Crawler-type self-walking wood crusher

A self-propelled, wood chipper technology, applied in wood processing equipment, grain processing, manufacturing tools, etc., to achieve the effect of reducing labor intensity, reducing work intensity, and reducing installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail now in conjunction with accompanying drawing.

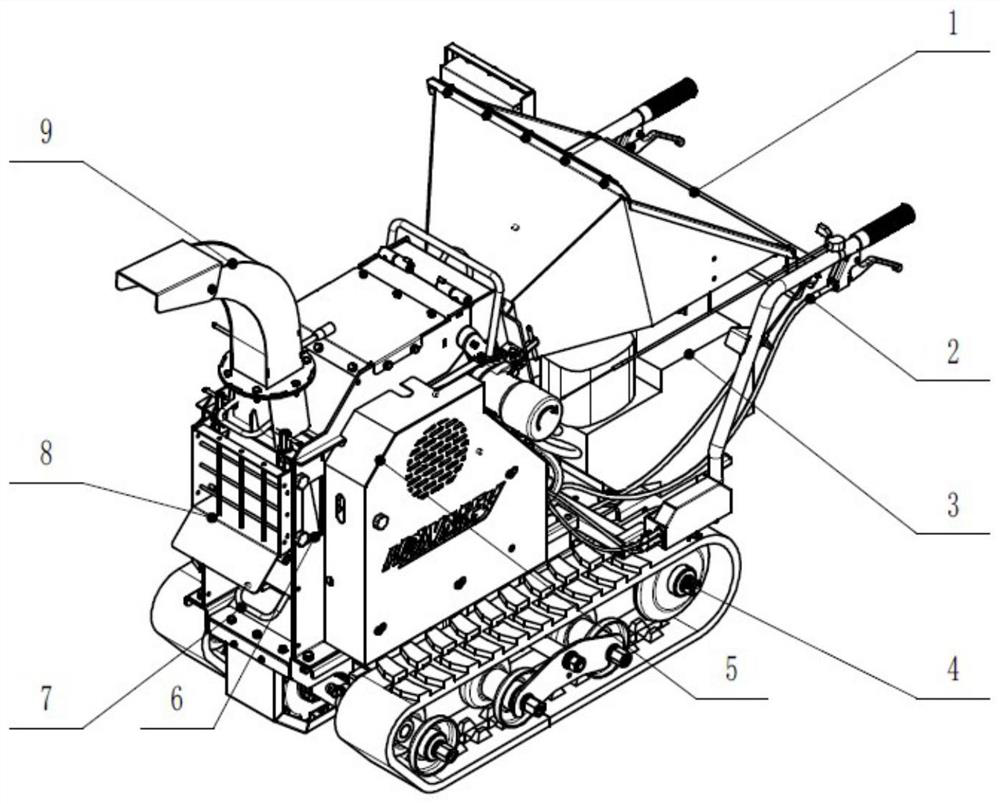

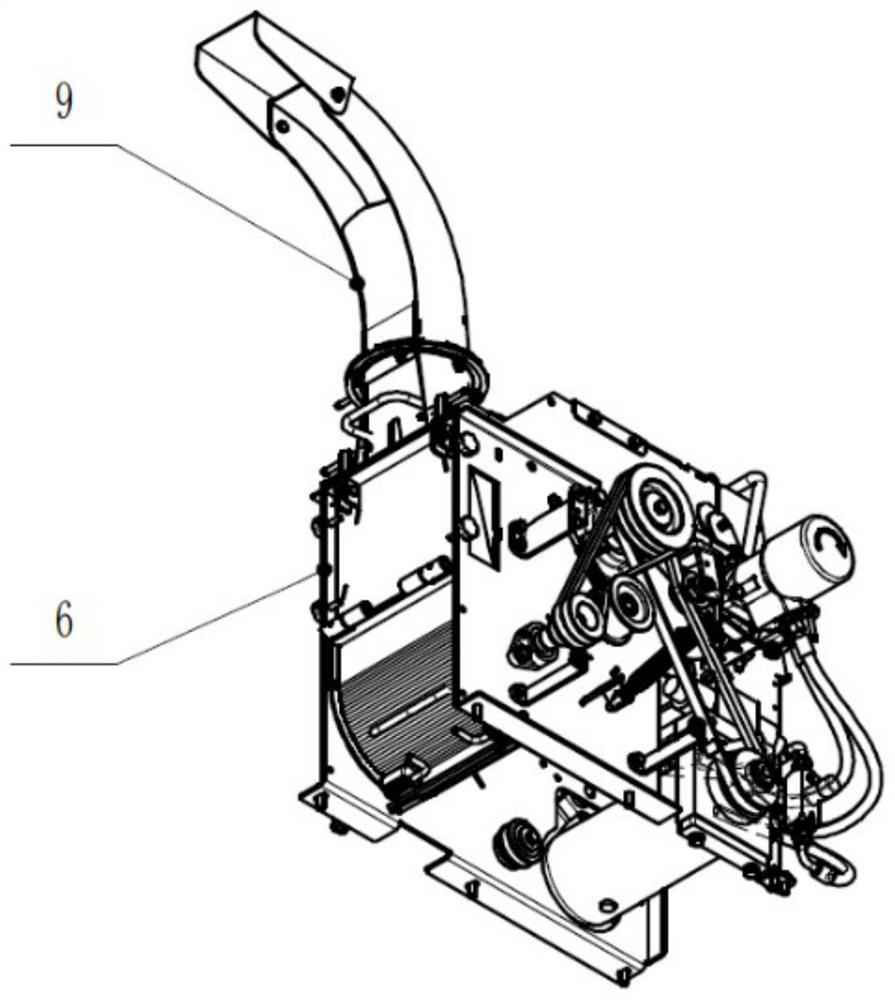

[0034] refer to figure 1 , a crawler type self-propelled wood chipper, including a crawler chassis 4, a machine cover 5, a hopper 1, a discharge port, a crushing device 6, an engine 3, an operating mechanism 2 and an electric control system; the engine 3 is connected to the The crawler chassis 4 is connected to the crushing device 6; the crawler chassis 4 is fixedly connected to the crushing device 6 and the operating mechanism 2 respectively; the feeding hopper 1 is connected to the crushing device 6 through a rotating shaft, and the feeding hopper 1 can rotate relative to the crushing device 6 around the rotating shaft.

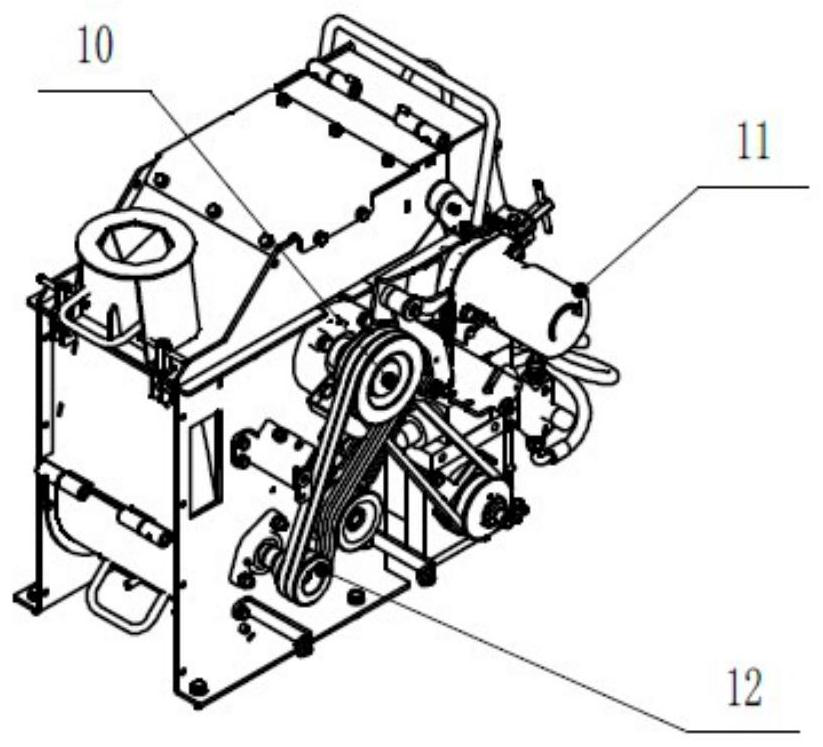

[0035] refer to Figure 5-6 , crawler chassis 4 comprises guide wheel 19, supporting wheel 20, driving wheel 21, vehicle frame 22, traveling drive device 23, crawler belt 24; Engine 3 is connected with walking driving device 23 by belt, guiding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com