Double-motor cutting machine

A cutting machine and dual motor technology, applied in the parts of boring machine/drilling machine, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of reducing the working efficiency of the cutting machine, affecting the cutting process, and long cutting time, etc. Achieve the effect of reducing difficulties, increasing cutting force and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

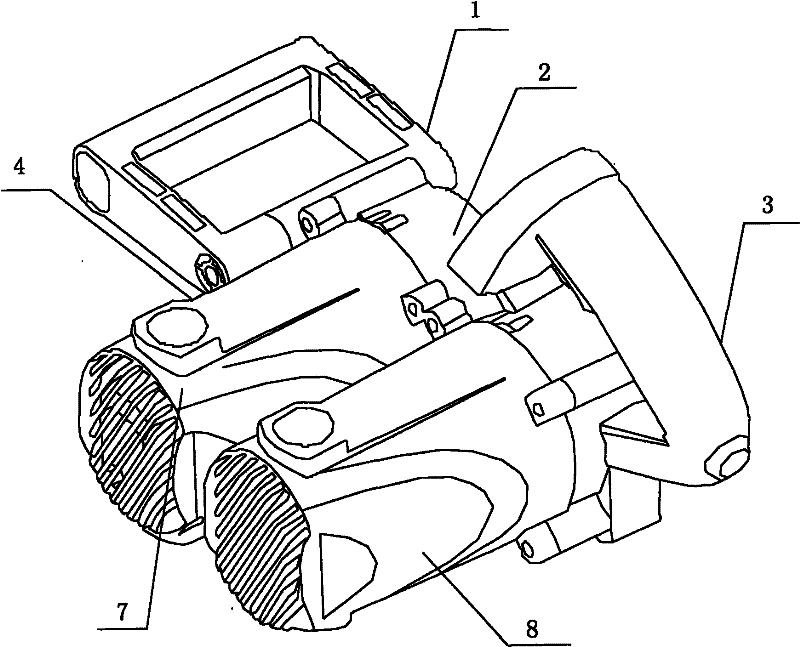

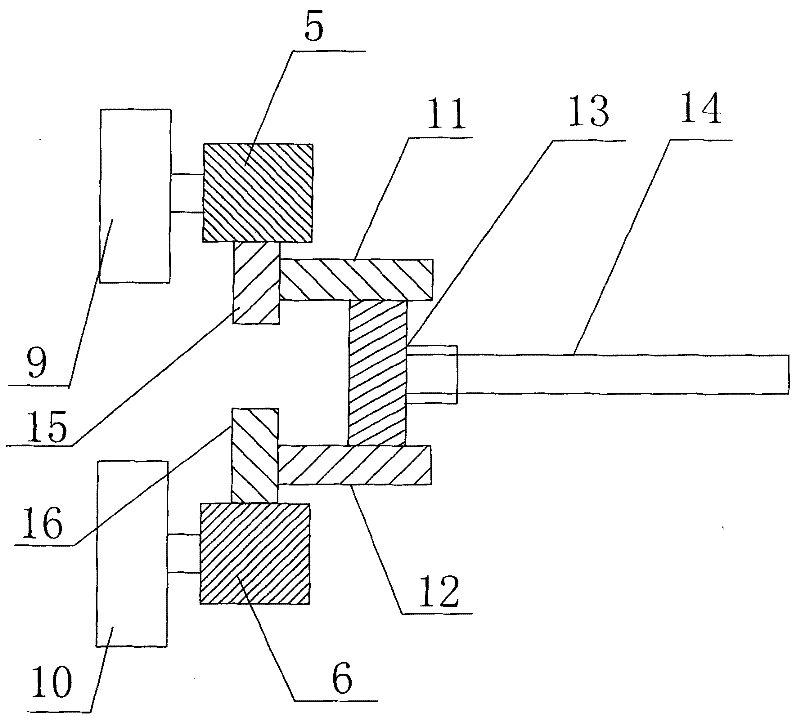

[0011] like Figure 1 to Figure 3 As shown, a dual-motor cutting machine includes a motor A8, a motor B7, a rotating shaft A9, a rotating shaft B10, a rotating shaft gear A5, a rotating shaft gear B6, a motor front cover 2, a cutting machine housing 4 and a saw blade shaft 14, It also includes a handle A3 and a handle B1. The two ends of the handle A3 are fixed on the front cover of the motor A8, and the handle A3 is perpendicular to the rotation axis; the handle B1 is installed on the outer casing of the motor B9, and the handle B1 is parallel to the rotation axis; Gear A15 meshes with gear B6, and gear B6 meshes with transmission gear B16. Pinion A11 and pinion B12 are respectively fixed on transmission gear A15 and transmission gear B16. Both pinion A11 and pinion B12 are in mesh with saw blade shaft gear 13. mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com