Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Increase cutting power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

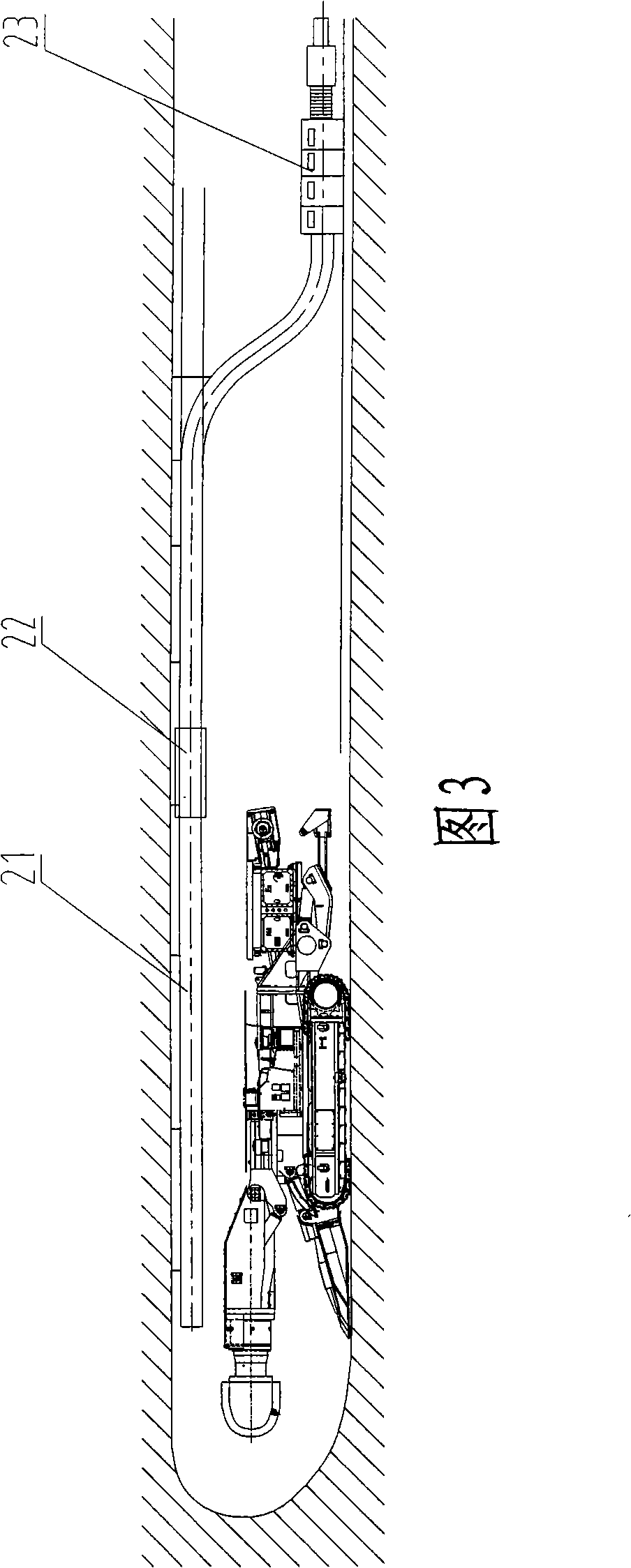

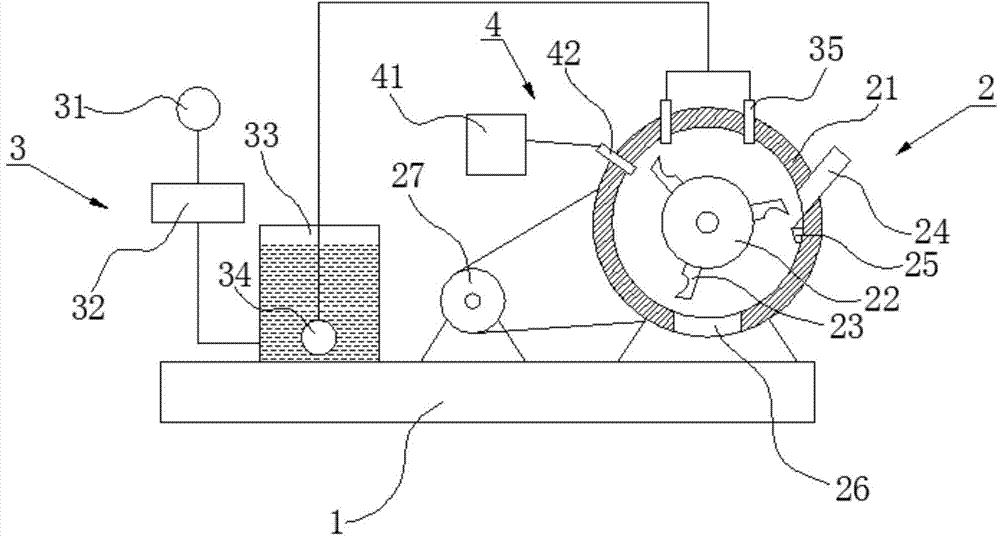

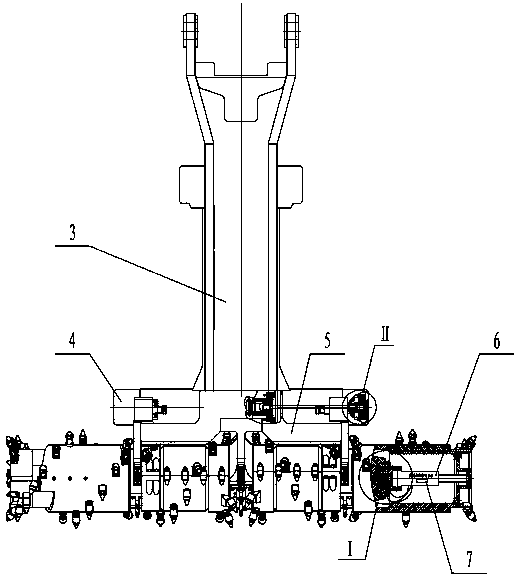

Hard rock tunneling machine

InactiveCN101289936AImprove structural strengthMajorDriving meansCutting machinesWorking environmentHardness

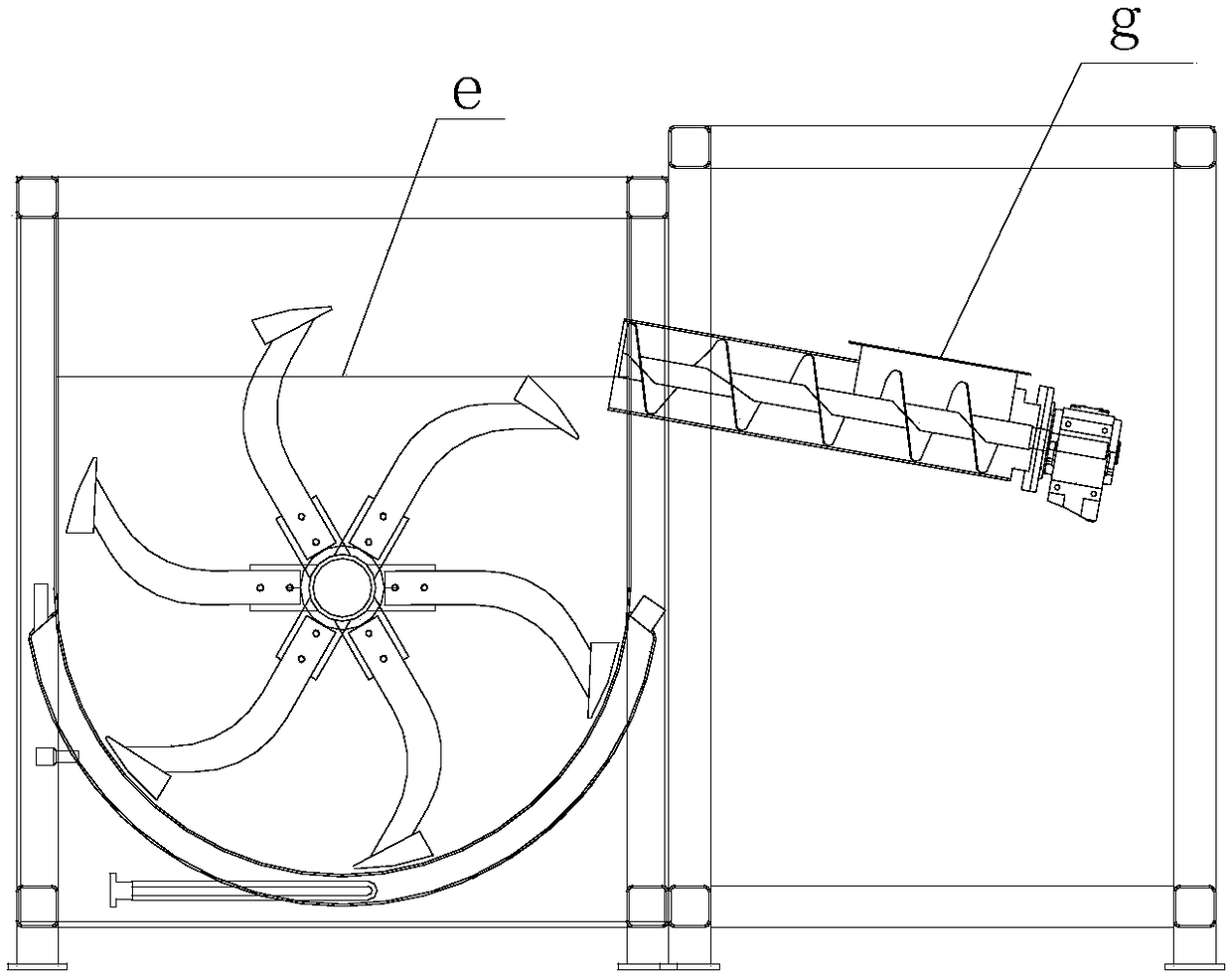

The invention relates to the coal mine roadway drivage machinery, in particular to a heavy hard rock tunneling machine which can cut a semi-rock roadway and a whole-rock roadway with high hardness. The tunneling machine solves the problem that the prior mole is not suitable for rock roadway drivage, can greatly improve the drivage working efficiency of the whole-rock roadway, and dramatically reduce working intensity of operators. The tunneling machine has an integral structure with high strength, a complete machine with heavy weight, a horizontal side support arranged on the back of the machine, and a device with high stability; the machine is provided with a mighty dust absorption system and an inside and outside spray dust suppression system, which effectively improves working environment of the operators; a traction of the tunneling machine adopts a full-sealed structure to increase traction driving force and improve propulsive force of the cutting; the tunneling machine has a small assembly, a large diameter and an inertia cutting head, adopts a reliable and highly-efficient hydraulic system matched with a high-strength point-attack pick, which greatly improves unidentate cutting force, thereby the tunneling machine has the ability of cutting the semi-rock roadway and the whole-rock roadway with high-hardness (f8).

Owner:SANY HEAVY EQUIP

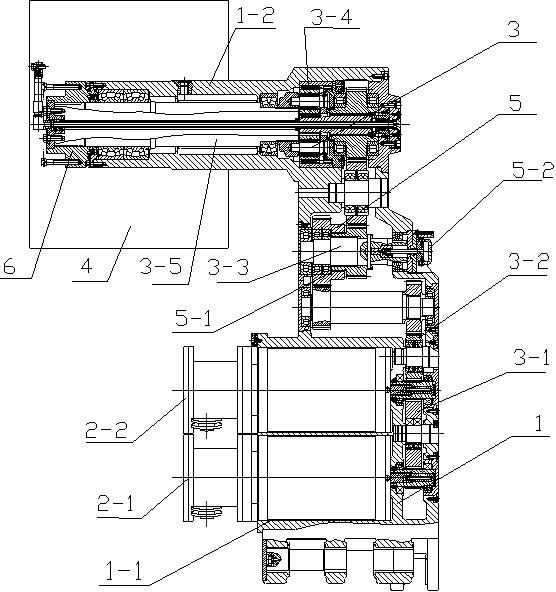

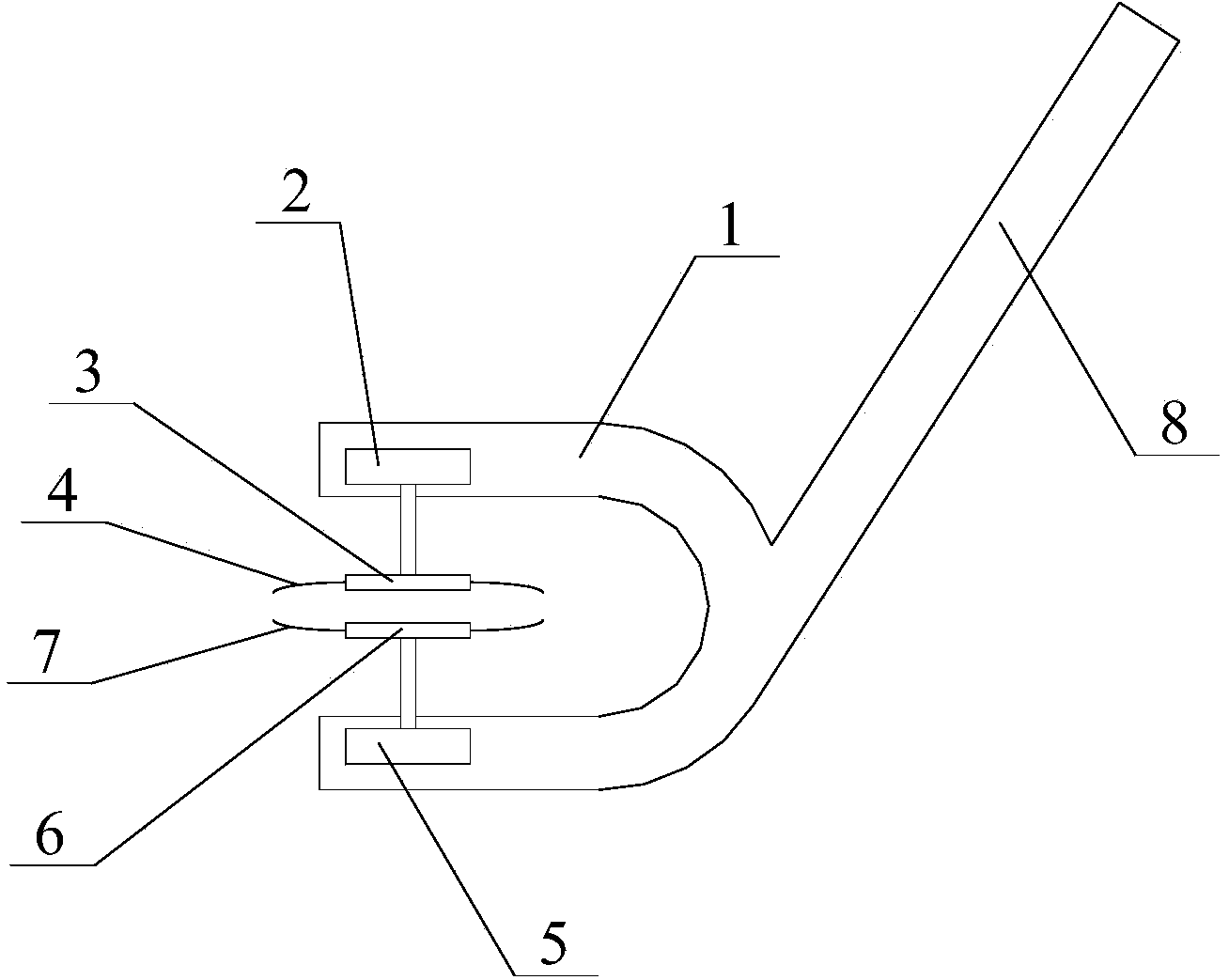

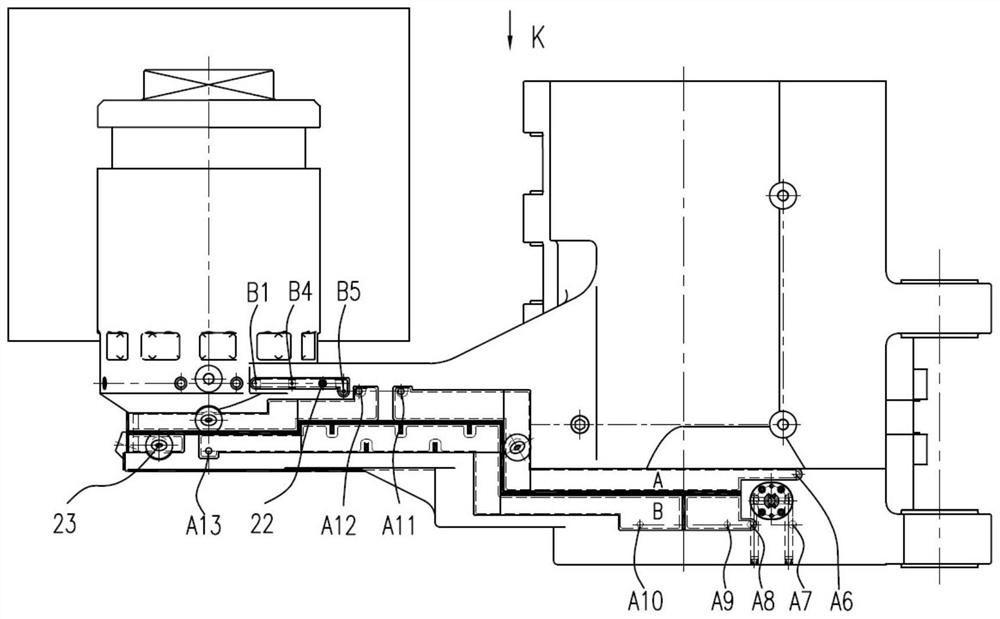

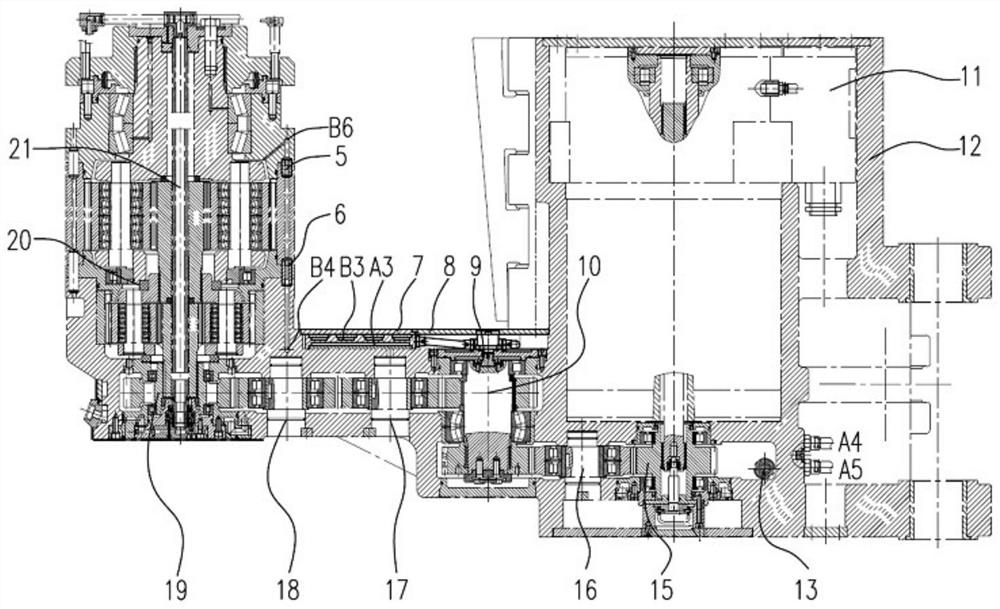

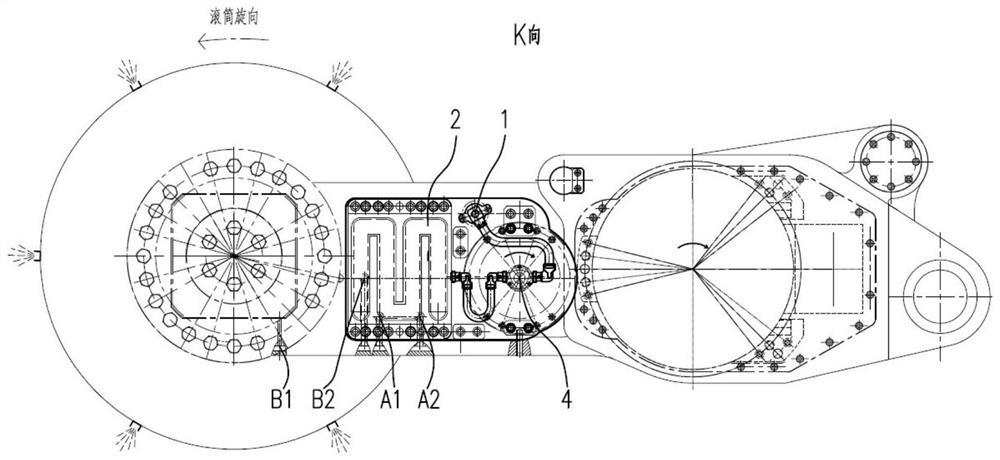

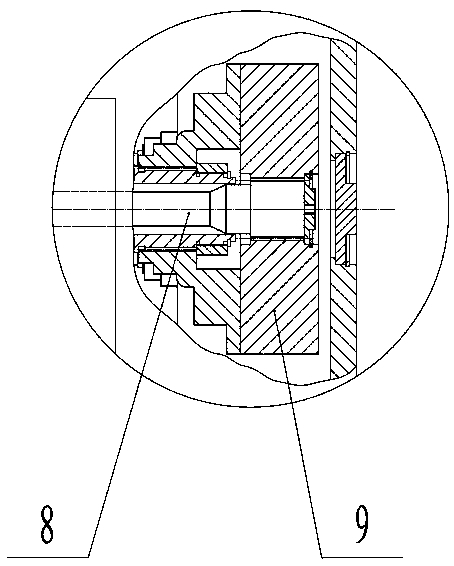

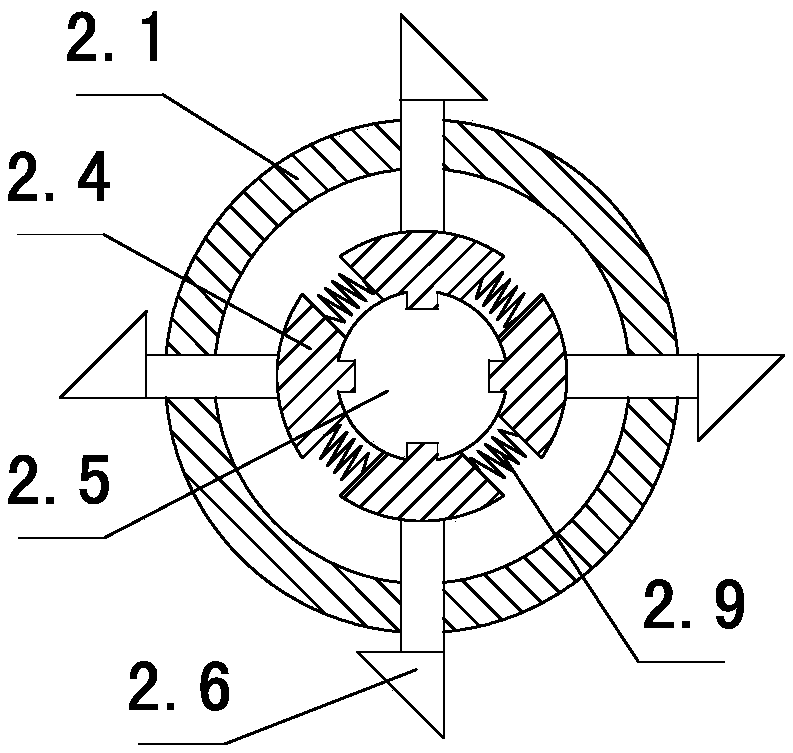

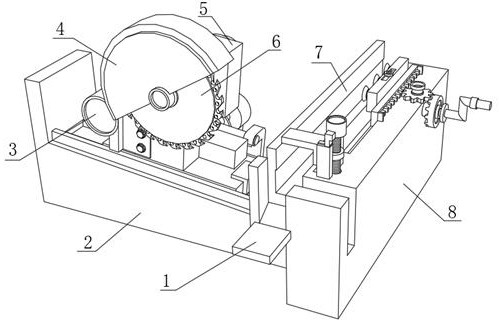

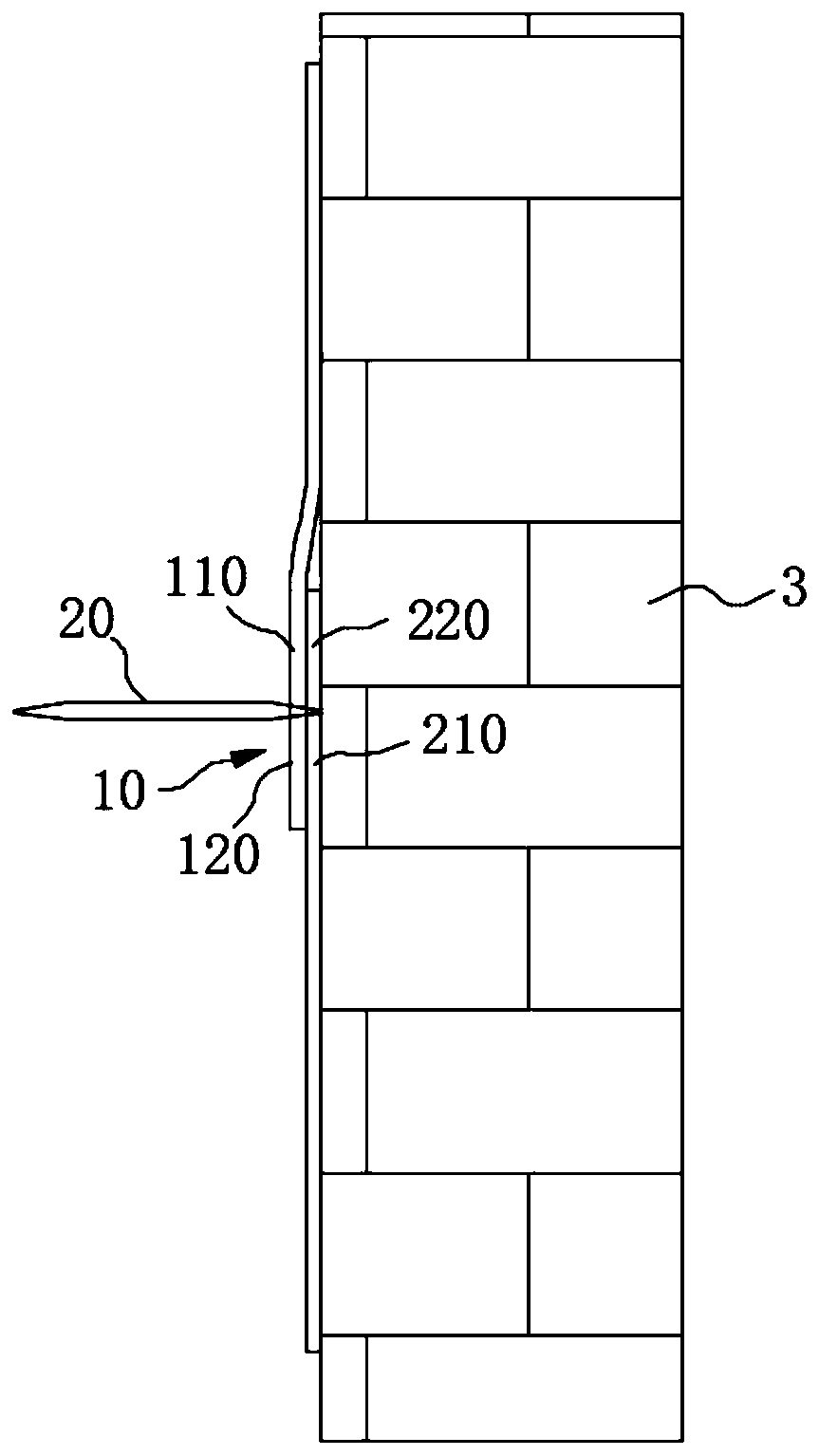

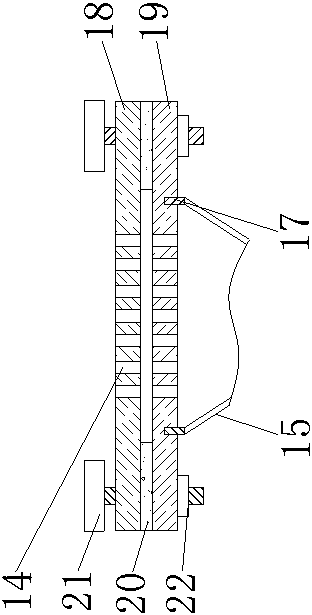

Double-motor U-shaped cutting portion of thin seam mining machine

InactiveCN102644461AIncrease cutting powerImprove coal loading effectMultiple motor speed/torque controlCutting machinesClutchRocker arm

A double-motor U-shaped cutting portion of a thin seam mining machine comprises a rocker arm casing, two cutting motors, a rocker arm reduction gearbox and a cutting roller. A motor installing cavity of the rocker arm casing and an extending end of the rocker arm casing are on the same side, and the contour of the motor installing cavity and the contour of extending end of the rocker arm casing are in a U shape, and the extending end of the rocker arm casing is elongated. The rocker arm reduction gearbox comprises a clutch, a third-stage idle gear, a fourth-stage cylindrical gear and a planetary gear mechanism, the clutch is arranged on a third-stage cutting shaft group of a transmission chain, the planetary gear mechanism is arranged at the tail end of the transmission chain, the two cutting motors transmit power to the rocker arm reduction gearbox through a first idle gear and a second idle gear, the power is transmitted to the cutting roller after speed reduction through the fourth-stage cylindrical gear and the planetary gear mechanism, an involute spline of the third-stage cutting shaft group of the transmission chain is disconnected by pulling a clutch handle, and the transmission chain is cut off so as to avoid accidents during overhaul. The cutting portion is large in installed power, strong in mining capability, good in coal charging effect, safe and reliable, and a large cutting deep roller can be installed to develop a hard-coal working surface.

Owner:CHINA UNIV OF MINING & TECH +1

Ocean fishing vessel propeller

The invention relates to an ocean fishing vessel propeller, and belongs to the technical field of ship accessories. The ocean fishing vessel propeller comprises a cover body, a waterproof separating plate, propeller blades, a propeller shaft, a screw nut, a first motor, a cutter blade, a heating piece, a heater, a second motor, a machine base, slide rails, slide blocks, supporting plates, a bottom plate, air cylinders, a bearing base, a lead screw and a connecting shaft. The propeller blades are installed at the left and right sides of the propeller shaft. The waterproof separating plate is installed on the propeller blades. The cover body is installed at the left side of the waterproof separating plate. The lower end of the cover body is installed on the propeller shaft. The opening of the cover body faces the left. The slide rails are installed at the top surface and the lower bottom surface of the cover body respectively. The slide blocks are installed on the slide rails. The supporting plates are installed on the slide blocks. The bottom plate is installed at the right ends of the two supporting plates. Two air cylinders are installed at the right side wall in the cover body. The piston rods of the air cylinders are connected with the bottom plate. The advantages of the ocean fishing vessel propeller are that the ocean fishing vessel propeller has a function of automatically cutting foreign matters.

Owner:ZHOUSHAN WONDERFUL MARINE DESIGN CO LTD

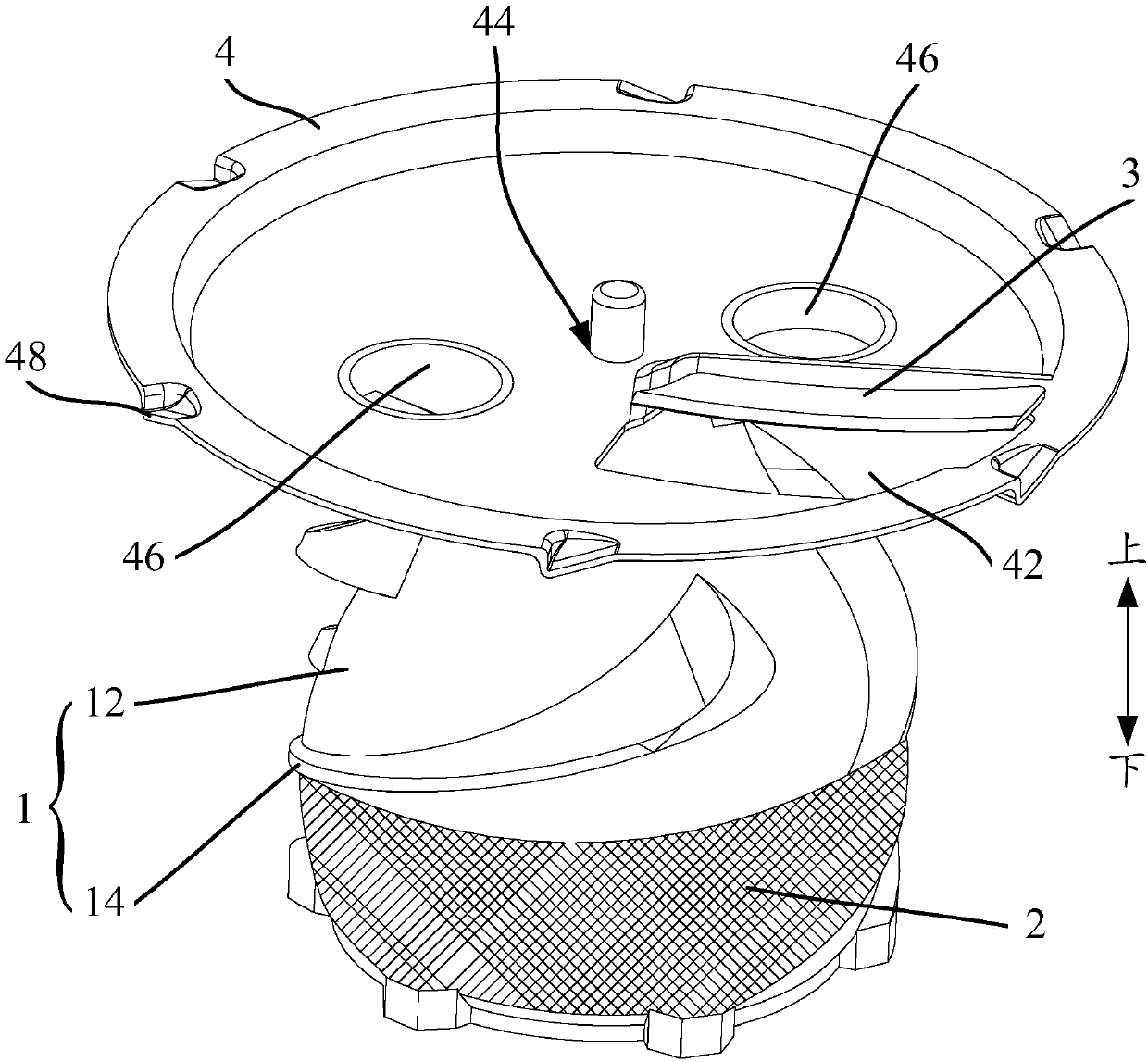

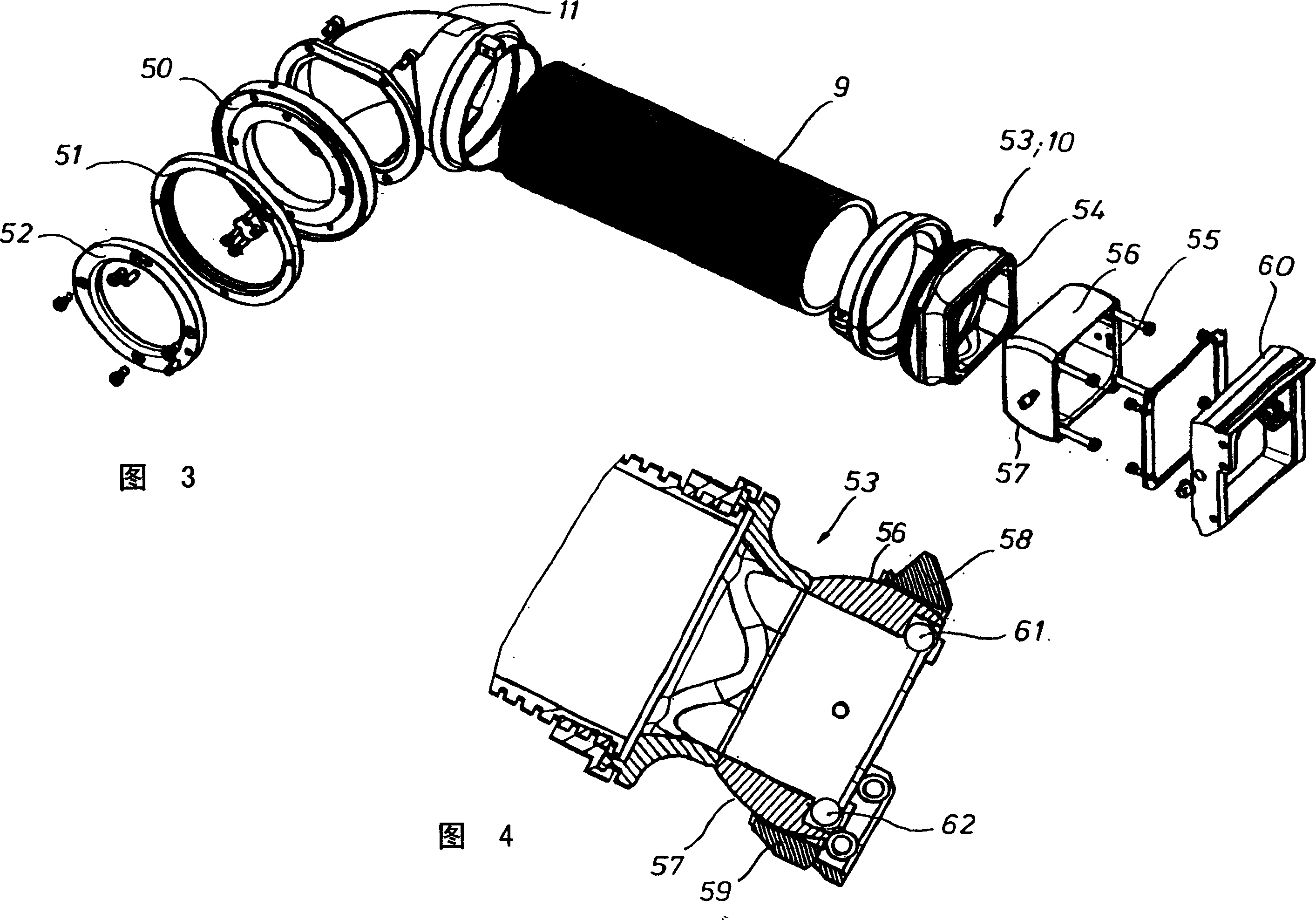

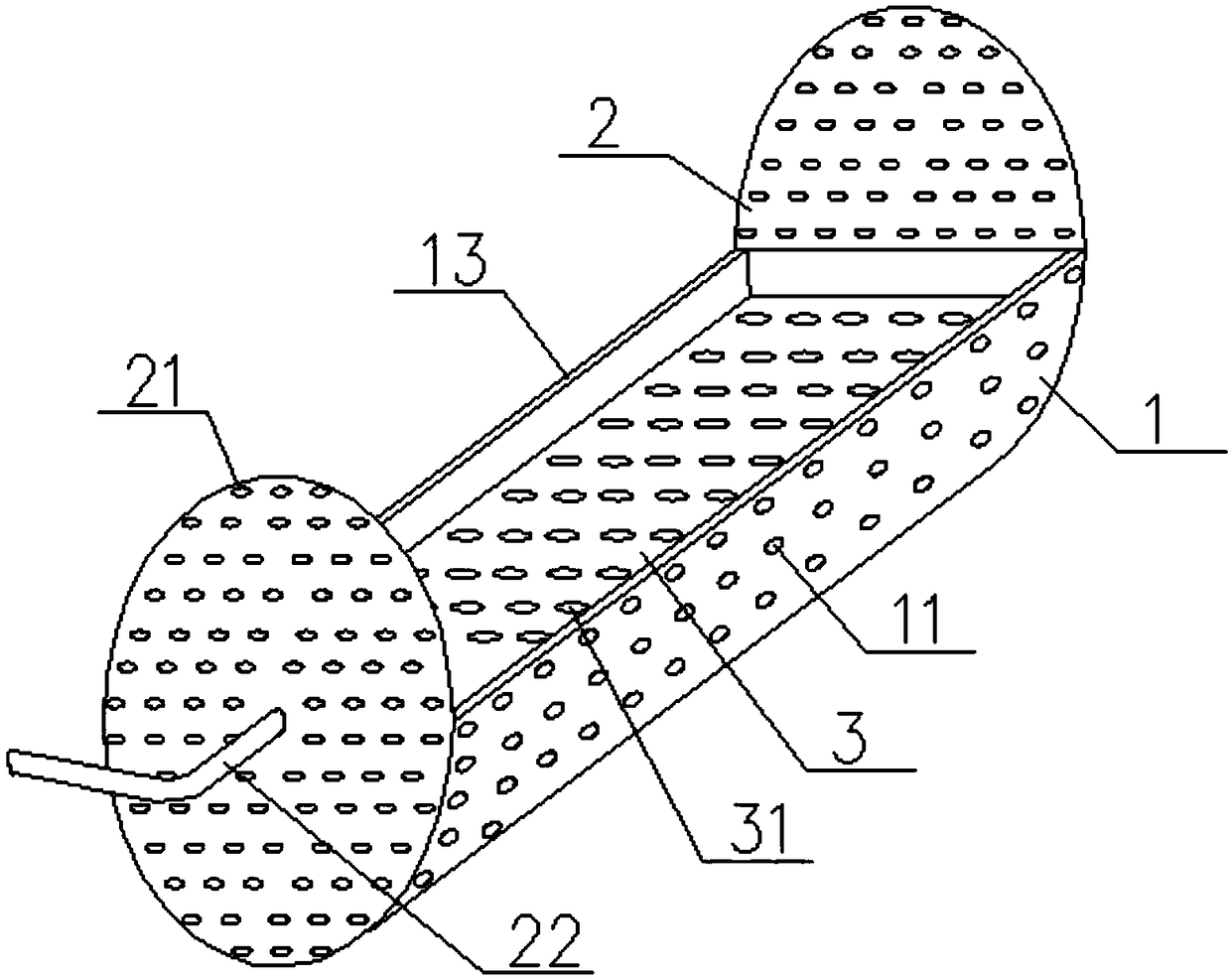

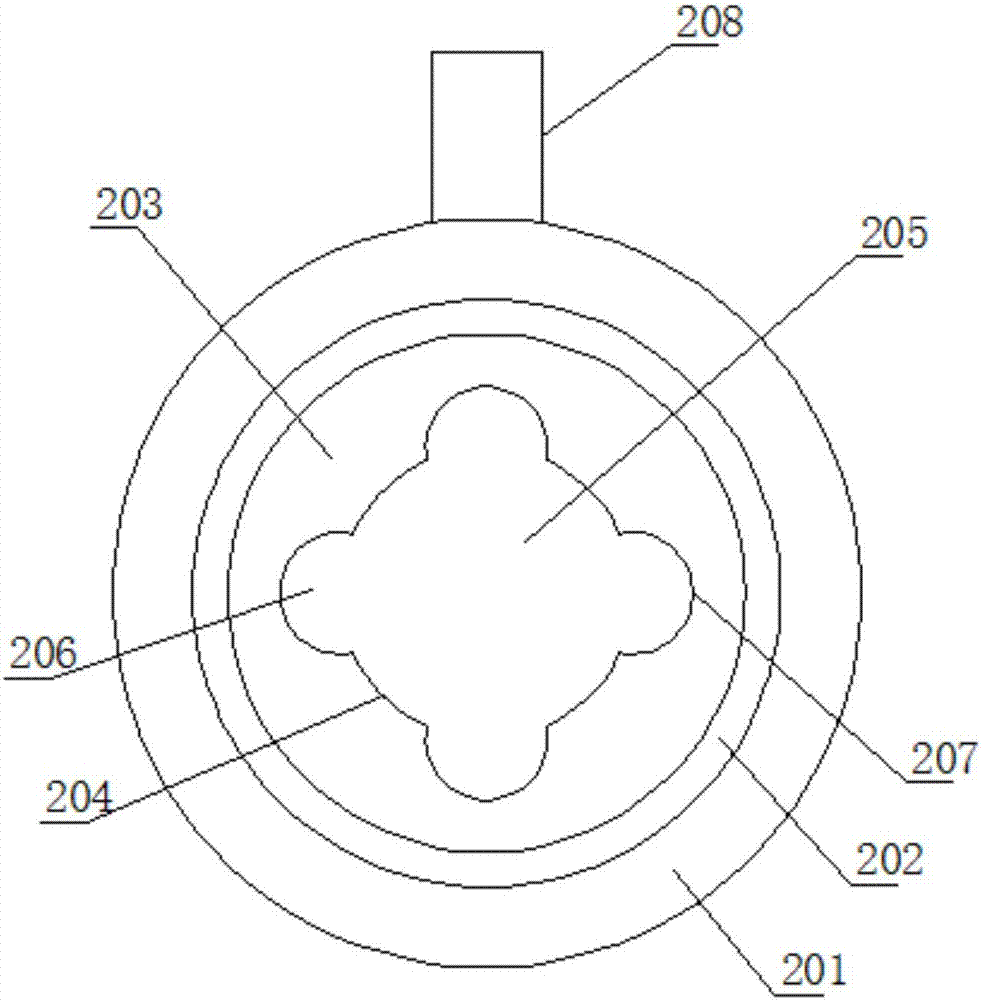

Screw rod and food processor

The invention provides a screw rod and a food processor. The screw rod comprises a screw rod body and a blade, wherein a juicing net is arranged at a first end of the screw rod body; the blade is mounted at a second end of the screw rod body. According to the technical scheme provided by the invention, the blade is arranged at the second end of the screw rod body, therefore, after hard food materials or crude fiber food materials and the like enter a juicing cup and before the screw rod carries out squeezing, the blade is utilized for cutting the hard food materials or crude fiber food materials and the like into small broken blocks, thus the food materials cut by the blade can be easily squeezed to be broken by the screw rod, the clamping of the screw rod seldom occurs, meanwhile, the food materials are cut into the small broken blocks in advance, so that particles of food dregs are small, and thus the food dregs can be easily discharged and can not block a dreg discharge hole. In addition, the hard food materials or crude fiber food materials and the like are cut into the small broken blocks in advance, therefore, the food materials can be sufficiently squeezed by the screw rod in the juicing cup to form juice, and thus the juice yield is improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Heading machine and abrasive jet flow auxiliary rock breaking device thereof

ActiveCN112196543ASpray Angle AdjustmentAdjustable angleBlast gunsAbrasive feedersJet flowRock cutting

The invention discloses a heading machine and an abrasive jet flow auxiliary rock breaking device thereof. The abrasive jet flow auxiliary rock breaking device comprises jet flow nozzles used for jetting a mixture of abrasive and water, an executing mechanism, an abrasive supply device used for supplying the abrasive to the jet flow nozzles, and a pressure water supply device used for supplying water with certain pressure to the jet flow nozzles. The jet flow nozzles are installed on the executing mechanism and driven by the executing mechanism to move so as to achieve adjustment of the spraying angles, the target distances and the radial positions of the jet flow nozzles, and the executing mechanism is provided with shooting equipment used for obtaining tunnel face information in real time. In the using process of the abrasive jet flow auxiliary rock breaking device, the jet angles, the target distances and the radial positions of the jet flow nozzles can be adjusted through the executing mechanism, excessive jet flow nozzles are prevented from being arranged, the pressure of abrasive jetted by each jet flow nozzle is guaranteed, and therefore the rock cutting efficiency and quality are guaranteed.

Owner:CHINA RAILWAY CONSTR HEAVY IND

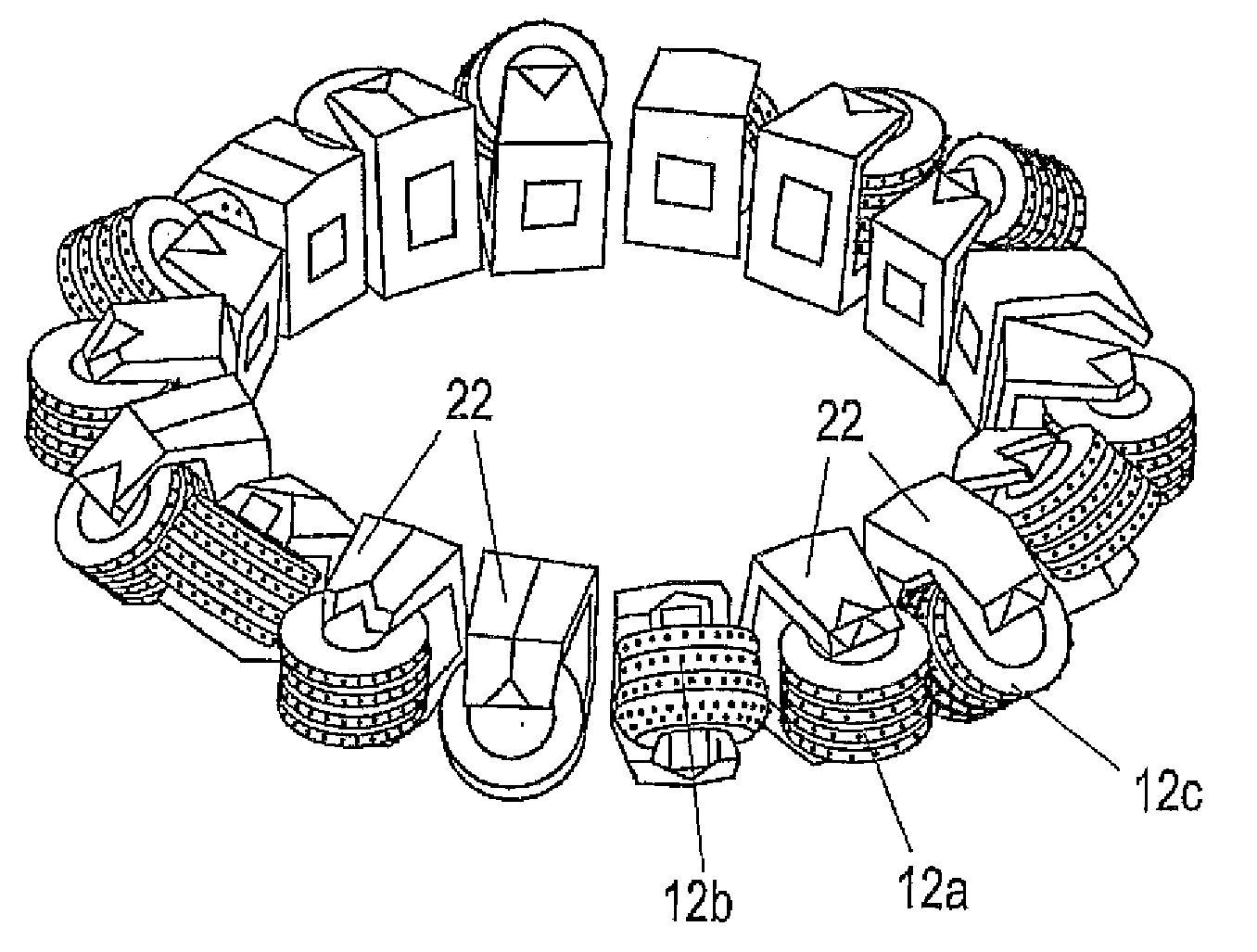

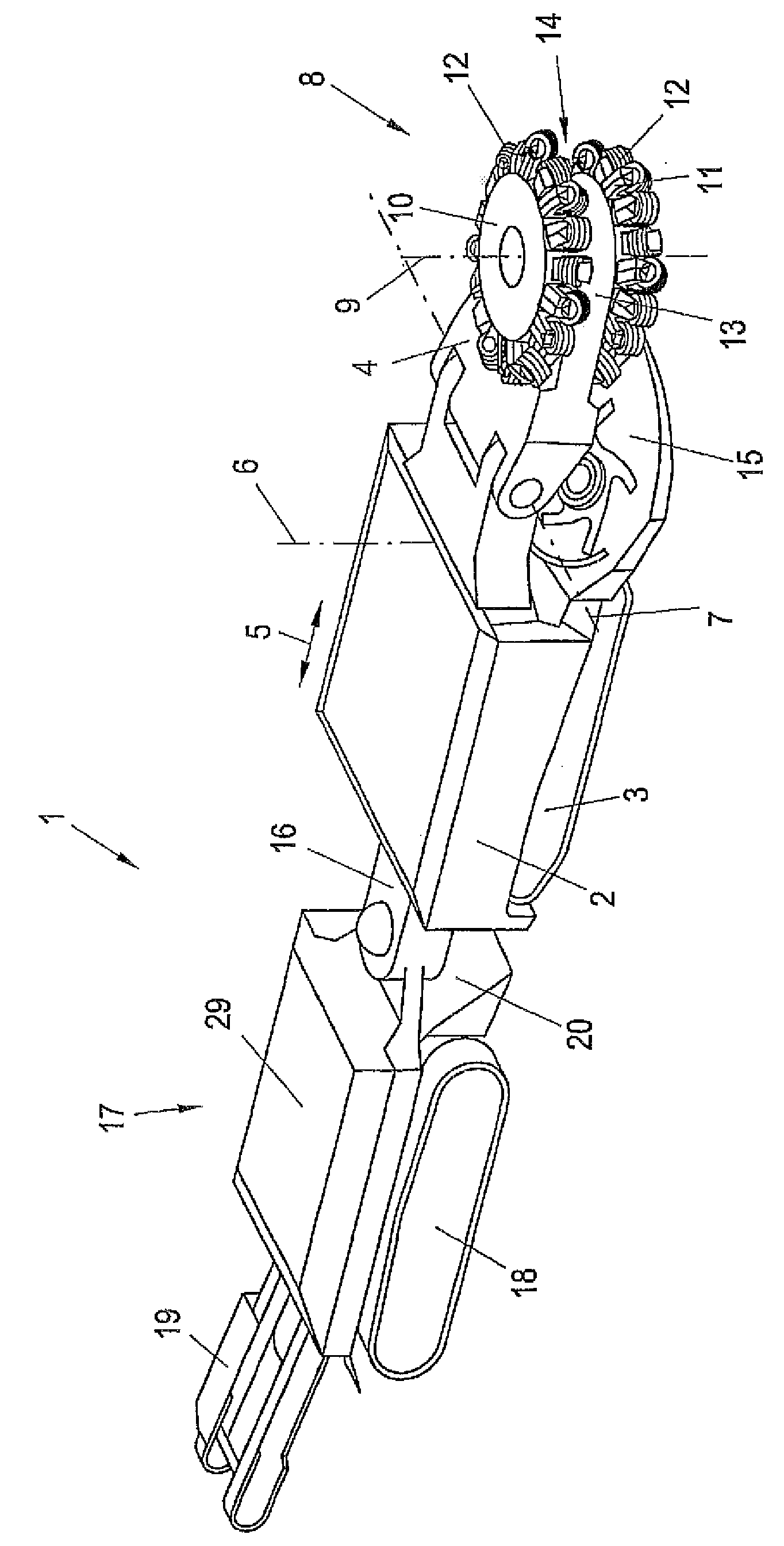

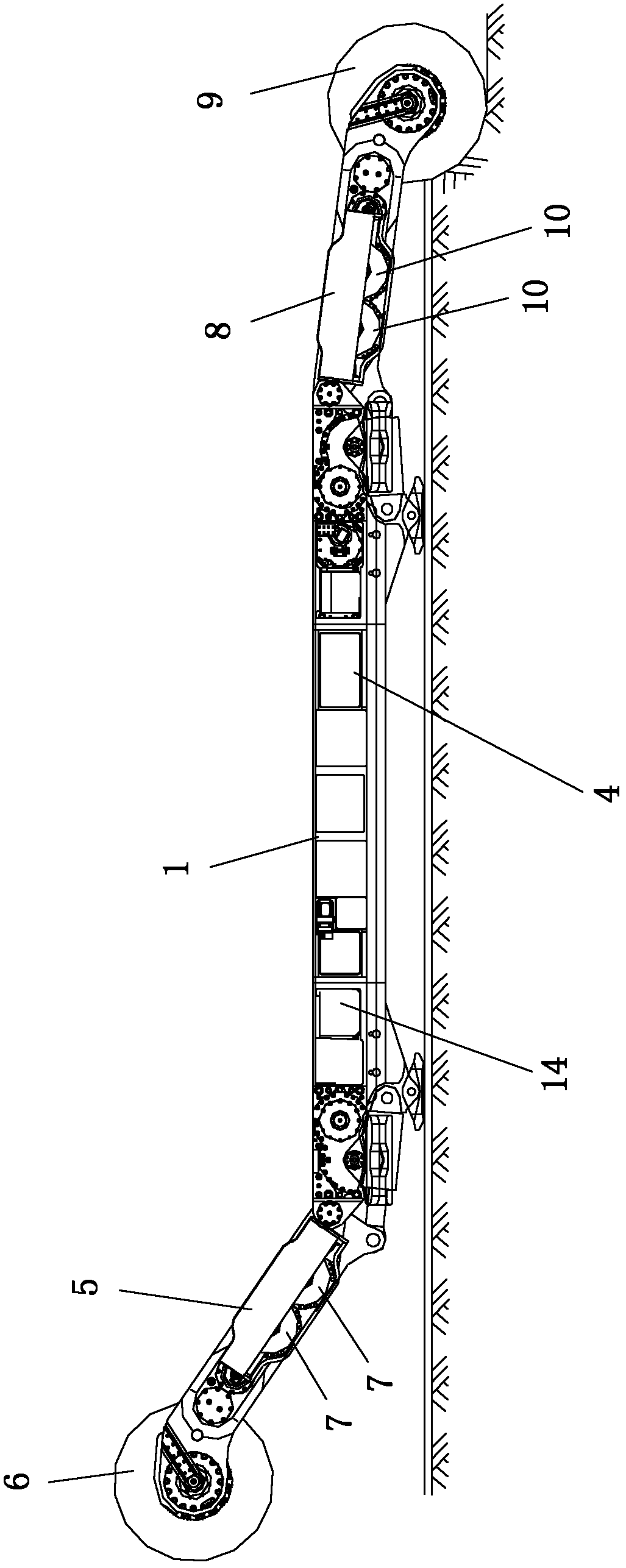

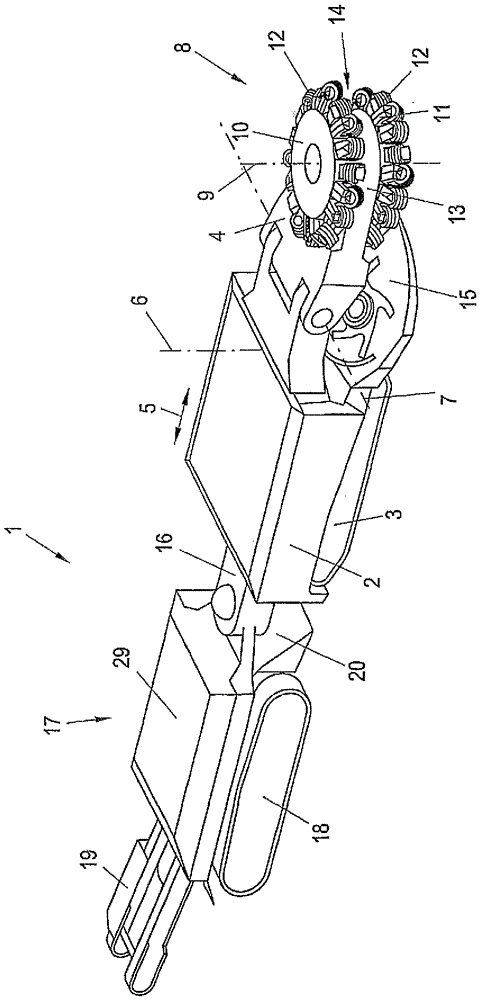

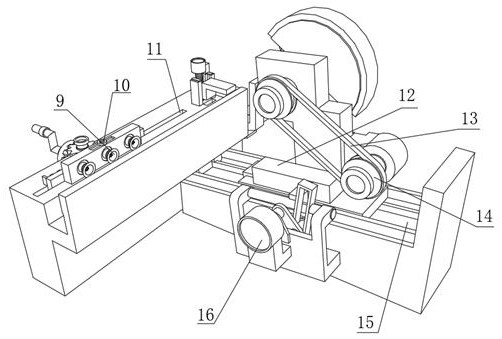

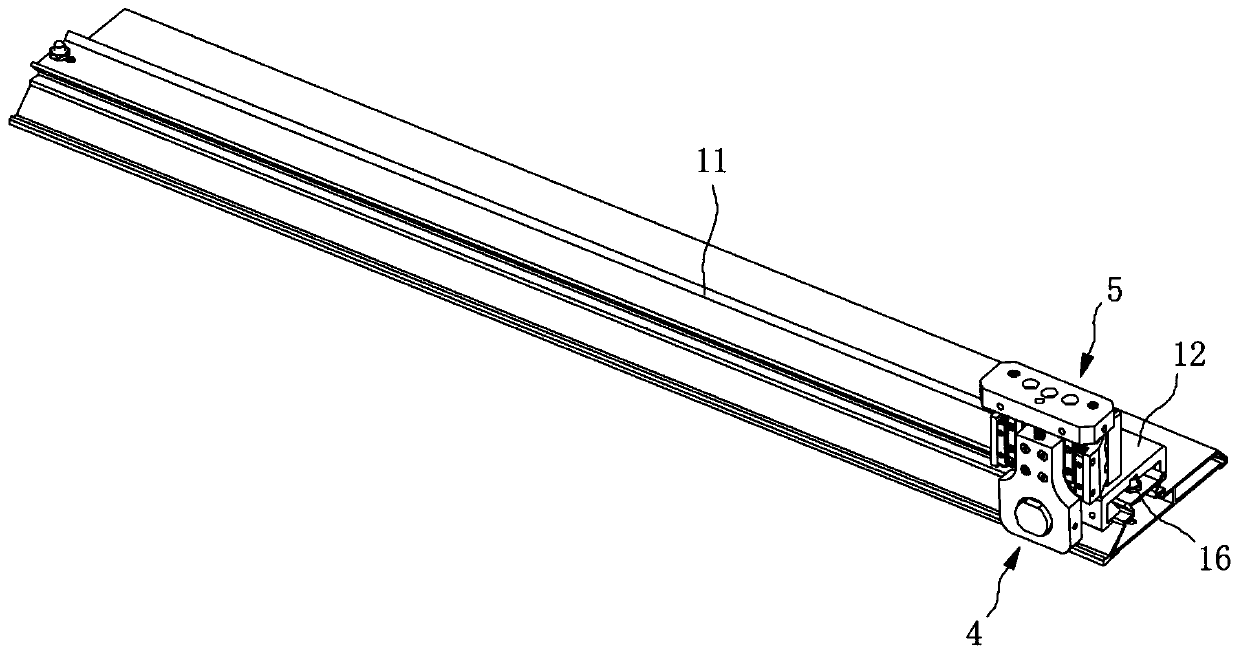

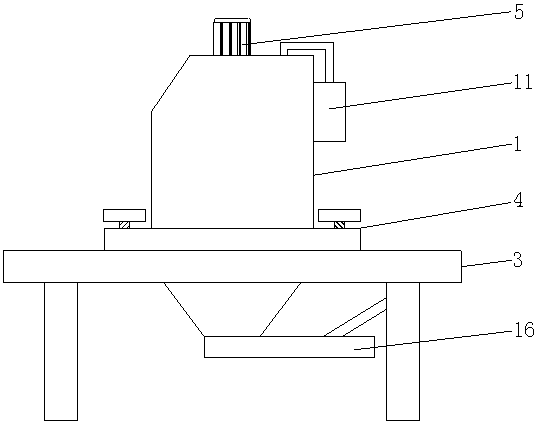

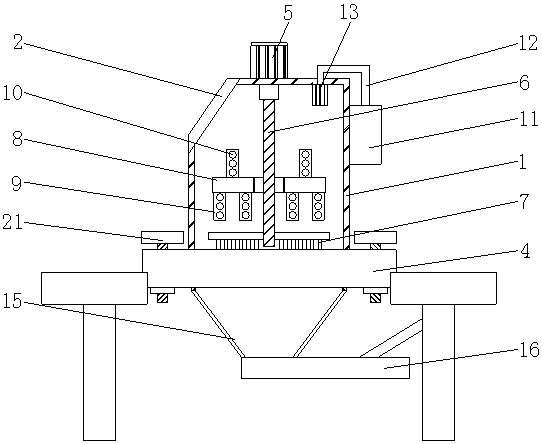

Tunneling machine

The invention relates to a tunneling machine comprising a base frame (2) having a travelling mechanism, and a bracket (4) which can be horizontally and vertically swiveled and is provided with a cutting device (8) that has at least one tool support (10, 11). Said tool support is rotatably mounted on the bracket (4) and can be driven so as to rotate and carries a plurality of cutting tools (12) on its circumference. The cutting device (8) comprises at least two parallel disk-shaped tool supports (10, 11) which are rotatably mounted on an end section (13) of the bracket (4) that is located between the tool supports (10, 11) and is at least partially disk-shaped.

Owner:SANDVIK MINING & CONSTR OY

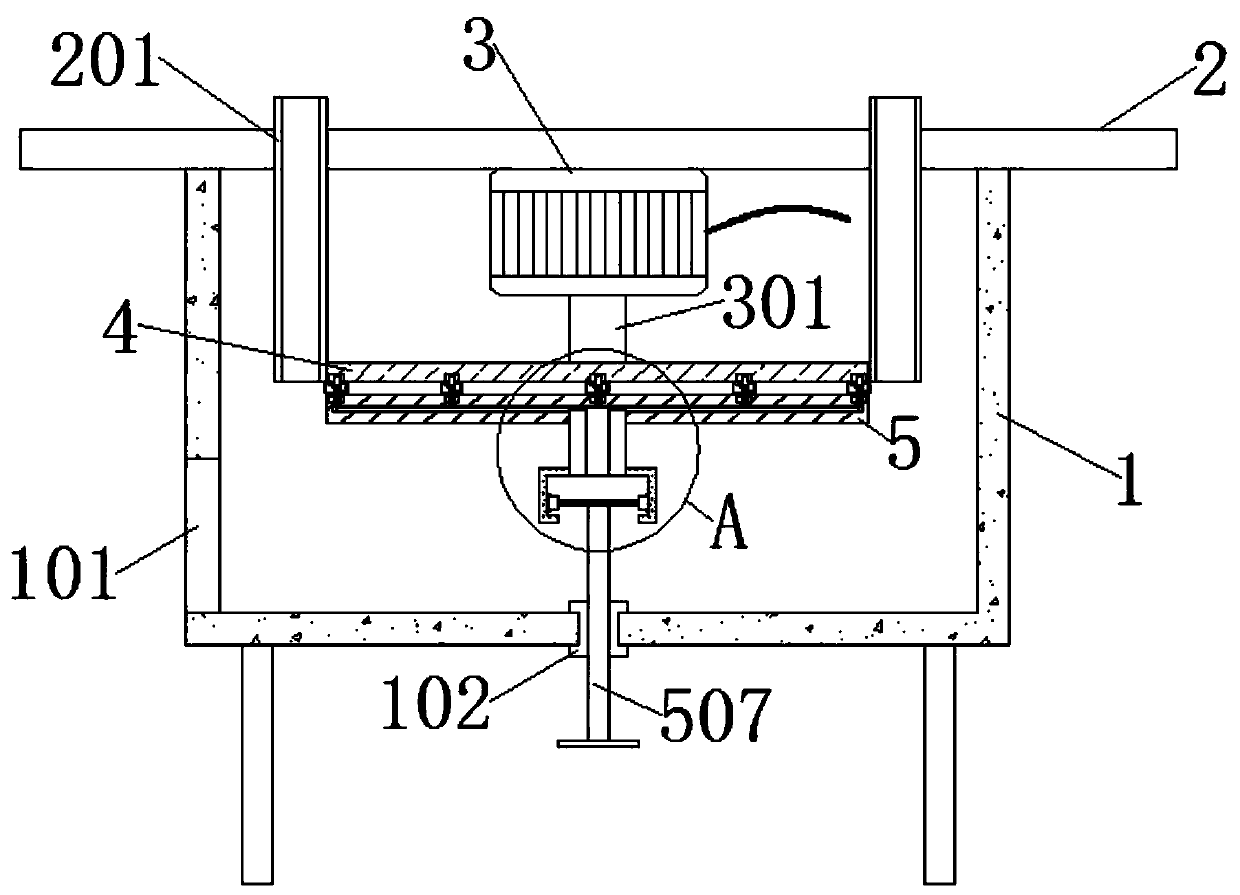

Device for recycling and reducing treatment of organic matter waste

PendingCN108500040ACompletely brokenIncrease cutting powerSolid waste disposalLitterEnvironmental engineering

The invention discloses a device for recycling and reducing treatment of organic matter waste, wherein the device comprises a sorting platform for sorting the organic matter waste, a crushing device for crushing the sorted organic matter waste, a dewatering device for removing water from the crushed organic matter waste, and a fermentation device for fermentation treatment of the organic matter waste dewatered by the dewatering device. After sorting of the organic matter waste is completed by the sorting platform, the organic matter waste is successively crushed and dewatered, then transportedto the interior of a biochemical bin and subjected to biochemical reaction, and finally an organic matter waste treated product is obtained. The finally obtained organic matter waste treated productcan be transported out for recycling and reusing. In the process of garbage treatment, produced waste gas can also be treated by a waste gas treatment device, that is to say, the organic matter wastecan be reasonably treated and is suitable for batch treatment, and the pollution of the organic matter waste to the environment is reduced.

Owner:ZHEJIANG YANHANG INTELLIGENT TECH CO LTD

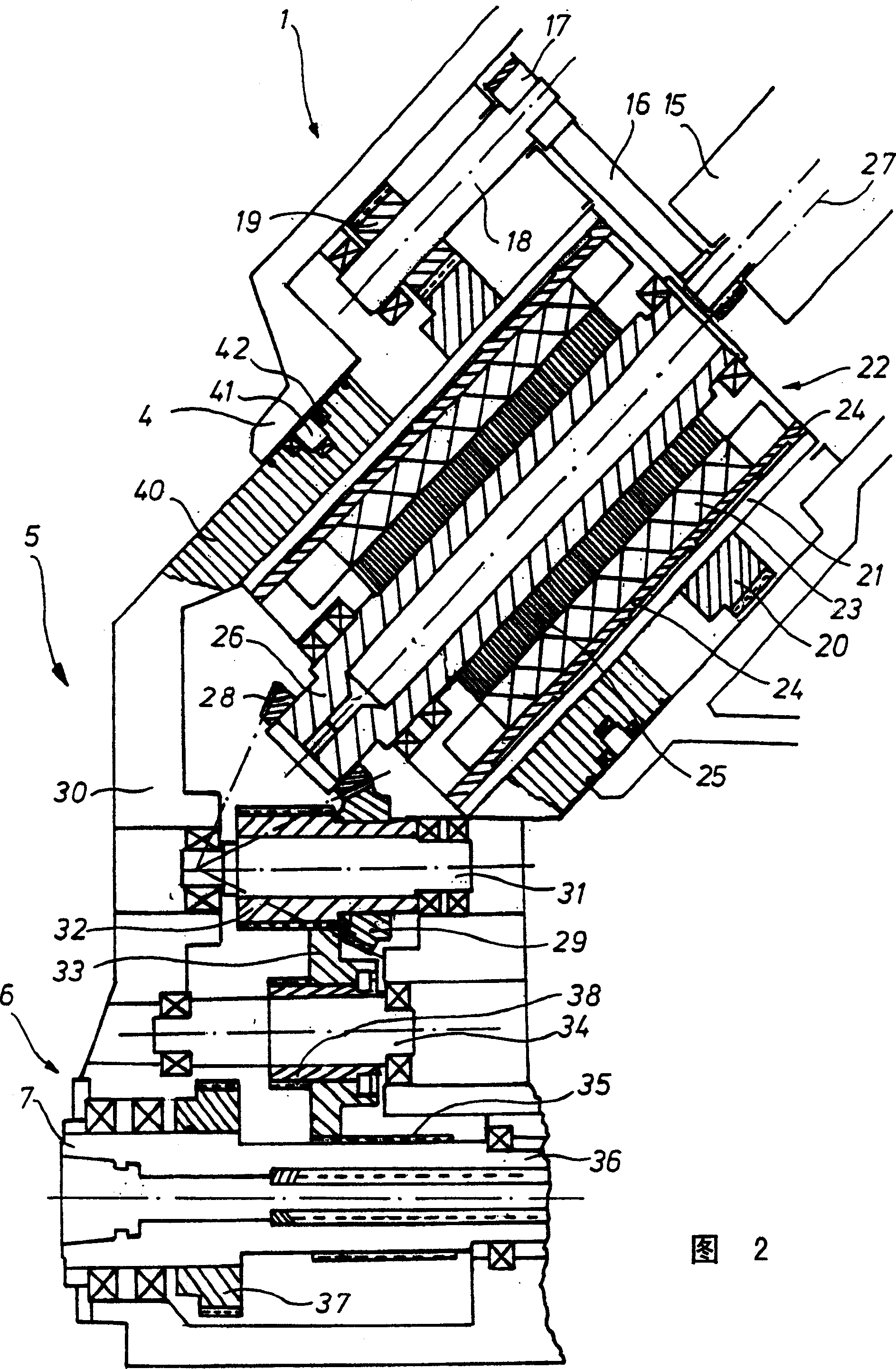

Working unit for programme-controlled milling and boring machines

InactiveCN1500590AIncrease cutting powerPrecise positioningGearboxesToothed gearingsWork unitEngineering

The pivot head (5) includes a cylindrical casing section (40) extending coaxial to the pivot head rotation axis (27) and having a spindle motor (22) secured inside it. The head support (1) includes a casing extension (4) in which the cylindrical casing section is rotatably mounted. The head support can be moved along various coordinate axes and contains a 45 deg. rotation axis extending downwards in the forwards direction. The pivot head is mounted on one of the faces of the head support and is rotatable about the 45 deg. axis via a motor. A spindle head (6) fixed to the pivot head is connected to a spindle (7) extending at an angle of 45 deg. relative to the pivot head rotation axis. The spindle motor extends coaxial to the pivot head rotation axis. An angle gear mechanism (28, 29) for the spindle drive is located inside the pivot head.

Owner:DECKEL MAHO PFRONTEN GMBH

Lawn mower allowing cutting in two directions

The invention discloses a lawn mower allowing cutting in the two directions. The lawn mower comprises a rack, a first drive motor, a first rotating disc, a first blade, a second drive motor, a second rotating disc, a second blade and an armrest. The first drive motor and the second drive motor are installed in the rack, and the rack is provided with the armrest. The first rotating disc is installed on an output shaft of the first drive motor, the second rotating disc is installed on an output shaft of the second drive motor, and the output shaft of the first drive motor and the output shaft of the second drive motor are oppositely arranged. The first blade is arranged on the edge of the first rotating disc. The second rotating disc is located below the first rotating disc, and the second blade is arranged on the edge of the second rotating disc. Cutting edges of the first blade are slightly inclined downwards, cutting edges of the second blade are inclined upwards, and the cutting edges of the first blade are higher than those of the second blade. According to the lawn mower, the two blades are driven by the two drive motors, the rotating direction of the two blades are opposite, in this way, the lawn mower produces cutting force in the opposite directions on an article, and therefore cutting intensity and cutting efficiency are enhanced.

Owner:WUHU XINDA LANDSCAPING GRP

Peanut planting method capable of rapidly harvesting

InactiveCN109429969AGuaranteed moisture contentIncrease moisture contentFabaceae cultivationDigger harvestersEmbryoDisease free

The invention discloses a peanut planting method capable of rapidly harvesting, which comprises the following steps: I, selecting plump disease-free peanut seeds for accelerating germination; II, taking out the peanut seeds after embryo roots of the peanut seeds are exposed to white, and after sequentially soaking the peanut seeds in cold water and dressing seeds, obtaining the peanuts to be sown;III, digging a plurality of planting holes in a peanut planting field, and placing one peanut planting device in one planting hole; IV, covering soil and sowing in the planting device; V, harvestingpeanut straws and peanut pods. According to the method, the peanut seeds are directly planted into the planting device, and when the peanuts are ripe, the planting device is taken out from the land, so that the recovery ratio of the peanut pods and the integrity rate of the pods are ensured and the working hours required by harvesting the peanuts are shortened. The method saves time and effort inthe process of taking out the planting device. The planting device is simple in structure and low in manufacturing cost. The method can be widely popularized in the market and is suitable for the national conditions of China as a large agricultural country.

Owner:林芝

Water chestnut slicing device with cutting force convenient to adjust

ActiveCN109807970AIncrease cutting powerQuality improvementMetal working apparatusWater ChestnutsHardness

The invention provides a water chestnut slicing device with the cutting force convenient to adjust. The water chestnut slicing device with the cutting force convenient to adjust comprises a collectioncylinder, a motor, eight sliding bars, an upper disk plate, a lower disk plate and a carrier plate. The carrier plate is welded to the top of the collection cylinder. The motor is welded to the middle of the bottom of the carrier plate. The bottom of the motor is provided with the upper disk plate in a welded manner. The lower disk plate is arranged under the upper disk plate. Eight slicing barsare rotationally connected between the lower disk plate and the upper disk plate. According to the water chestnut slicing device with the cutting force convenient to adjust, a piston frame can drive apiston plate to squeeze water in a piston cylinder into the slicing bars, so that the mass of the slicing bars are increased, the inertia of the slicing bars is improved, and then the cutting force of the slicing bars is improved; and in this way, people can adjust the cutting force of the slicing bars through vertically pulling the piston frame, so that it can be avoided that the slicing bars are excessively worn due to excessively large cutting force of the slicing bars, the situation that since the cutting force on the tops of the slicing bars is excessively small, water chestnut cannot bewell sliced is also avoided, and the slicing bars can slice water chestnut of various different hardnesses.

Owner:临沂草之美医药科技有限公司

Large-sized cutter with long service life

InactiveCN107414947AAvoid crashesMaximum cutting hardnessMechanical energy handlingMetal working apparatusMain bearingEngineering

The invention discloses a large-scale cutter with long service life, which includes a support base plate, a support bar is fixed on the bottom of the support base plate, and a mounting groove is arranged at the center of each support bar bottom, and the support bar The insides on both sides of the mounting groove are connected with the main rotating shaft through the main bearing, a roller is fixed between the ends of the two opposing main rotating shafts, and a motor is fixed on one side of the upper surface of the supporting substrate by bolts. The housing is fixed, and the center of the upper surface of the motor fixing housing is provided with a motor installation groove. As a cutting device for large parts, the present invention has a turbocharger mechanism, which can increase the upper limit of the cutting force of the device, thereby cutting harder materials. In addition, the device has a motor overload protection mechanism, and the motor overload protection mechanism has a function Controllability, it can control the protection of the motor overload mechanism to go online, so as to take emergency disengagement measures, which can effectively prevent the motor from crashing.

Owner:钱丽芳

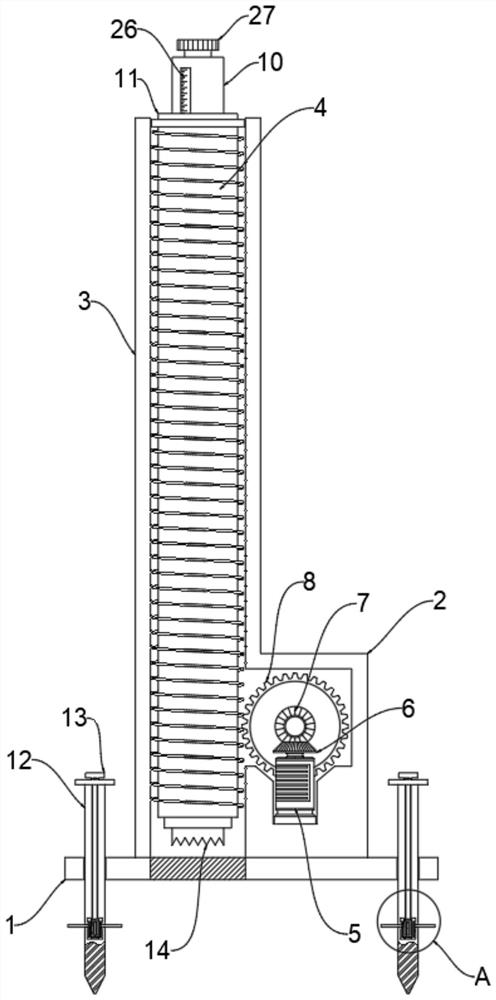

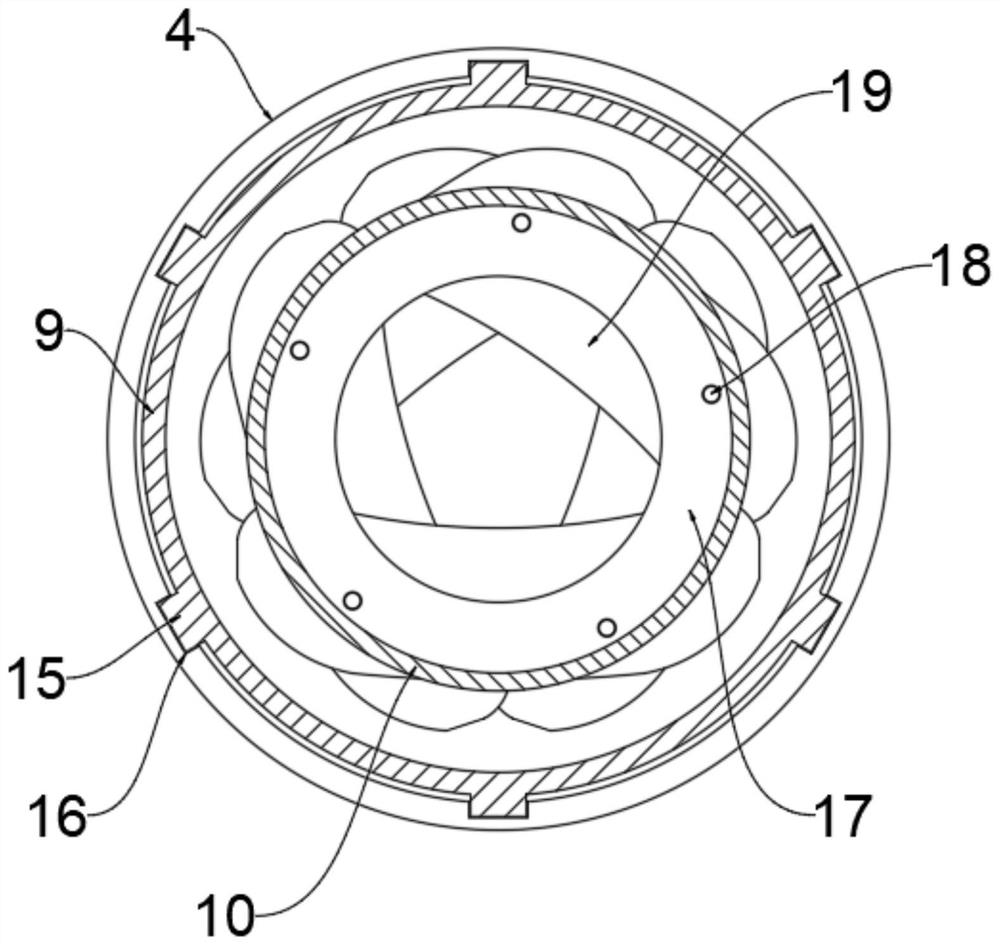

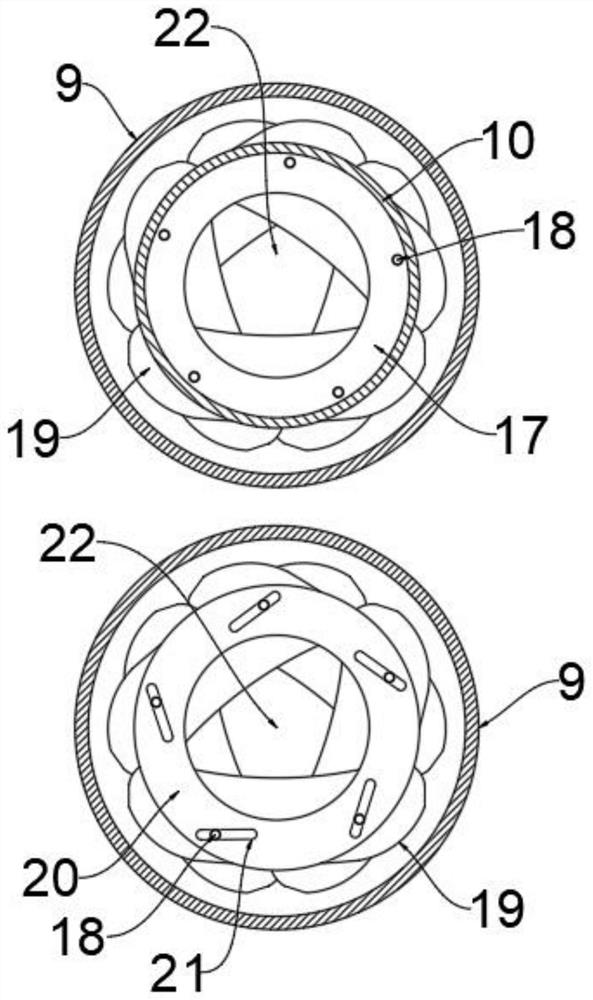

Building engineering material witness sampling device and sampling method thereof

ActiveCN113237690ASampling implementationIncrease cutting powerWithdrawing sample devicesGear wheelConstruction engineering

The invention discloses a building engineering material witness sampling device and a sampling method thereof, relates to the technical field of building engineering material sampling, and aims to solve the problem that an existing witness sampling device cannot effectively and quickly sample materials. The device is characterized in that a fixing cylinder is arranged on one side of the upper end of a base, a driving box is arranged on the other side of the upper end of the base, a worm rod is installed in the fixing cylinder and is in sliding connection with the fixing cylinder, a driving gear is arranged at the lower end of one side of the worm rod, the driving gear is located in the driving box, the driving gear is matched with the external threads of the worm rod, an inner cylinder is arranged in the worm rod and slidably connected with the worm rod, a sampling cylinder is mounted in the inner cylinder, a sawtooth cylinder is integrally arranged at the bottom of the sampling cylinder, an adjusting ring and a fixing ring are arranged at the lower end in the sampling cylinder, metal blades are arranged between the adjusting ring and the fixing ring, the number of the metal blades is five, and the metal blades are distributed in a staggered and stacked mode.

Owner:南通市建设工程质量检测站有限公司

Fish cutter

InactiveCN104489046AUniform thicknessSimple structureDrying gas arrangementsCleaning using liquidsEngineering

The invention discloses a fish cutter. The fish cutter comprises a base, a fish cutting enclosure, a fixed knife, a cutter head, movable knives and a driving mechanism, wherein the fish cutting enclosure is arranged on the base; a material inlet is formed in one side of the middle of the fish cutting enclosure; the bottom of the fish cutting enclosure is provided with a material outlet; the fixed knife is fixedly arranged in the fish cutting enclosure, and a blade of the fixed cutter corresponds to the material inlet; the cutter head is arranged in the fish cutting enclosure in a rotational mode; a plurality of movable knives are peripherally and uniformly arranged on the cutter head, and the blades of the plurality of movable knives correspond to the blade of the fixed knife; the driving mechanism is used for driving the cutter head to rotate. The fish cutter is also provided with a cleaner and a dryer. According to the invention, the cutter head drives the movable knives to rotate, so that movable knives and the fixed knife are matched to cut the fish into pieces; processed fish slices or fish sticks are uniform in thickness, and the fish cutter can cut the fish head smoothly. The fish cutter also can clean, disinfect and dry conveniently.

Owner:南宁市西真电子科技开发有限公司

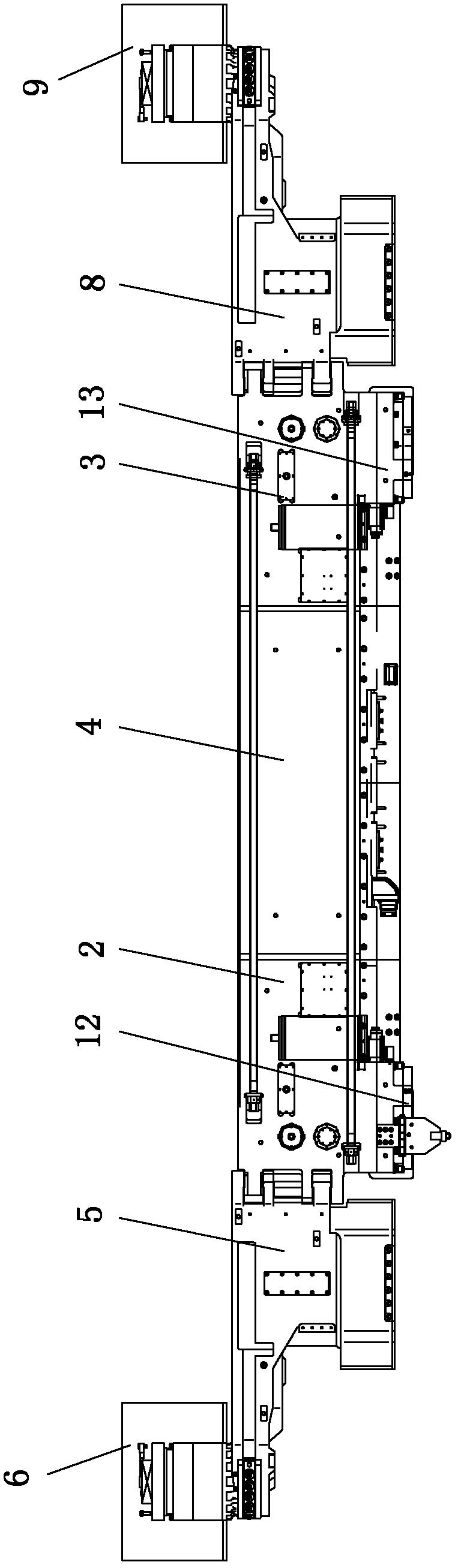

External circulating lubricating and cooling system for coal mining machine and coal mining machine cutting device

PendingCN113216957ALower operating temperatureImprove lubrication environmentLighting and heating apparatusGear lubrication/coolingCoal miningSuction tubing

The invention relates to an external circulating lubricating and cooling system for a coal mining machine and a coal mining machine cutting device. The external circulating lubricating and cooling system comprises a plate cooler, a cycloid lubricating pump and an oil suction filter, and the oil suction filter is installed at the inlet end of an oil suction pipe of the cycloid lubricating pump and located at the bottom of an oil pool of the cutting device; an outlet end of an oil return pipe of the cycloid lubricating pump is connected with an oil duct inlet of the plate cooler, an oil duct outlet of the plate cooler is connected with the oil pool of the cutting device, and an inlet and an outlet of a water channel of the plate cooler are correspondingly connected with an outlet and an inlet of a cooling water jacket of a box body of the cutting device; and the cutting device comprises the lubricating and cooling system, the plate cooler is fixed to the outer side face of the coal wall side in the middle of the box body of the cutting device, the cycloid lubricating pump is installed on the box body of the cutting device, and a main shaft of the cycloid lubricating pump is coaxially connected with a third gear shaft set in the box body. The problems that a high-power-density cutting device is high in operation temperature and a transmission system is poor in lubrication can be solved, and the requirements for efficient lubrication and continuous cooling are met.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

High-power heavy low seam mining machine

ActiveCN102287185BReasonable structural designEasy to operateMechanical energy handlingDriving meansEngineeringElectric control

Owner:XIAN COAL MINING MACHINERY

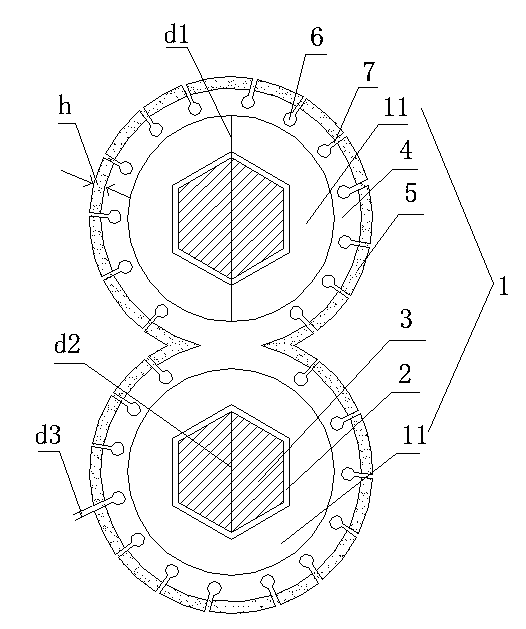

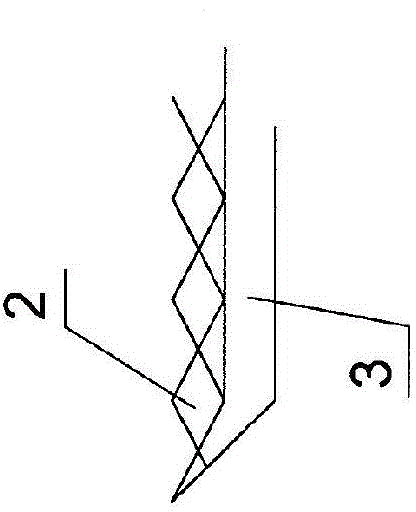

Silicon wafer cutting steel wire

InactiveCN103722626AHigh hardnessHigh strengthMetal sawing toolsFine working devicesCylindrical channelAlloy

The invention relates to a dull-polished silicon wafer cutting steel wire which comprises two steel wire bodies. The two steel wire bodies are mutually overlapped to form an integrated structure shaped like the Arabic number 'eight', channels are formed in the steel wire bodies, the cross sections of the channels are in regular hexagon shapes, the channels are filled with hard alloy, the outer surfaces of the steel wire bodies are wrapped by protective layers made of high manganese steel, dull-polishing processing is carried out on the surfaces of the protective layers, liquid storage bags are arranged in the protective layers and are of spherical structures, cylindrical channels are directly formed in the liquid storage bags and the outer walls of the protective layers, the diameters of the cylindrical channels are 0.05mm+ / -0.01mm, the cutting grinding liquid sticking capacity of the dull-polished silicon wafer cutting steel wire is improved to a certain degree, and the production efficiency is greatly improved.

Owner:FORTUNATE SOLAR TECH JIANGSU CO LTD

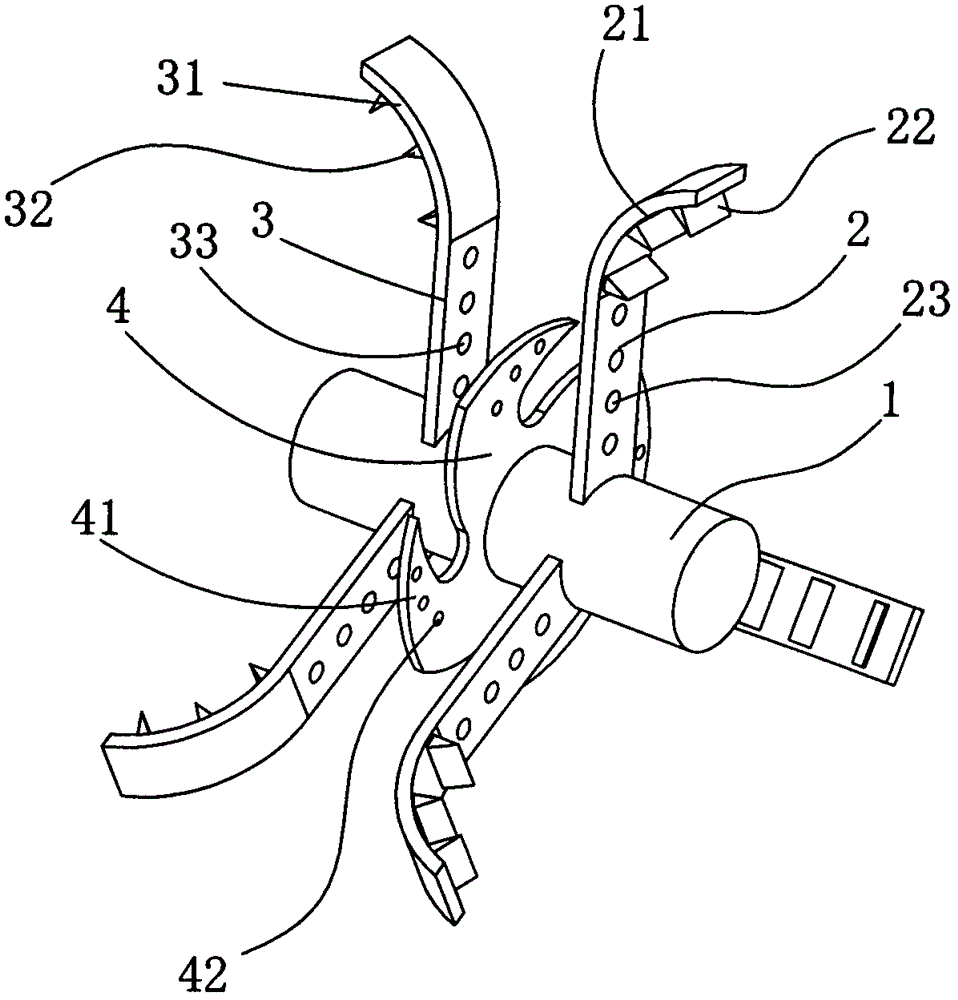

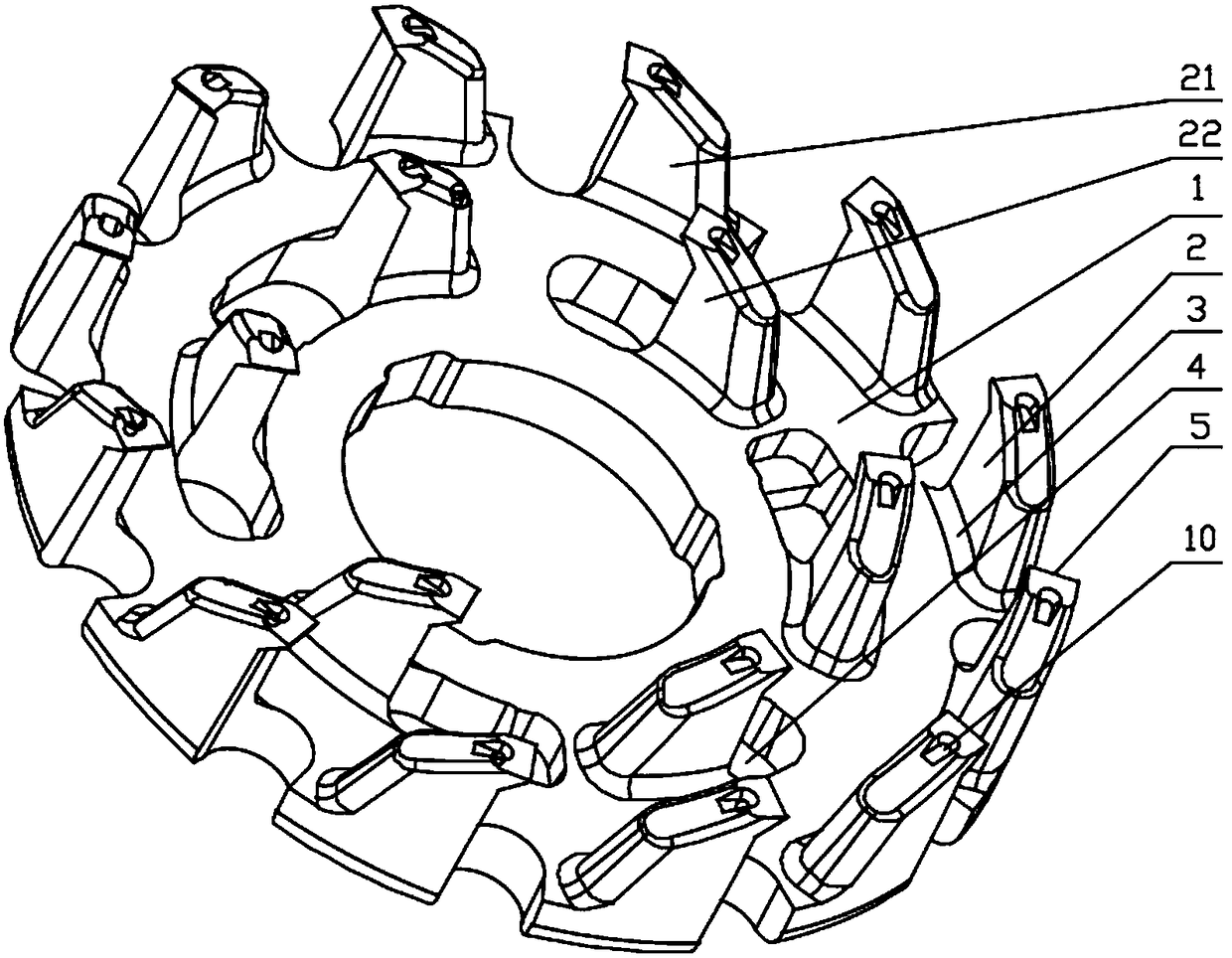

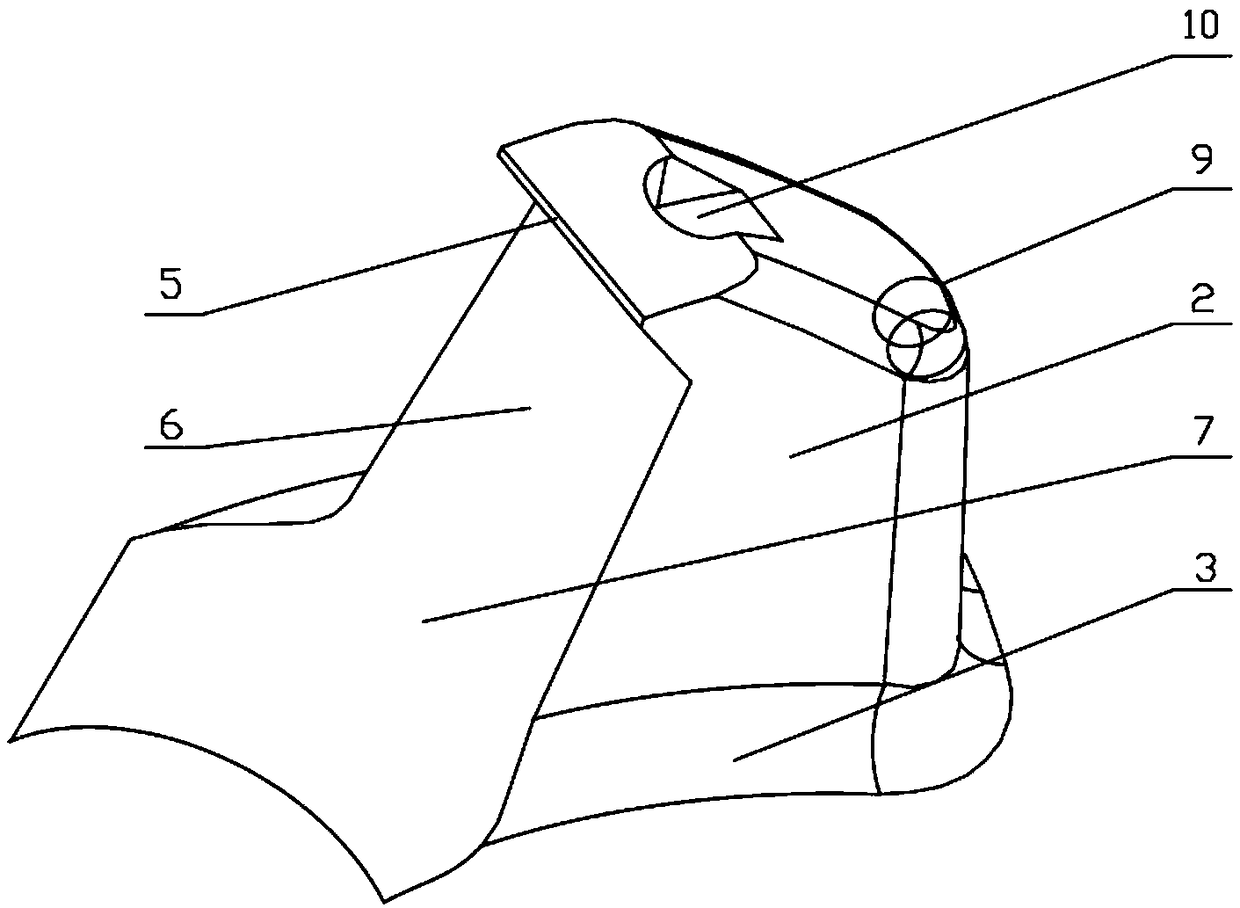

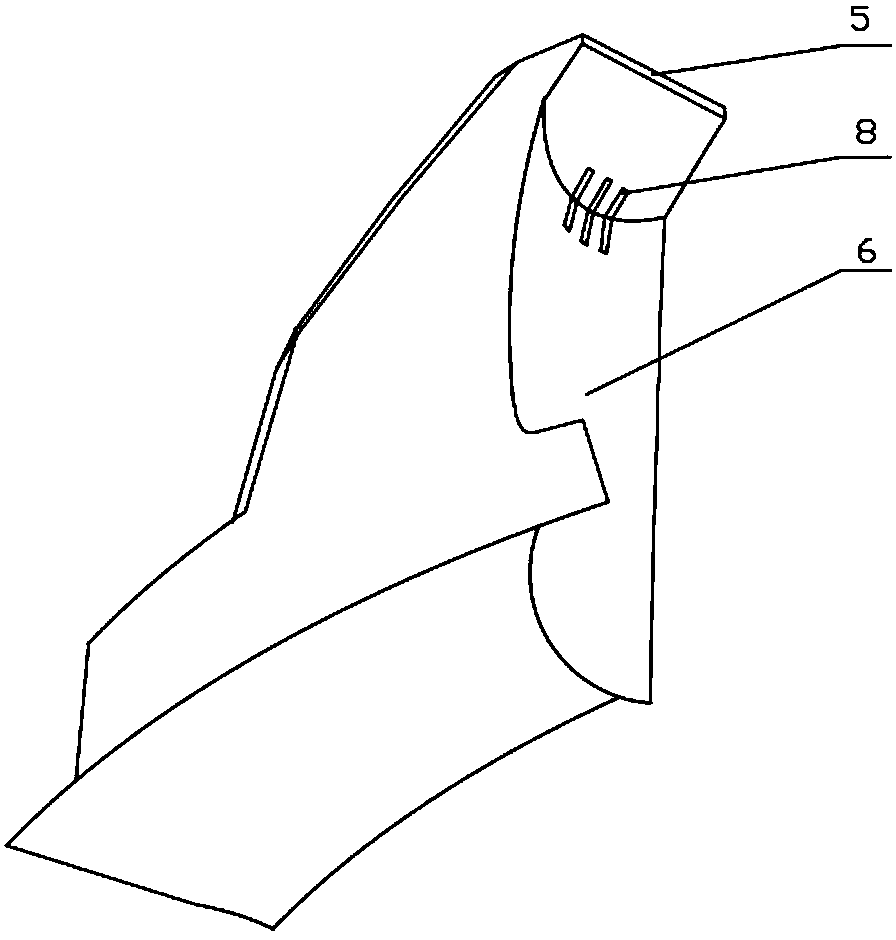

Internal hinge type anti-drag coulter of rotary cultivator

The invention relates to an internal reaming type anti-drag coulter of a rotary cultivator. The internal reaming type anti-drag coulter comprises a coulter shaft and a coulter blade on the coulter shaft, wherein the coulter blade comprises positive coulter blades and negative coulter blades, and the positive coulter blades and the negative coulter blades are symmetrically mounted on the coulter shaft; positive bent parts and negative bent parts are respectively arranged at the outer ends of the positive coulter blades and the outer ends of the negative coulter blades and bent towards the outer end of the coulter shaft; an internal reamer, which is of a disk-shaped structure, is mounted on the coulter shaft between the positive coulter blades and the negative coulter blades; the internal reamer is provided with cutting teeth which are symmetrically distributed around the center of the internal reamer and are alternately arranged; first anti-drag holes are formed in the positive coulter blades; first cutting teeth are formed in the concave surface sides of the positive bent parts of the positive coulter blades; second anti-drag holes are formed in the negative coulter blades; second cutting teeth are formed in the concave surface sides of the negative bent parts of the negative coulter blades; third anti-drag holes are formed in the cutting teeth. The internal reaming type anti-drag coulter has the characteristics of being high in rotary cultivation efficiency and good in effect.

Owner:WUXI HUSHAN PLANT PROTECTION MACHINERY FACTORY

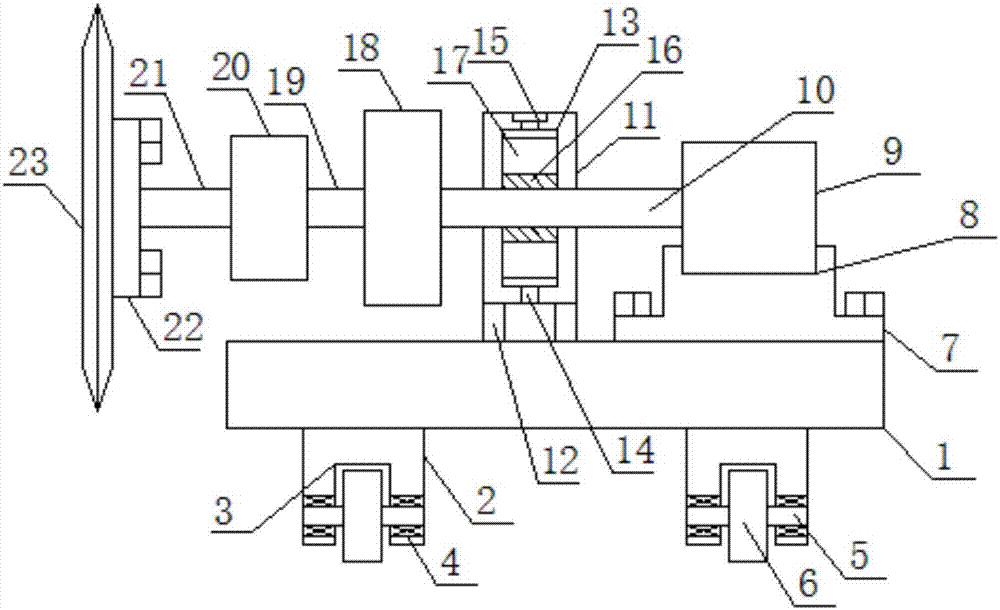

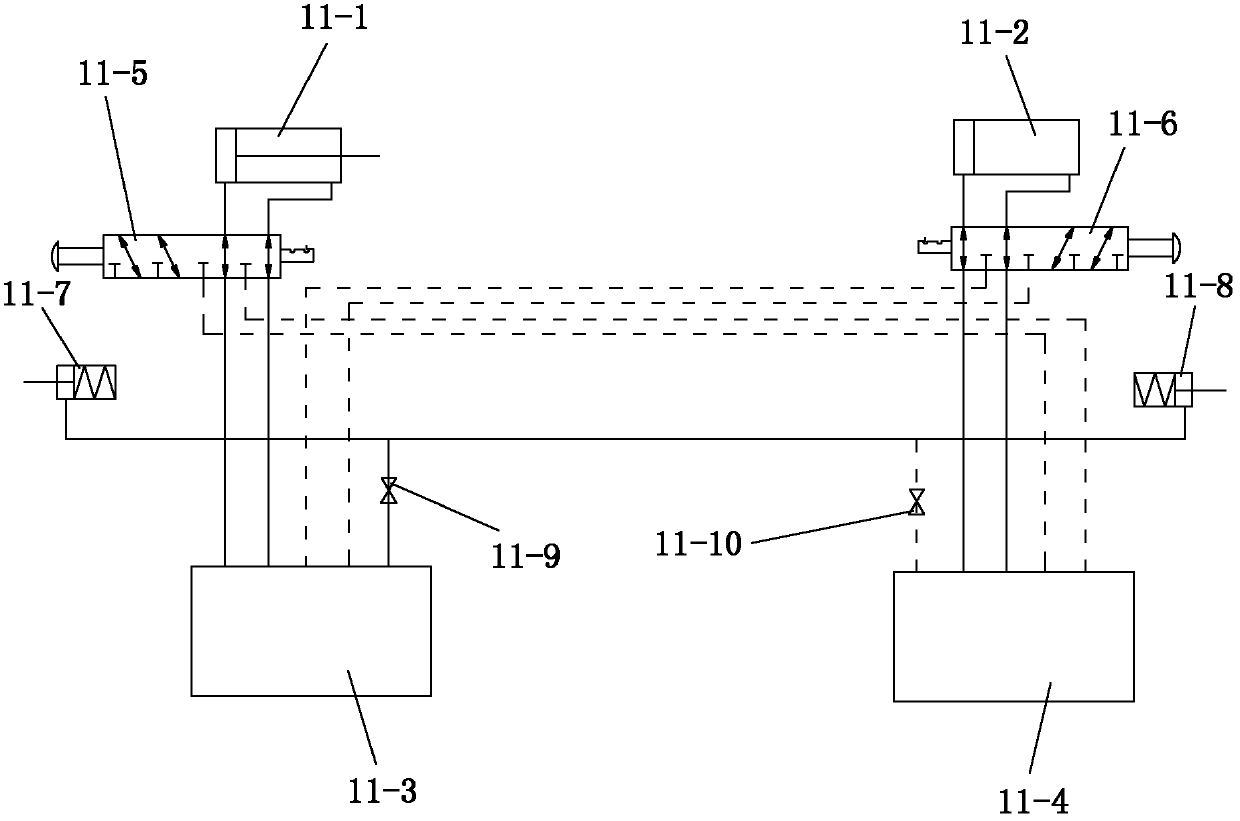

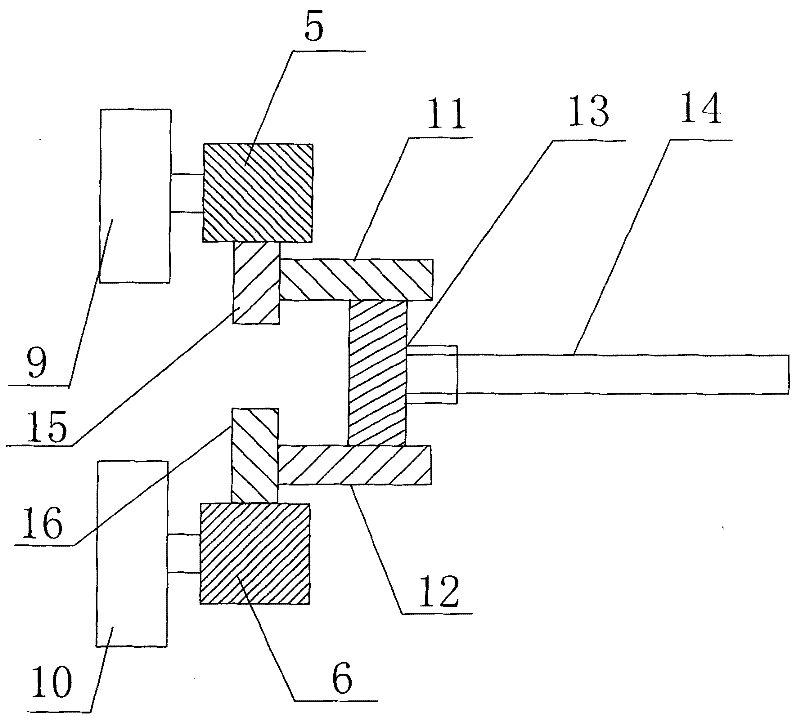

Two-drive telescopic roller cutting mechanism for excavating and anchoring integrated machine

ActiveCN110242294AImprove tunneling efficiencyQuality improvementDriving meansCutting machinesReduction driveReducer

The invention belongs to the technical field of parts of coal mine underground mining equipment, and particularly relates to a two-drive telescopic roller cutting mechanism for an excavating and anchoring integrated machine. The two-drive telescopic roller cutting mechanism comprises cutting motors, a cutting arm, a speed reducer, a middle section cutting roller, telescopic section cutting rollers and cutting roller telescopic oil cylinders, the speed reducer is mounted on the cutting arm, and the two cutting motors are transversely and symmetrically arranged outside the cutting arm and connected with the input ends of the two sides of the speed reducer correspondingly and drive the speed reducer; and the middle section cutting roller and the telescopic section cutting rollers are mounted at the transverse shaft output ends of the speed reducer, the cutting roller telescopic oil cylinders are arranged in the telescopic section cutting rollers, and the telescopic section cutting rollers are arranged at the two ends of the middle section cutting roller and driven by the cutting roller telescopic oil cylinders to extend and retract towards the two ends. According to the two-drive telescopic roller cutting mechanism, the transverse shaft telescopic full-width cutting rollers are adopted, full-width excavating is achieved, one-time forming of the roadway section is achieved, the coal mine excavating efficiency and the roadway forming quality are improved, and the safe, efficient and fast excavating requirements for a large-scale mine large-section roadway are met.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

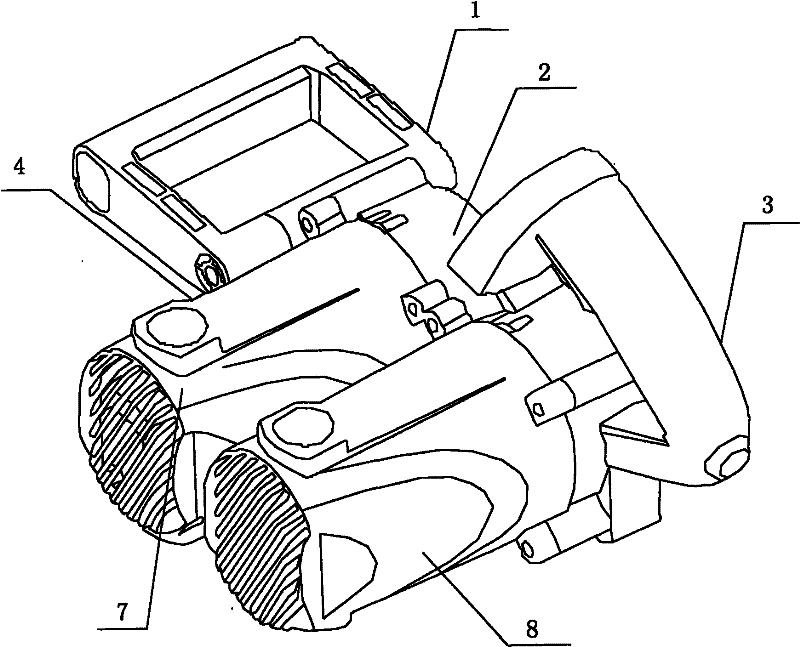

Double-motor cutting machine

InactiveCN102233449AIncrease cutting powerReduce lossBoring/drilling componentsGear wheelEngineering

The invention relates to a double-motor cutting machine. The double-motor cutting machine is characterized by comprising a motor A, a motor B, a rotating shaft A, a rotating shaft B, a rotating shaft gear A, a rotating shaft gear B, front covers of the motors, a cutting machine shell and a saw blade shaft, a handle A and a handle B, wherein, two ends of the handle A are fixed on the front cover of the motor A, and the handle A is vertical to the rotating shafts; the handle B is arranged on a shell of the motor B and is parallel to the rotating shafts; the rotating shaft gear A is meshed with a transmission gear A, and the rotating shaft gear B is meshed with a transmission gear B; and the transmission gear A and the transmission gear B are respectively fixed with a small gear A and a small gear B, and the small gear A and the small gear B are meshed with a saw blade shaft gear. The double-motor cutting machine has the advantages of strengthened cutting force, reduced difficulties during the construction process, lowered loss during the use process and prolonged service life.

Owner:成英

Silicon wafer cutting machine

The invention relates to a silicon wafer cutting machine comprising a silicon wafer cutting wire. The silicon wafer cutting wire comprises two wire bodies which are mutually overlapped to be of an integrated structure shaped like an Arabic number '8', wherein channels are arranged inside the wire bodies; the cross section of each channel is in a regular hexagon shape; the channels are filled with hard alloy; the outer surface of each wire body is wrapped with a protective layer made of high manganese steel; the surfaces of the protective layers are polished; each protective layer is internally provided with liquid storage bags of a spherical structure; a cylindrical channel is arranged directly between each liquid storage bag and the outer wall of the corresponding protective layer. The cutting grinding liquid adhesion capacity of the silicon wafer cutting wire is improved, and the production efficiency is improved greatly.

Owner:FORTUNATE SOLAR TECH JIANGSU CO LTD

Mold engraving and milling machine with conveying device

The invention discloses a mold engraving and milling machine with a conveying device. The mold engraving and milling machine comprises a workbench base, and a working table is arranged on the upper portion of the workbench base. Two vertical supports are arranged at the two ends of the working table, and each vertical support is fixedly provided with a stand column. A cross beam is arranged between the two stand columns, and the two ends of the cross beam are connected with the stand columns through locking mechanisms. An engraving and milling machine body is arranged in the middle of the cross beam, and a horizontal guide rail is arranged in the middle of the cross beam. According to the mold engraving and milling machine with the conveying device, a transmission gear is adopted, the engraving efficiency is greatly improved, working is stable, noise is small, and meanwhile the cutting force is large.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

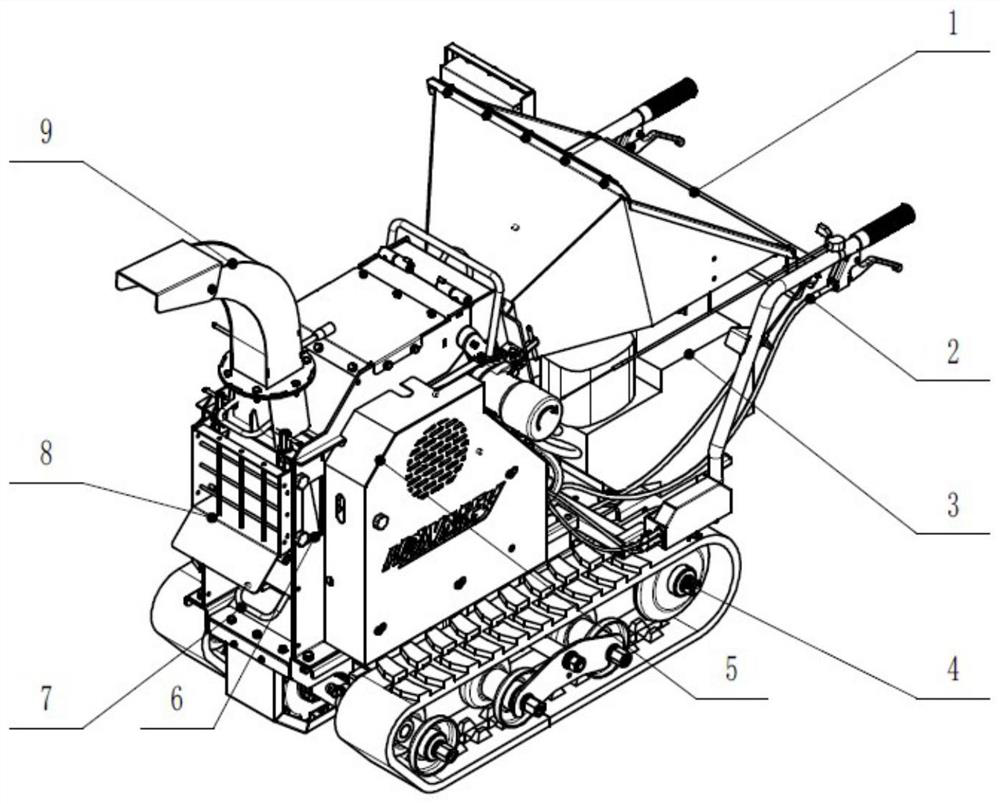

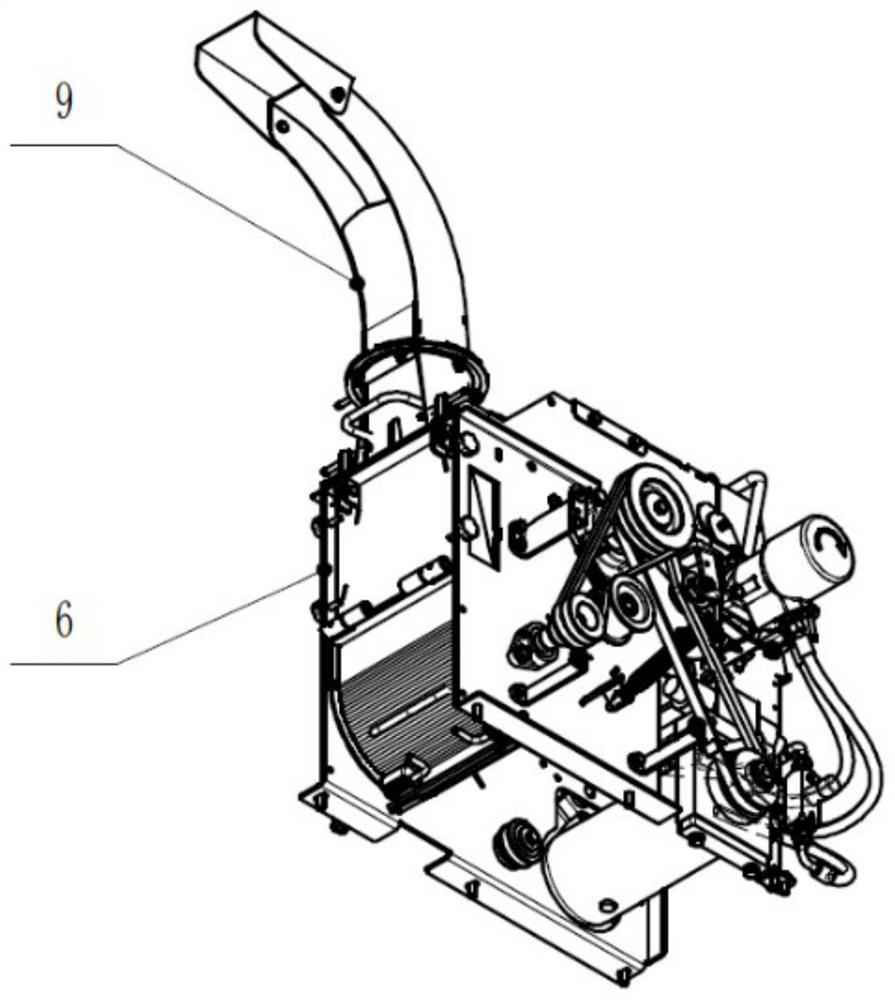

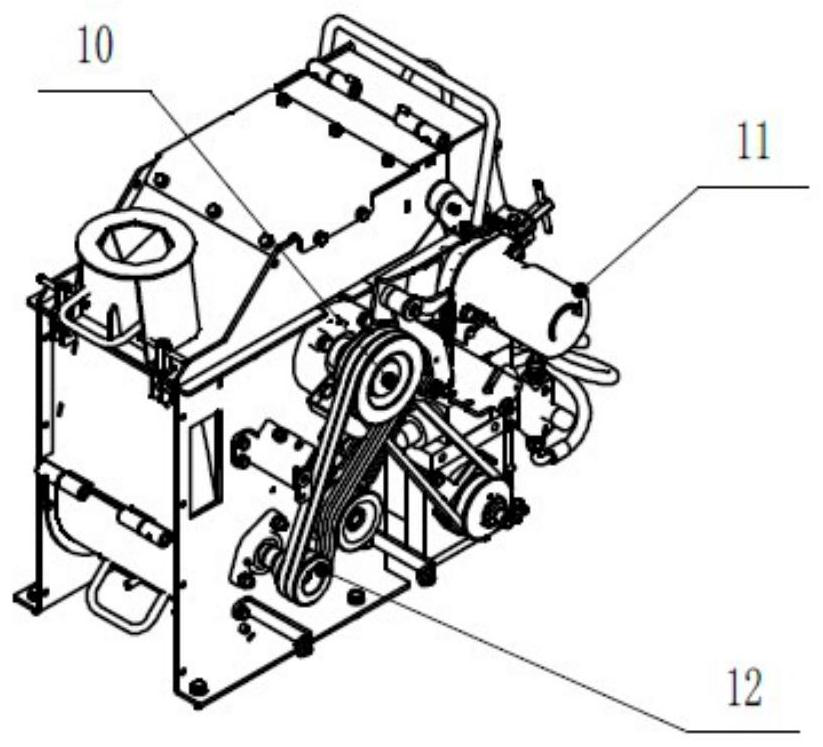

Crawler-type self-walking wood crusher

PendingCN112570130AReduce labor intensityIncrease cutting powerWood working apparatusGrain treatmentsVehicle frameAgricultural engineering

The invention relates to the field of agricultural machinery, in particular to a crawler-type self-walking wood crusher which comprises a crawler chassis, a feeding hopper, a discharging port, a crushing device, an engine, a control mechanism and an electric control system. The engine is connected with the crawler chassis and the crushing device through belts, the crawler chassis is fixedly connected with the crushing device and the control mechanism, and the feeding hopper is rotationally connected to the crushing device. The engine is connected with a walking driving device through a belt, the walking driving device is fixedly installed on the front side of a frame, a driving wheel, a thrust wheel and a guide wheel are sequentially installed on the lower side of the frame through a suspension from the front side to the rear side, and a crawler belt is arranged on the outer sides of the driving wheel, the thrust wheel and the guide wheel in a sleeving manner. The wood crusher is provided with the crawler chassis, can walk autonomously, is provided with an automatic overload protection device, can effectively prevent damage caused by overload work of the machine, prolongs the service life of the machine, is provided with the walking driving device arranged in a preposed manner, reduces the mounting height of the feeding hopper, and achieves the effect of saving power during feeding.

Owner:常州汉森机械股份有限公司

Shaver tool bit

The invention relates to the field of shaver tools, and particularly relates to a shaver tool bit. The shaver tool bit comprises a chassis and tool bits, wherein a plurality of bases are arranged on the chassis; a corresponding waste hole is formed in front of each base in the rotation direction; one tool bit is arranged on each base; a cutting edge is arranged at the top of each tool bit; each cutting edge stretches out forwards relative to the position of the corresponding tool bit; the space just below each cutting edge is aligned with the corresponding waste hole; and a stopping part is arranged below each cutting edge and in front of the cutting edge in the rotation direction. According to the shaver tool bit disclosed by the invention, the structure is improved; through addition forthe bases and the waste holes, and through the arrangement for the double-ring tool bits, the surface of the chassis of a shaver is clean and sanitary, beard is not liable to fall off, and the shavingefficiency is increased; the problem that a ceramic tool bit is liable to be broken is solved; and moreover, the production cost is effectively lowered.

Owner:DEQING DEYAN CERAMICS CO LTD

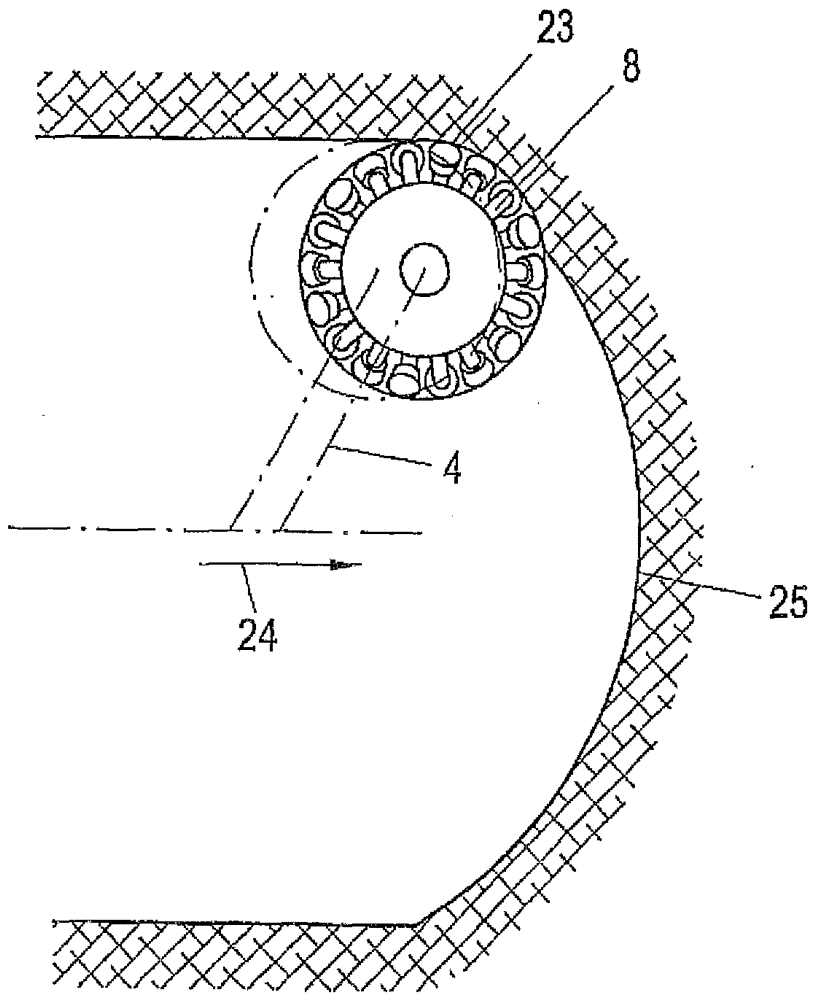

tunnel boring machine

The invention relates to a tunneling machine comprising a base frame (2) having a chassis, and a bracket (4) which can be horizontally and vertically swiveled and is provided with a cutting device (8) that has at least one tool support (10, 11). Said tool support is rotatably mounted on the bracket (4) and can be driven so as to rotate and carries a plurality of cutting tools (12) on its circumference. The cutting device (8) comprises at least two parallel disk-shaped tool supports (10, 11) which are rotatably mounted on an end section (13) of the bracket (4) that is located between the tool supports (10, 11) and is at least partially disk-shaped.

Owner:SANDVIK MINING & CONSTR OY

Resin tile leftover material cutting device

ActiveCN109203030AIncrease cutting powerFast cutting speedMetal working apparatusEngineeringMechanical engineering

The invention relates to a resin tile leftover material cutting device. The resin tile leftover material cutting device comprises a support. The support is provided with a cutting roll. The cutting roll is mounted on the support. The cutting roll is of a hollow structure. A heating roll is arranged above the cutting roll. The left and right ends of the heating roll are both sleeved with supportingblocks. End covers are mounted on the supporting blocks at the two ends of the heating roll correspondingly. A connecting sleeve is mounted on each end cover. A heater is arranged in the heating rollin a penetrating mode. The two ends of the heater are both connected with power lines. The cutting roll comprises a cutting roll shaft. The left end of the cutting roll shaft is provided with a firstconnecting shaft. The right end of the cutting roll shaft is provided with a second connecting shaft. A cone body is arranged in the cutting roll shaft. The cone body is provided with conical bearingbushes. The cone body is sleeved with the conical bearing bushes through a tension spring. Cutters are fixed to the conical bearing bushes. A first adjusting screw is mounted on the first connectingshaft in a penetration mode, and a second adjusting screw is mounted on the second connecting shaft in a penetration mode. The resin tile leftover material cutting device increases the cutting speed.

Owner:TAIZHOU HUANGYAN JUKE IND & TRADE CO LTD

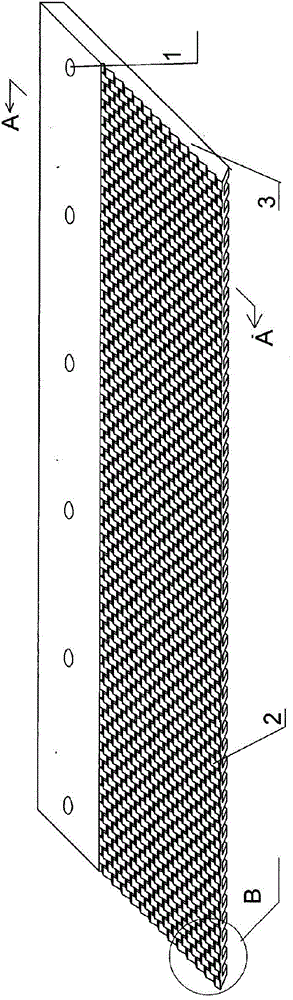

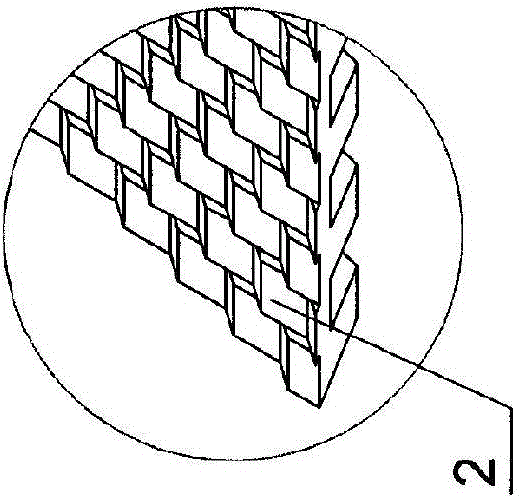

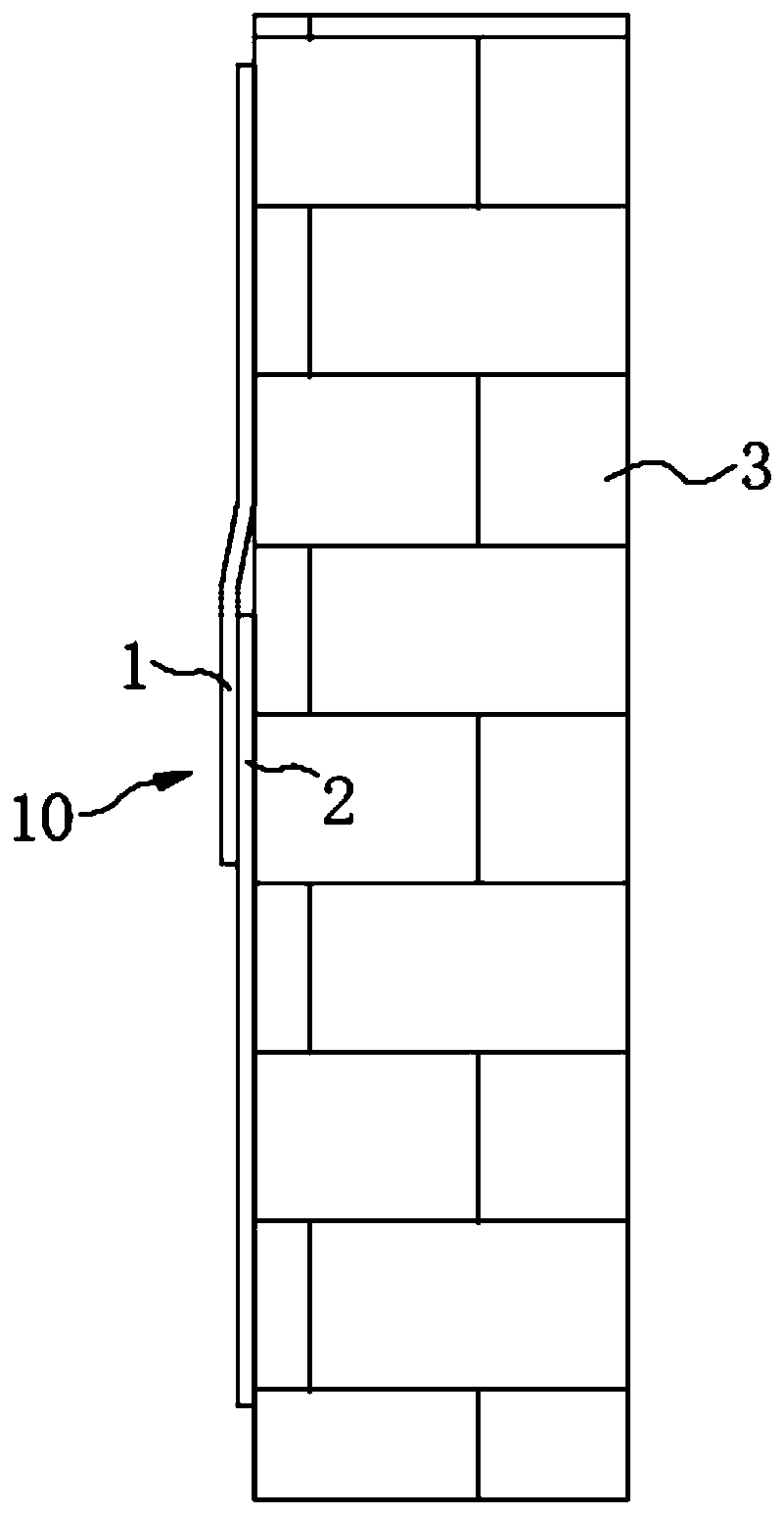

Hollow-out semi-hollow-out tooth blade snow shoveling cutting board

The invention discloses a hollow-out semi-hollow-out tooth blade snow shoveling cutting board. The front side of the front half portion of the cutting board is provided with a plurality of rows of teeth (2), every row of teeth are arranged in a staggered mode, the front half portion of the back of the cutting board is provided with rectangular grooves (4) which are uniformly arranged, and accordingly a semi-hollow-out structure is formed. Every rectangular groove is provided with a reinforcing rib (5); the reinforcing ribs which are mutually staggered do not in the same line; an installation hole (1) is formed in the rear half portion of the cutting board. Transparent holes (6) are formed between the plurality of rows of teeth of a hollow-out structure and are distributed in a stagger mode. According to the hollow-out semi-hollow-out tooth blade snow shoveling cutting board, the plurality of rows of teeth are arranged in a stagger mode, a plurality of small-zigzag-shaped tooth tops on the teeth are adhered to the ice and snow on the road surface during snow shoveling walking, the tooth tops are not easy to be abraded to lose the sharpness and slide, and a non-slip characteristic can be well reflected on a compact ice and snow road surface; the hollow-out semi-hollow-out tooth blade snow shoveling cutting board can rapidly cut through and separate the ice and snow under driving of power due to the semi-hollow-out structure of the rectangular groove in the back side and the 45-degree ice and snow entering angle, a rectangular frame on the back of the cutting board is in a sharp state and can rapidly cut through the snow and ice and not damage the road surface.

Owner:呼伦贝尔市雪帕奇冰雪防滑科技有限公司

Cold saw sizing equipment for steel structure production and machining

InactiveCN111843035AMove quicklyImprove stabilityMetal sawing devicesMetal sawing accessoriesRotational axisElectric machine

The invention discloses cold saw sizing equipment for steel structure production and machining, and relates to the technical field of cold saw sizing. The cold saw sizing equipment solves the problemof stability of square steel sawing work, and specifically comprises an inclined base and a material containing base, wherein a guide groove is formed in the outer wall of the top of the inclined base, limiting strips are welded to the outer walls of the two sides, close to the guide groove, of the inclined base, a fixing plate is slidably connected into the guide groove, a first motor is arrangedon the outer wall of the back face of the fixing plate, an output shaft of the first motor is provided with a first rotating shaft, a second rotating shaft is fixed to the outer wall of one side of the fixing plate through a bearing, the circumferential outer walls of the first rotating shaft and the second rotating shaft are sleeved with belt wheels, the circumferential outer walls of the two belt wheels are sleeved with the same belt, one end of the second rotating shaft is sleeved with an alloy saw blade, the same cold saw cover is fixed to the two ends, close to the alloy saw blade, of the second rotating shaft through bearing seats. According to the cold saw sizing equipment, the cutting integrity and burr-free effect of the alloy saw blade are guaranteed, and the translation stability of the alloy saw blade is promoted.

Owner:六安伟宏钢结构有限公司

Wall paper cutting device

ActiveCN111590678AGuaranteed cutting accuracyIncrease cutting powerMetal working apparatusStructural engineeringElasterell

The invention provides a wall paper cutting device, and relates to the technical field of building machines. The wall paper cutting device comprises a guide rail, a sliding base, a cutter assembly, and a pressure adjusting assembly, the sliding base is mounted on the guide rail and in sliding connection with the guide rail, the cutter assembly is used for cutting wall paper, the pressure adjustingassembly comprises a first sliding frame, a pressing plate and an elastic part, the first sliding frame is mounted on the sliding base, the cutter assembly is slidingly mounted on the first sliding frame, the elastic part is mounted between the pressing plate and the cutter assembly, during wall paper cutting, external force acts on the pressing plate, the pressing plate is in abut joint with thesliding base and is spaced from a target cutting face by the preset distance, the pressing plate acts on the cutter assembly through the elastic part, the cutter assembly is in abut joint with the target cutting face and enables the elastic part to be compressed, according to the all paper cutting device, the strength for wall paper cutting is constant in magnitude, the cutting efficiency and precision are improved, and the wall paper damage is prevented.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Smashing and filtering integrated feeding station

InactiveCN108380097AImprove crushing effectGuaranteed uniformityRotary stirring mixersTransportation and packagingEngineeringDust collector

The invention discloses a smashing and filtering integrated feeding station which comprises a shell, a support and a filtering device. The top of the shell is fixedly connected with a motor, an outputshaft of the motor is fixedly connected with a rotating rod, the outer surface of the rotating rod is fixedly connected with stirring rods, the surface of each stirring rod is fixedly connected withstirring blades, an input end of a dust collector is fixedly connected with a communicating pipe, one end of the communicating pipe is fixedly connected with a filter element, and the bottom of the shell is fixedly connected with the filtering device; the filtering device comprises an upper retaining plate and a lower retaining plate, bolts are arranged at the top of the upper retaining plate, theupper retaining plate is movably connected with the lower retaining plate through the bolts, a sealing ring is arranged between the upper retaining plate and the lower retaining plate, and the outersurface of each bolt is in threaded connection with a nut. By arranging the motor, the rotating rod, the stirring rods, the stirring blades, through holes, the upper retaining plate, the lower retaining plate and filtering holes, the problem that powder is prone to caking, accumulating inside the feeding station and having impact on normal running of the feeding station is solved.

Owner:新乡市辰威机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com