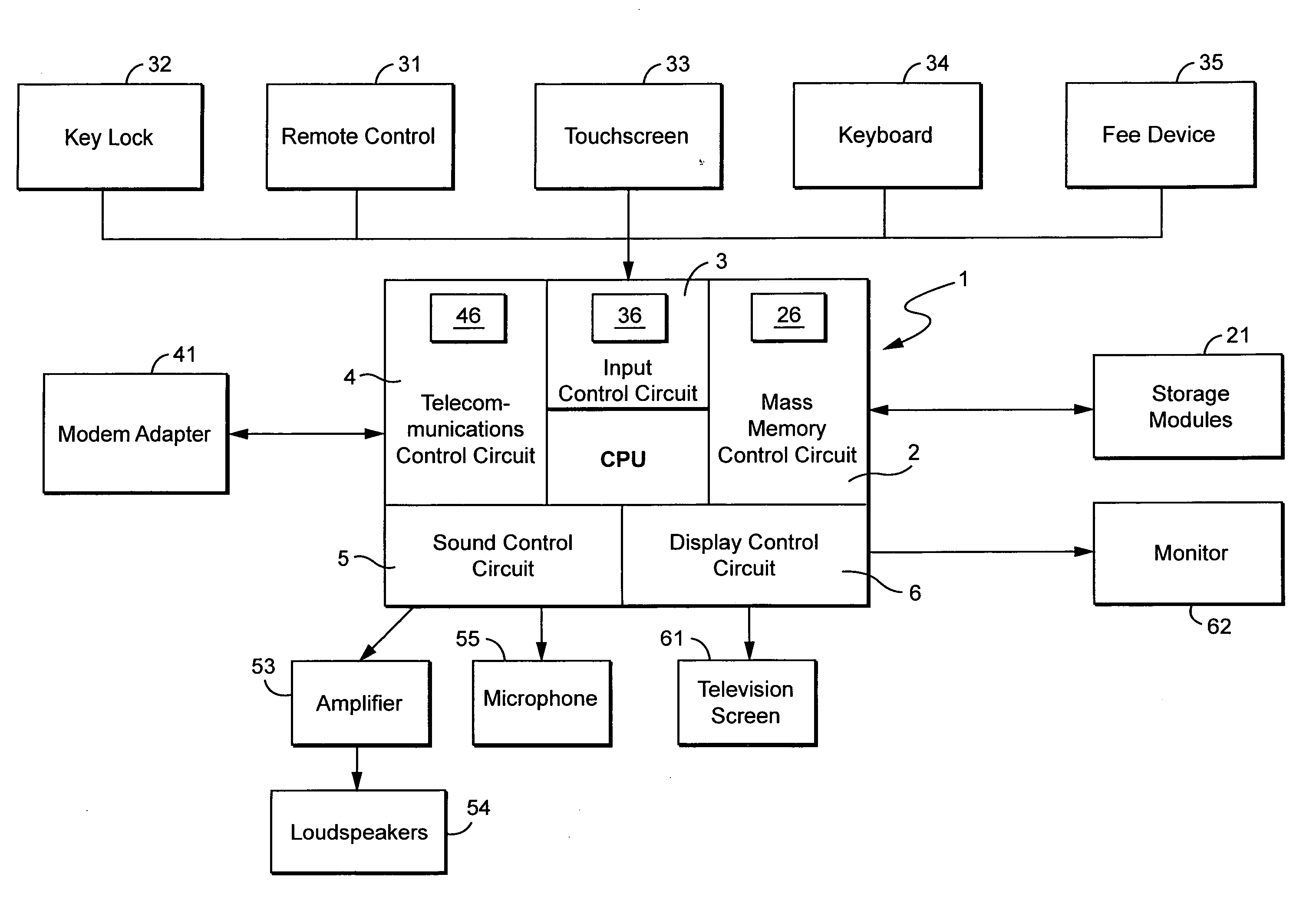

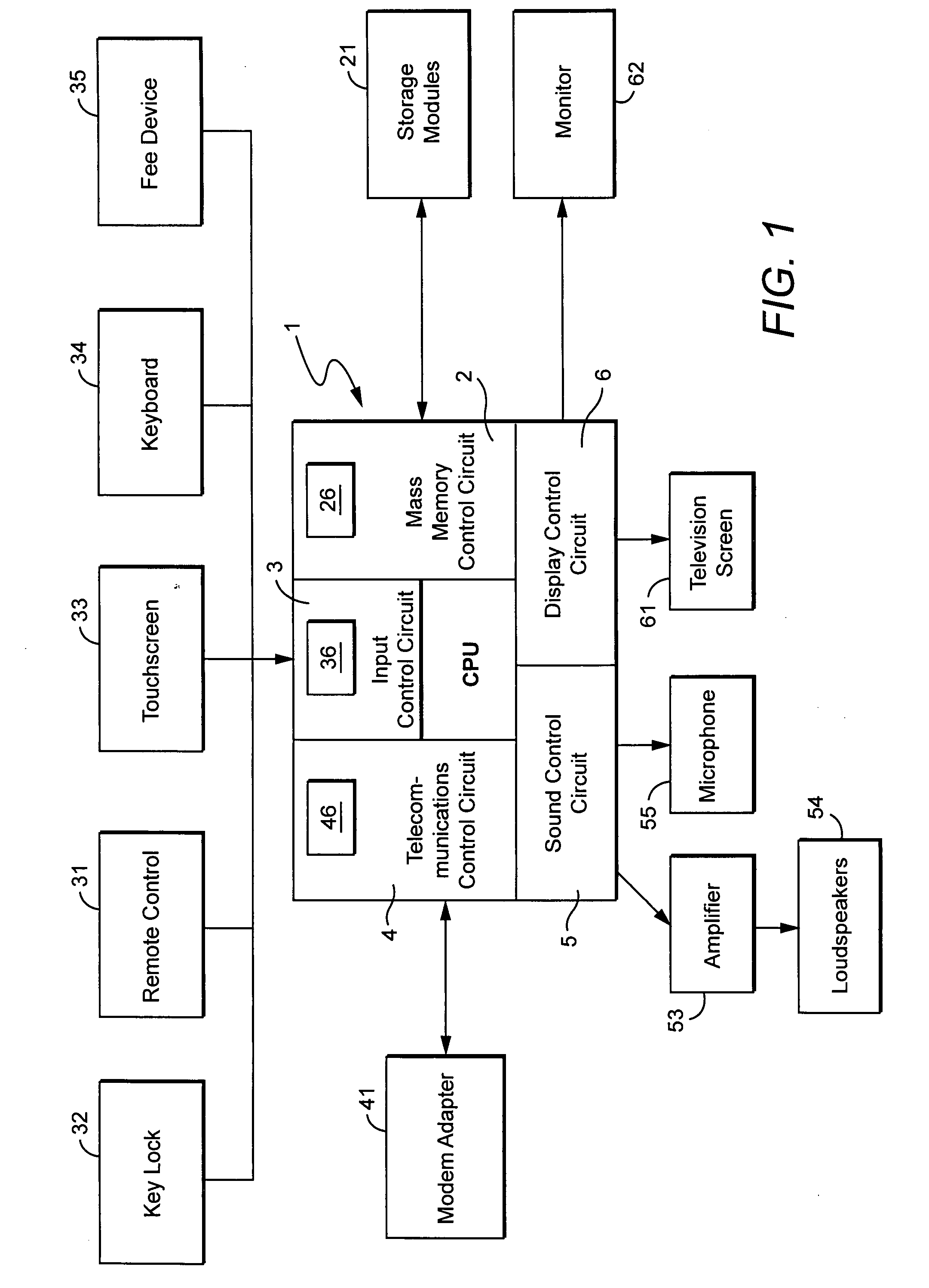

Audiovisual reproduction system

InactiveUS7231656B1Enhanced interactionEasy to useTelevision system detailsElectrophonic musical instrumentsOperational systemModem device

Audiovisual reproduction system comprising a central unit managing a sound control circuit, and a telecommunications modem connected to a distribution network controlled by a host server, through a multitask operating system created around a tools and services library, characterized in that the operating system comprises a function that adjusts the sound control circuit to couple volumes in the various areas in which the loudspeakers in the audiovisual reproduction system are used, this function being accessible through a management mode of the multitask operating system, the coupling maintaining the ratios between the various volumes in each area when the volume in one area is modified.

Owner:TOUCHTUNES MUSIC CORP

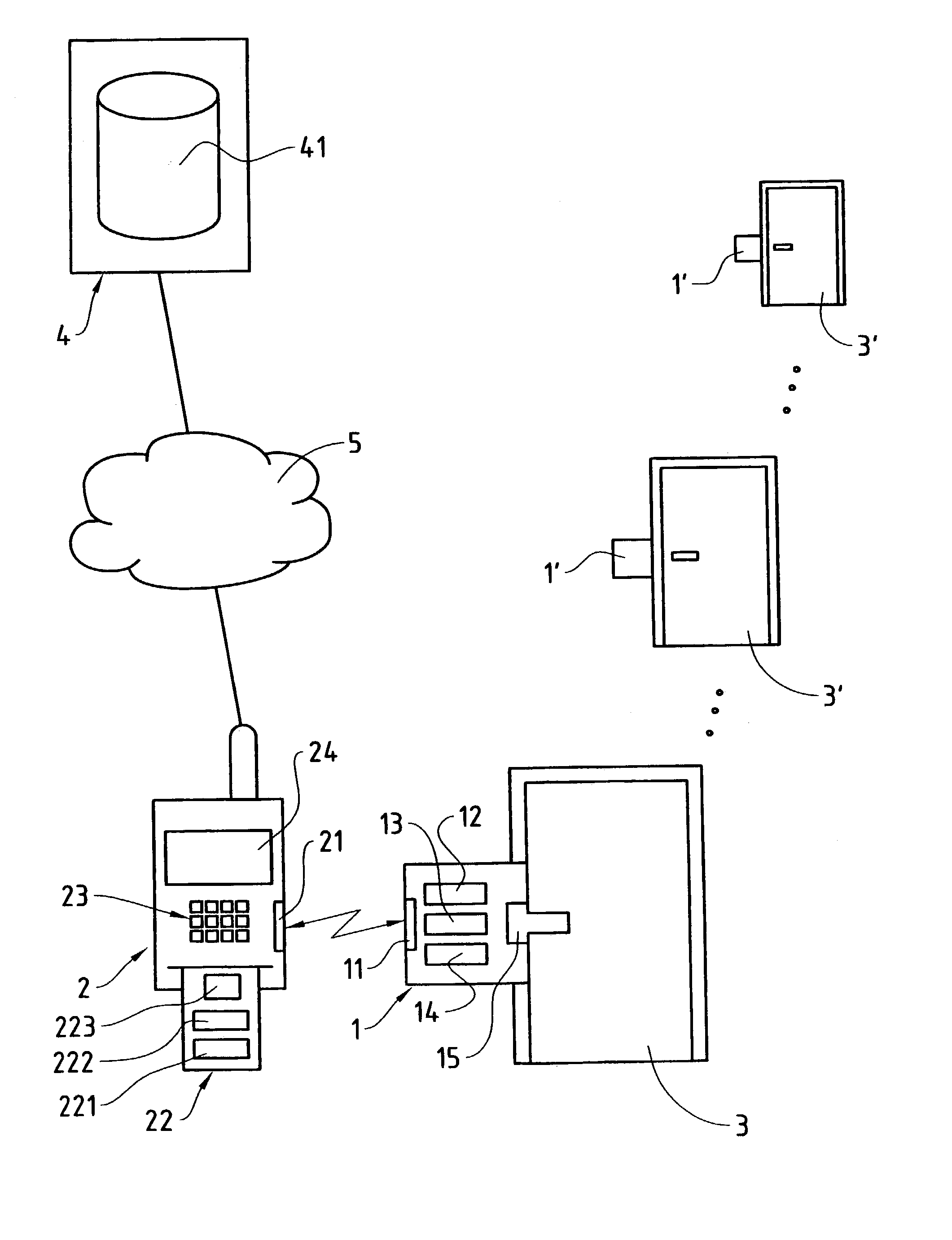

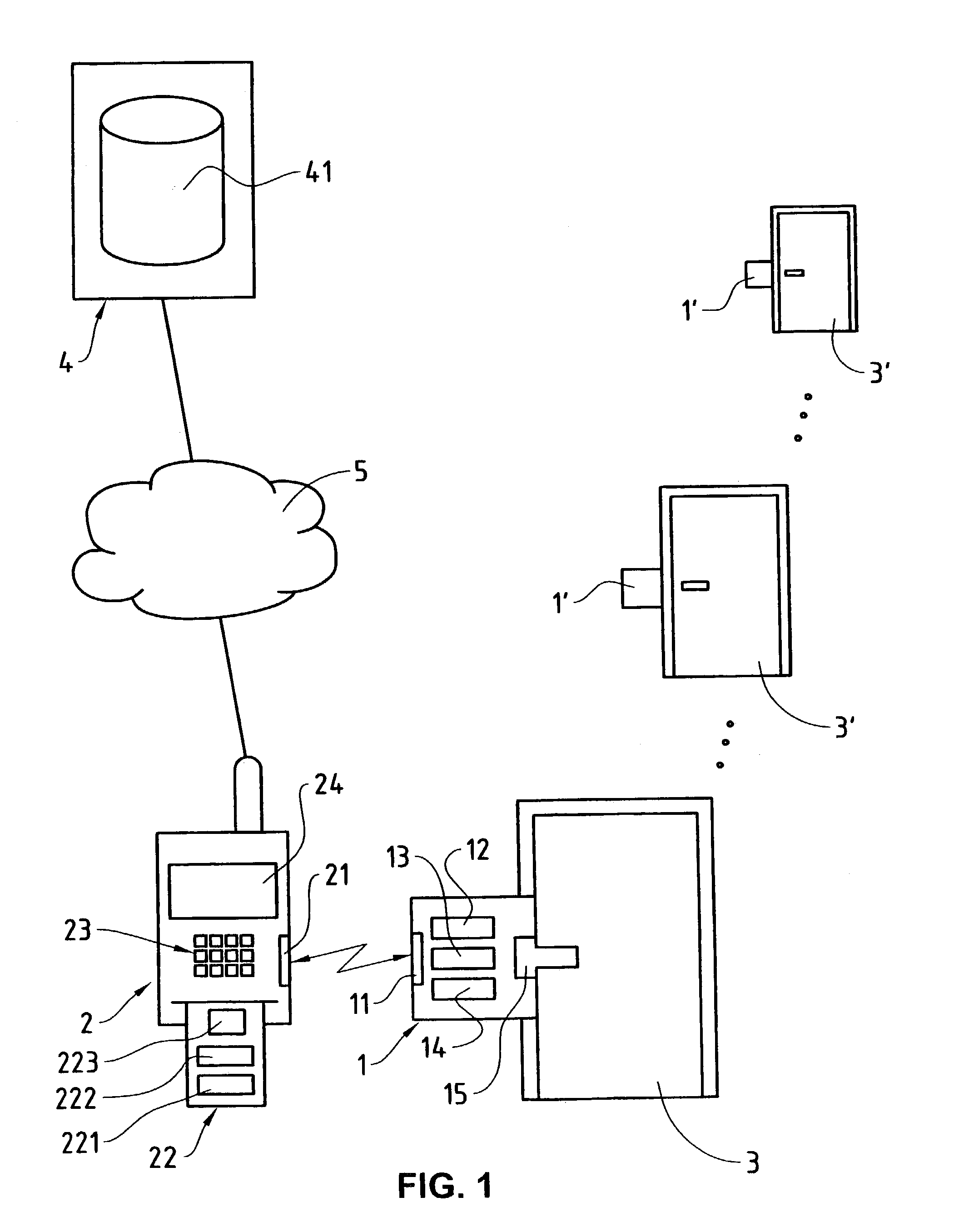

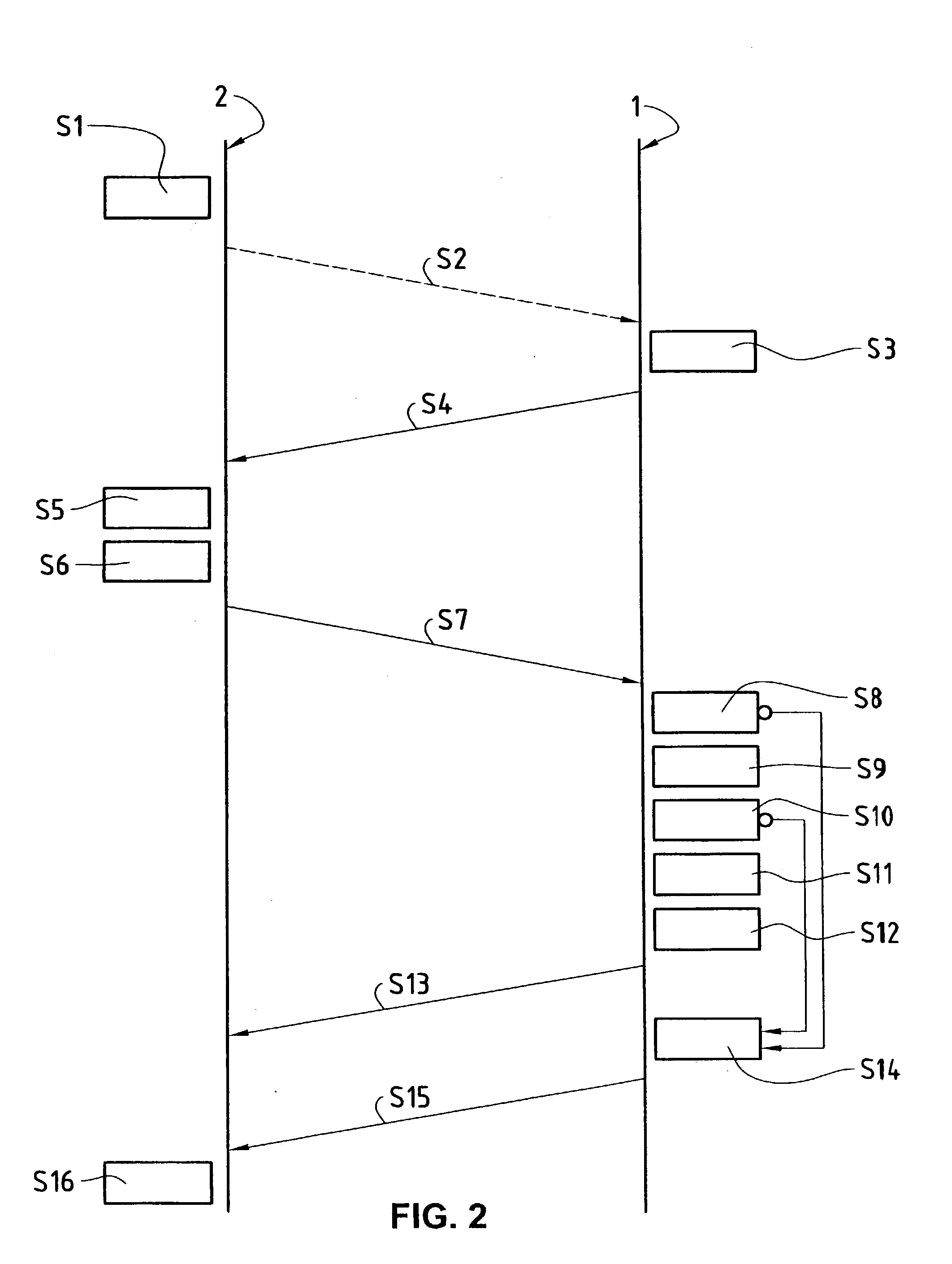

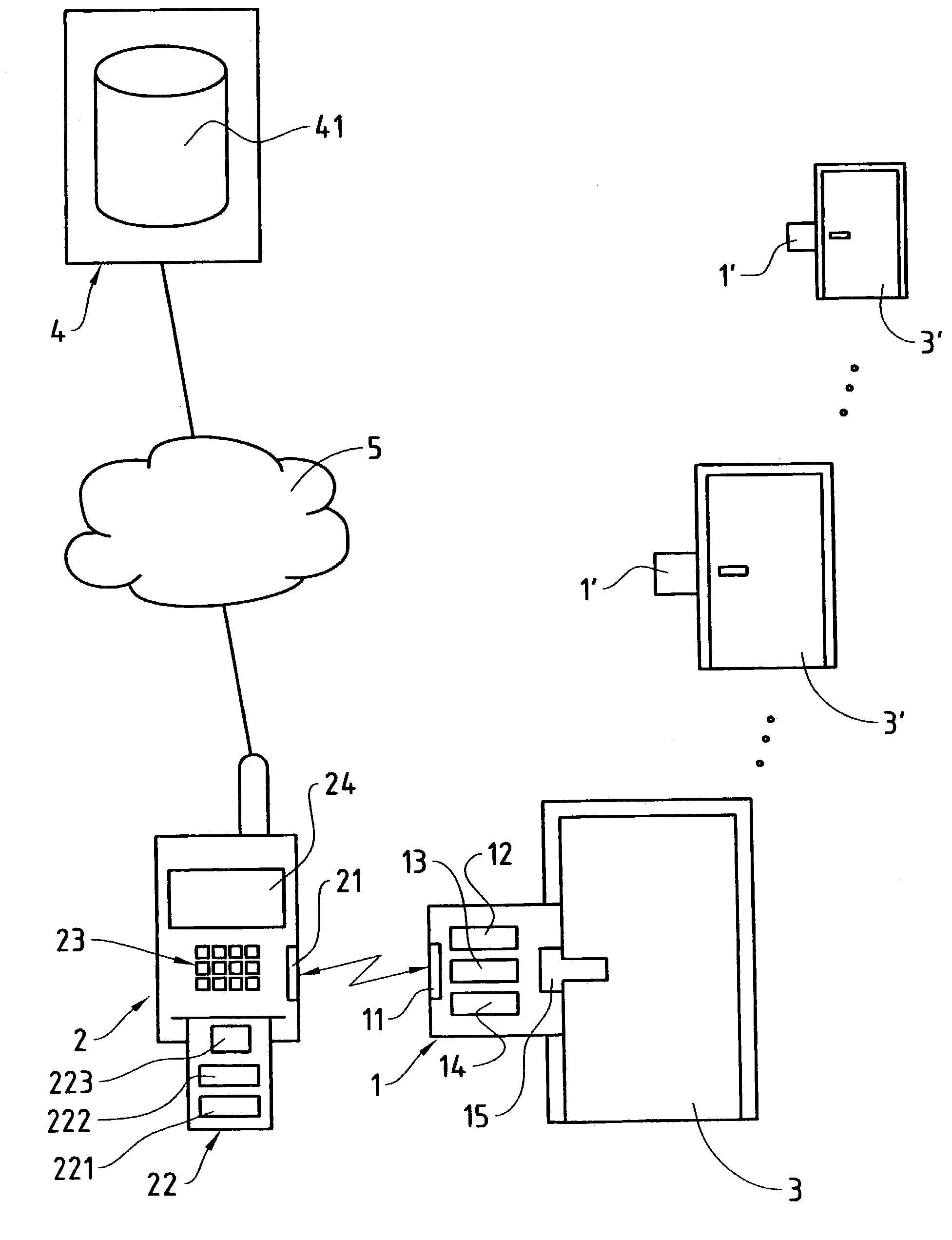

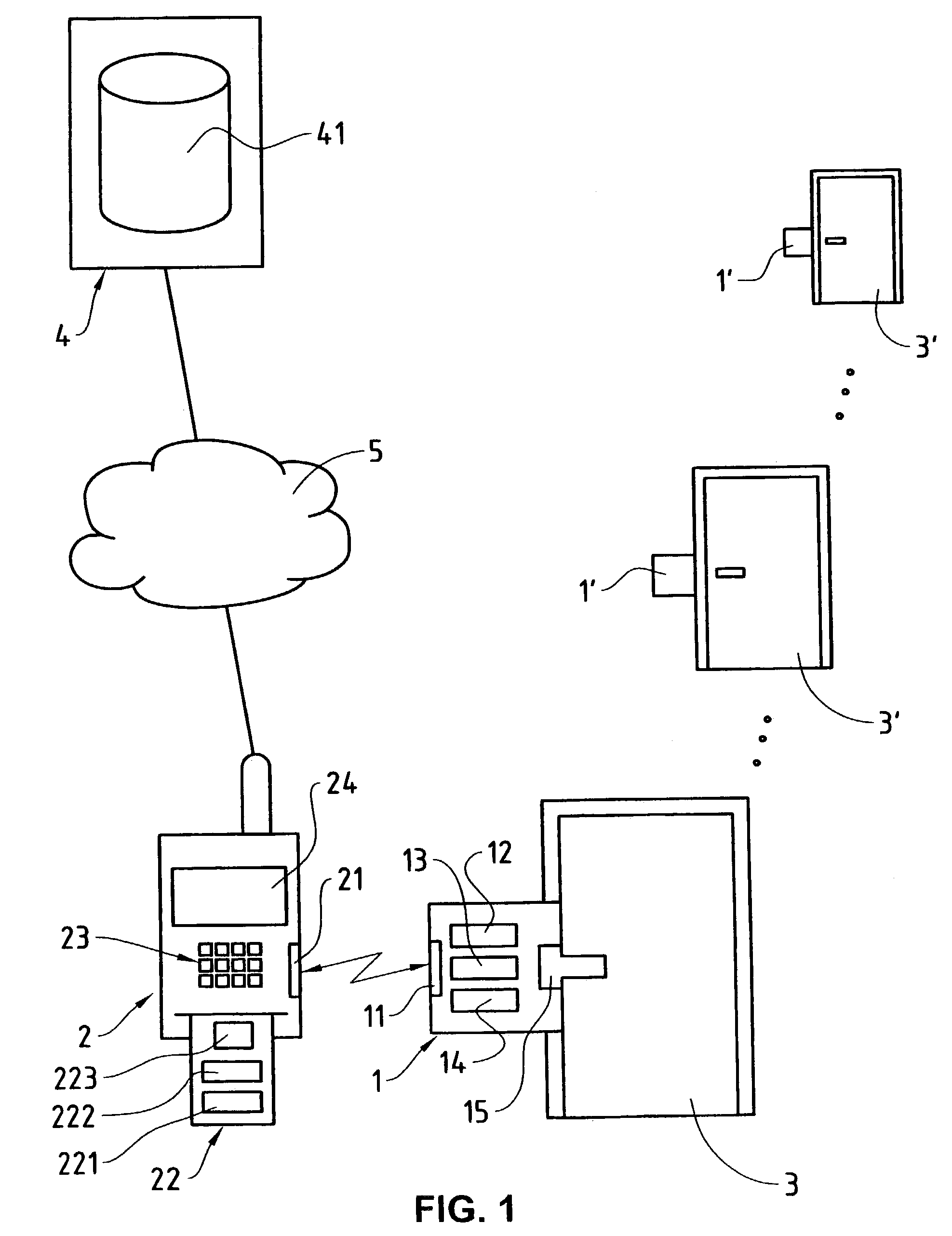

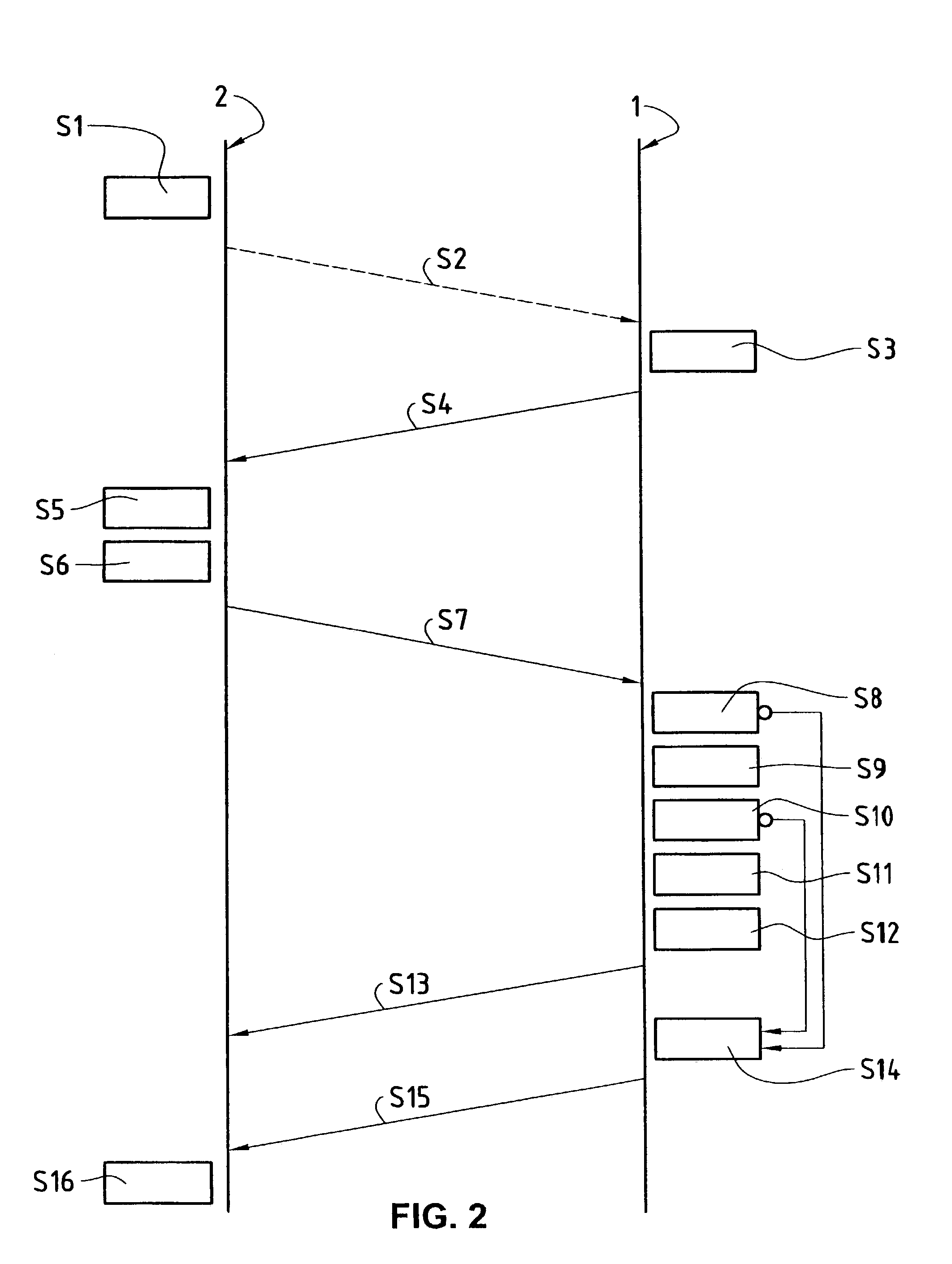

Access control system, access control method and devices suitable therefor

InactiveUS20030151493A1Electric signal transmission systemsMultiple keys/algorithms usageControl systemCentral unit

An access control system comprises a plurality of access control devices in each of which is stored an access code. Specific access codes and access rights for a plurality of access control devices are transmitted from an access control central unit over a mobile radio network to the mobile communication terminal of a user. Transmitted to the mobile communication terminal by an access control device to be passed is an access control device identification. In the mobile communication terminal, on the basis of the received identification, the access code and the access rights for the access control device to be passed are determined, and are transmitted to the access control device. The access control device clears the user for access if the received access rights suffice and the received access code agrees with the stored access code.

Owner:ZEIT

Audiovisual reproduction system

InactiveUS20070209053A1Enhanced interactionEasy to useTelevision system detailsElectrophonic musical instrumentsModem deviceOperational system

Audiovisual reproduction system comprising a central unit managing a sound control circuit, and a telecommunications modem connected to a distribution network controlled by a host server, through a multitask operating system created around a tools and services library, characterized in that the operating system comprises a function that adjusts the sound control circuit to couple volumes in the various areas in which the loudspeakers in the audiovisual reproduction system are used, this function being accessible through a management mode of the multitask operating system, the coupling maintaining the ratios between the various volumes in each area when the volume in one area is modified.

Owner:TOUCHTUNES MUSIC CORP

Optical fiber communications method and system without a remote electrical power supply

ActiveUS7469105B2Reduce power consumptionReduced Power RequirementsElectromagnetic transmissionWireless communicationElectrical conductorEngineering

The present invention allows remote antenna units for radio frequency signal transmission and receipt to operate without the requirement for remote electrical power supplies or for connecting cables that incorporate electrical conductors. According to an aspect of the present invention, an optical communications system employing radio frequency signals comprises a central unit; at least one remote unit having at least one optoelectronic transducer for converting optical data signals to radio frequency signals and converting radio signals to optical signals and at least one antenna to receive and send radio frequency signals; at least one optical fiber data link between the central unit and the remote unit for transmitting optical data signals therebetween; and at least one optical fiber power link between the central unit and the remote unit for providing electrical power at the remote unit.

Owner:NEXTG NETWORKS INC

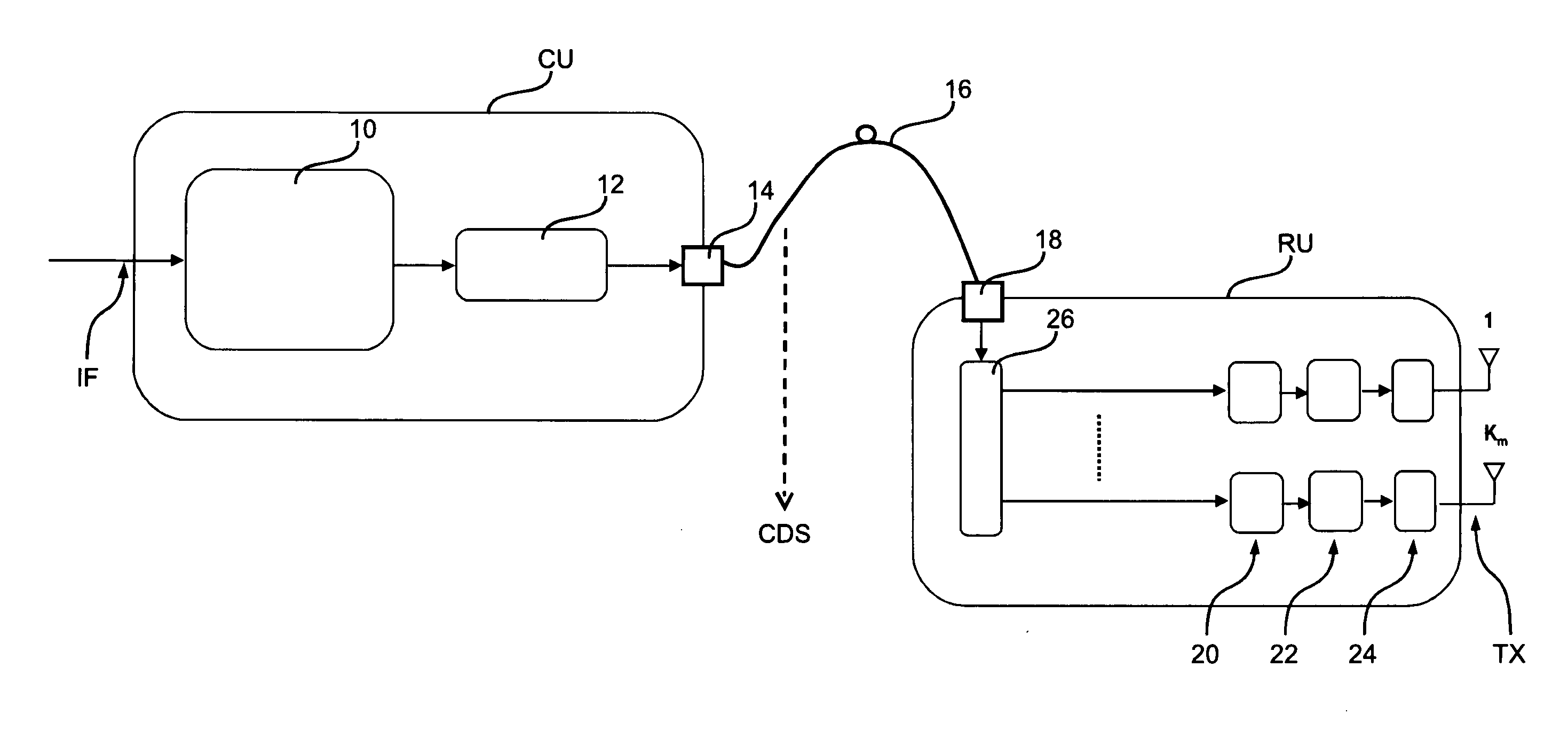

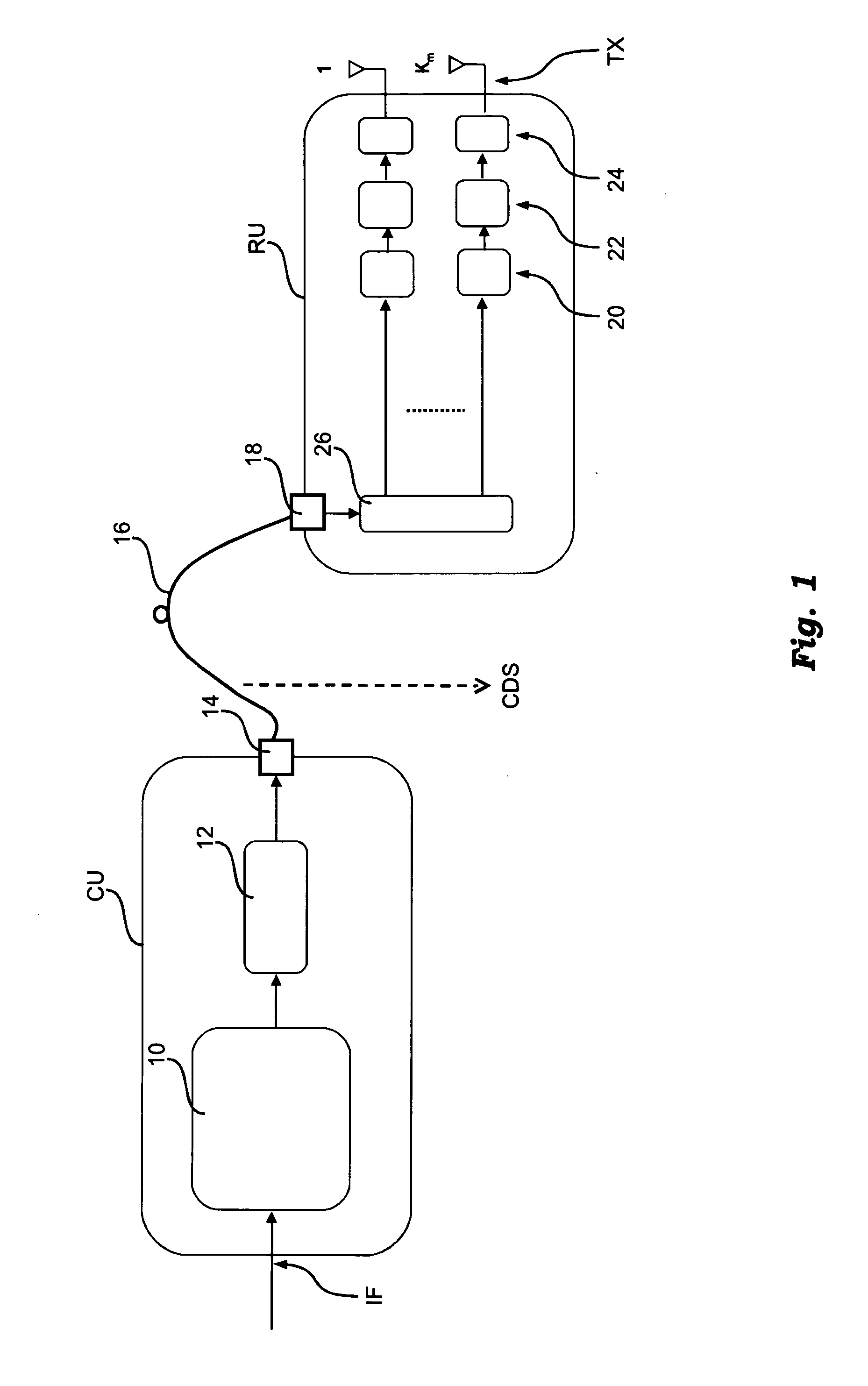

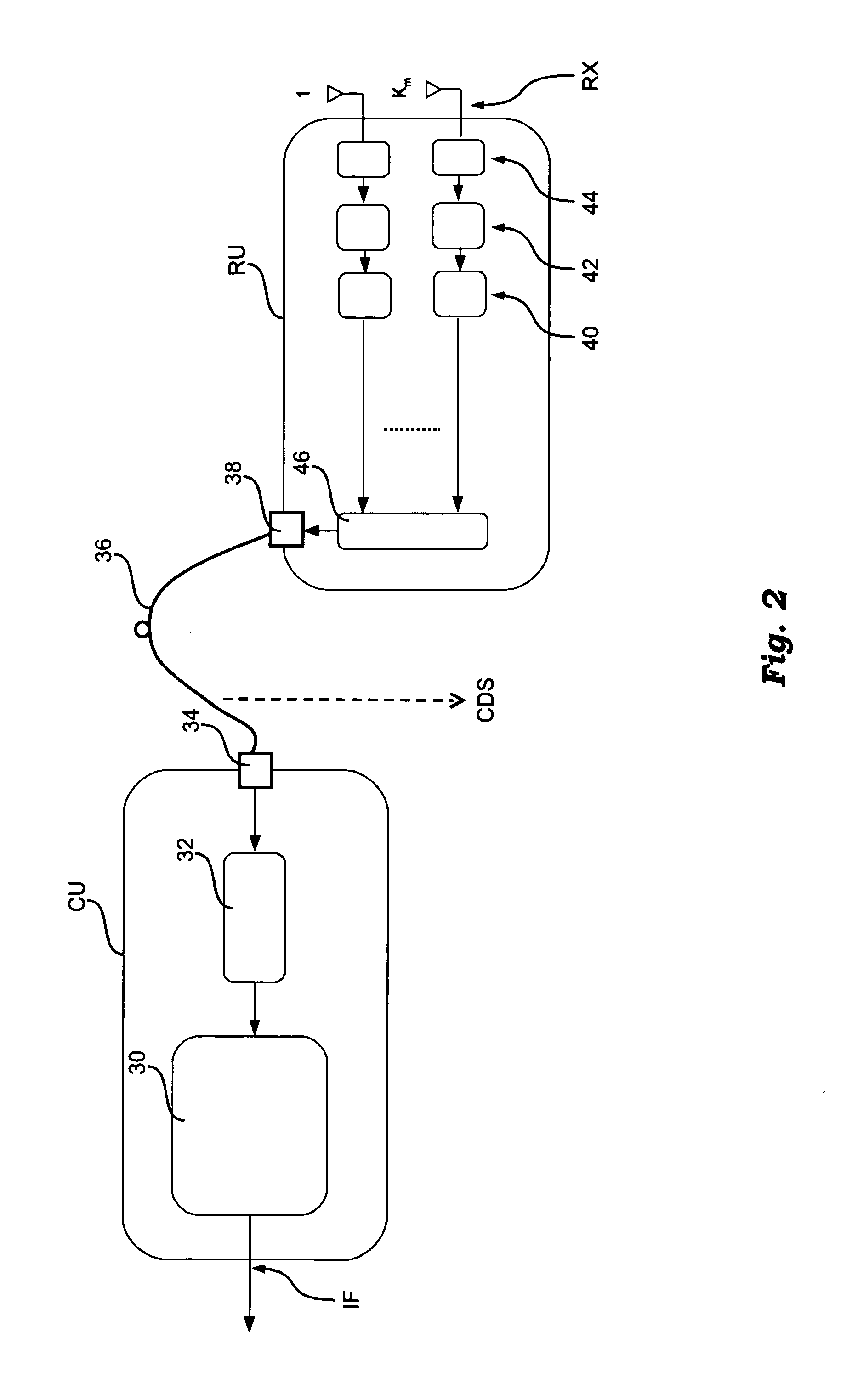

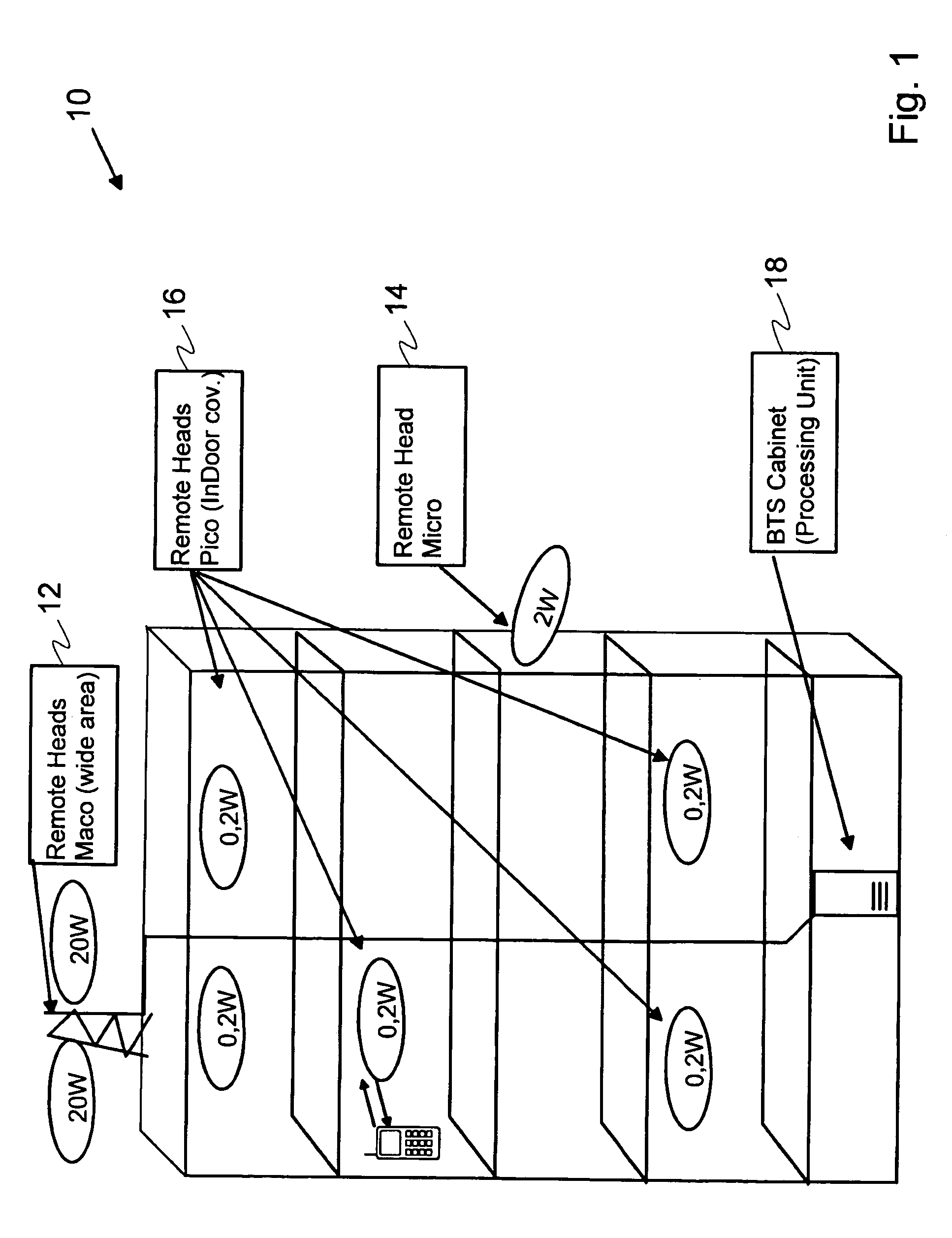

Method for distributed mobile communications, corresponding system and computer program product

ActiveUS20110268033A1High levelImprove scalabilitySite diversityInformation formatCentral unitEngineering

A method of arranging exchange of signals between user terminals in a cellular communication system and at least one base station. The base station includes a central unit and a plurality of remote units. The signals are exchanged between the central unit and the remote units as aggregated signals for plural user terminals. The signals are processed at the remote units as distinct signals each associated with a respective one of the plural user terminals.

Owner:TELECOM ITALIA SPA

Generating a root key for decryption of a transmission key allowing secure communications

ActiveUS7725740B2Digital data processing detailsUnauthorized memory use protectionSecure communicationThird party

A method is used to restore the security of a secure assembly such as a chip card, after the contents of its second memory zone have been read by a third party. The method is for generating a security key implemented by a secure module comprising a central unit, a first conditional access memory zone and at least one second memory zone containing all or part of the user program. The method includes reading of all or part of the second memory zone, and generation of at least one root key based on all or part of the second zone data and on at least one item of secret information stored in the first memory zone.

Owner:NAGRAVISION SA

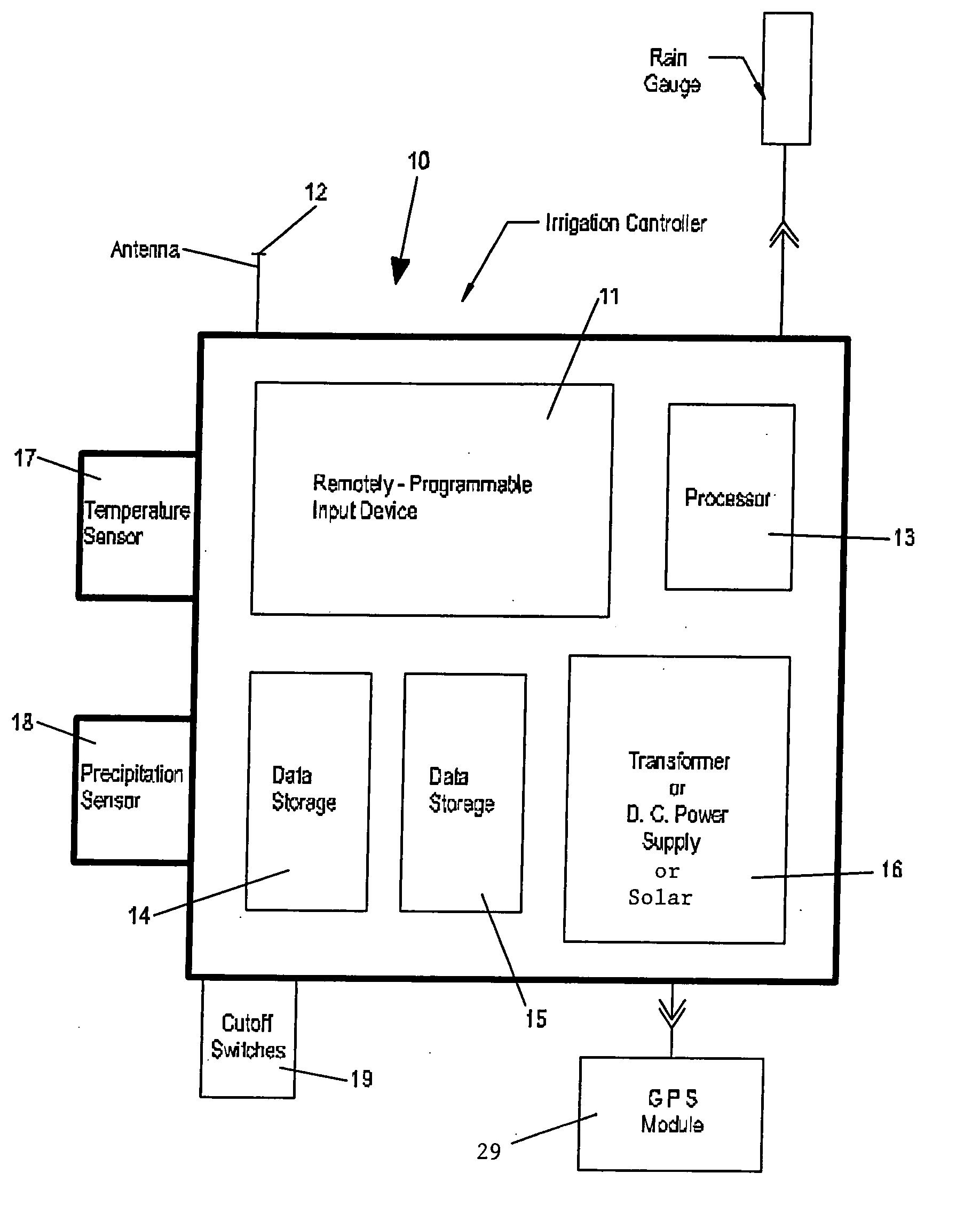

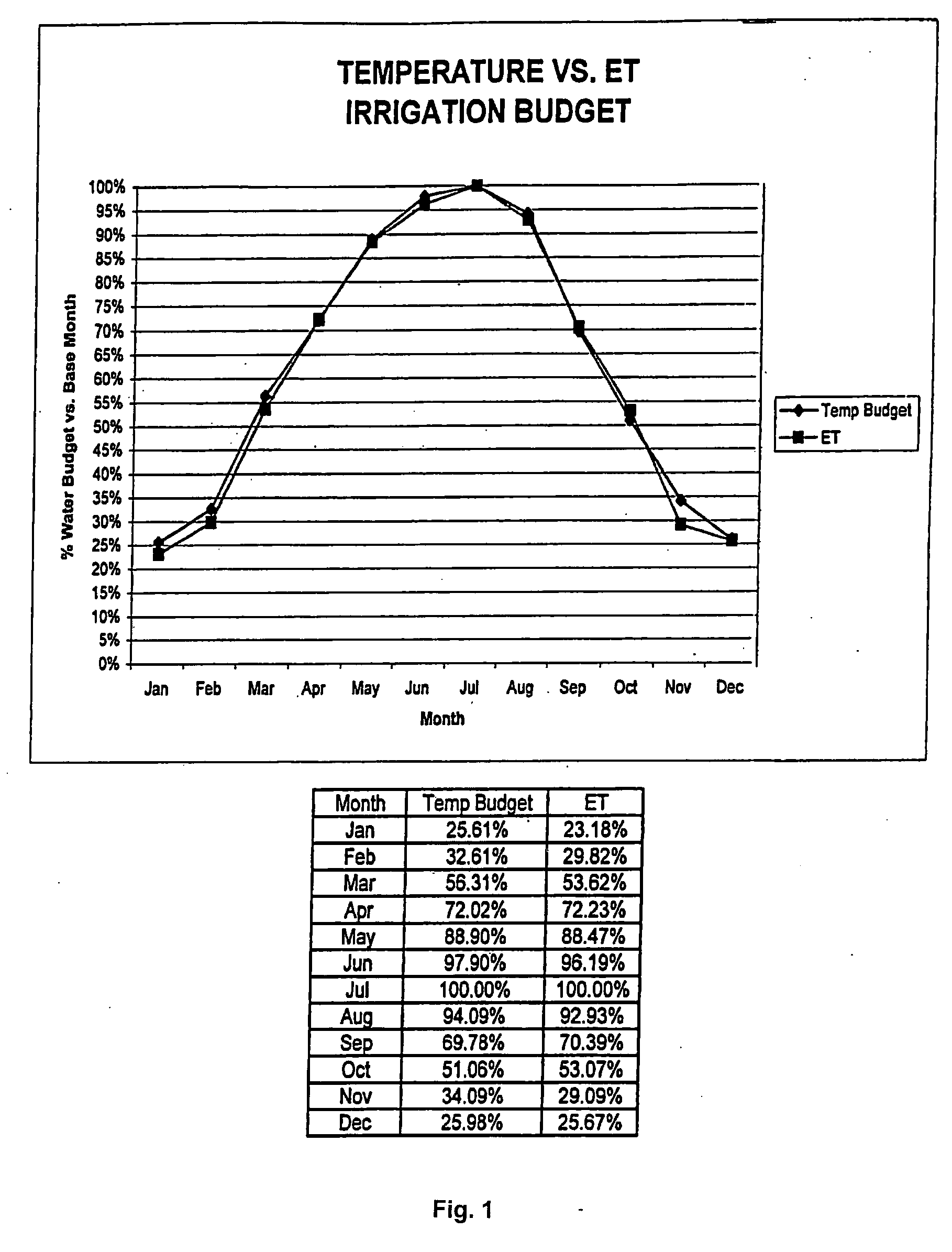

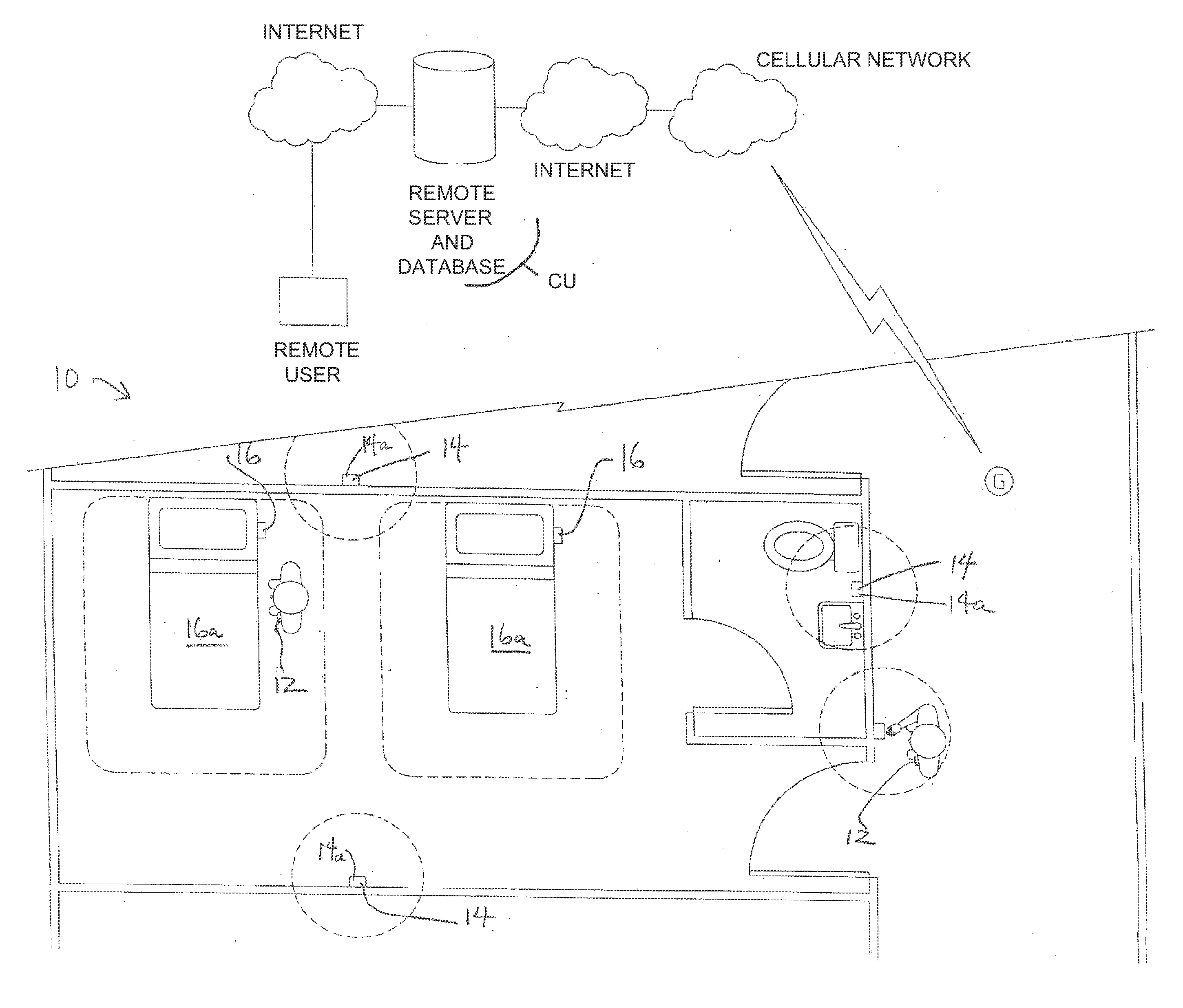

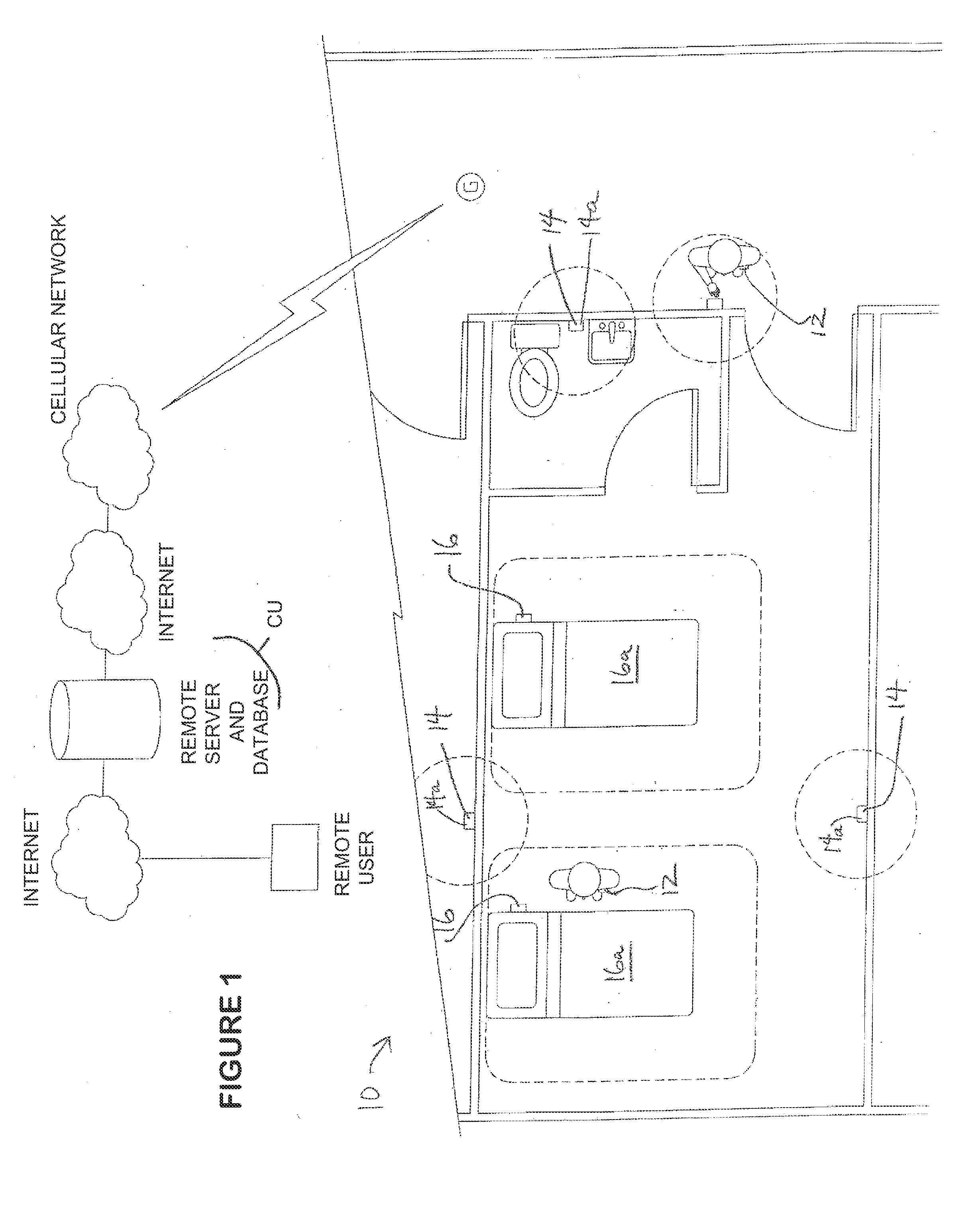

Irrigation water conservation with temperature budgeting and time of use technology

ActiveUS20070293990A1Minimizes runoffEasy and less-expensive to installSelf-acting watering devicesWatering devicesEngineeringCentral unit

The present invention provides numerous methods, systems and apparatus that use a novel form of water budgeting technology for water conservation without the use of complex ET (Evapotranspiration) data or methods. Embodiments include incorporating the technology directly into irrigation controllers, into modules added on to existing controllers, or into central units that broadcast a water budget that can alter the schedules of one, many, or selected groups of remotely located controllers or modules. The various methods of the present invention offer the choice of adjusting the station run times, accumulating the water budgets, altering the watering intervals, and / or combining the present water budgeting technology with local watering communities' restricted watering schedules. The result offers residential, commercial, and municipal users a wide range of practical choices for effective water conservation in landscape irrigation with temperature based water budgeting.

Owner:HUNTER INDUSTRIES

Sanitization Compliance Monitoring System

A sanitization compliance monitoring system comprises care giver badges, patient bed beacons associated with patient beds, dispenser beacons associated with sanitization dispensers, and a central unit for wirelessly communicating with the badges.

Owner:ECOLAB USA INC

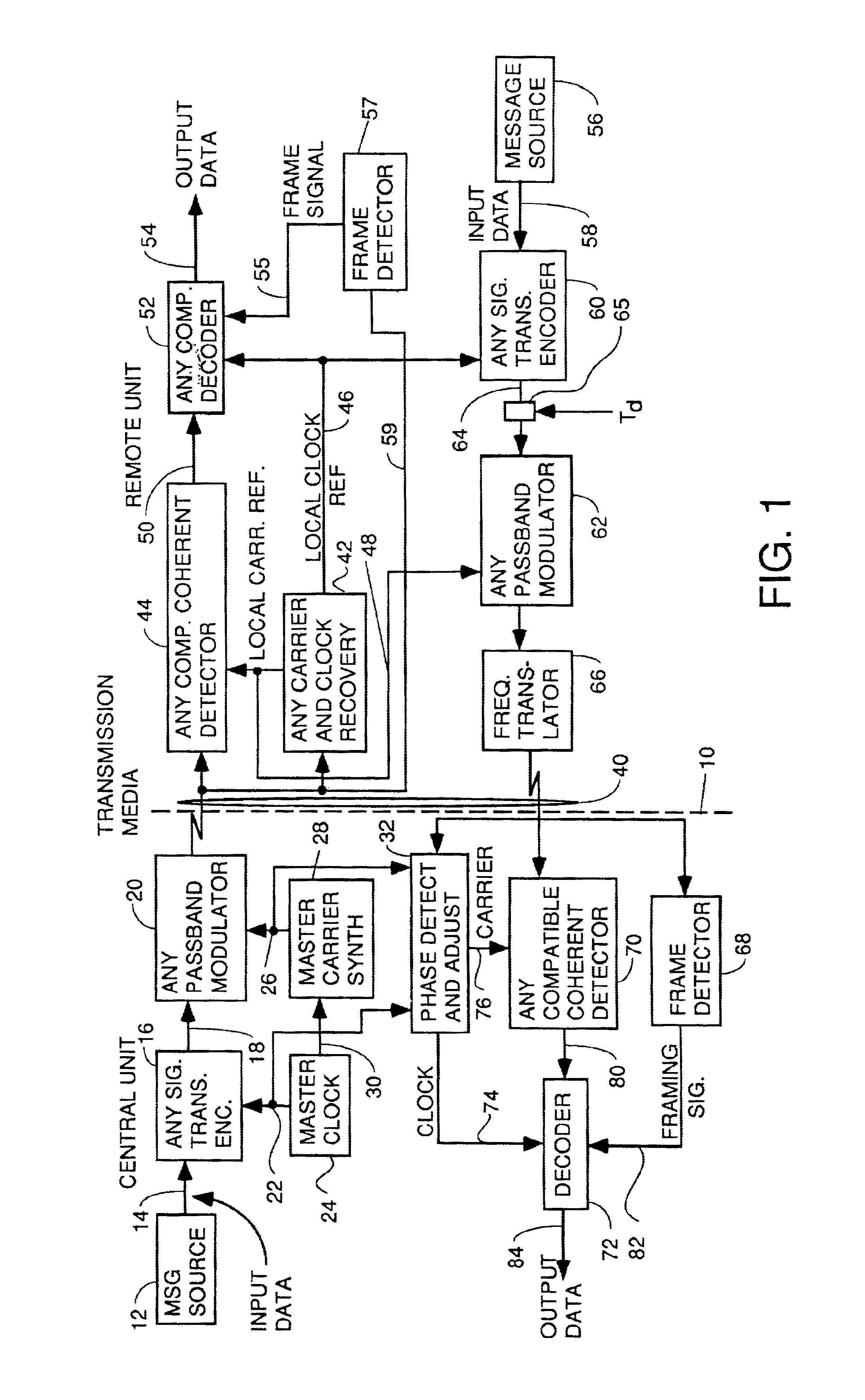

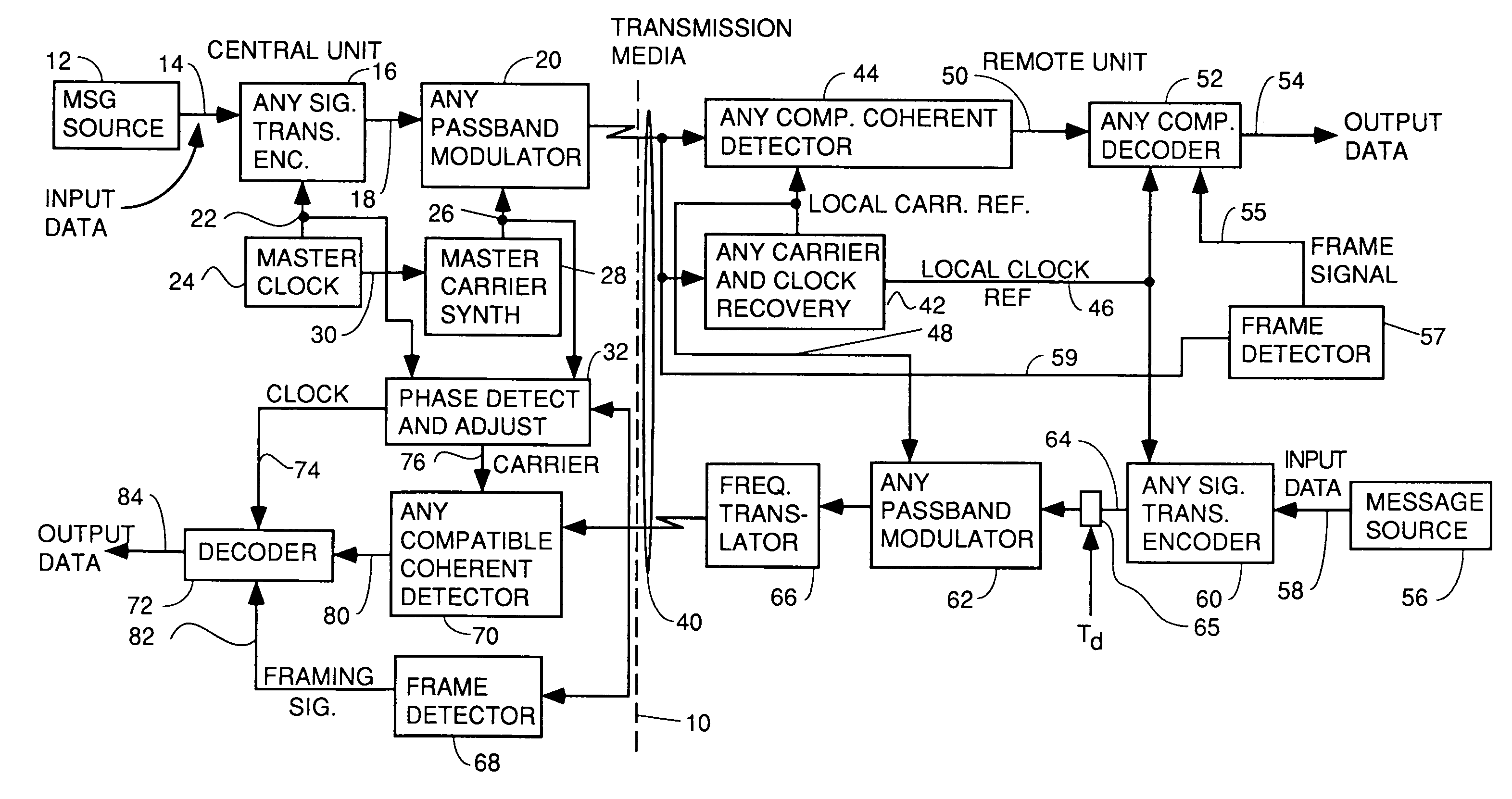

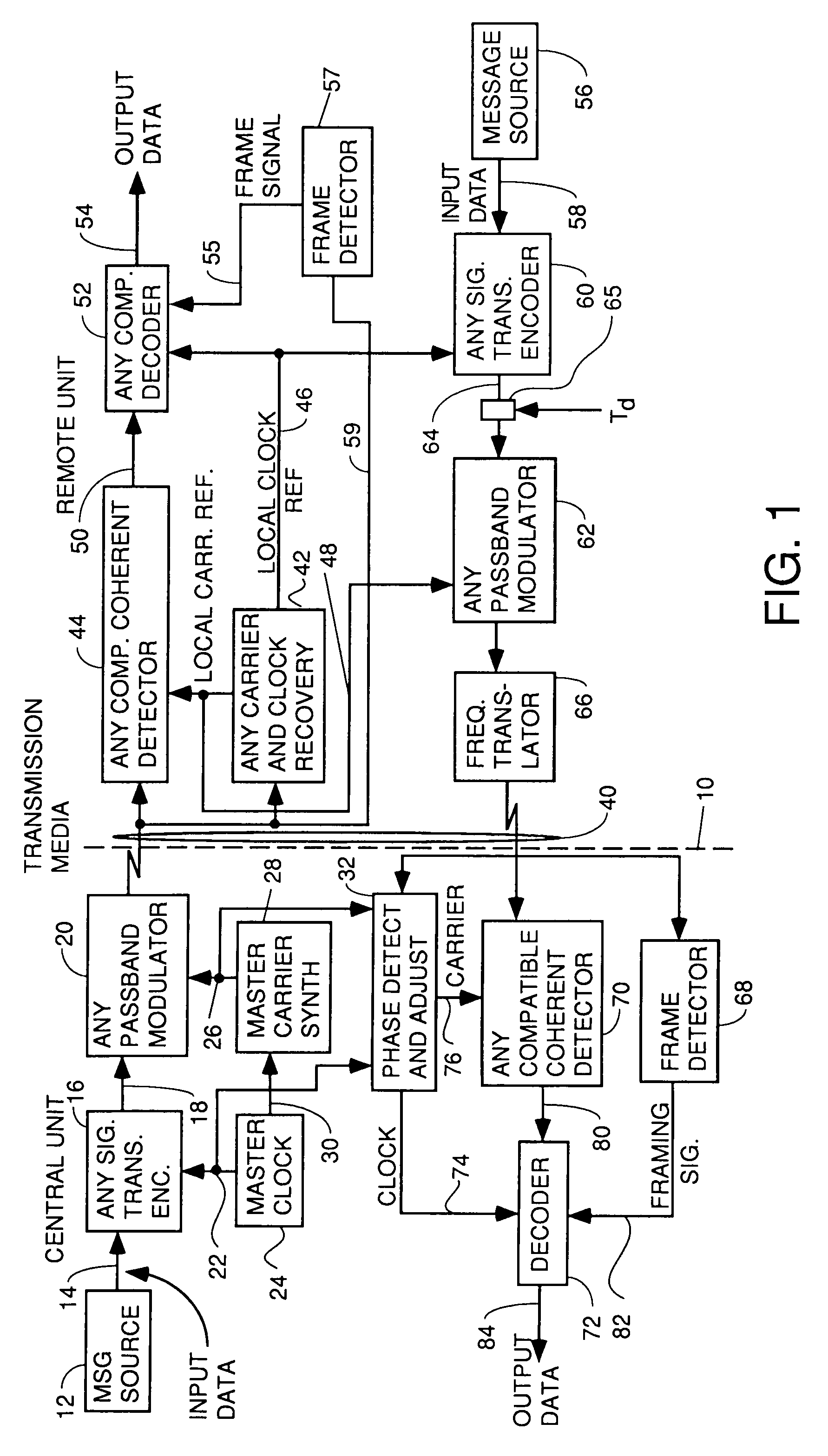

Apparatus and method for trellis encoding data for transmission in digital data transmission systems

InactiveUS6937617B2Sufficient redundancyIncorrect determinationPulse modulation television signal transmissionError preventionDigital dataPhase difference

A system for bidirectional communication of digital data between a central unit and a remote unit wherein the need for tracking loops in the central unit has been eliminated. The central unit transmitter generates a master carrier and a master clock signal which are used to transmit downstream data to the remote units. The remote units recover the master carrier and master clock and synchronize local oscillators in each remote unit to these master carrier and master clock signals to generate reference carrier and clock signals for use by the remote unit receiver. These reference carrier and clock signals are also used by the remote unit transmitters to transmit upstream data to the central unit. The central unit receiver detects the phase difference between the reference carrier and clock signals from the remote units periodically and adjusts the phase of the master carrier and master clock signals for use by the central unit receiver to receive the upstream data.

Owner:GOOGLE TECH HLDG LLC

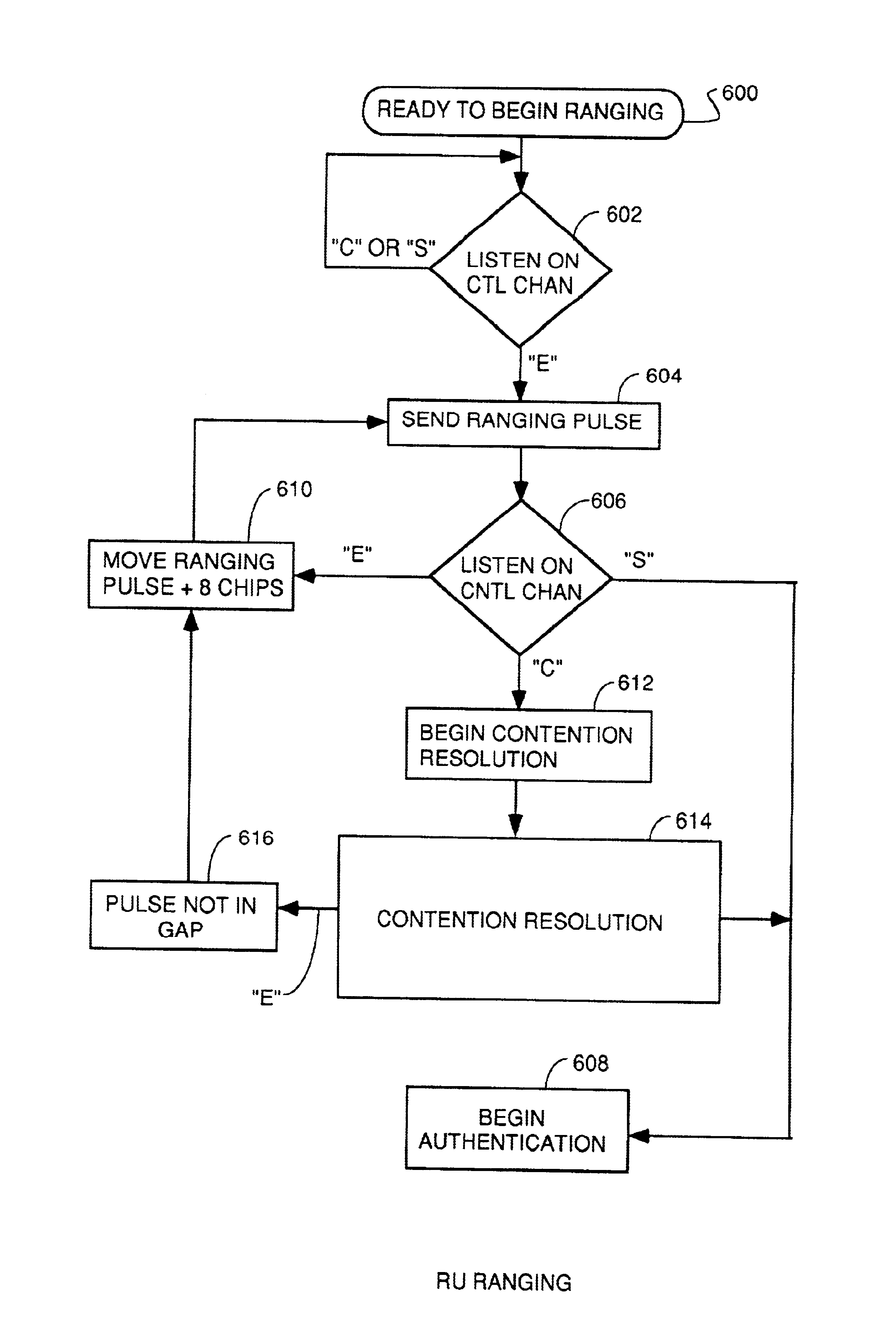

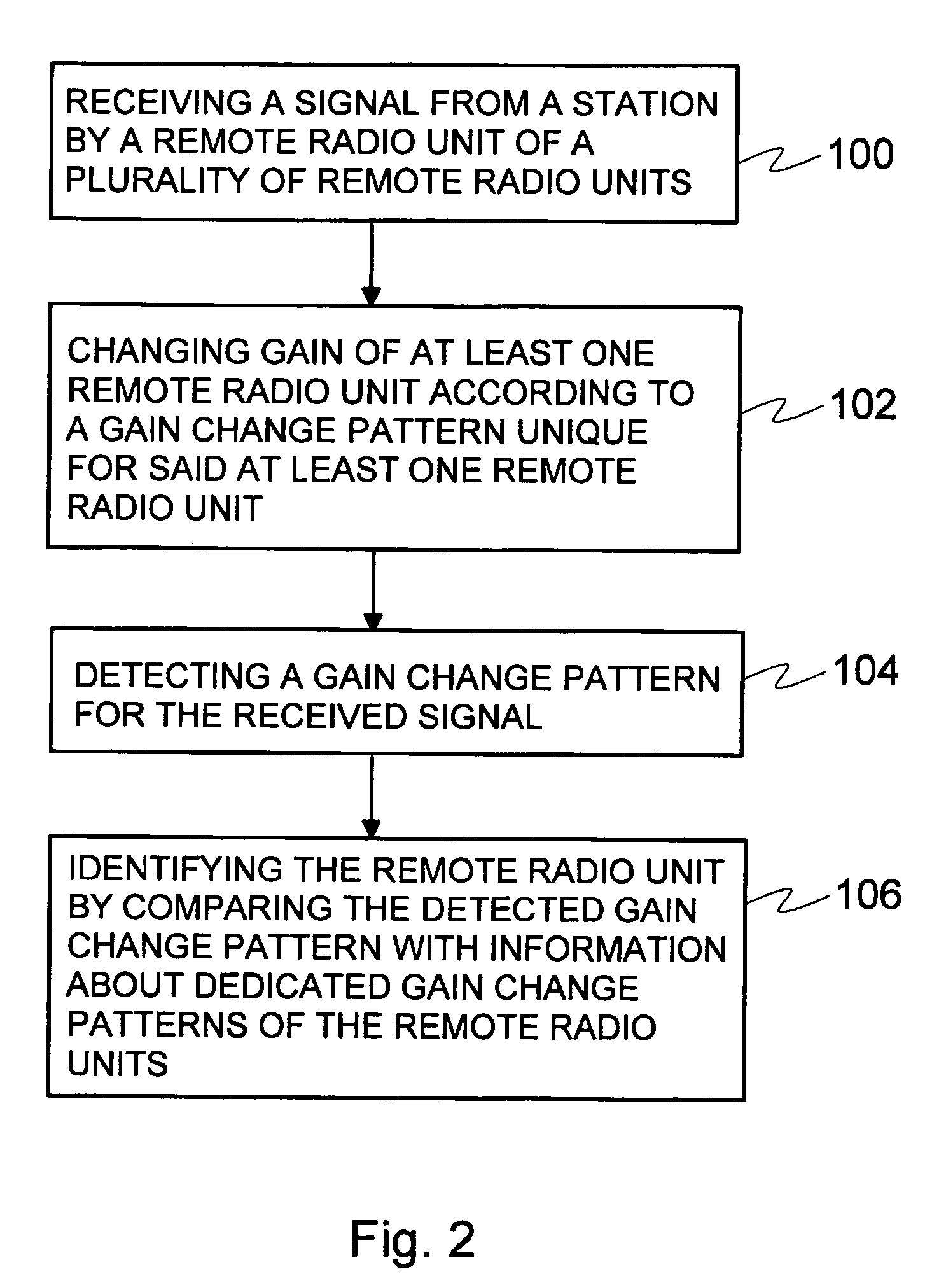

Identifying remote radio units in a communication system

InactiveUS7286843B2Error preventionFrequency-division multiplex detailsCommunications systemCentral unit

Owner:NOKIA SOLUTIONS & NETWORKS OY

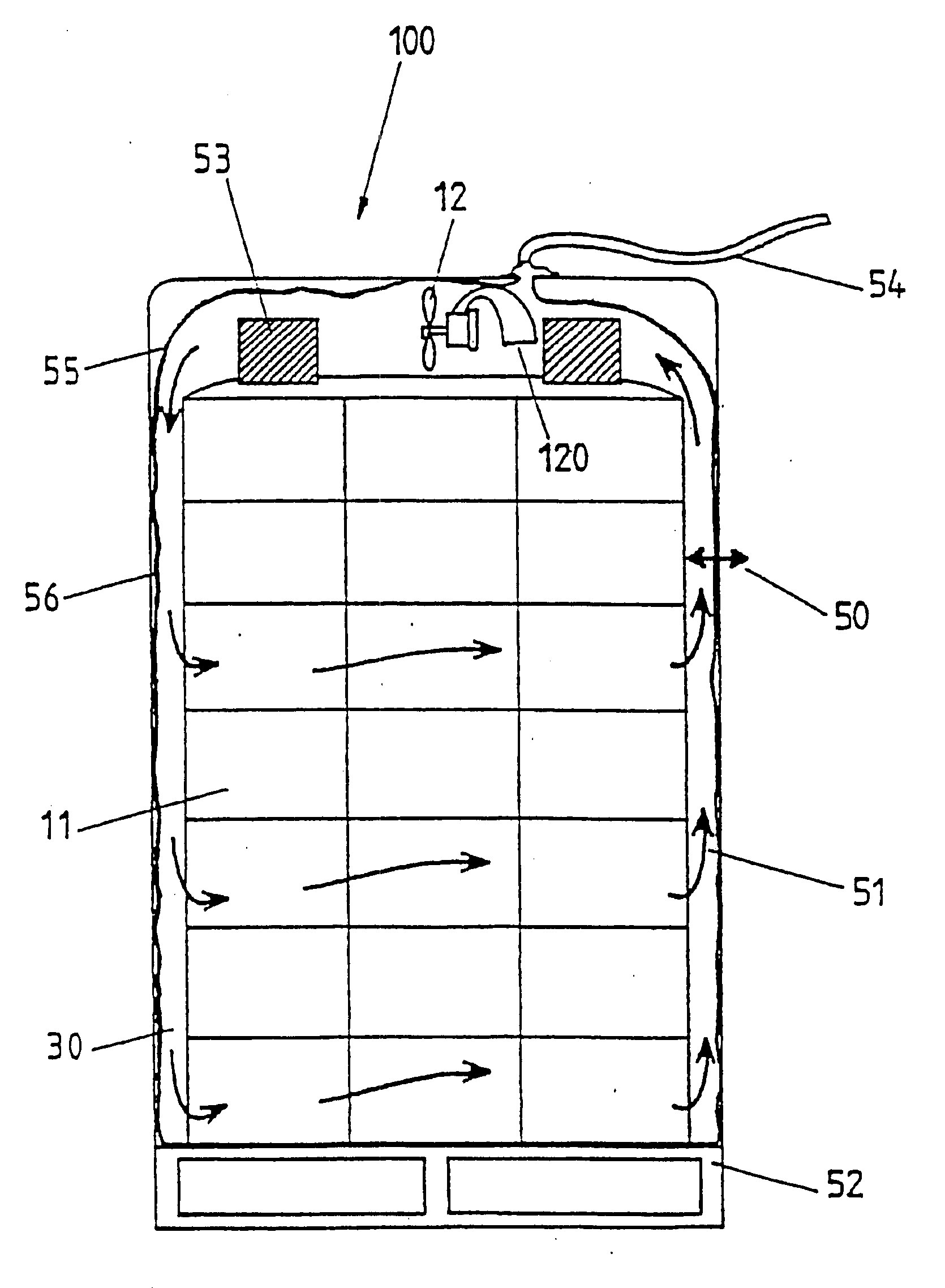

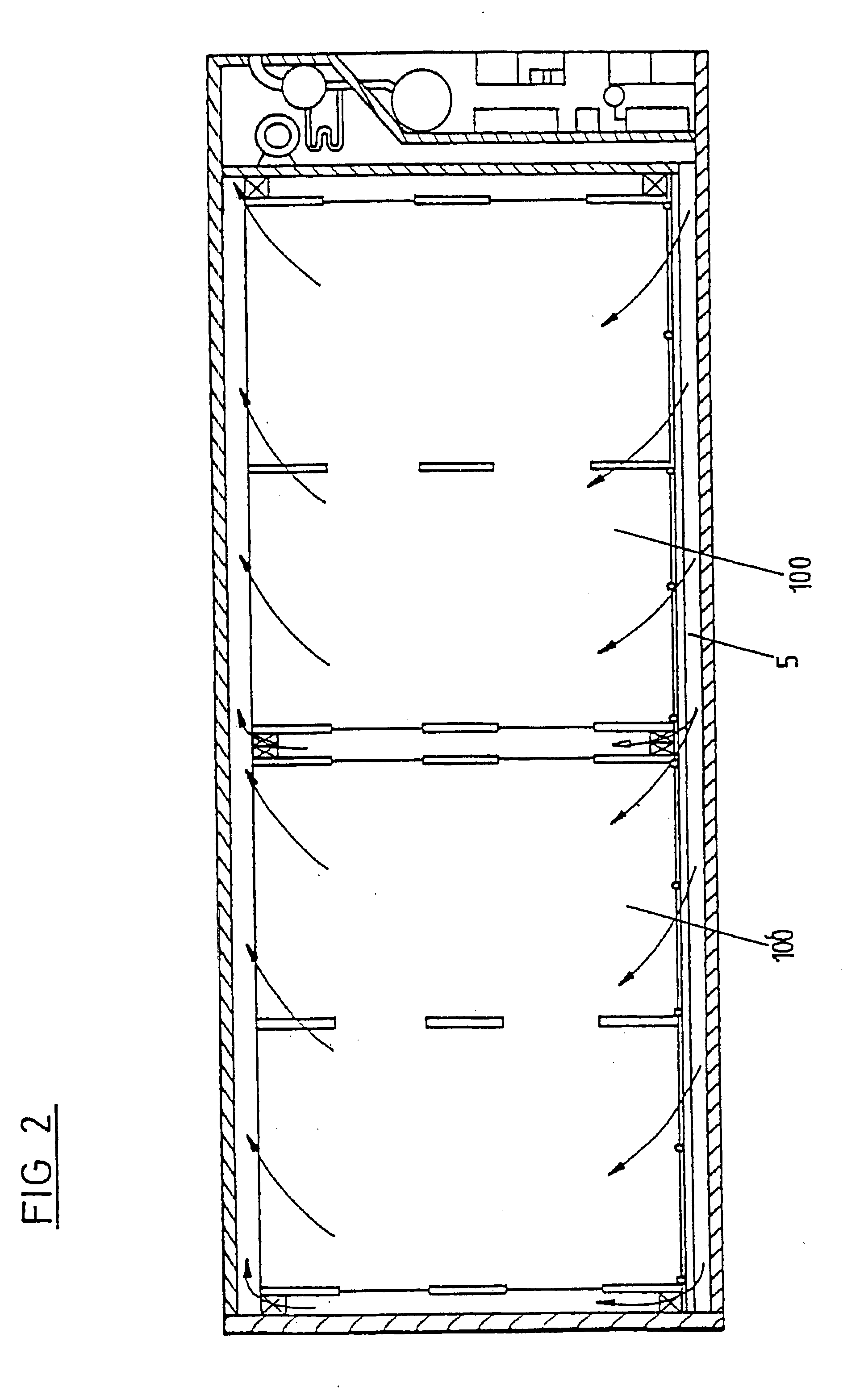

Method of transporting or storing perishable produce

InactiveUS6615908B1Convenient infusionIncrease humiditySpace heating and ventilationOperation mode of machinesGas compositionProduct gas

The invention allows cool rooms or sea containers designed for frozen goods to handle produce requiring more precisely controlled temperatures and conditions, e.g., vegetables and fruits requiring temperatures in the chilling range and often also needing control or modification of the atmosphere. Each load of produce (100) (e.g. of pallet size) is held in the sea container or cool room but is sealed from the air of the refrigerated environment by, for example, a plastics bag (56). The atmosphere within the bag is then circulated by a fan (12) (or by convection currents from a heating element) so as to pass through the load and around it via ducts (30) provided adjacent the bag (56). Heat exchange (50) between the circulating gas and the refrigerated environment, via the plastics film, serves to cool the load. However, if cooling is excessive a heating element can be used to raise the temperature of the circulating atmosphere. Gas composition of the atmosphere can be controlled by scrubbing, flushing, etc. via pipes from a central unit or at each load individually or by choosing semi-permeable plastic for the sealing bags.

Owner:TRANSPHERE SYST

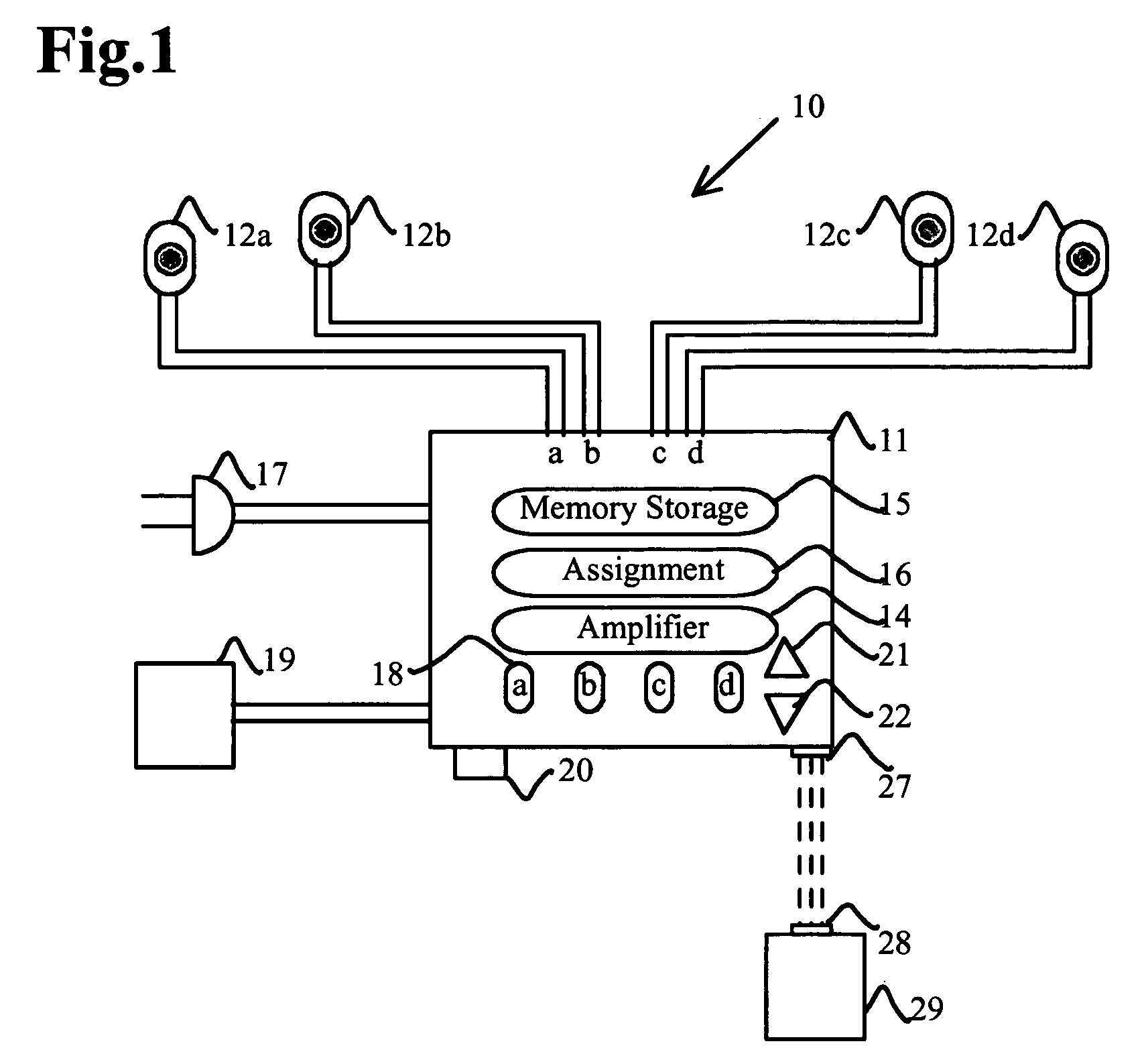

Sampling playback doorbell system

InactiveUS20060038663A1Quality improvementEasy constructionSound producing devicesElectric/electromagnetic audible signallingDocking stationDoorbell

A digital sampling playback doorbell system has two or more doorbell buttons and a central unit with solid state memory storage for multiple digitally sampled sound files. User assignment means are provided for assigning a particular sound file to a particular doorbell button. The digital sampling playback doorbell has computer interface of RS-232, or USB, or infrared wireless connection type and relies on computer installed software to download digitally sampled sound files stored in the computer hard drive to the memory of the digital sampling playback doorbell system central unit. The digitally sampled sound files stored in the computer hard drive are obtained by accessing a web site through the Internet or capturing sound through an audio computer connection to a microphone, CD player, radio broadcast or mass music storage device using software resident in the computer. Alternatively, an IPOD can be used as a source for sounds that can be transferred or sent to play on the doorbell. Such sound transfer can take place via a blue tooth communication link, or by a docking station that resides on the doorbell. Taking advantage of the intelligence contained within the IPOD, one can then select sounds or files that have been previously converted by either the IPOD or the computer that the IPOD was previously attached to, and send them to the doorbell.

Owner:PREDOMINANCE

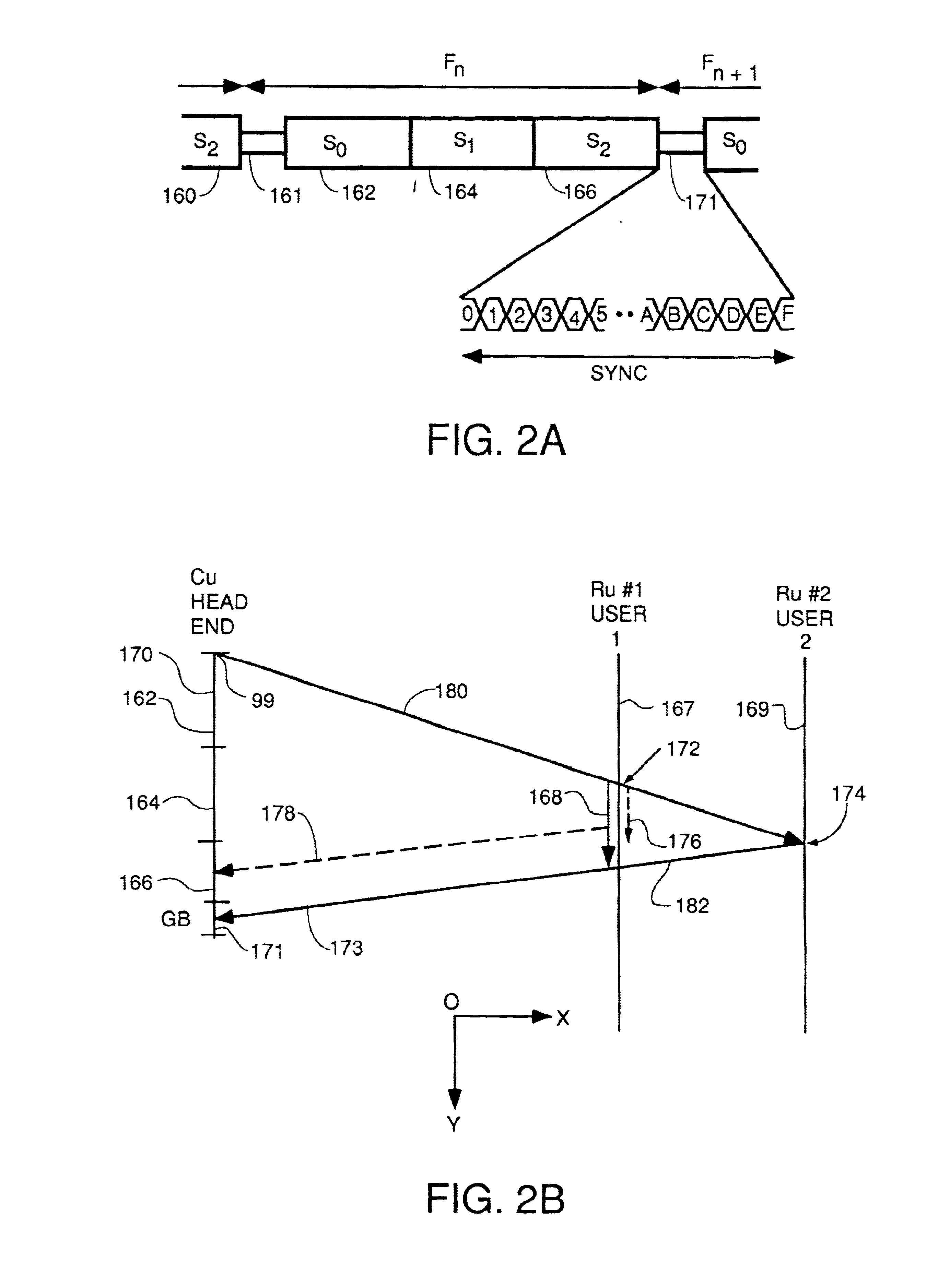

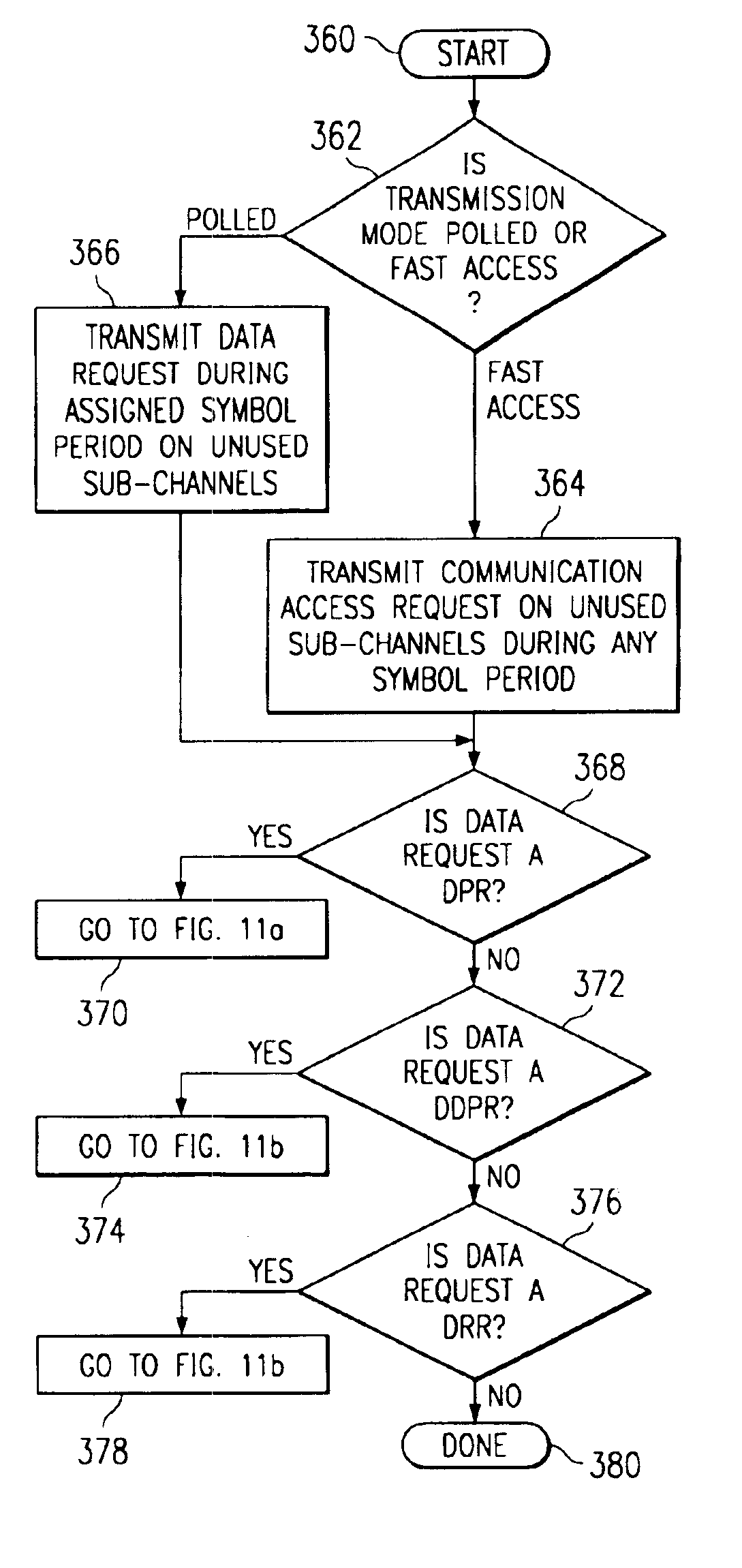

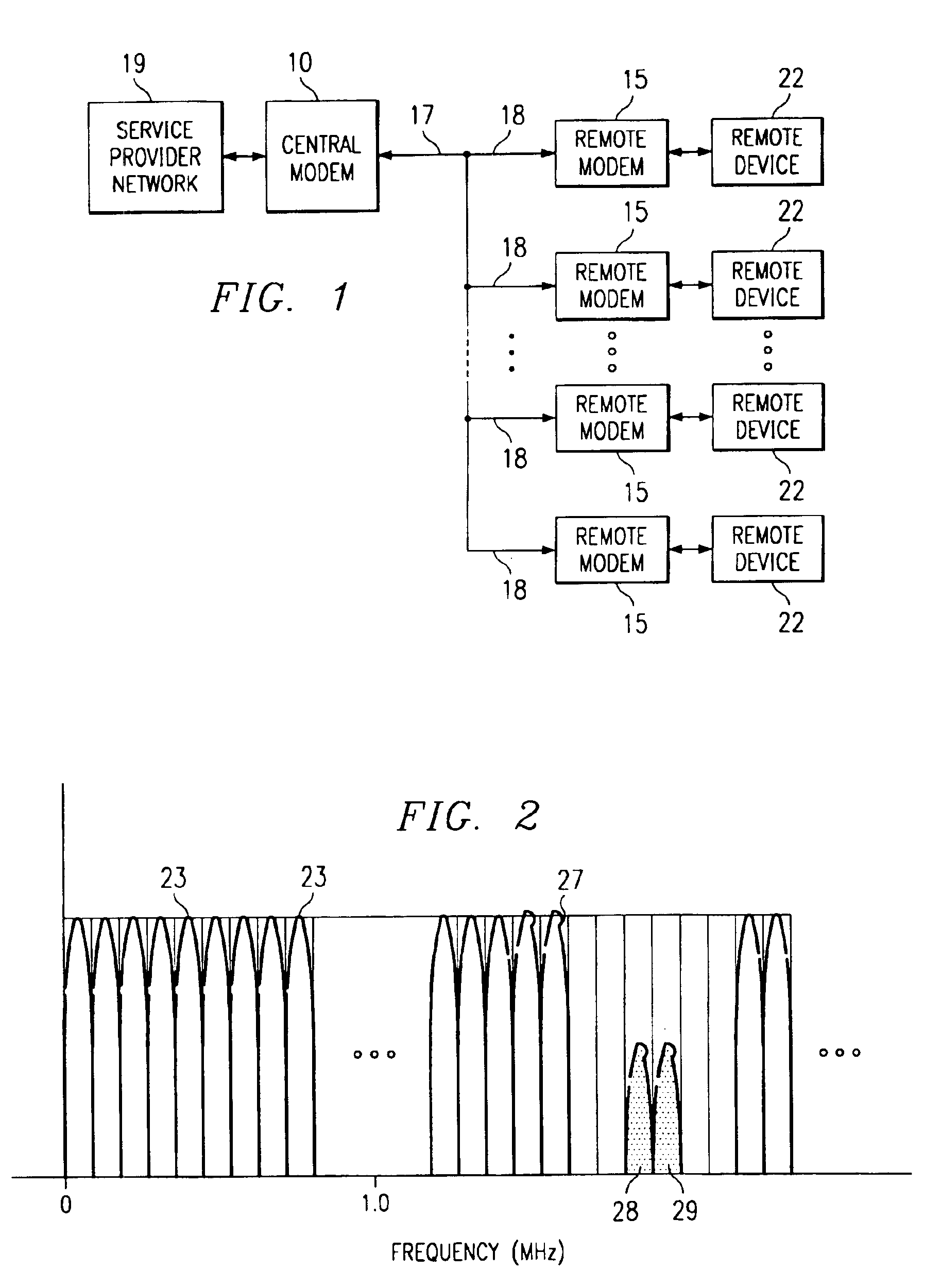

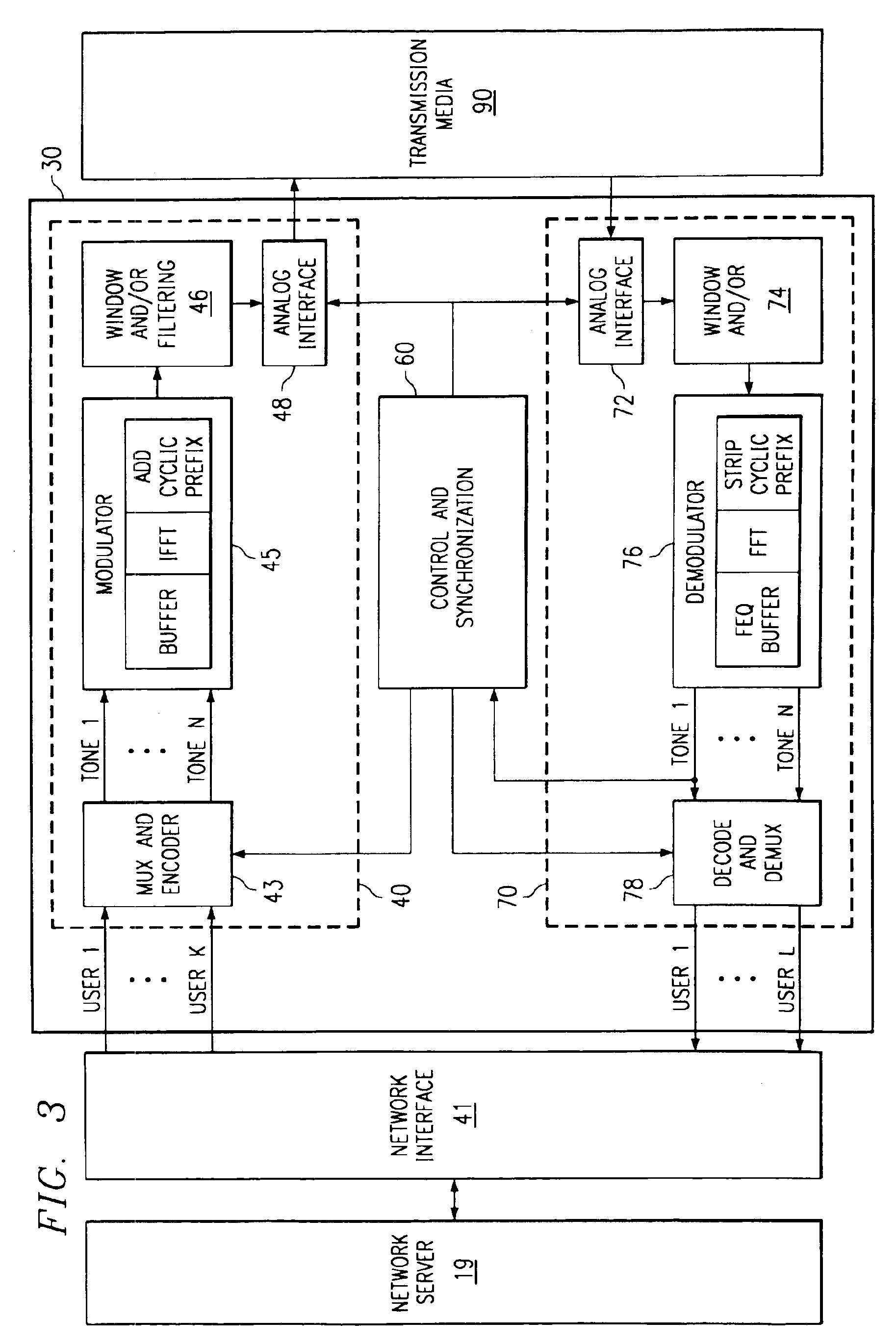

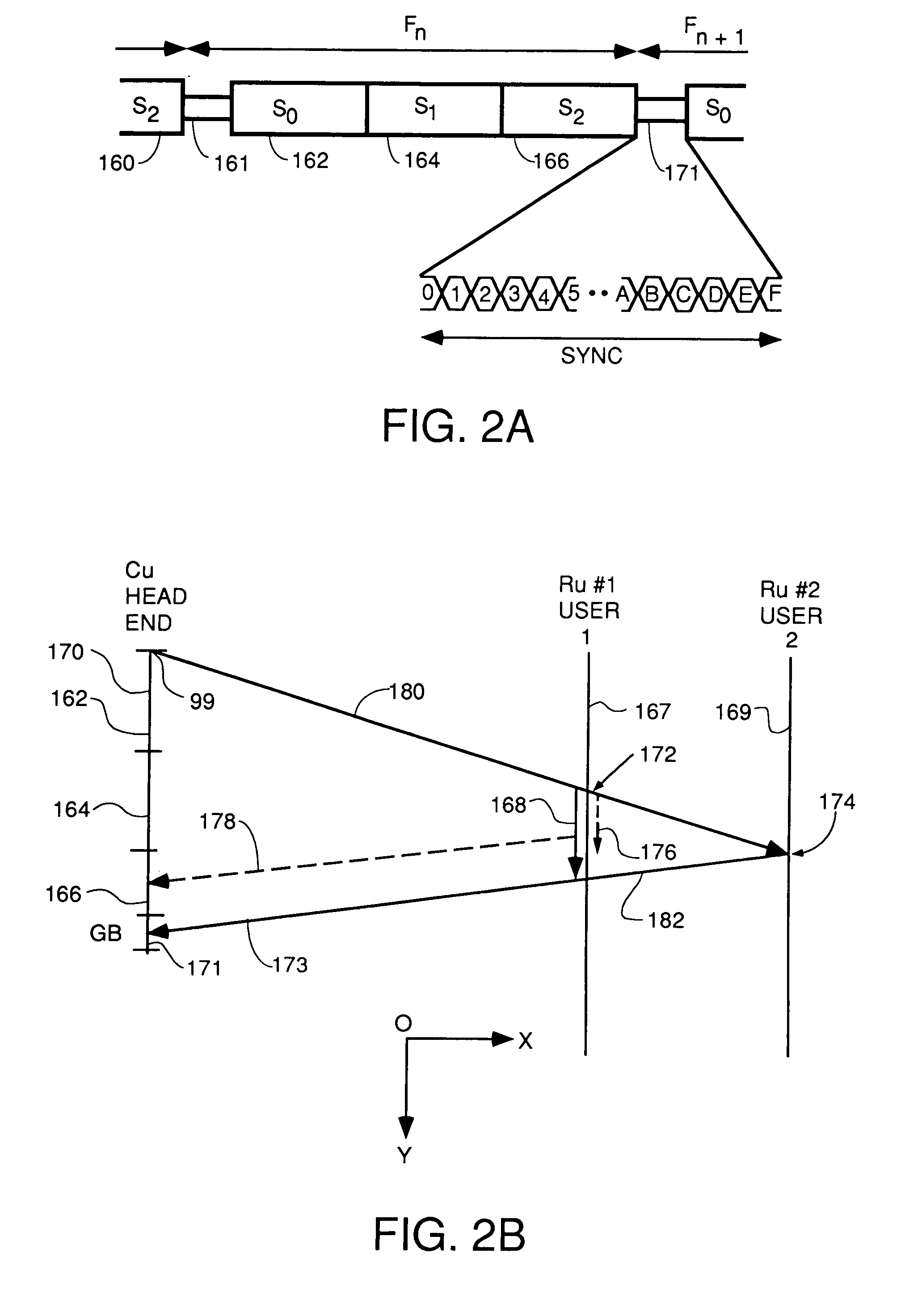

Method and apparatus for coordinating multi-point to point communications in a multi-tone data transmission system

InactiveUS7068678B2Optimize bandwidth allocationFacilitate communicationError detection/prevention using signal quality detectorTransmission path divisionFiberModem device

A variety of bi-directional data transmission systems that facilitate communications between a plurality of remote units (15) and a central unit (10) using a frame based discrete multi-carrier transmission scheme are disclosed. In each of the systems, frames transmitted from the plurality of remote units (15) are synchronized at the central unit (10). A variety of novel modem arrangements and methods for coordinating communications between a plurality of remote units (15) and a central unit (10) to facilitate multi-point-to-point transmission are disclosed. The invention has application in a wide variety of data transmission schemes including Asymmetric Digital Subscriber Line systems that includes the transmission of signals over twisted pair, fiber and / or hybrid telephone lines, cable systems that includes the transmission of signals over a coaxial cable, and digital cellular television systems that include the transmission of radio signals.

Owner:TEXAS INSTR INC

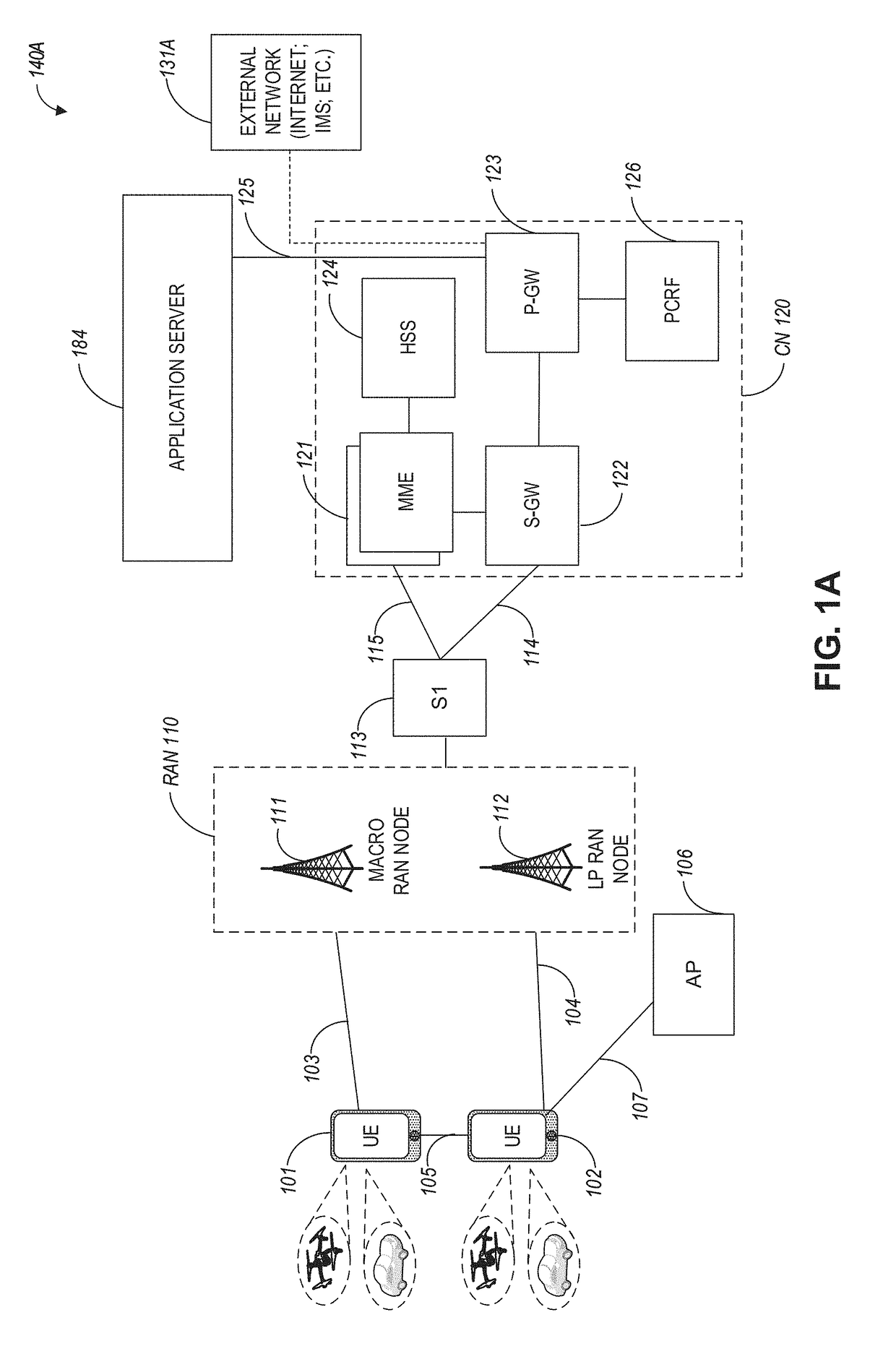

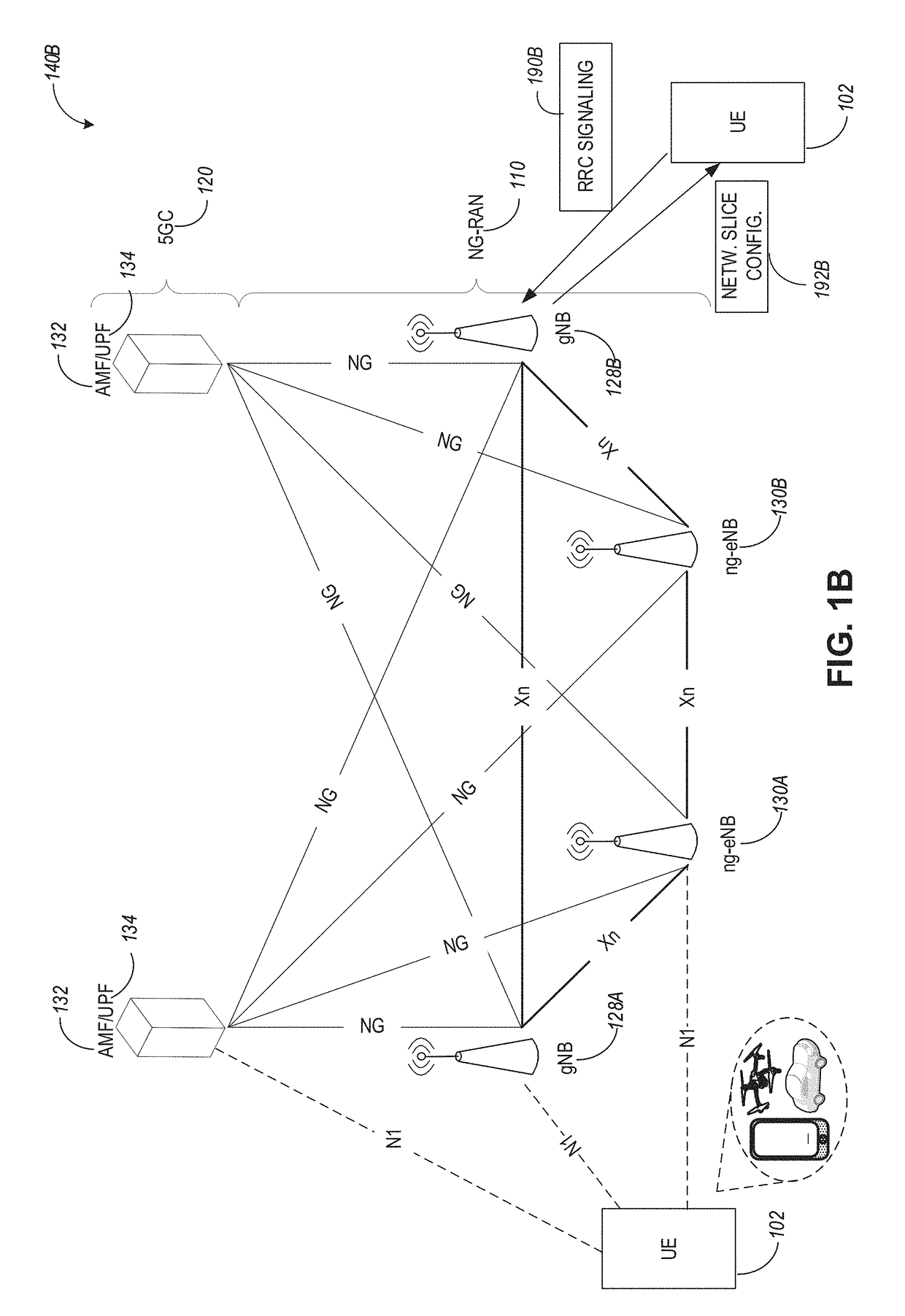

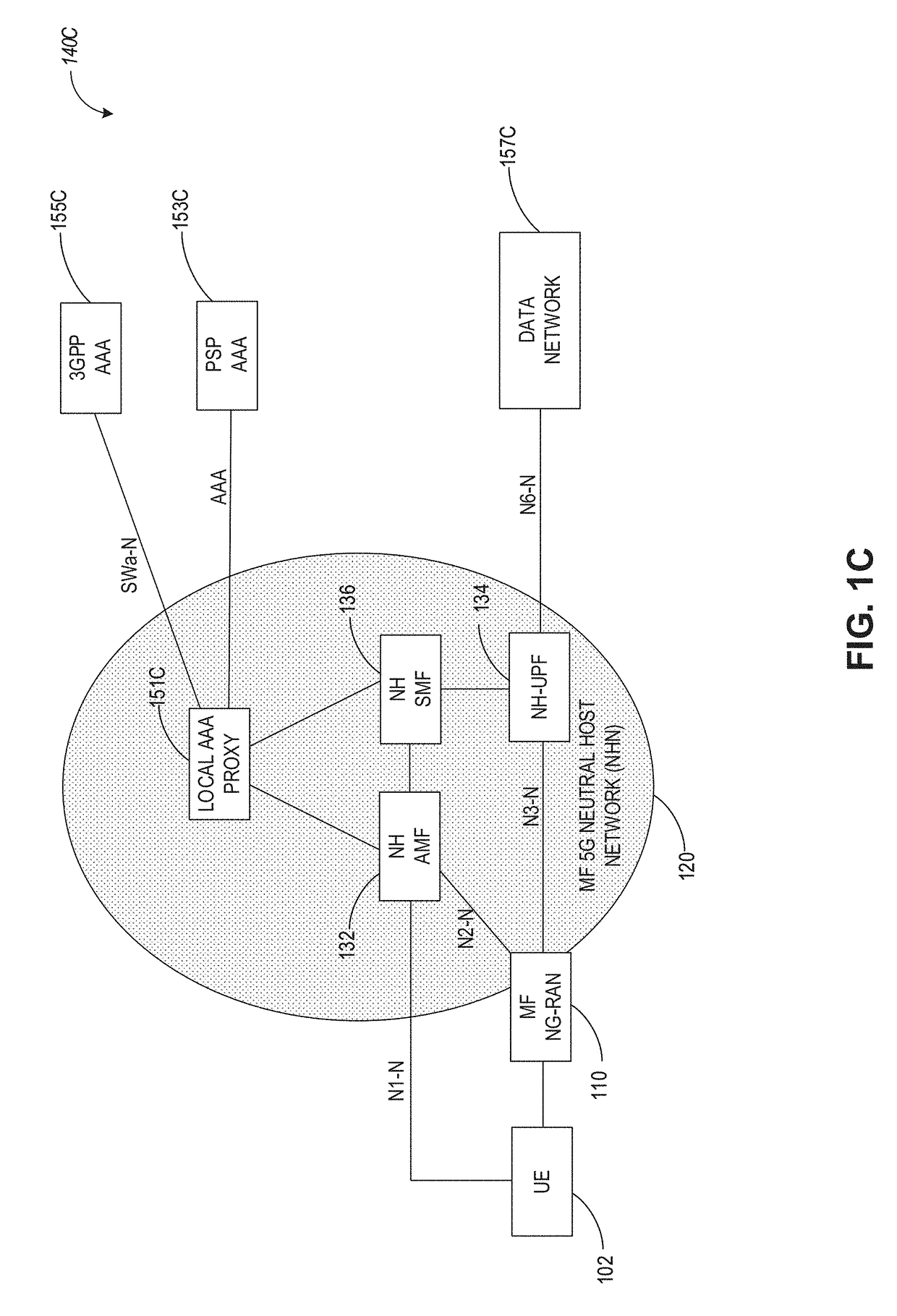

Enabling network slicing in a 5g network with cp/up separation

An apparatus of a Next Generation Node-B (gNB) with a CP-UP separation includes processing circuitry configured to decode a radio resource control (RRC) request message from the UE for establishing a connection between the UE and a UPF of a 5G NR architecture in a network slice. In response to a confirmation message that the UE is authorized to communicate via the network slice, encode a Central Unit User plane (CU-UP) resource status request message for transmission by a Central Unit Control Plane (CU-CP) entity of the gNB to a plurality of CU-UP entities. A CU-UP resource status response message from each of the plurality of CU-UP entities is decoded at the CU-CP entity. The resource status response message including resource availability information for the CU-UP entities. A CU-UP entity is selected by the CU-CP entity from the plurality of CU-UP entities based on the resource availability information.

Owner:APPLE INC

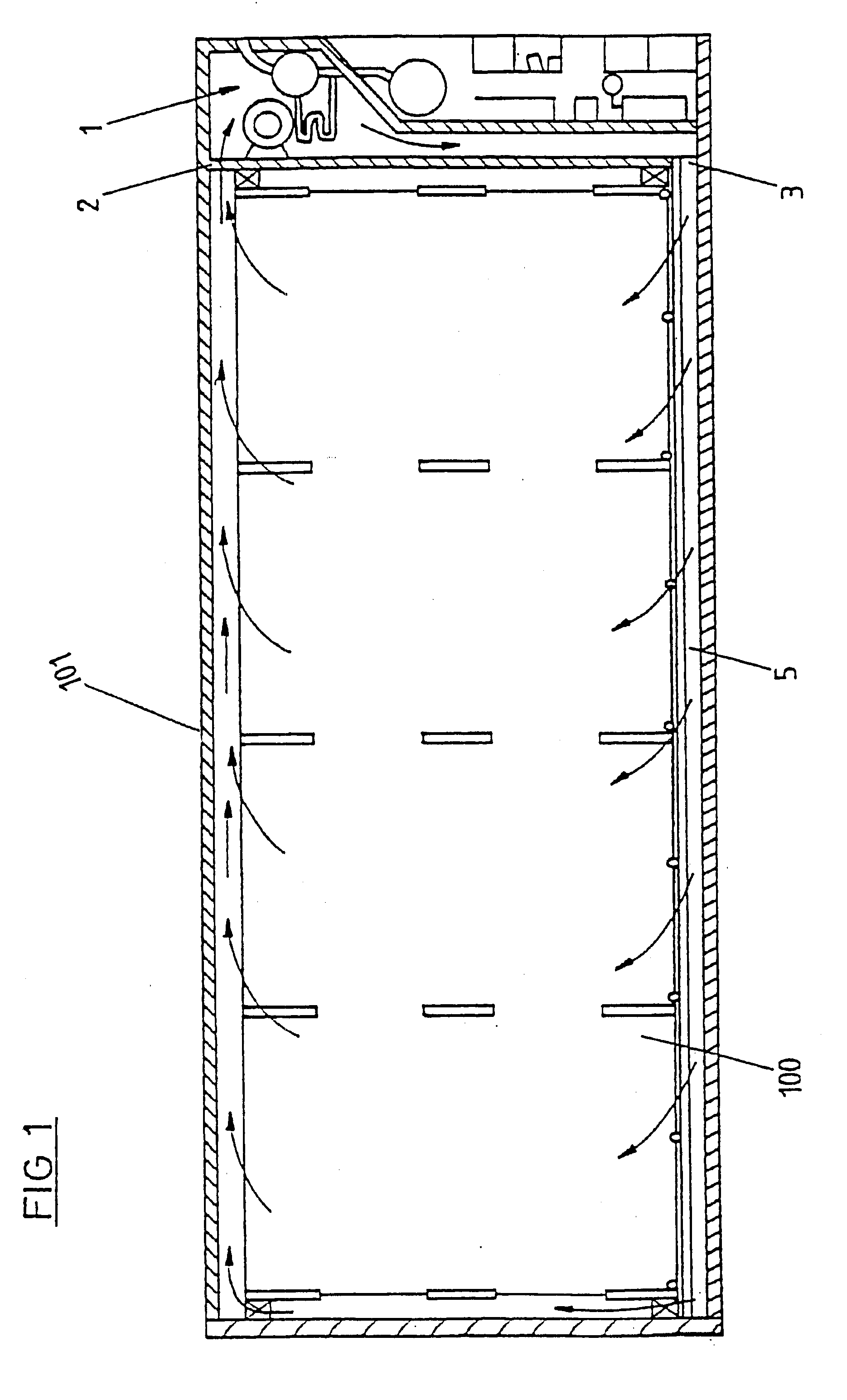

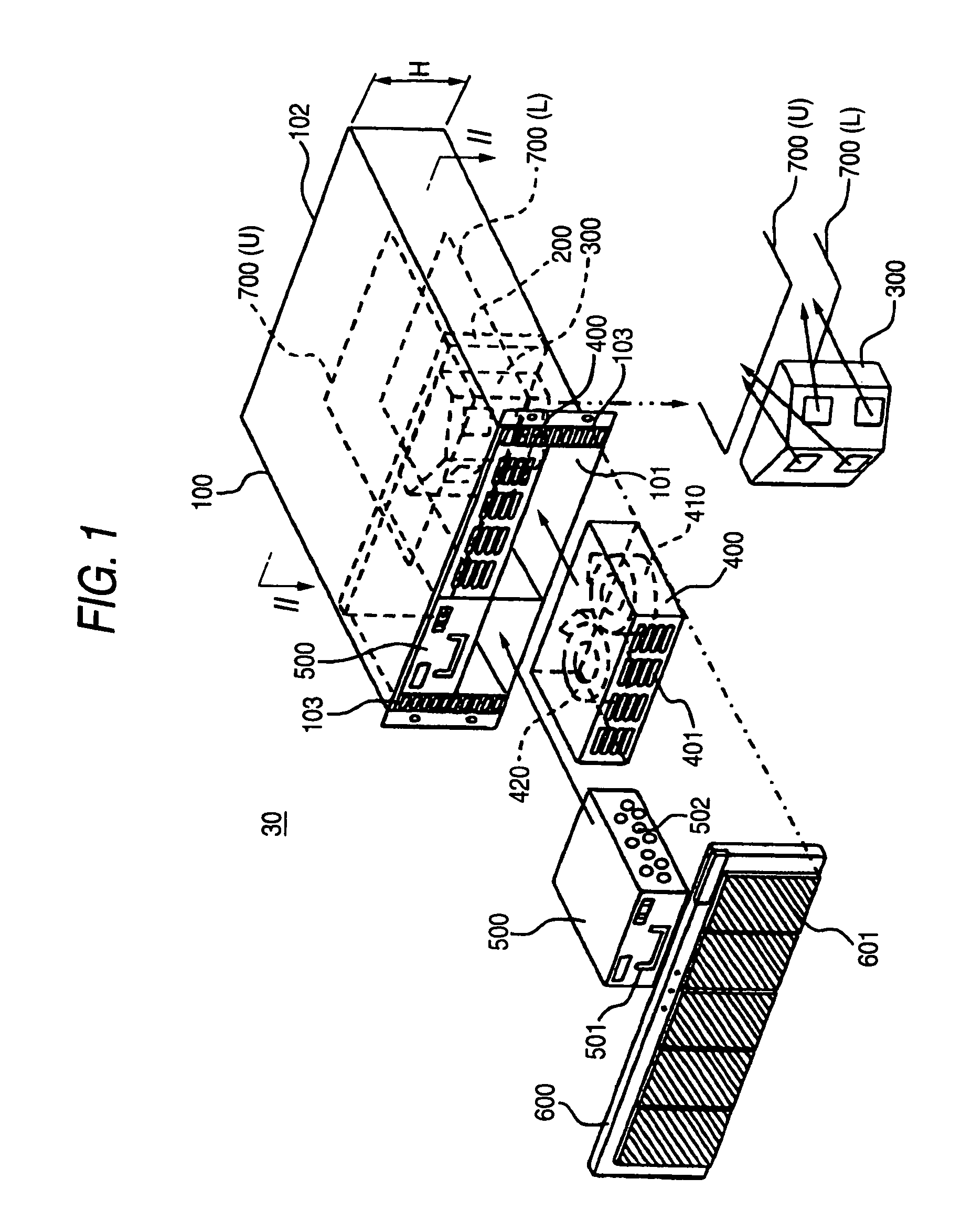

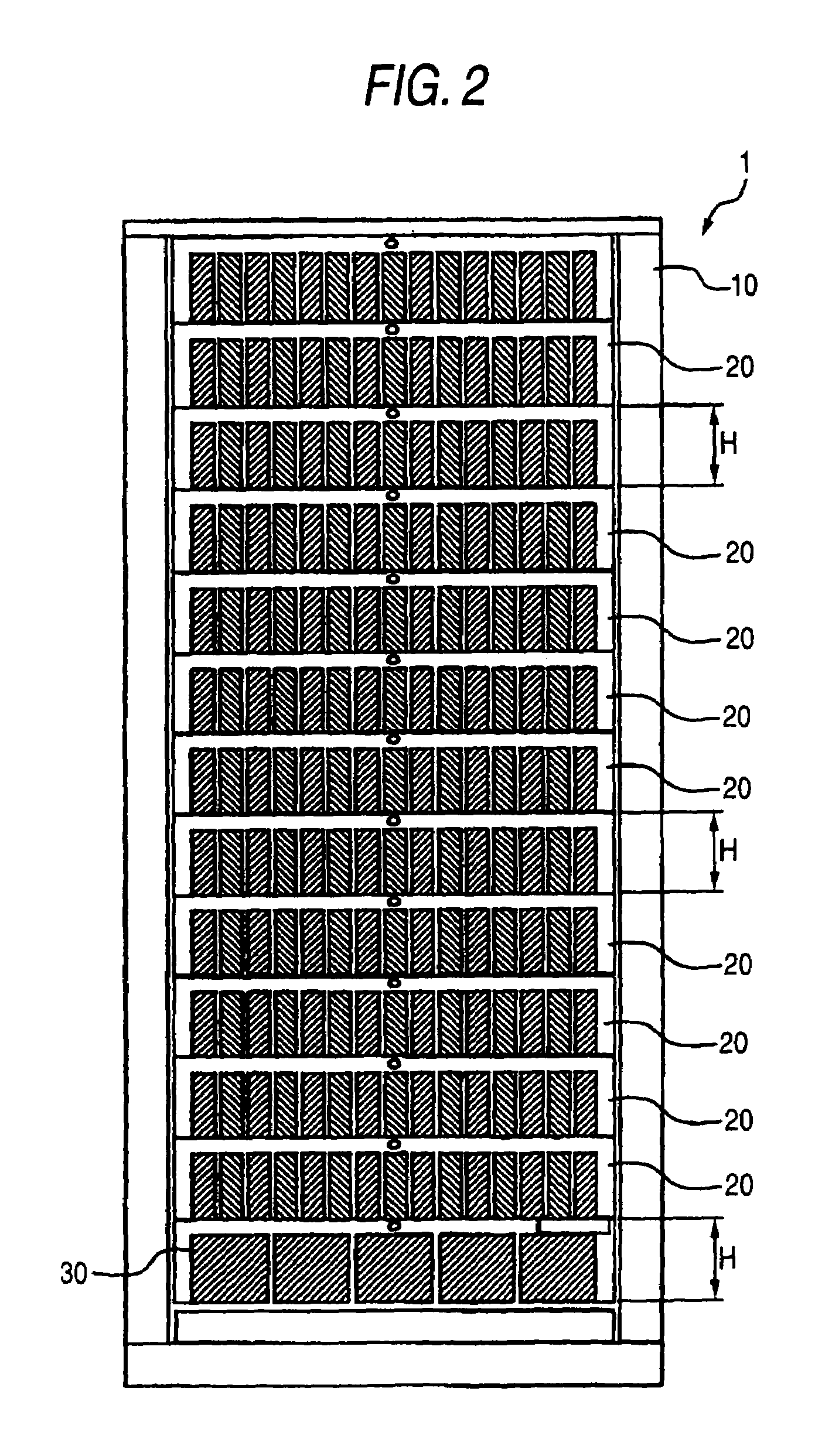

Electronic equipment

InactiveUS7042722B2Improve reliabilityEfficient use ofDigital data processing detailsReducing physical parameters of carriersComputer moduleEngineering

An object is to effectively cool down an electronic equipment which is face with height limitations and tends to readily increase in heat generation amount to thereby provide the reliability required. The interior of a chassis of a control unit is partitioned by a back board into a front side space and a rear side space. In the rear side space, two control modules are attached so that these are stacked up and down, while two fan modules and a single duct member are attached in the front side space. Each fan module has two fans as built therein. A cooling air stream or “wind” from each fan flows into the lower-side control module through the duct member and others, whereas a cooling wind from the other fan flows into the upper-side control module. Even when either one of the fan modules goes down during operation, it is still possible by using the remaining fan module to cool down the both control modules.

Owner:HITACHI LTD

Motor vehicle navigation system that receives route information from a central unit

InactiveUS6853915B2Communication cost be accountedTransaction cost be accountedInstruments for road network navigationArrangements for variable traffic instructionsMobile vehicleDriver/operator

Data indicative of an instantaneous location, a destination and a route from the instantaneous location to the destination are transmitted from a motor vehicle navigation unit to a central unit. Traffic information about the route between the instantaneous location and the destination are transmitted from the control unit to the vehicle unit. The received traffic information data are used by the vehicle unit to determine a desirable route between the instantaneous location and the destination given the traffic information. The data of the route thus determined are made available to the vehicle driver, so that he is able to steer toward his desired destination along this specified route.

Owner:HARMAN BECKER AUTOMOTIVE SYST

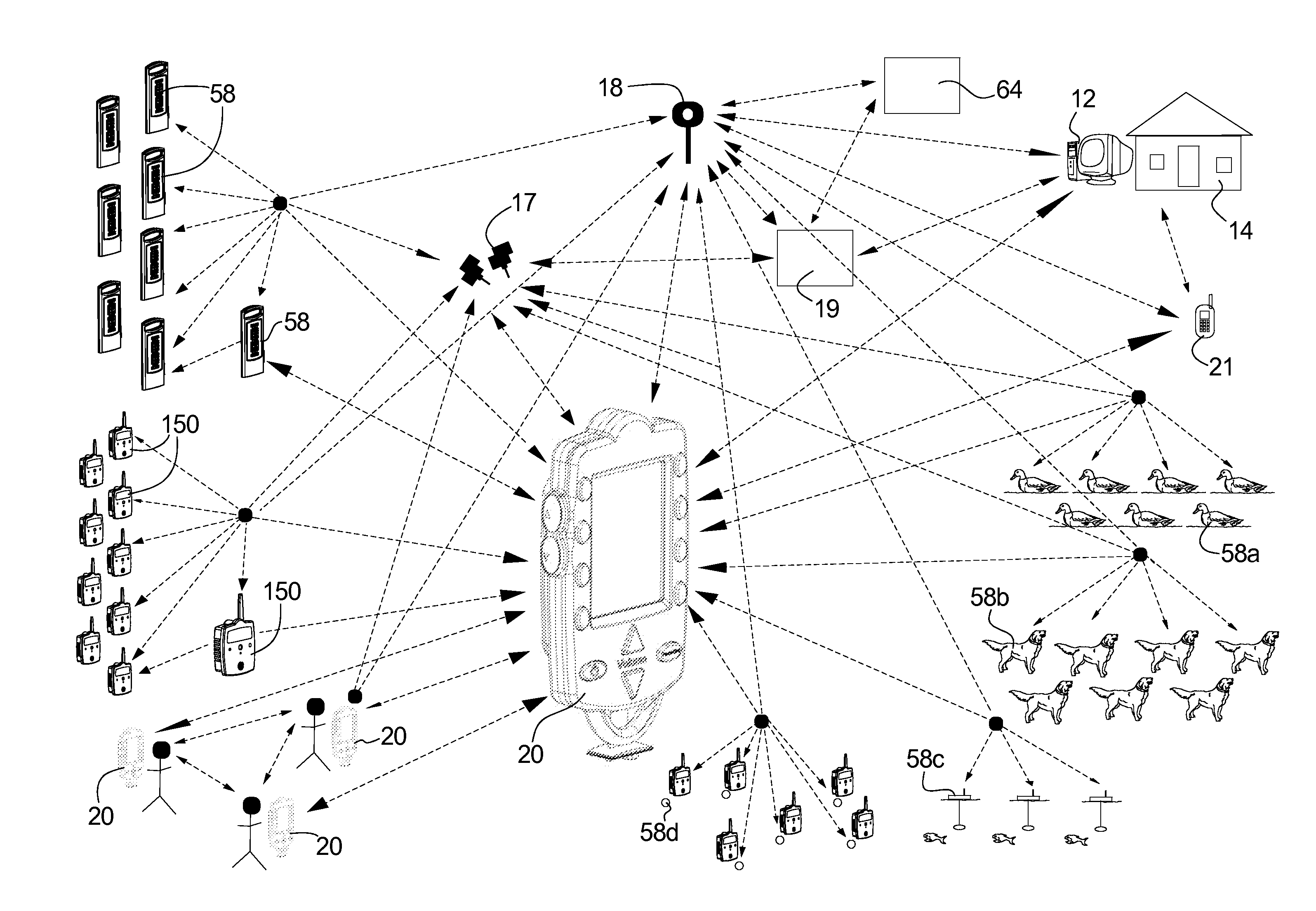

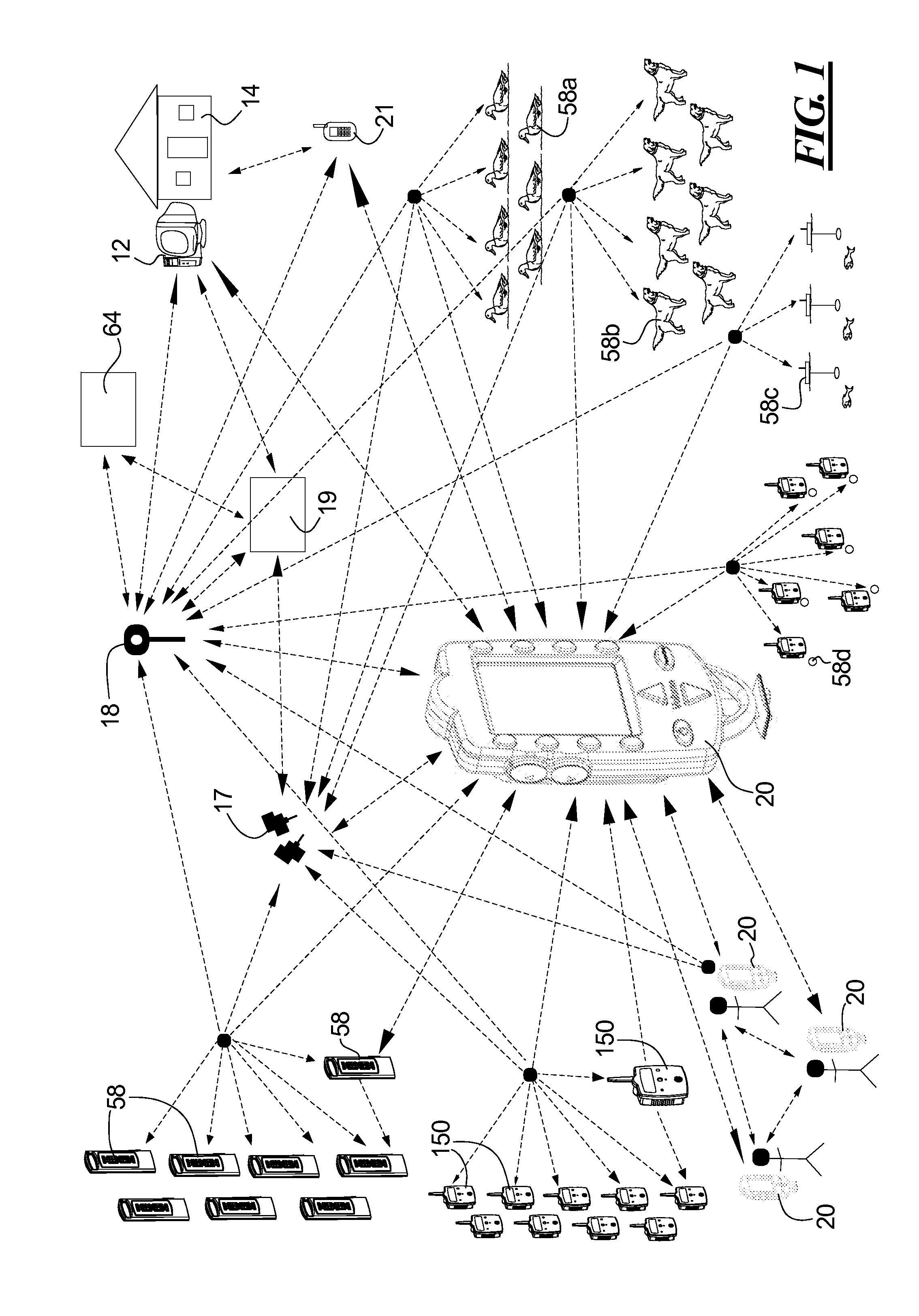

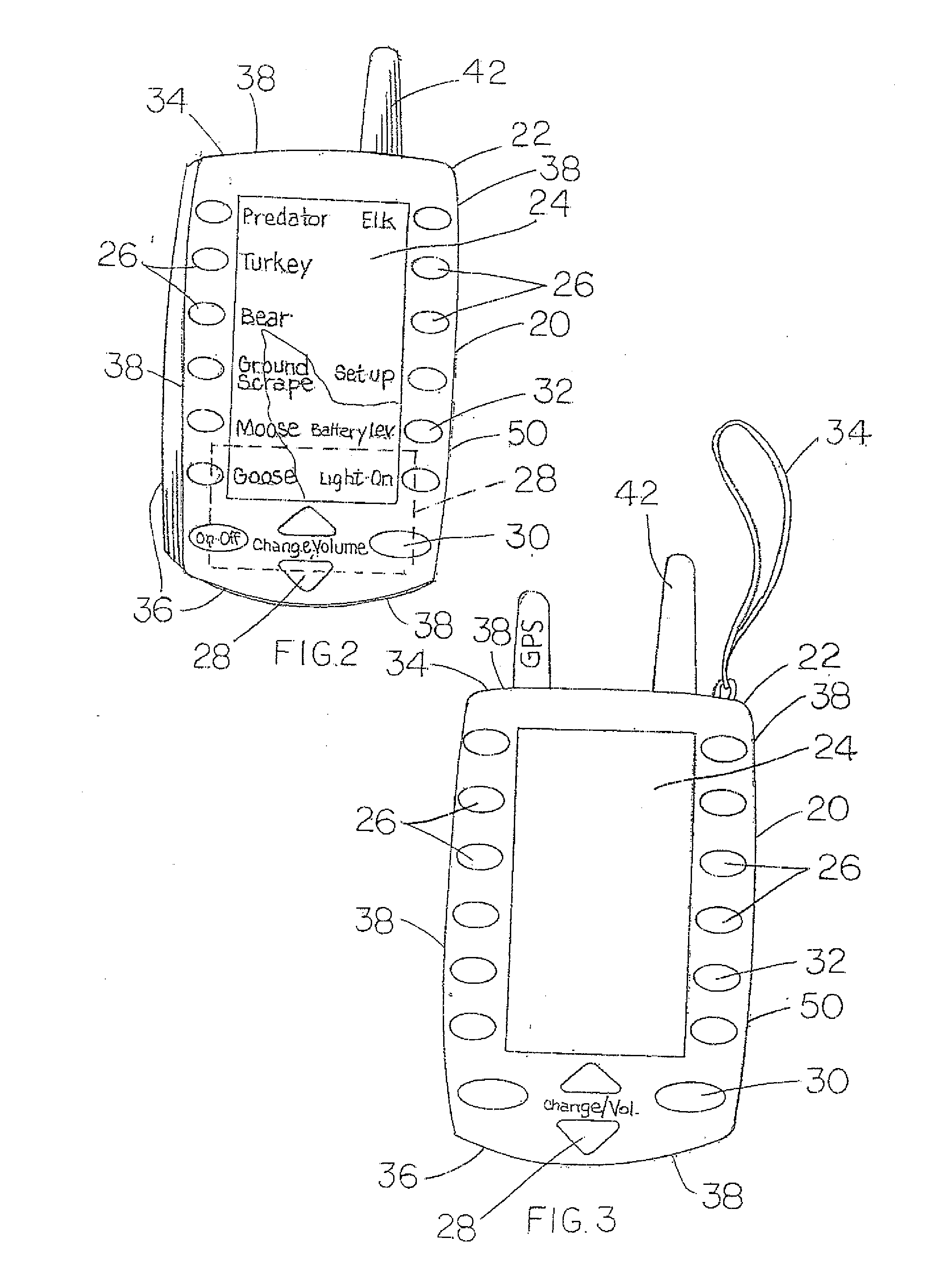

Remotely Operable Game Call or Monitoring Apparatus

A came call and / or monitoring apparatus is disclosed that includes a handheld central unit and one or more remote modules. The central unit includes a user input and a display screen, and communicates with the remote module(s). Each remote module is capable of generating a game call, taking an image, or executing some other function related to the hunting and monitoring of wildlife. The remote module may further be capable of communicating back to the central unit.

Owner:DESIGNLINK

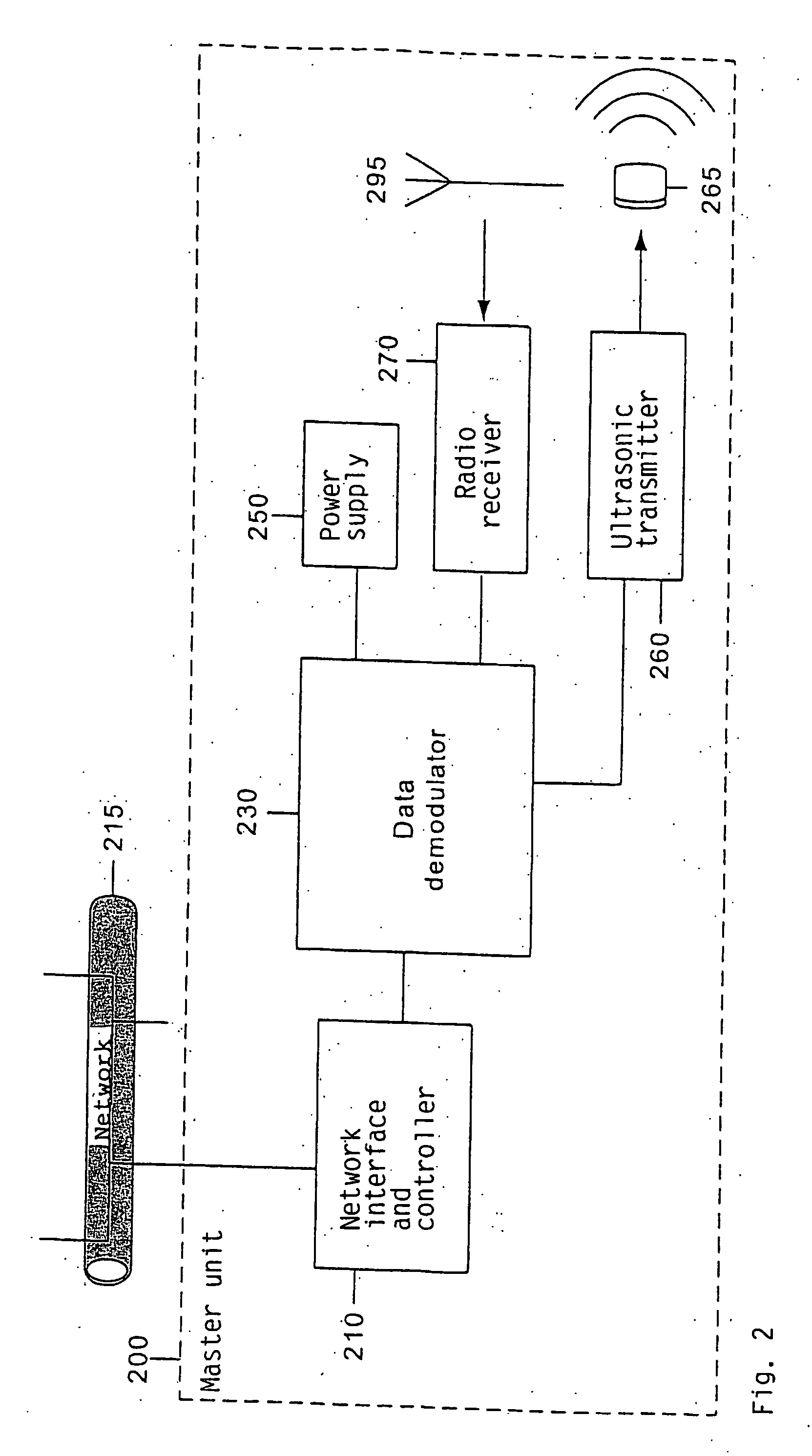

Ultrasonic locating system

ActiveUS20060077759A1Improve data transfer performancePosition fixationUsing reradiationRadiotransmitterEngineering

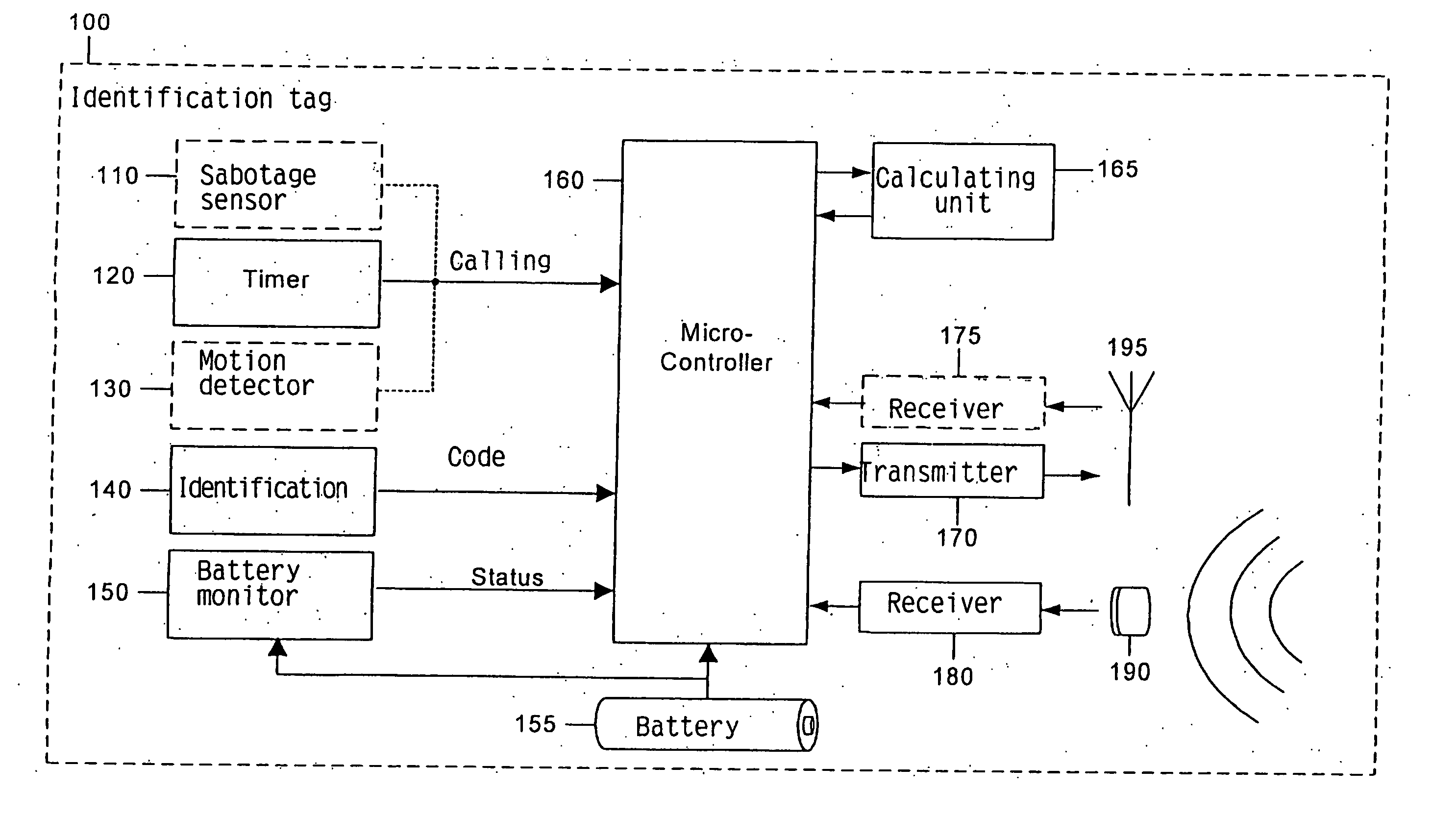

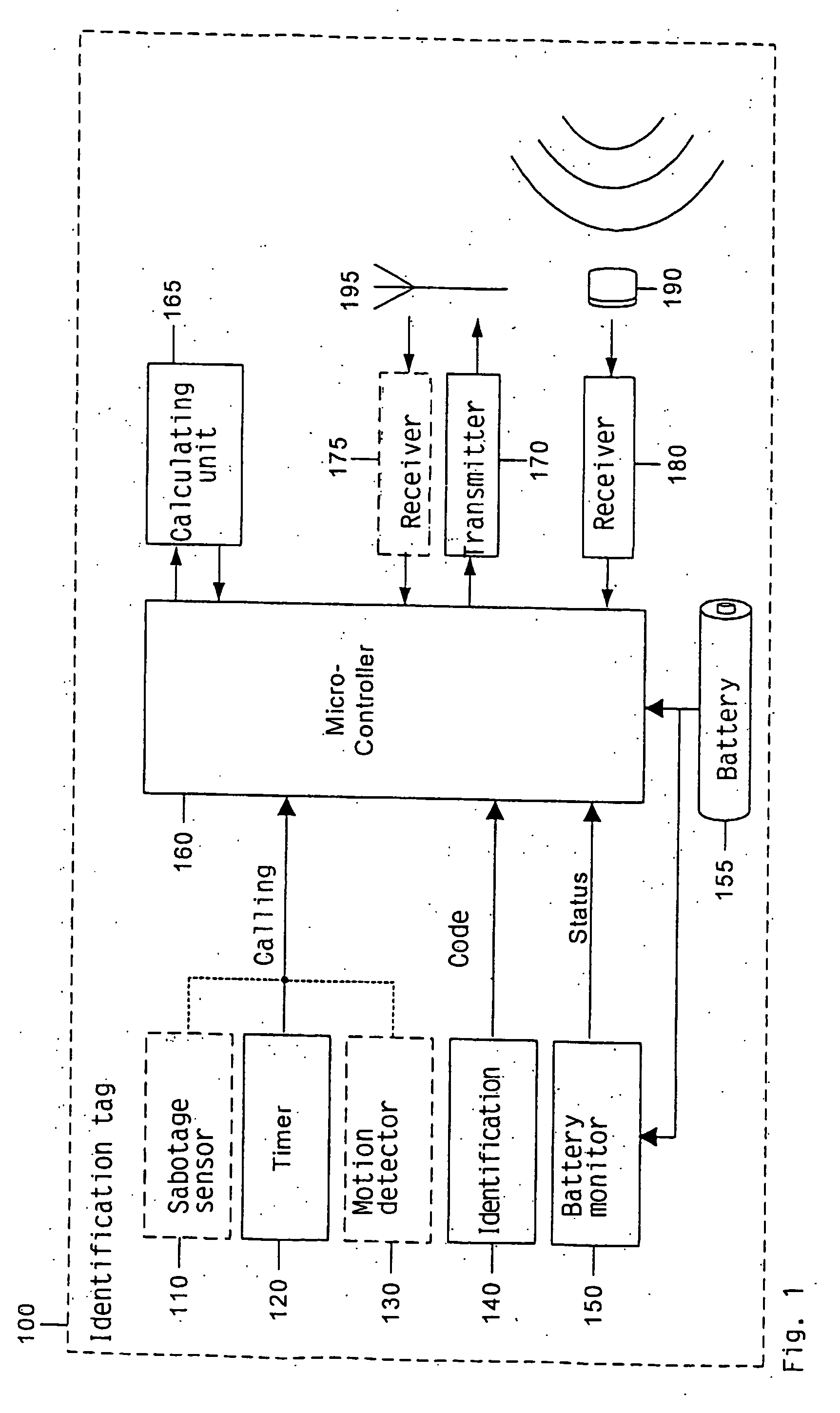

The invention relates to a method and a system for monitoring and position determination of objects and / or living beings within an area, such as, e.g. a room in a building or a road tunnel. The system comprises a plurality of identification tags equipped with an ultrasonic receiver and radio transmitter which is attached to the objects that have to be monitored. The identification tags receive ultrasonic signals whose arrival time they measure. This information together with the identification tags'ID code are transmitted by radio waves to a central unit which calculates the position of each of the identification tags.

Owner:SONITOR TECH

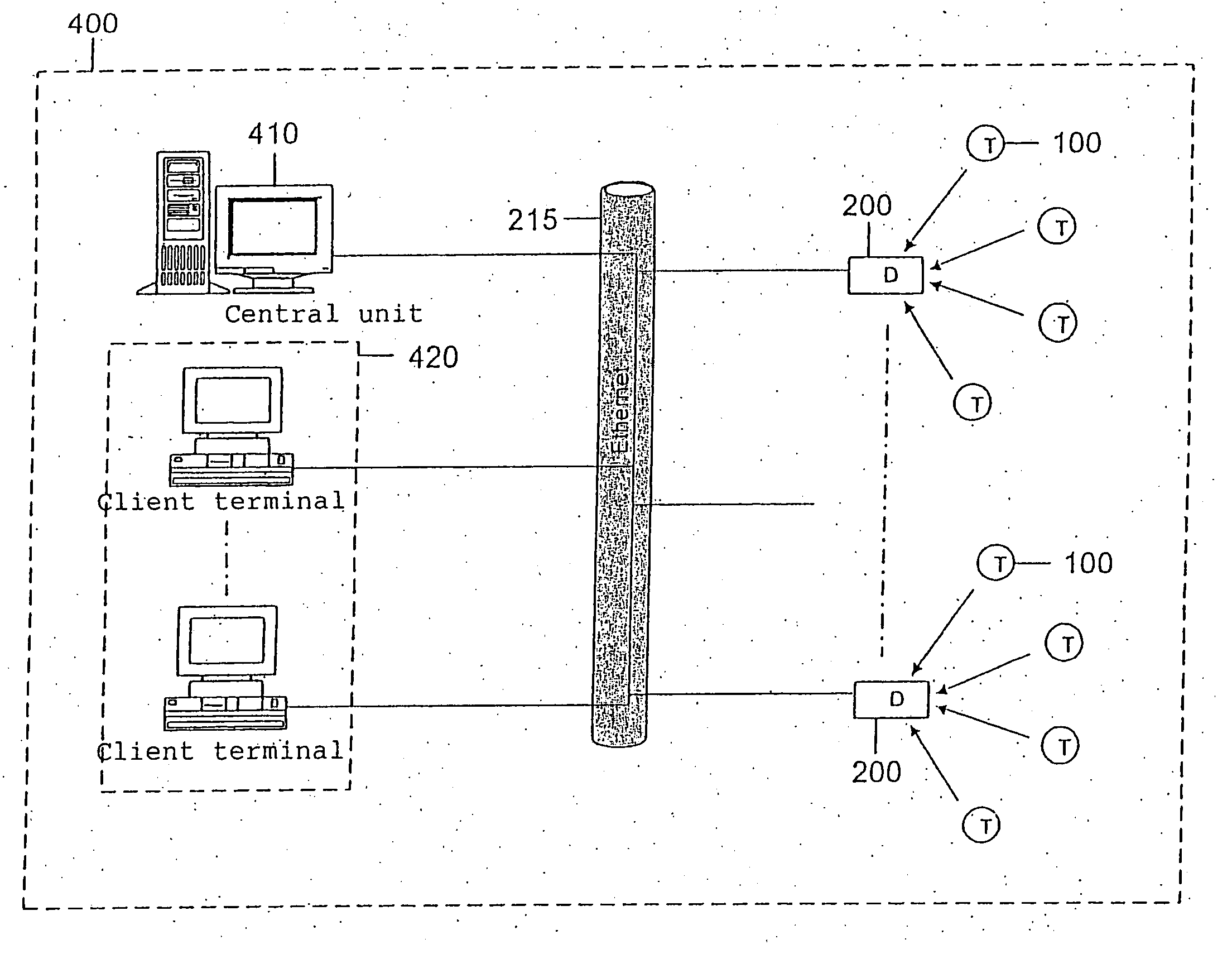

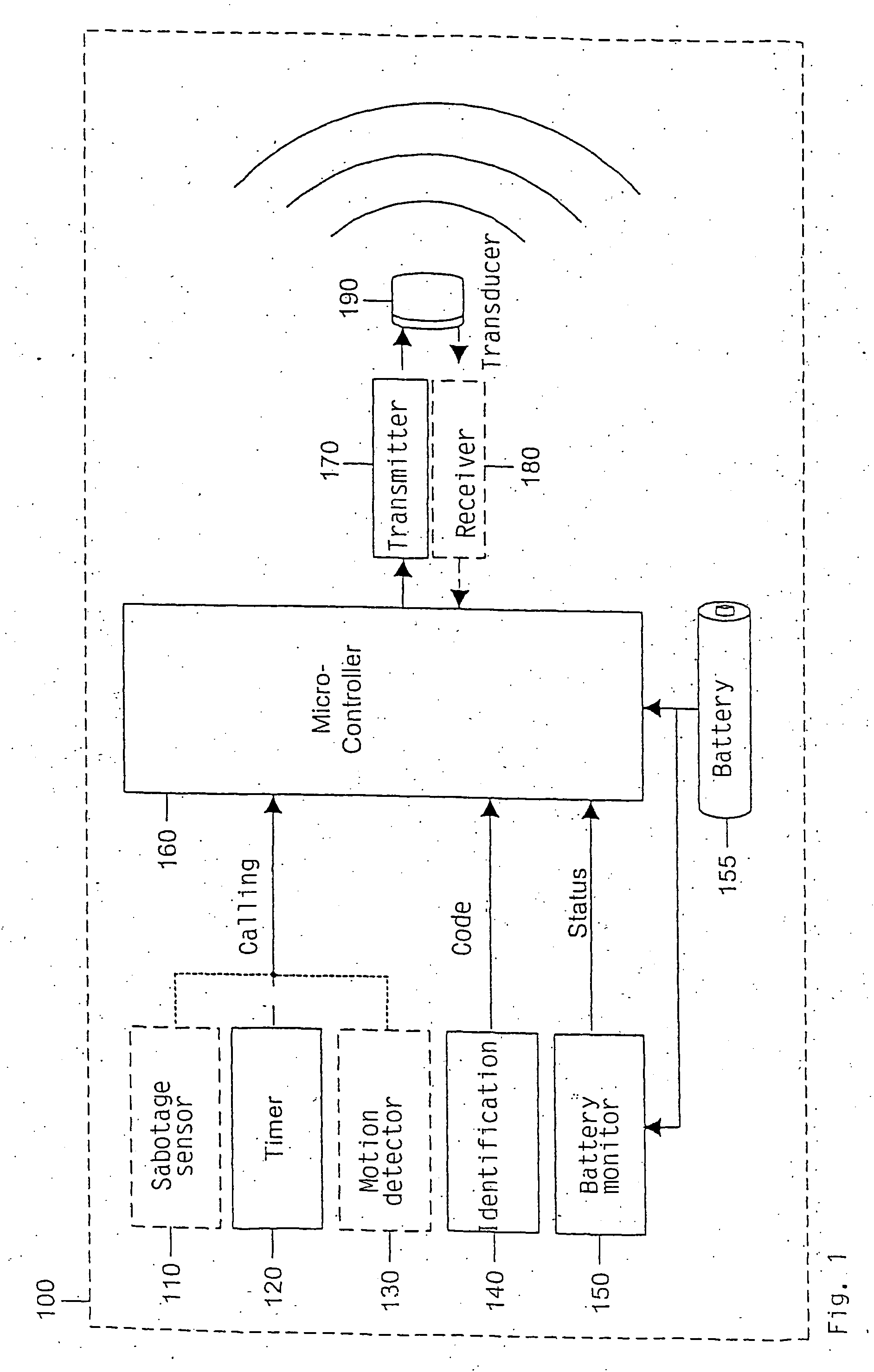

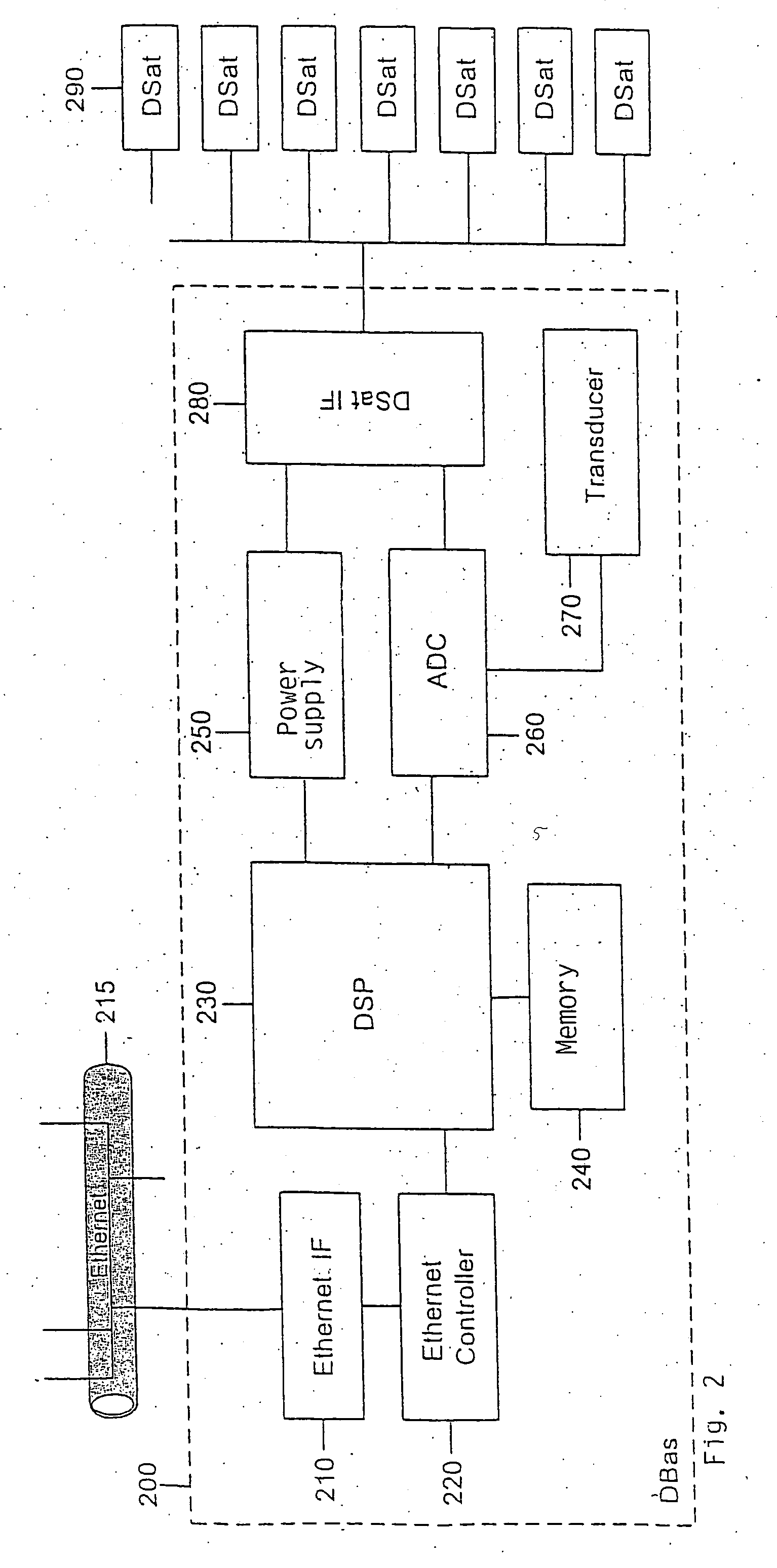

System and method for position determination of objects

ActiveUS20050141345A1Easy to measureEasy and cost-effective to implementPosition fixationAcoustic wave reradiationElectronic identificationEngineering

A method and a system (400) for detection and position determination of chips (100), which transmit ultrasound signals in a room. The system (400) comprises electronic identification chips (100), which are attached to objects that have to be monitored. Each chip (100) is equipped with a transmitter (179) and a receiver (180). The signals are received by a plurality of detector units (290), which are connected to a detector base unit (200) that registers and interprets the signals transmitted form the identification chips (100). Detector base units (200) located in different rooms are interconnected in a network (215) and transmit processed information to one or more central units (410) for further interpretation and sorting. The special feature of the invention is that line interference is substantially removed, and it is possible to determine position even though the identification chips (100) are in motion.

Owner:SONITOR TECH

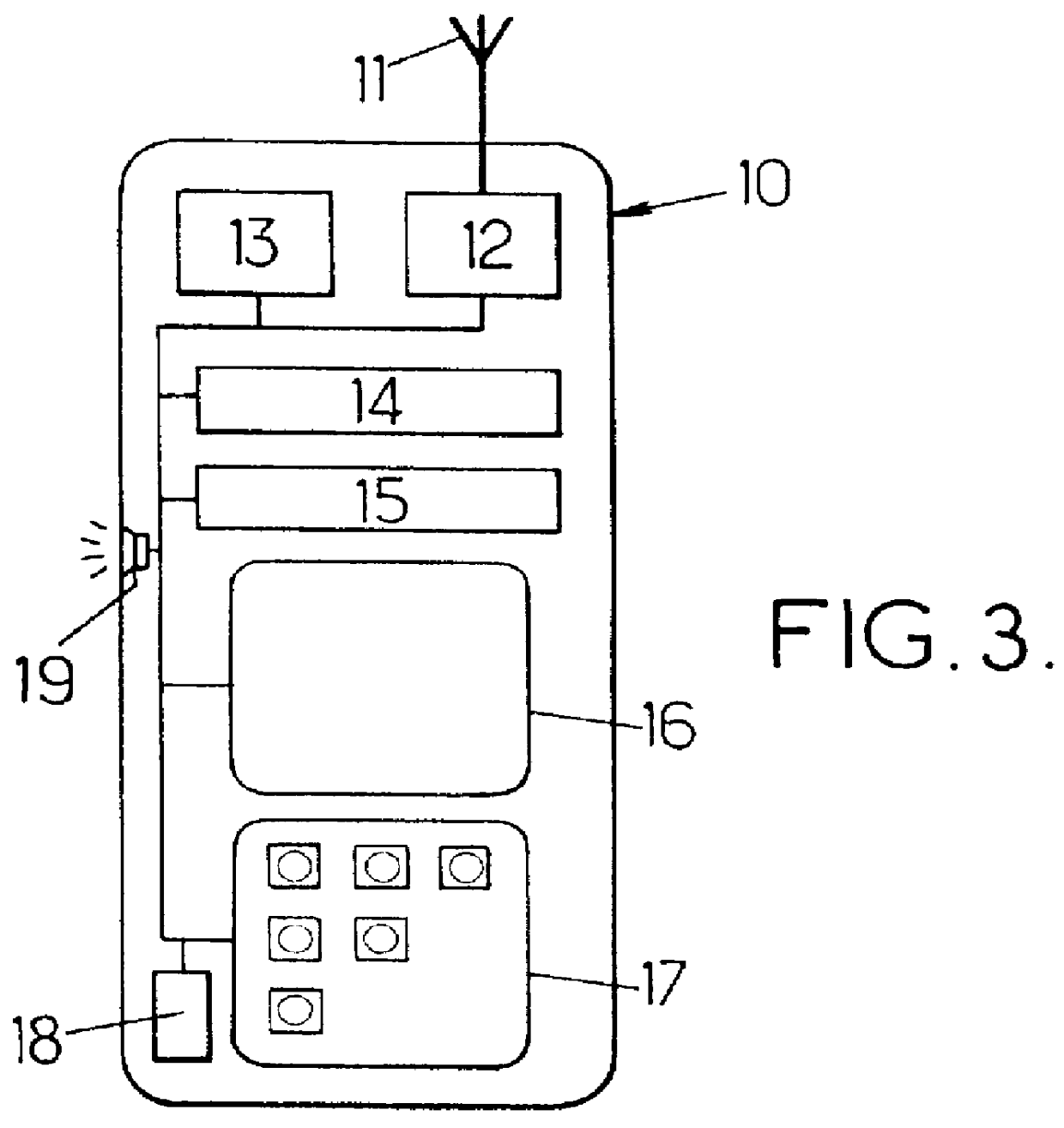

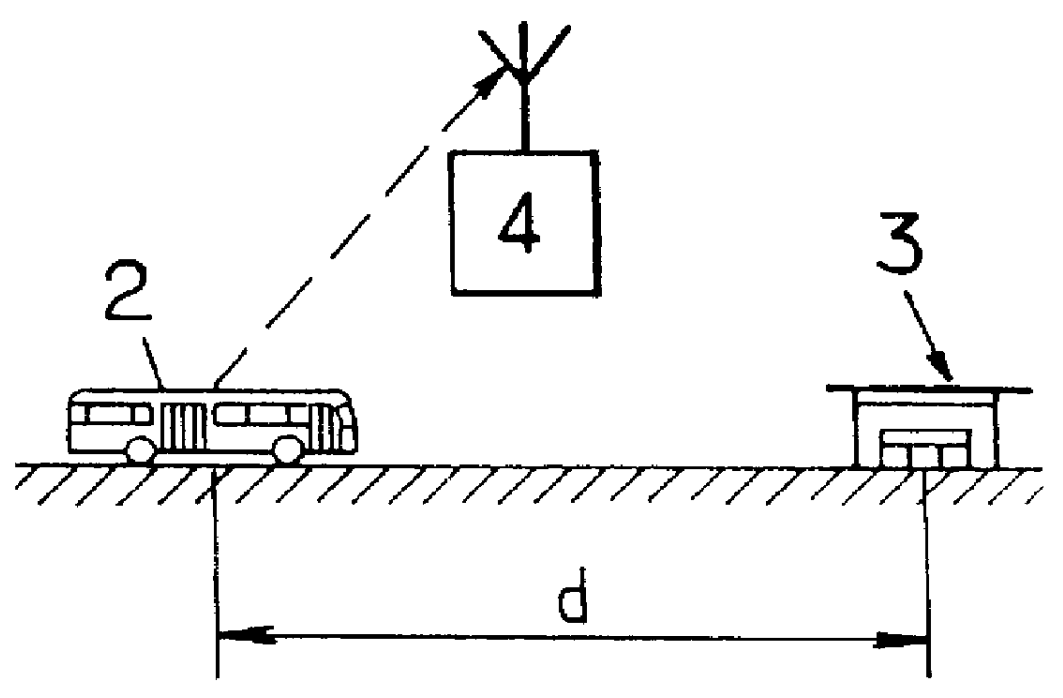

Portable appliance for informing the users of a bus network about waiting times at stops in the network

InactiveUS6097317AAnalogue computers for vehiclesAnalogue computers for trafficRadio receiverRadio reception

The portable appliance informs users about waiting times at stops in a bus network, the appliance comprising a radio receiver to receive data enabling waiting times to be determined, an interrogation keypad, a central unit for evaluating the estimated time of arrival of the next bus at a particular stop, a screen for displaying the waiting time for said bus, and a sound emitter. The central unit is designed to update cyclically the estimated time of arrival for the next bus and to actuate the sound emitter when said estimated time of arrival differs excessively from the time of arrival initially estimated the last time the appliance was interrogated by the user.

Owner:JCDECAUX

Apparatus and method for trellis encoding data for transmission in digital data transmission systems

InactiveUS7020165B2Improve throughputReduce error ratePulse modulation television signal transmissionError preventionDigital dataPhase difference

A system for bidirectional communication of digital data between a central unit and a remote unit wherein the need for tracking loops in the central unit has been eliminated. The central unit transmitter generates a master carrier and a master clock signal which are used to transmit downstream data to the remote units. The remote units recover the master carrier and master clock and synchronize local oscillators in each remote unit to these master carrier and master clock signals to generate reference carrier and clock signals for use by the remote unit receiver. These reference carrier and clock signals are also used by the remote unit transmitters to transmit upstream data to the central unit. The central unit receiver detects the phase difference between the reference carrier and clock signals from the remote units periodically and adjusts the phase of the master carrier and master clock signals for use by the central unit receiver to receive the upstream data.

Owner:GOOGLE TECH HLDG LLC

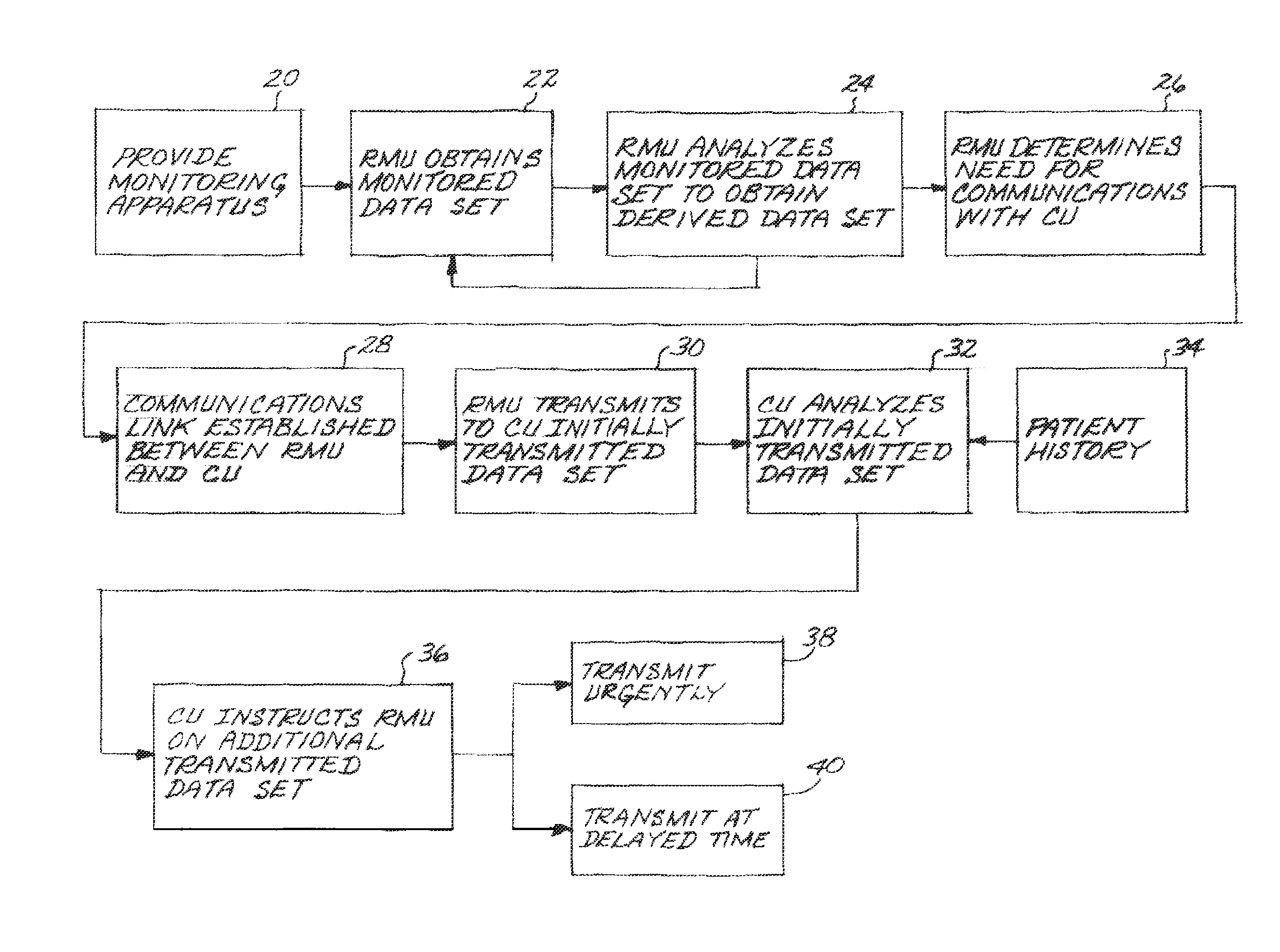

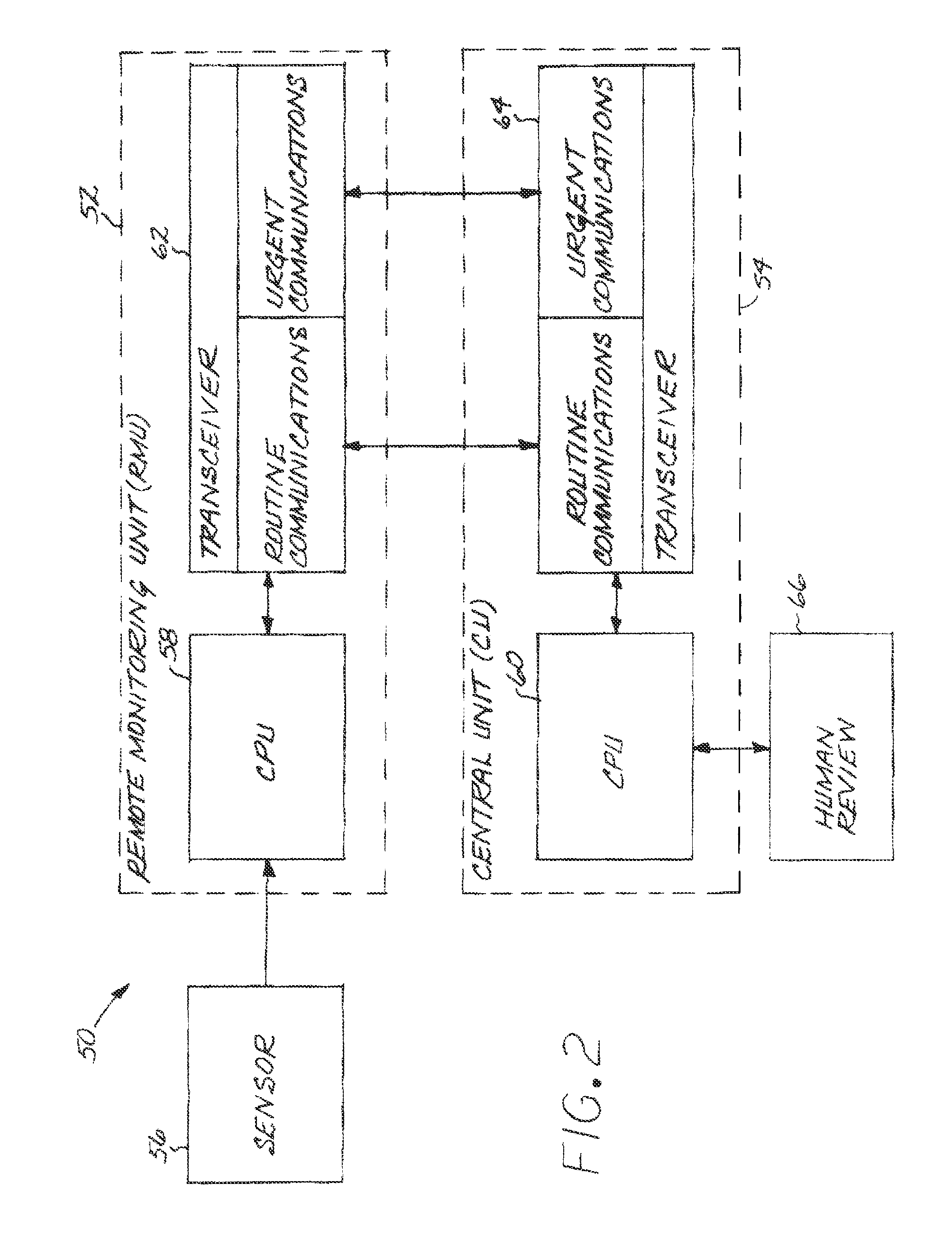

Control of data transmission between a remote monitoring unit and a central unit

InactiveUSRE43767E1Reduce data volumeExtended service lifeSensorsTelemetric patient monitoringData setTelecommunications link

A patient is monitored using a monitoring apparatus including a remote monitoring unit associated with the patient and having a sensor that measures a physiological characteristic of the patient, a central unit, and a communications device which selectively establishes a communications link between the remote monitoring unit and the central unit. The remote monitoring unit obtains a monitored data set for the patient, analyzes the monitored data set to obtain a derived data set from the monitored data set, and determines from the derived data set that communication with the central unit is required. A communications link is established with the central unit, and the remote monitoring unit transmits to the central unit an initially transmitted data set related to the monitored data set. The central unit analyzes the initially transmitted data set and instructs the remote monitoring unit as to any additional transmitted data set related to the monitored data set that is to be transmitted from the remote monitoring unit to the central unit and a time at which the additional transmitted data set is to be transmitted.

Owner:BRAEMAR MFG

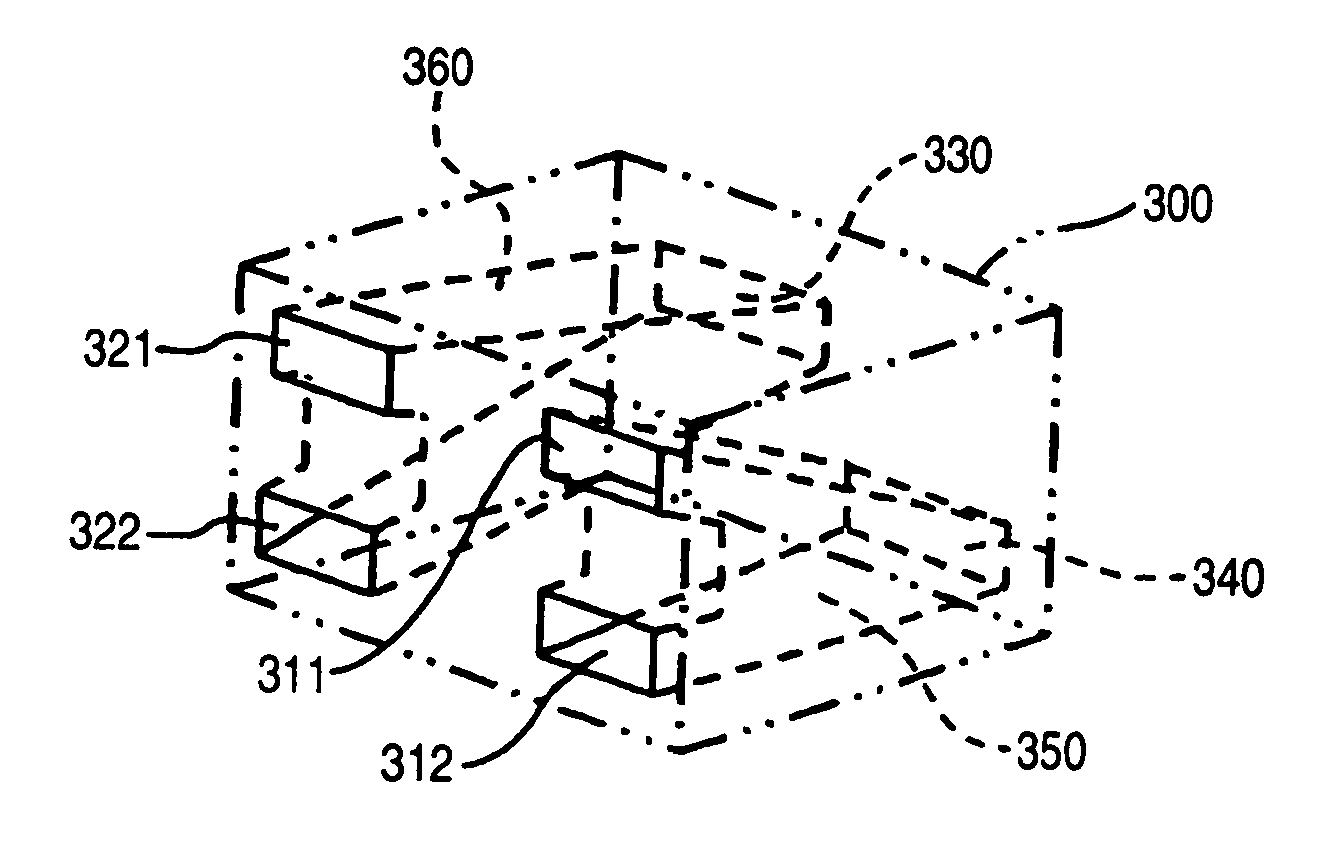

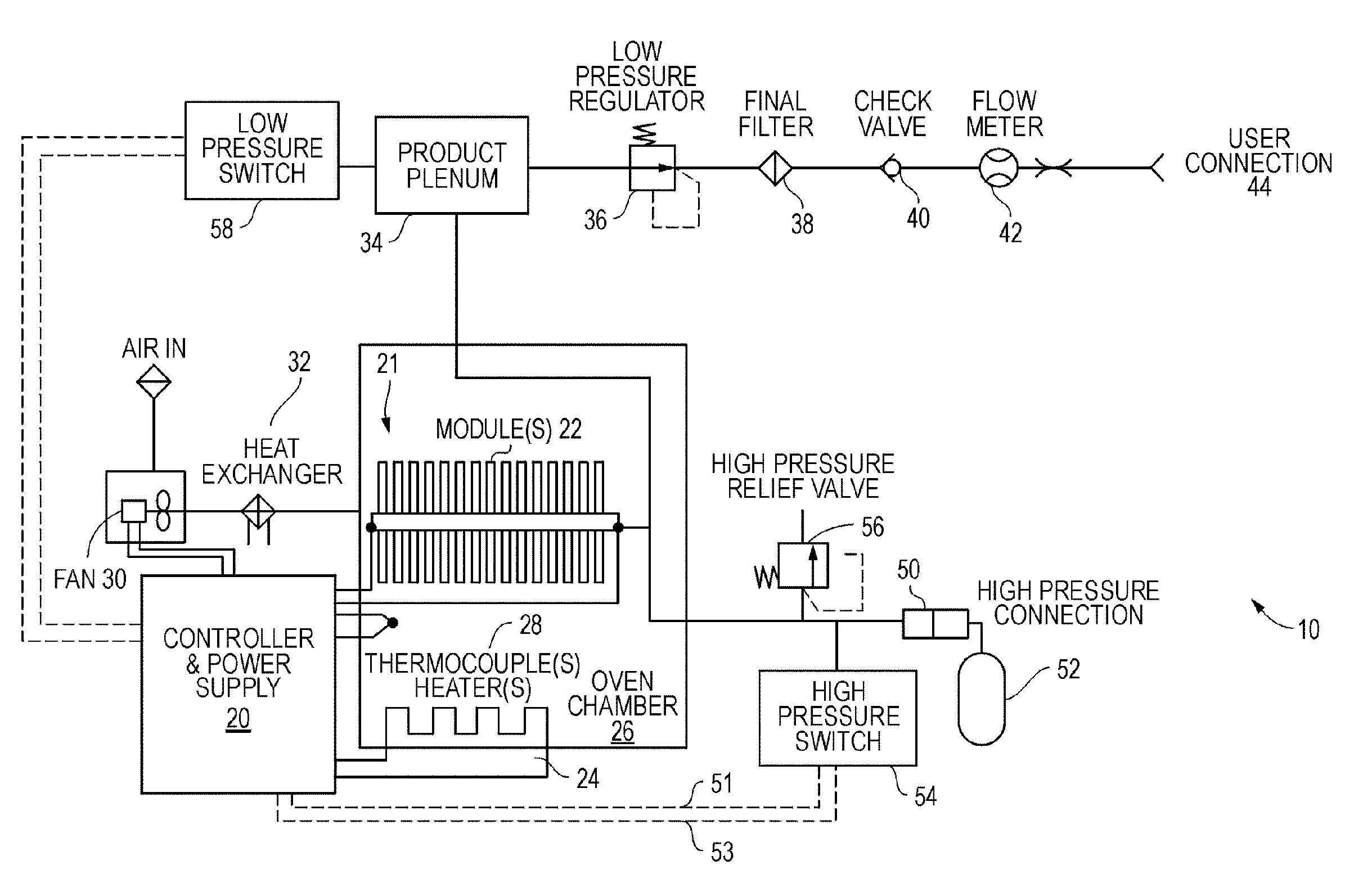

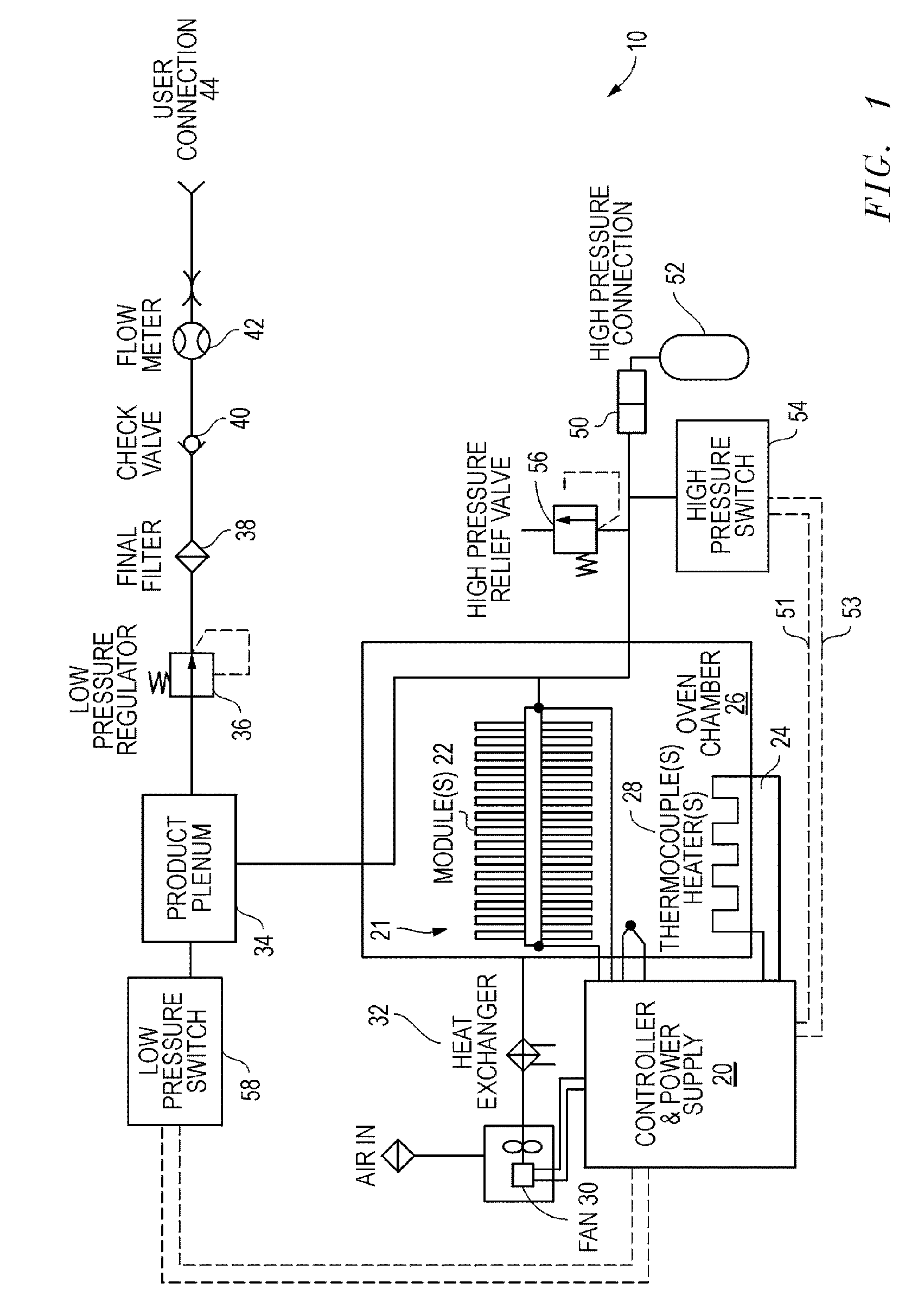

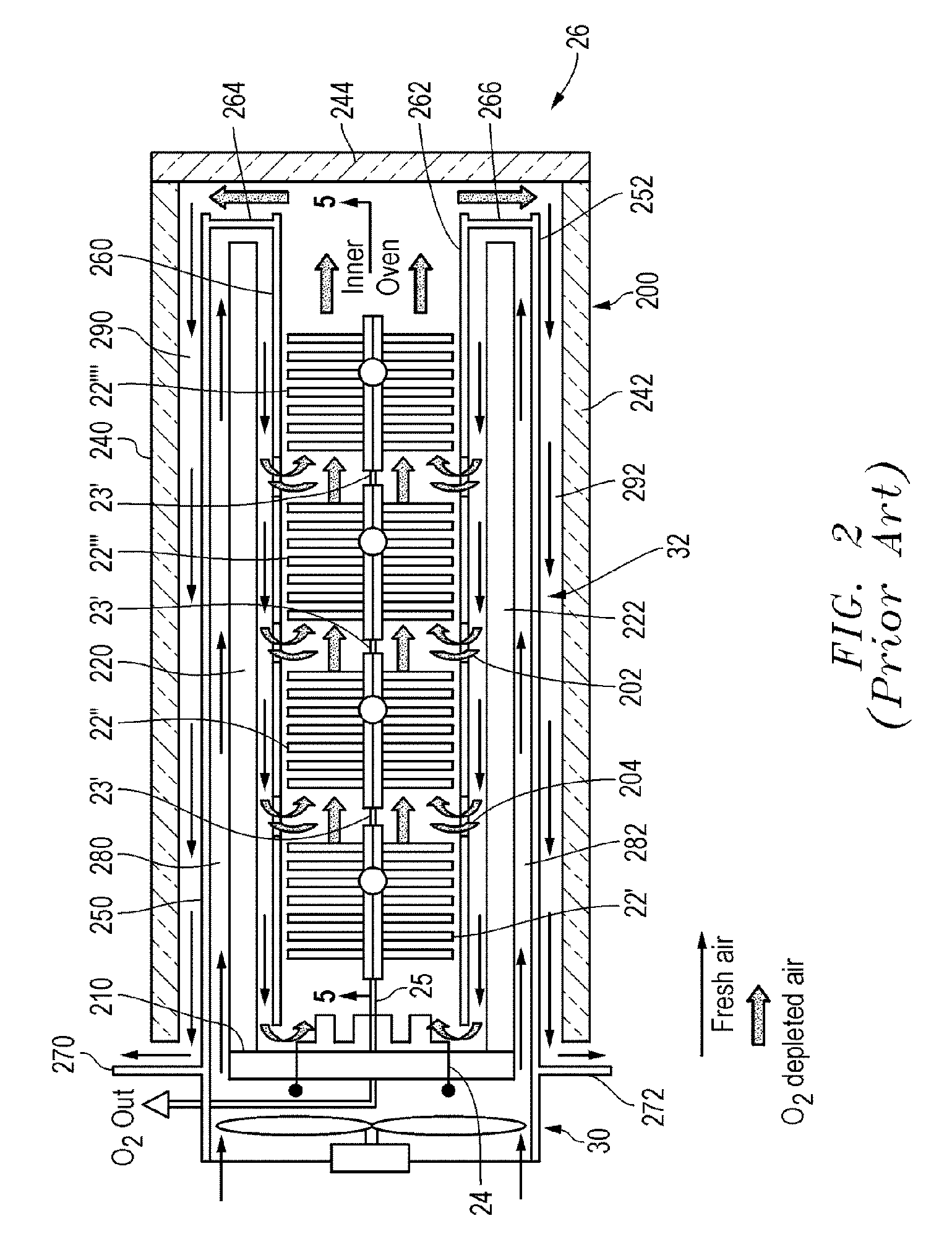

Electrochemical oxygen generator module assembly

ActiveUS20060175194A1Improve oxygen production performanceIncrease capacityPhotography auxillary processesElectrical-based machining electrodesInterior spaceEngineering

An ionically conductive ceramic element includes a central unit (703). The central unit (703) is composed of a plurality of integrated manifold and tube modules (IMAT) (22) joined end to end along a central axis (A). Each IMAT module (22) has a tube support portion (804) and a plurality of tubes (802) extending from the first surface (803). The tubes (802) each have a closed end (805) and an open end. The second surface (807) is at least partially open to the atmosphere. The open ends of the tubes (802) are open to the atmosphere through the second surface (807). An interior space (830) is formed in the interior of the IMAT (22) for collecting a desired product gas. A collection tube (710) is operable joined with a first end (714) of the central unit (703) for transporting the desired product gas collected in the interior space (730) of the connected IMAT modules (22).

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

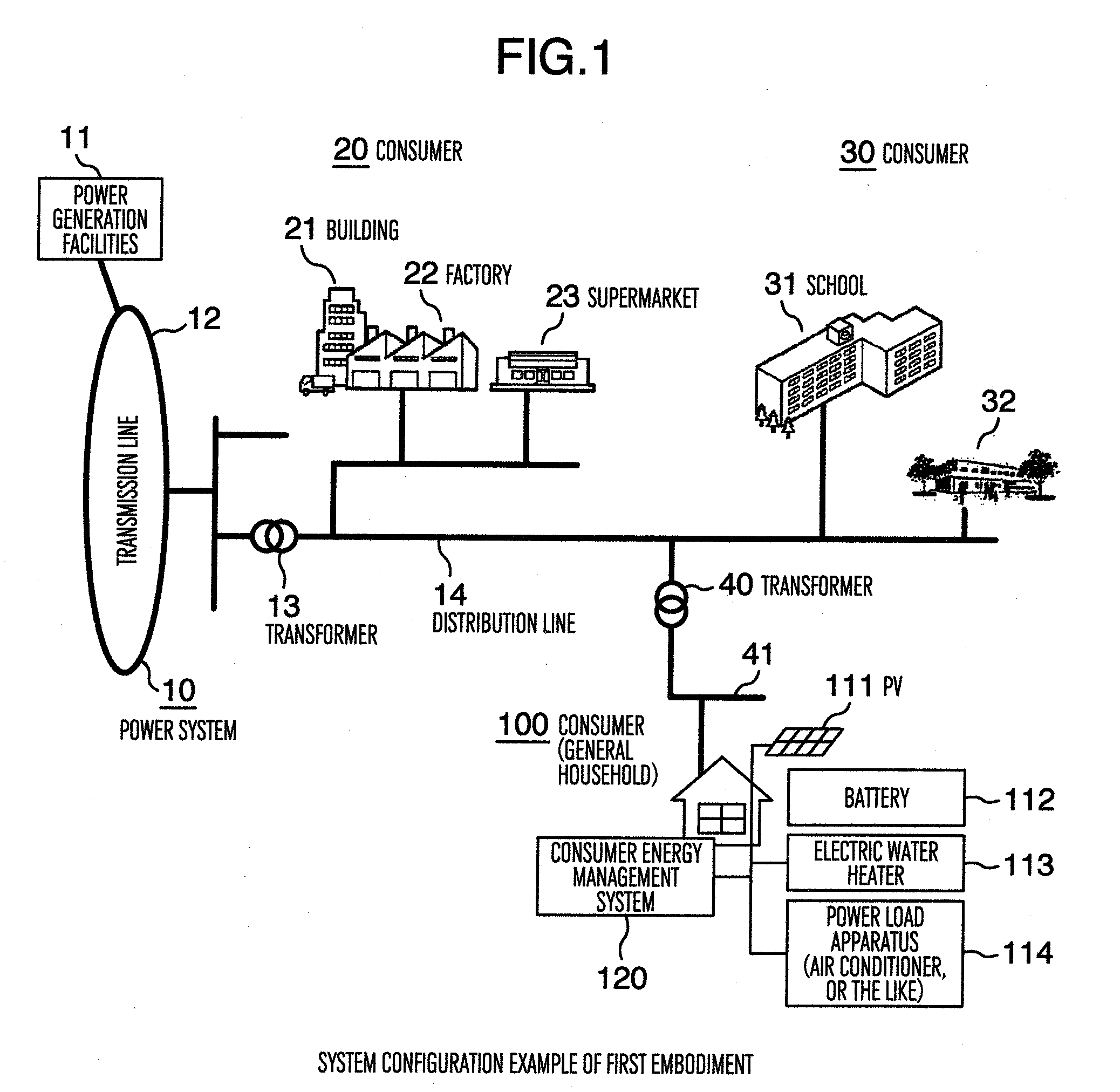

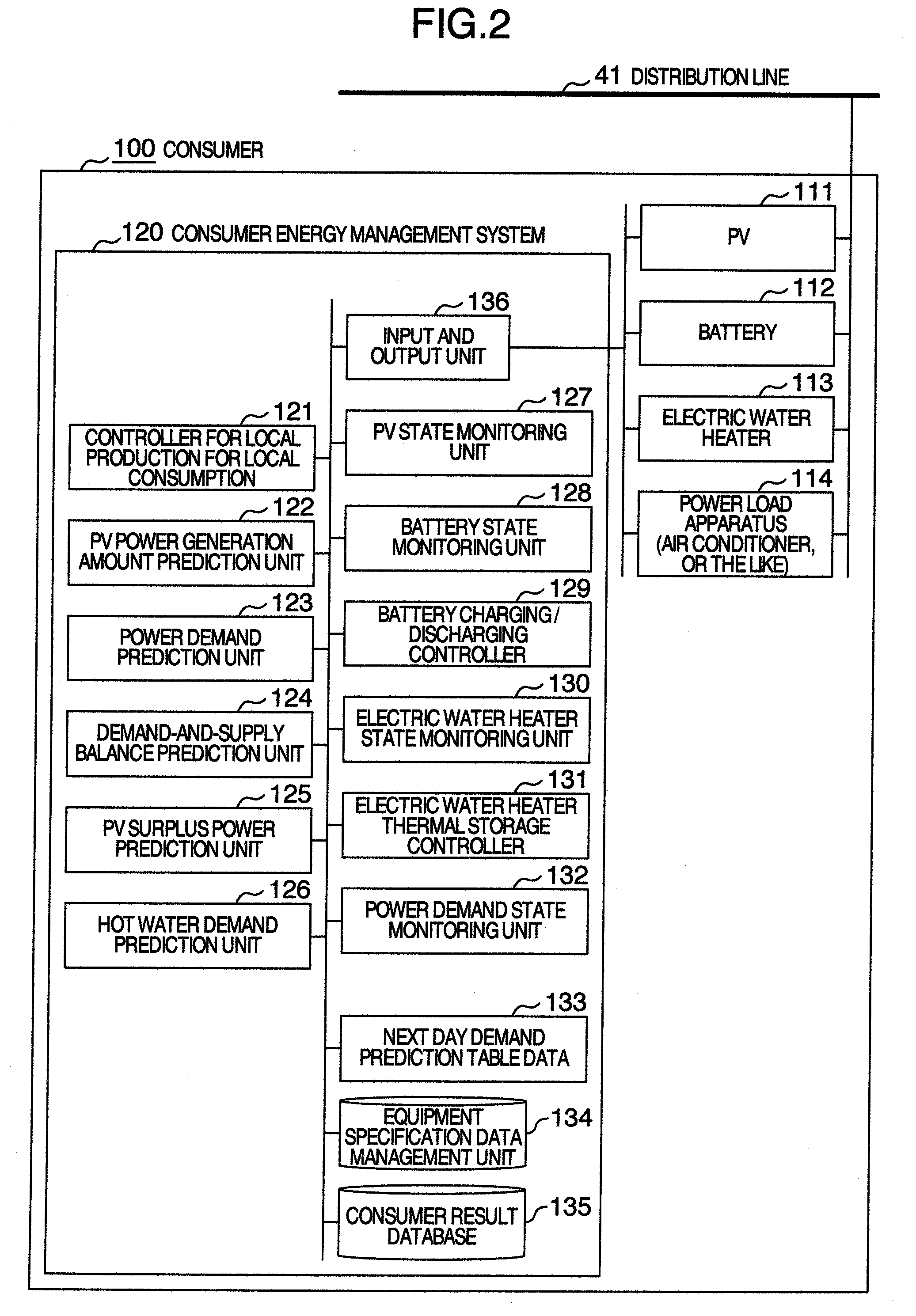

Energy management system, energy management apparatus, and energy management method

ActiveUS20110238232A1Reduce the impactIncrease photovoltaic power generation amountElectrical storage systemMechanical power/torque controlRadiation lossElectric power system

An energy management system includes an equipment data management unit which manages charging / discharging loss of a battery and heat radiation loss of an electric water heater, and causes a control unit to perform control to give priority based on the comparison to the energy storage facility more reducing loss and store energy. The energy management system includes a system operation calculation unit which predicts voltage distribution of the next day of a distribution system or demand-and-supply balance amount of the entire system by state monitoring data of a power system, calculates a demand amount increasing target value necessary for avoiding a photovoltaic power generation amount suppression on a consumer end by the voltage distribution of the next day of the distribution system or the demand-and-supply balance amount, and controls the energy storage facilities so as to satisfy the demand amount increasing target value on the consumer end.

Owner:HITACHI LTD

Access control system, access control method and devices suitable therefor

InactiveUS7196610B2Electric signal transmission systemsMultiple keys/algorithms usageControl systemCentral unit

An access control system comprises a plurality of access control devices in each of which is stored an access code. Specific access codes and access rights for a plurality of access control devices are transmitted from an access control central unit over a mobile radio network to the mobile communication terminal of a user. Transmitted to the mobile communication terminal by an access control device to be passed is an access control device identification. In the mobile communication terminal, on the basis of the received identification, the access code and the access rights for the access control device to be passed are determined, and are transmitted to the access control device. The access control device clears the user for access if the received access rights suffice and the received access code agrees with the stored access code.

Owner:ZEIT

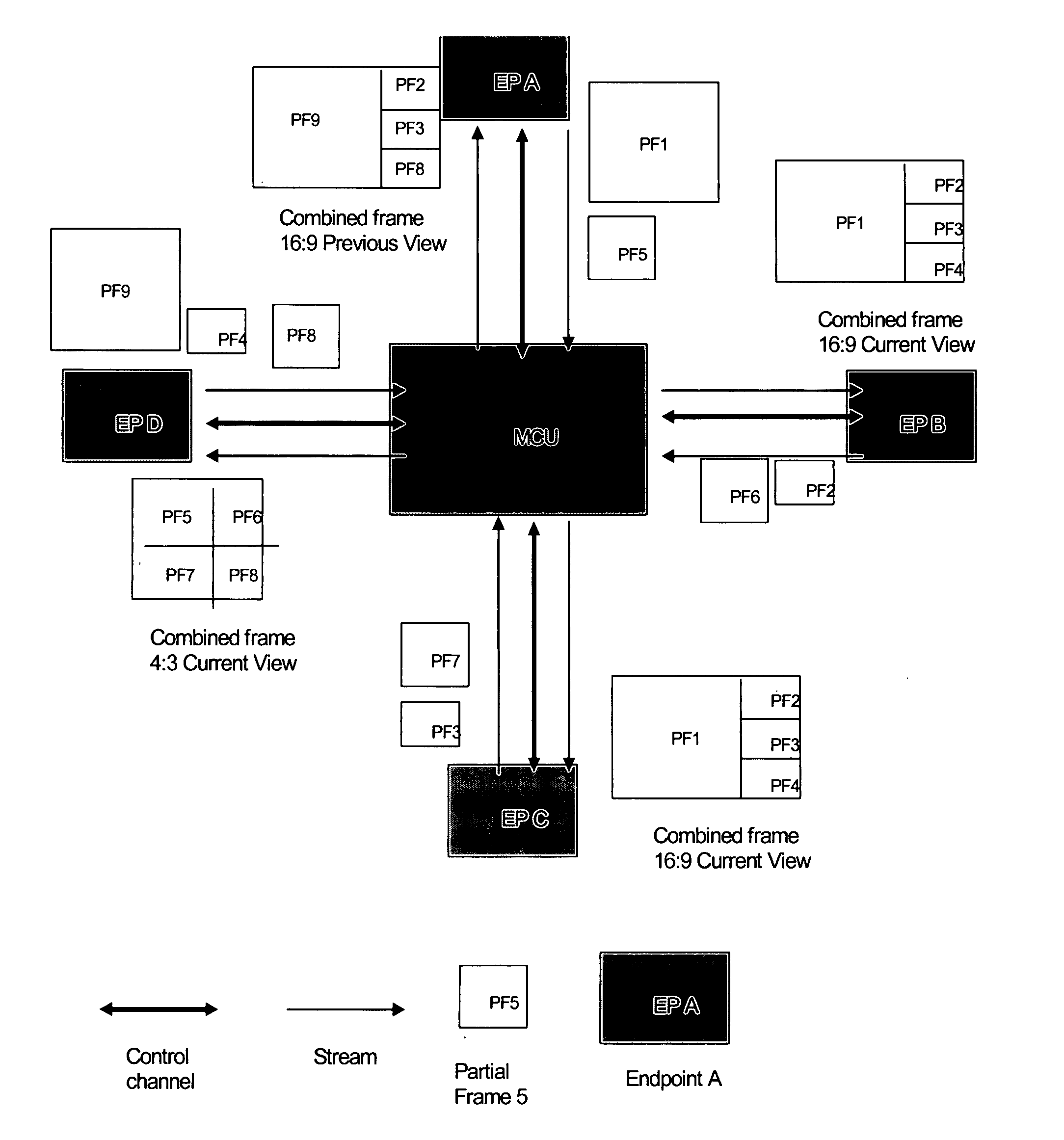

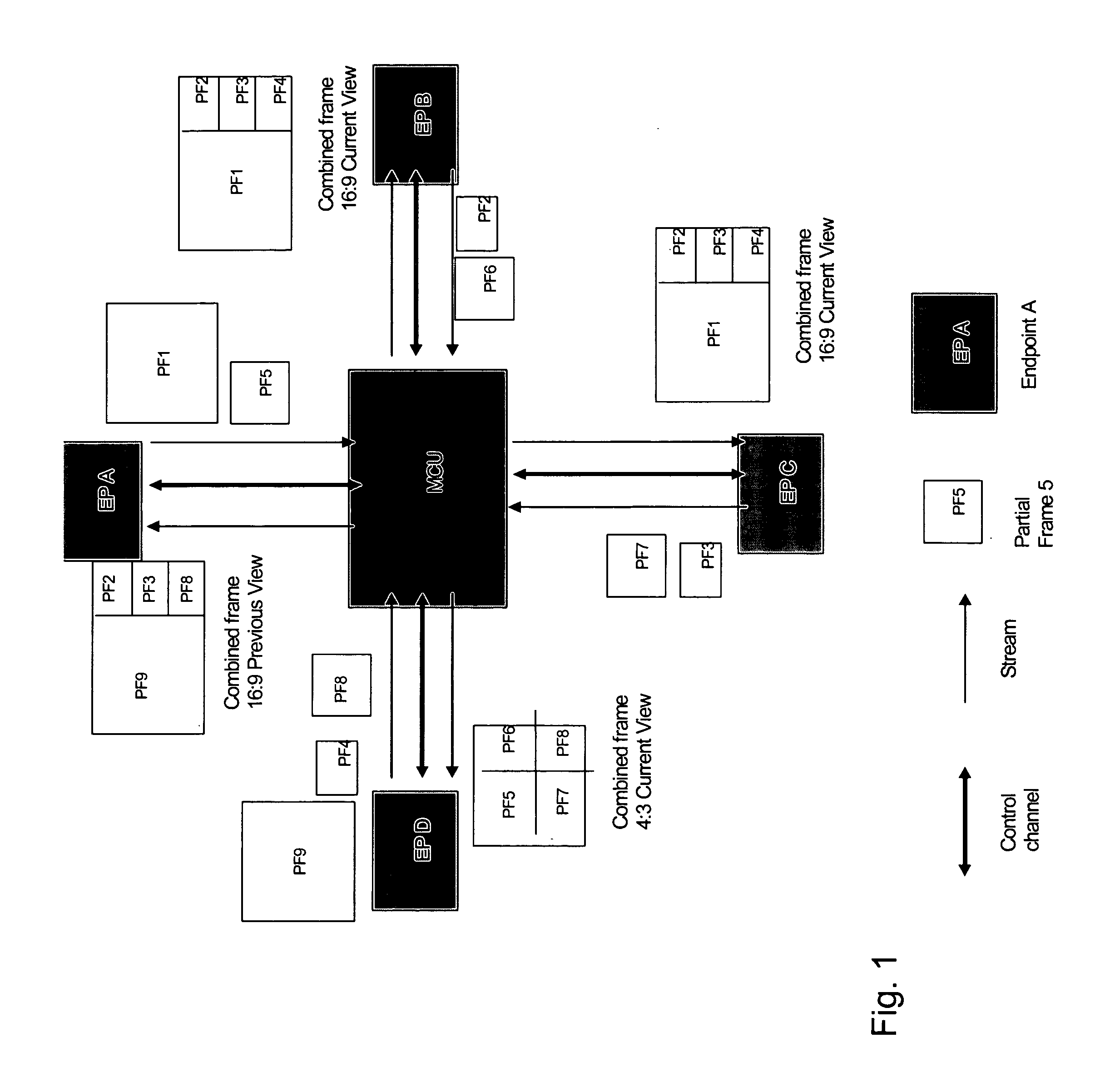

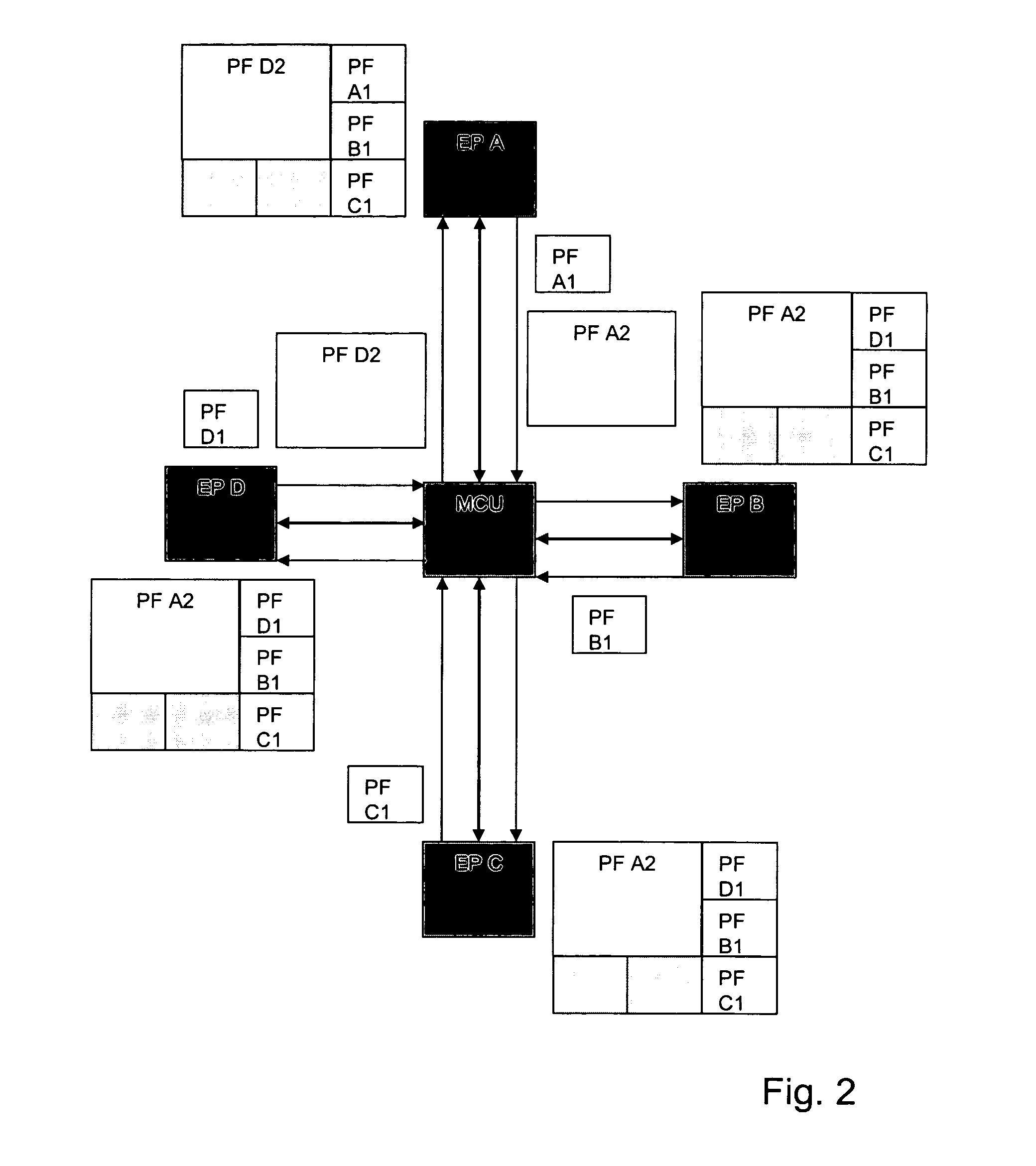

Distributed real-time media composer

ActiveUS20050122392A1Drawback can be obviatedTelevision conference systemsSpecial service for subscribersData informationCentral unit

A system and a method allowing simultaneous exchange of audio, video or data information between a plurality of units over a communication network, supported by a central unit, wherein the central unit is, based on knowledge regarding one or more of the units, adapted to instruct said one or more units to generate multimedia data streams adjusted to fit into certain restrictions to be presented on other units participating in a same session.

Owner:CISCO TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com