Two-drive telescopic roller cutting mechanism for excavating and anchoring integrated machine

A telescopic roller, dual-drive technology, applied in cutting machinery, driving device, slitting machinery, etc., can solve the problems of difficult to play fast excavation, high geological conditions, and reduced excavation speed, etc. The effect of strong coal capacity and single-knife force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

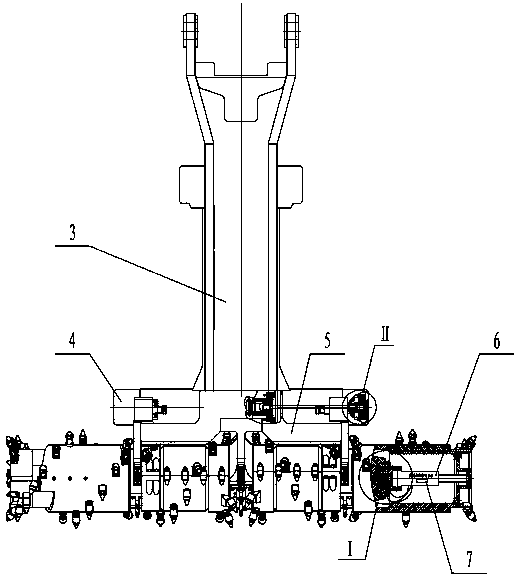

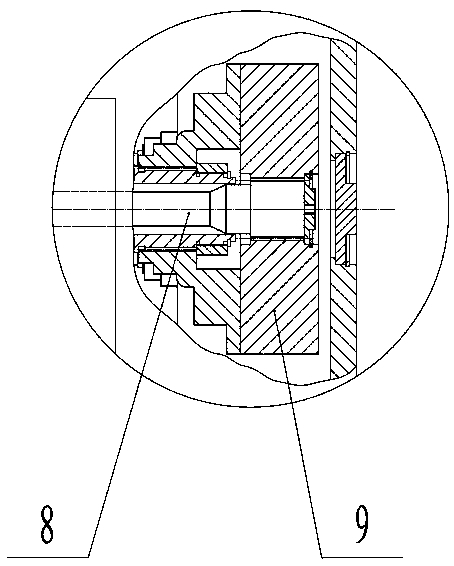

[0029] figure 1 , 2 , 3, the main structure of the present invention consists of cutting motor 4, cutting arm 3, speed reducer 5, torque shaft 8, torque limiter 9, middle section cutting drum 2, telescopic section cutting drum 1, cutting drum Telescopic oil cylinder 6 forms. A speed reducer 5 of a bolter cutting unit cutting device is installed on the cutting arm 3, and two cutting motors 4 are arranged symmetrically and laterally outside the cutting arm 3, respectively connected with a speed reducer of a bolter cutting unit cutting device 5 The input ends on both sides are connected to drive the reducer; the cutting drum 2 in the middle section and the cutting drum 1 in the telescopic section are installed on the output end of the reducer 5 horizontal axis of a cutting device of a bolter digging unit to break coal and rock; the cutting drum The telescopic oil cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com