A high-power heavy-duty thin coal seam shearer

A thin coal seam and shearer technology, applied in cutting machinery, electromechanical devices, earthwork drilling and mining, etc., can solve the problems of low mining efficiency, poor use effect, low power, etc., and achieve wide application, excellent performance, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

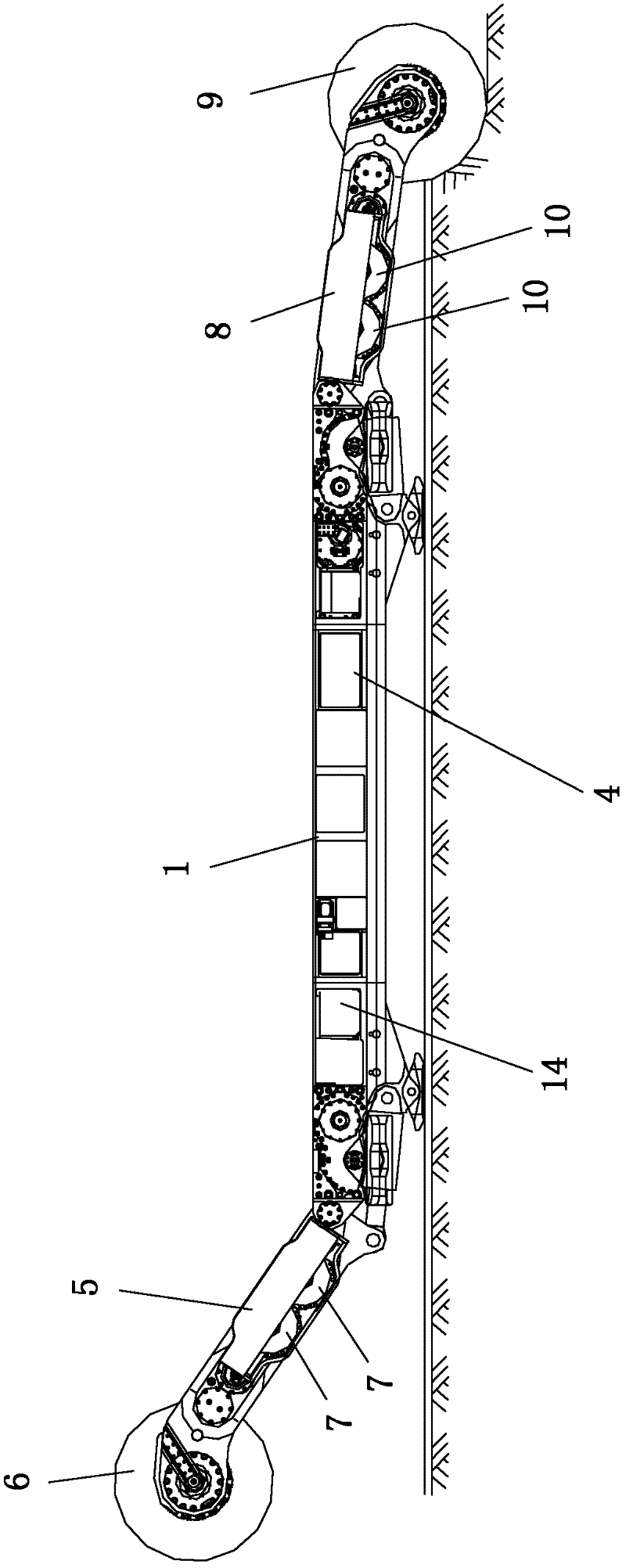

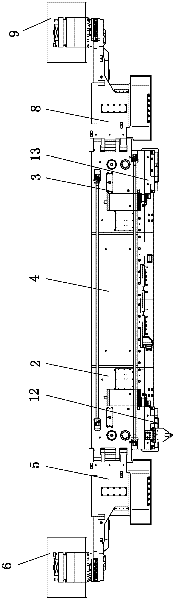

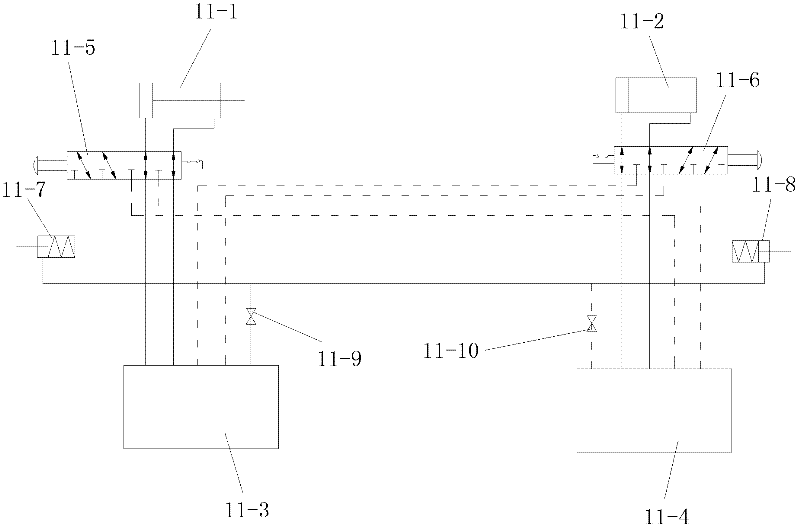

[0071] Such as figure 1 , figure 2 As shown, the present invention includes a fuselage 1, a left traction unit 2 and a right traction unit 3 installed on the left and right sides of the interior of the fuselage 1, and a left cutting unit and a right cutting unit respectively installed on the left and right sides of the outside of the fuselage 1. Department, the left traveling mechanism and the right traveling mechanism installed on the left and right sides of the fuselage 1 bottom, respectively, and the rocker arm height adjustment hydraulic system and electrical control system installed in the fuselage 1. The electrical control system includes an electric control box 4 installed on the fuselage 1 and a controller installed in the electric control box 4; The left cylinder 6 at the front end of the left rocker arm 5 and the left cutting motor 7 that drives the left cylinder 6, the left cutting motor 7 is installed in the left rocker arm 5 and is connected with the left cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com