Resin tile leftover material cutting device

A technology of scraps and resin tiles, applied in metal processing and other directions, can solve problems such as inability to cut, and achieve the effect of increasing cutting speed and increasing cutting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

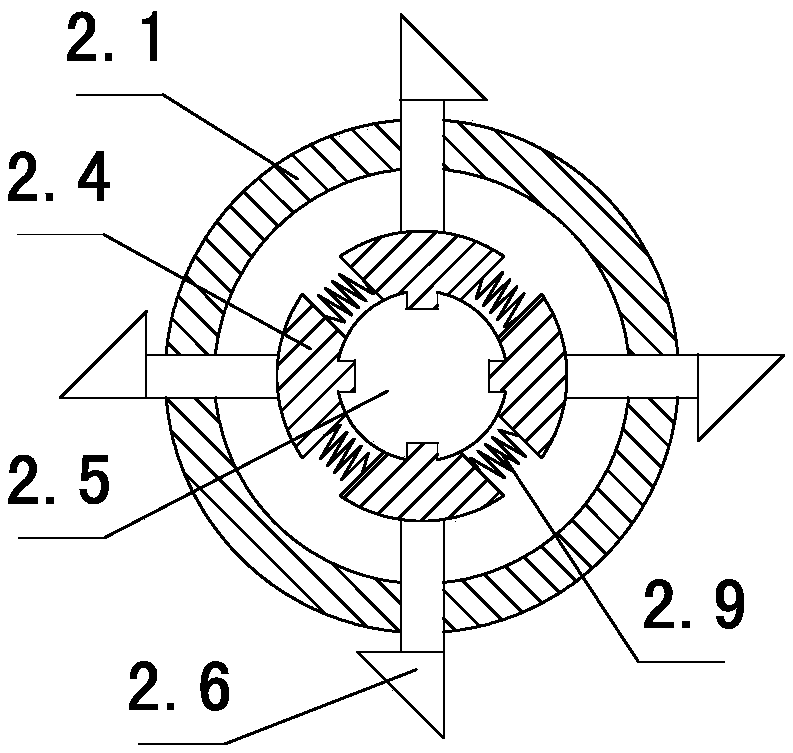

[0019] Such as figure 1 , figure 2 , image 3 As shown, the device for cutting resin tile leftovers includes a vertically arranged support 1, a cutting roller 2 is horizontally arranged on the support 1, and the two ends of the cutting roller 2 are installed on the support 1 through bearings, and the cutting roller 2 is Hollow structure, a heating roller 9 is arranged horizontally above the cutting roller 2, and supporting blocks 3 are set on both left and right ends of the heating roller 9, and both ends of the heating roller 9 are mounted on the supporting blocks 3 through bearings. The support blocks 3 at both ends of the roller 9 are installed on the bracket 1, end caps 4 are installed on the support blocks 3 at both ends of the heating roller 9, and connecting sleeves 5 are installed on each end cap 4. Inside the heating roller 9 A heater 10 is installed horizontally; the left end of the heater 10 passes through the end cover 4 on the left side and is fixed on the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com