Die and method for braiding curve limiting mesh of inflatable membrane

A technology of inflatable film and limiting net, which is applied in the direction of braided fabrics, hand-woven, textiles and papermaking, etc., and can solve problems such as inability to make arc-shaped and curved surface limiting nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

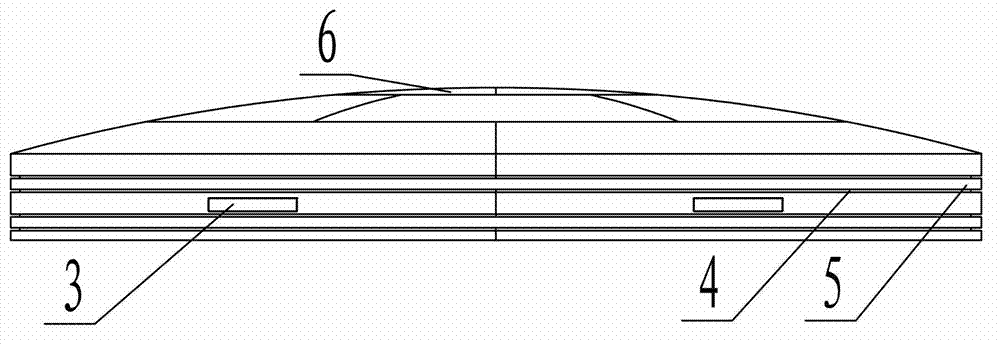

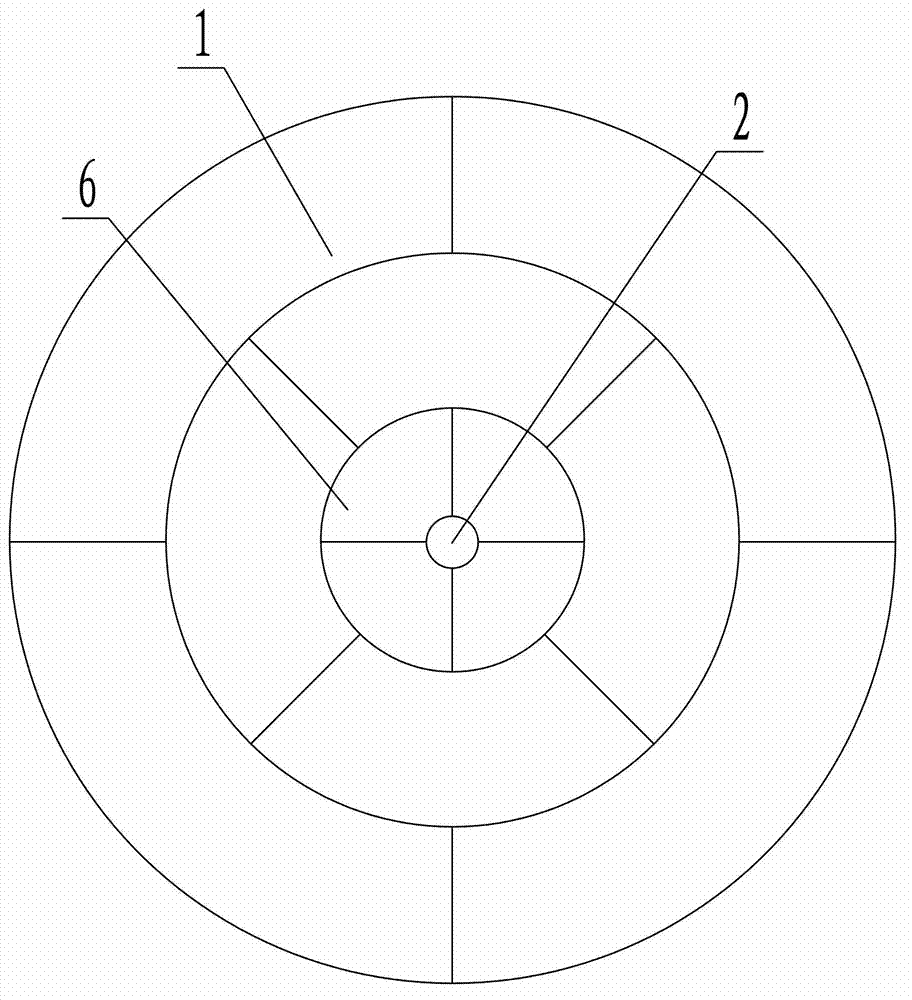

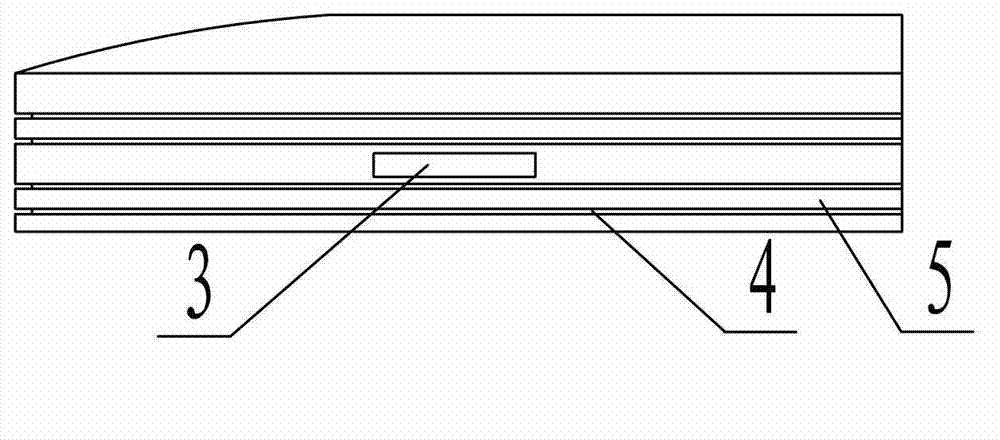

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a mold for weaving an inflatable film curved surface limiting net described in this embodiment, the mold includes a template 1, the template 1 is in the shape of a round cake, the lower end surface of the template 1 is a plane, and the upper surface of the template 1 The end face is an arc-shaped curved surface and the center position of the upper end face of the template 1 is the highest point of the arc-shaped curved surface.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, the formwork 1 described in this embodiment is composed of a central formwork 6 and a plurality of annular formworks, the central formwork 6 is cylindrical, and the plurality of annular formworks are connected in the center from the inside to the outside according to the order of the outer diameter from small to large. On the formwork 6, each annular formwork is composed of multiple arc-shaped plates, and the joints of the multiple arc-shaped formworks in each annular formwork are staggered in the ring direction from the joints of the multiple arc-shaped formworks in the adjacent annular formwork , set in this way, the template 1 is divided into multiple pieces, which facilitates the disassembly and assembly of the template 1, and the other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 Describe this embodiment, the mold described in this embodiment also includes a central column 2, the middle position of the upper end surface of the template 1 is provided with a column hole, the central column 2 passes in the column hole of the template 1, the upper end surface of the central column 2 and the template 1's upper surface coincides with each other, so that it is convenient to make concentric circles on the upper end surface of template 1 with the center point of the upper end surface of template 1 as the center, so that it is more convenient for the mold to weave the limit net. Other components and connection relations are the same as The second embodiment is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com