Oceanic mineral resource exploitation device and exploitation method

A mineral resource and marine technology, applied in the direction of mining fluid, mining minerals, earth drilling and mining, etc., can solve the problems of reducing the grounding specific pressure, subsidence, and large turning radius of the ore collector, so as to improve reliability, efficiency, and mining efficiency The effect of high altitude and low seabed disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

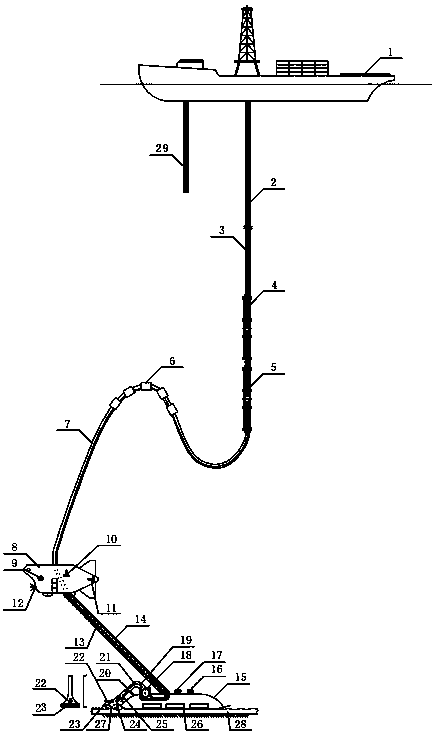

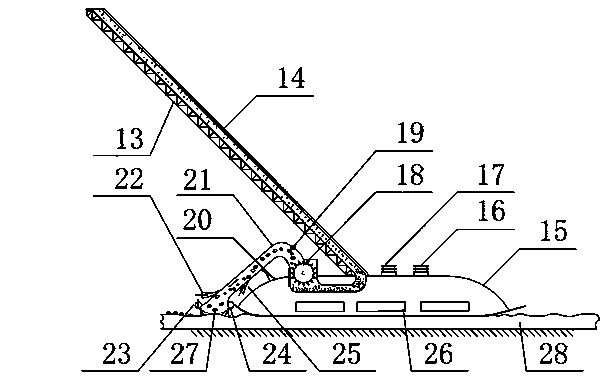

[0052] The core of the present invention provides a new method and apparatus for deep sea mineral resource mining, including mineral seabed collection, crushing and transport from seabed to surface mining vessels. The specific implementation is as follows:

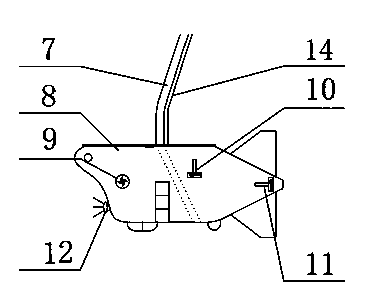

[0053] An apparatus for mining marine mineral resources, comprising a surface mining vessel 1 with a deployment tower, an upper lifting steel pipe 2 connected to the surface mining vessel 1 through a heave compensation device, and a multi-stage lifting electric pump connected in series with the lower lifting steel pipe 3 4 and 5 constitute a lifting electric pump station, the lifting hose 7 connected to the suction end of the lower lifting electric pump, the toothed roller crushing mechanism 18 connected to the suction end of the lifting hose 7, and the toothed roller crushing device 18 through the hinge 19. The mining mechanism is composed of front row and rear row disturbed jet nozzles 23, 24, front row and rear row asce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com