Method for controlling roof caving under condition of hardroof in coal mining

A hard roof and coal mine technology, applied in the field of hard roof control caving, can solve the problems of frequent blasting, large groove depth, analysis and comparison of caving workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

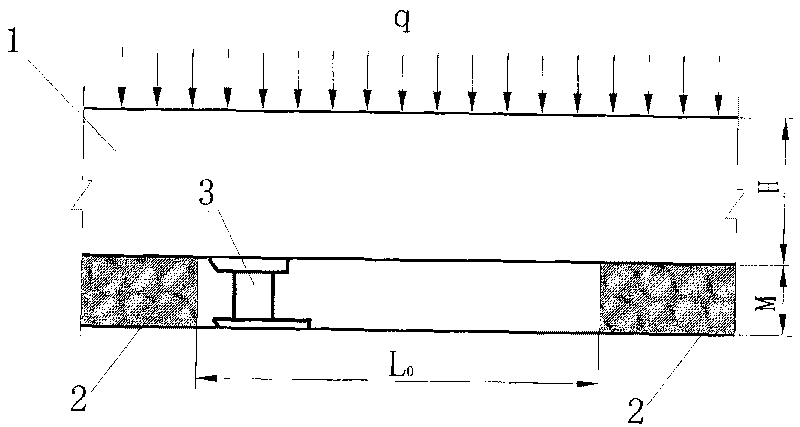

[0081] Take Jincheng Qiling Coal Mine as an example. The 15102 working face of this mine is 150m long, the mining height is 2m, and the cycle progress is 0.8m. The coal thickness is 1.8-2.2m, with an average thickness of 2m, including 1-2 layers of gangue. The roof of the coal seam is K 2 Limestone, the average uniaxial compressive strength is 96.77MPa, the tensile strength is 8.59MPa, and the elastic modulus is 35.4GPa. The rock beams on the hard roof are 8.16m thick. The coal seam floor is mudstone or bauxite mudstone.

[0082] The working face adopts four-column support and shielding support, the design rated working resistance of the support is 6075KN / frame, and the design support strength is 900KN / m 2 , the bracket control top distance is 4.5m. Table 1 shows the test results of the mechanical properties of coal and roof rock in the working face.

[0083] Table 1 Mechanical parameters of 15# coal and roof rock

[0084]

[0085] I. Determine the limit span of the ...

Embodiment approach 2

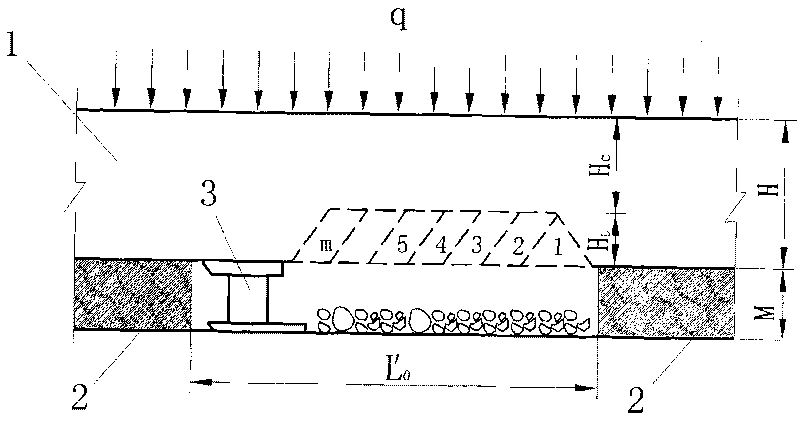

[0108] The initial collapse step of the roof is half of the limit span (that is, the limit span of the roof after treatment is 26m, n=2) according to the method of the middle part of the trough, and the trough with the middle part of the trough can be calculated from the formula (10) The depth and blasting volume are 5.27m; the main technical parameters of the blasting are shown in Table 3.

[0109] Table 3 Main Technical Parameters of Blasting

[0110]

[0111] Others are the same as Embodiment 1.

Embodiment approach 3

[0113] The initial collapse step of the roof is half of the limit span (that is, the limit span of the roof after treatment is 26m, n=2) according to the method of cyclic shallow hole pulling. The groove depth is 5.57m (α=0.4), and the cycle number m>1 of circular shallow hole groove treatment on the roof, the blasting engineering volume is 5.57m. The main technical parameters of the blasting are shown in Table 4.

[0114] Table 4 Main Technical Parameters of Blasting

[0115]

[0116] Others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com