Fully mechanized mining working face bending detection and straightening method and system

A technology of fully mechanized mining face and working face, which is applied in general control system, control/regulation system, measurement and other directions to achieve the effect of solving accurate measurement problems, detection and correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

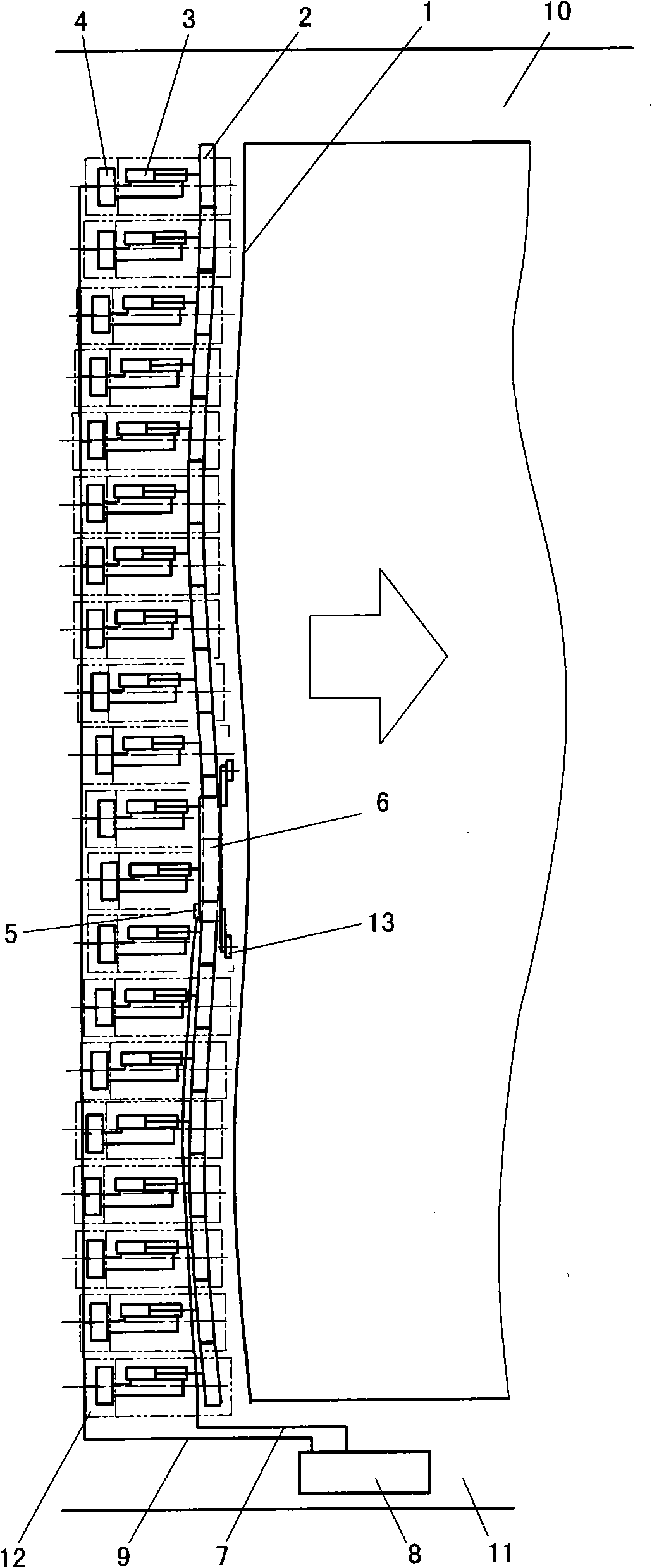

[0016] 1. The composition of the bending detection and straightening system of fully mechanized mining face:

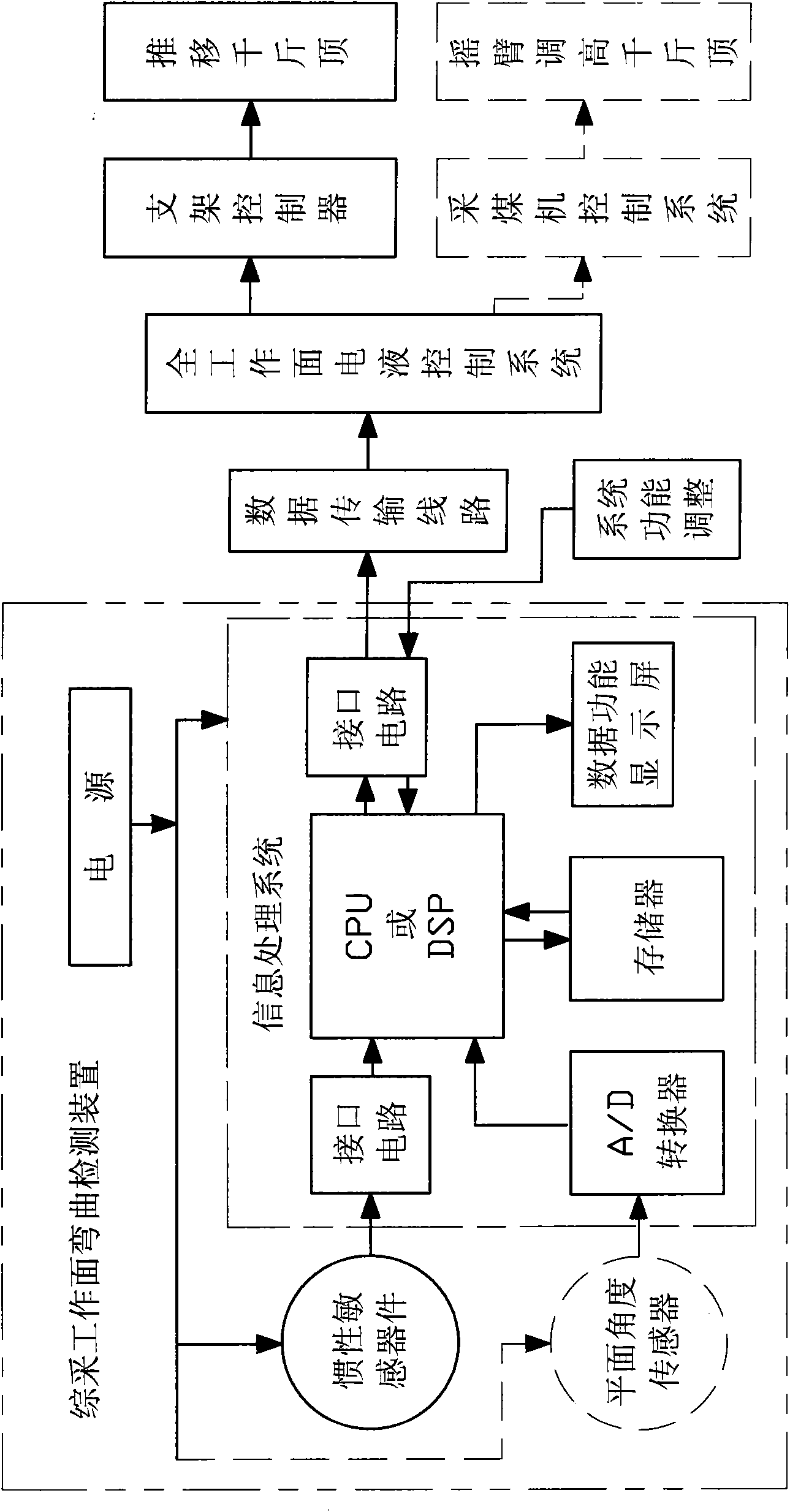

[0017] exist figure 1 The composition and basic principle of the bending detection and straightening system of the fully mechanized mining face of the present invention are shown in .

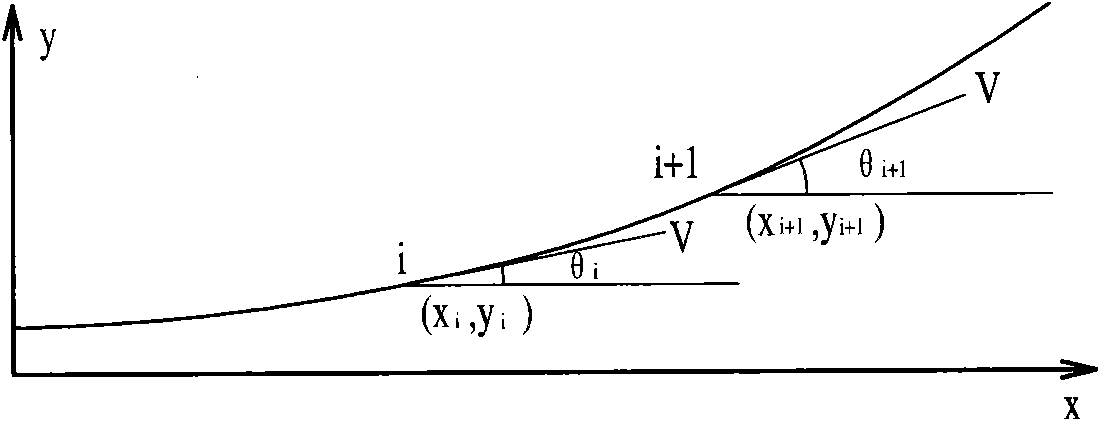

[0018] The bending detection and straightening system of the fully mechanized mining face is mainly composed of inertial sensing elements or a combination of inertial sensing elements and horizontal angle sensors, an information processing system with CPU or DSP as the core, data transmission lines, electro-hydraulic control systems for the entire working face, hydraulic The bracket controller of the bracket, and the push jack are composed. Among them, the inertial sensitive element or the combination of the inertial sensitive element and the horizontal angle sensor, the infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com