Blast method for realizing vibration attenuation and protection of early-age concrete lining during tunnel construction

A tunnel construction and concrete technology, which is applied in the field of blasting to realize the anti-vibration protection of early-age concrete lining, can solve the problems of reducing construction efficiency, delaying the progress of excavation, and increasing the number of blasting times, so as to ensure the safe and smooth construction of the project and reduce the vibration hazard , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

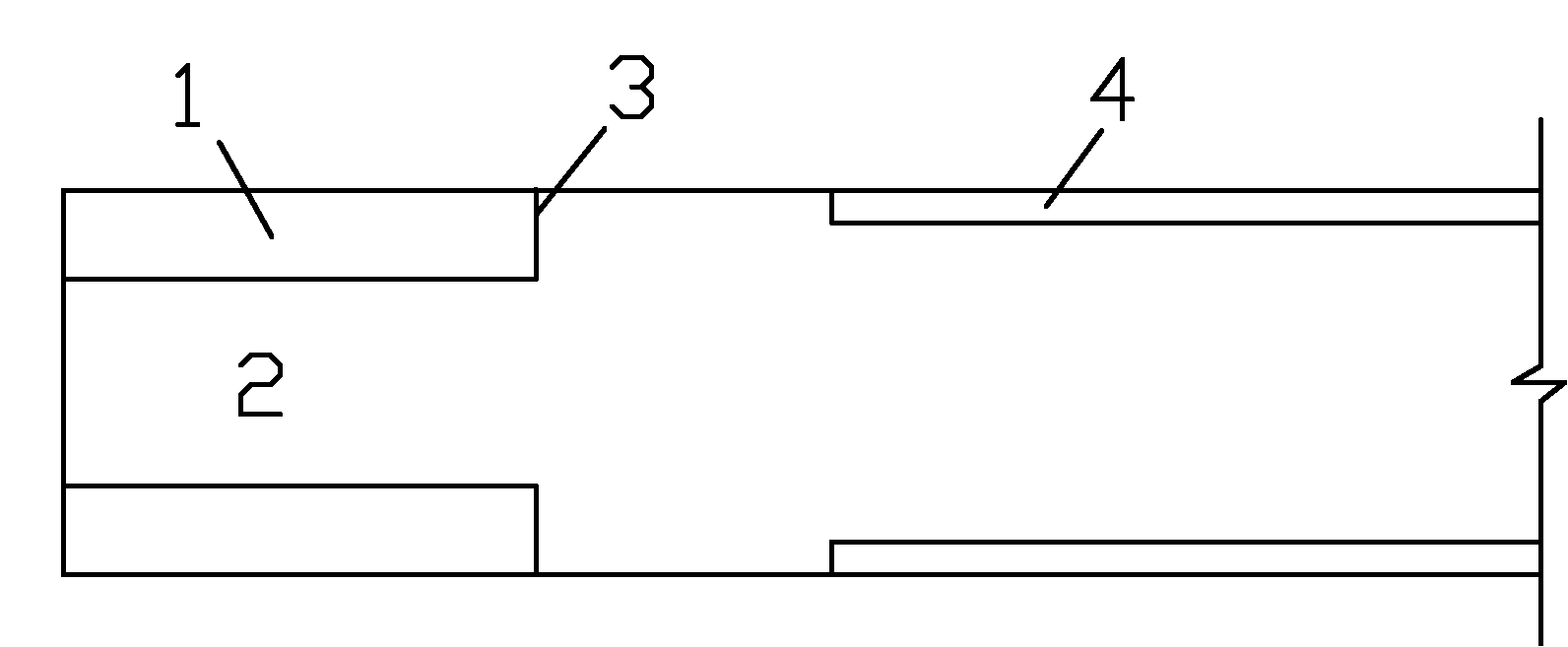

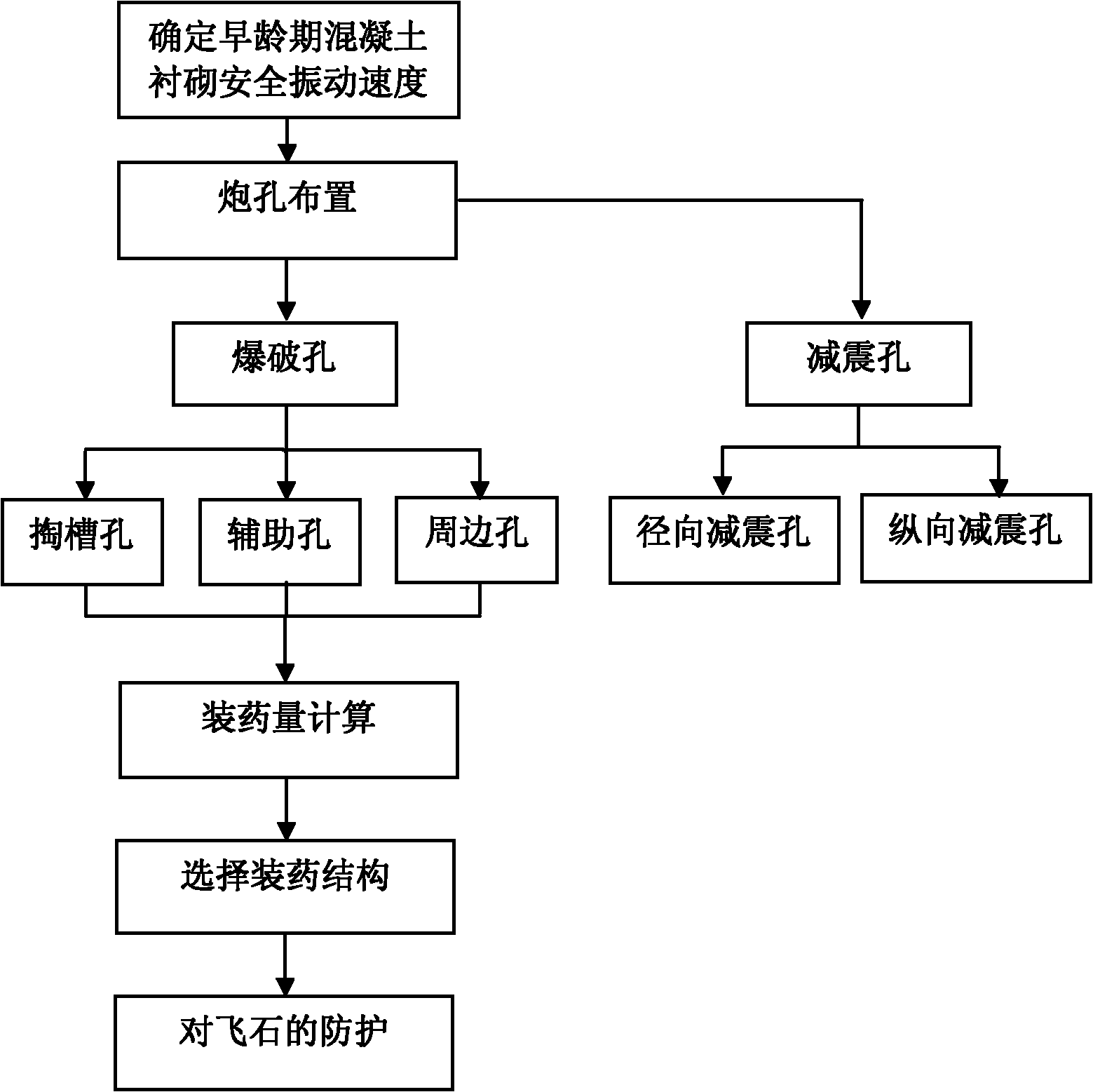

[0028] Such as figure 1 As shown, due to the schedule of the project, the distance between the blasting excavation point 3 and the early-age concrete lining 4 is relatively close, so shock-absorbing protective measures need to be taken. The overall technical route of the present invention is as figure 2 As shown, the specific method steps are as follows.

[0029] 1. Determine the safe vibration speed of the lining. Frank J. Lucca proposed that the safe vibration velocity (unit: cm / s) of early-age concrete lining can be determined by the following formula:

[0030] v=22.9×DF age is 1~3 days

[0031] v=30.5×DF age is 3~7 days

[0032] v=38.1×DF Age is 7~28 days

[0033] Among them, DF is the distance factor. When the distance between the blasting point and the concrete is 0-15m, DF=1, and when the distance is 15-46m, DF=0.8.

[0034] my country's "Blasting Safety Regulations" (GB6722-2003) stipulates that the safe vibration velocity of early-age concrete with an age of 0-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com